Cotton pulp and preparation method thereof, as well as carboxymethylcellulose and preparation method thereof

A technology of carboxymethyl cellulose and cotton pulp, applied in the field of materials, can solve the problems of low quality of cellulose ether derivatives, uneven polymerization degree of products, low reactivity of cotton pulp, etc., and achieve the reduction of crystallinity and consumption The effect of low volume and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

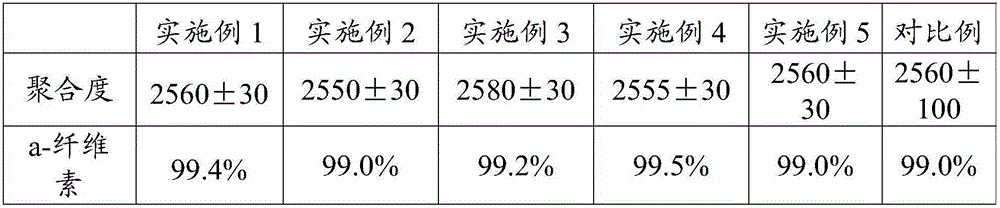

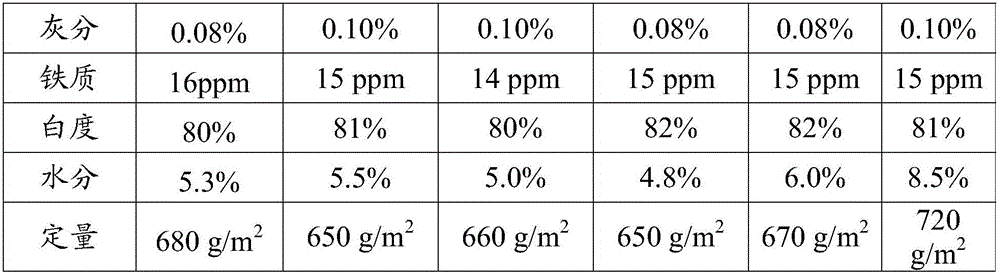

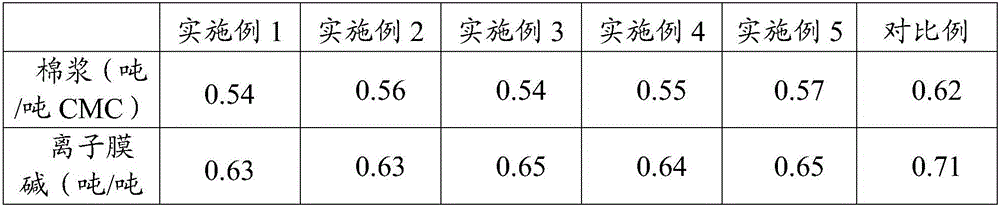

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of cotton pulp, comprises the following steps:

[0023] The lye is mixed with the cotton linters after impurity removal, and after continuous cooking, washing, beating, first desanding, first concentration, chloralkaliization, bleaching, acid treatment, water washing, second desanding, second 2. concentrating and papermaking to obtain cotton pulp;

[0024] The mass ratio of the mass of the alkali in the lye to the dry weight of the cotton linters is (13~15):100;

[0025] The temperature of the continuous cooking is 108-115° C., and the time of the continuous cooking is 55-65 minutes.

[0026] In the present invention, cotton linters are selected as raw materials for preparing cotton pulp. In the present invention, cotton linters with maturity ≥ 72%, sulfuric acid insoluble matter ≤ 3.0%, and ash content ≤ 1.5% are preferably used.

[0027] Before the cotton pulp is prepared, the cotton linters are firstly cleaned of ...

Embodiment 1

[0056] Cotton linters with high maturity, low sulfur value, and low ash content are selected, and the indicators are 72% maturity, 2.8% S value, and 1.5% ash content.

[0057] The above-mentioned cotton linters are subjected to dry impurity removal to remove cotton seeds, cotton husks, dust, etc., to obtain the impurity-removed cotton linters.

[0058] The cotton linters after impurity removal are mixed with NaOH solution, pre-soaked, and screw-pressed into the tubular continuous digester. The amount of NaOH added (relative to the dry weight of linters) is 15.0 wt%, and the bath ratio is 1:3.2. Add sodium dodecylsulfonate and sodium silicate to the tubular continuous digester. Wherein, the addition amount of sodium dodecylsulfonate is (relative to the absolute dry weight of cotton linters) 0.8wt%, and the addition amount of sodium silicate is (relative to the absolute dry weight of cotton linters) 0.9wt%. After the materials were added, the materials were continuously cooked...

Embodiment 2

[0086]Cotton linters with high maturity, low sulfur value, and low ash content are selected, and the indicators are respectively 74% maturity, 2.8% S value, and 1.2% ash content.

[0087] The above-mentioned cotton linters are subjected to dry impurity removal to remove cotton seeds, cotton husks, dust, etc., to obtain the impurity-removed cotton linters.

[0088] The cotton linters after impurity removal are mixed with NaOH solution, pre-soaked, and screw-pressed into the tubular continuous digester. The amount of NaOH added (relative to the dry weight of linters) is 14.0%, and the bath ratio is 1:3.3. Add sodium dodecylsulfonate and sodium silicate to the tubular continuous digester. Wherein, the addition amount of sodium dodecylsulfonate is (relative to the absolute dry weight of cotton linters) 0.75wt%, and the addition amount of sodium silicate is (relative to the absolute dry weight of cotton linters) 0.9wt%. After the materials were added, the materials were continuou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com