Method for manufacturing container component of sealing type switch device, and switch device

A switchgear, sealed technology, which is applied to the setting of switchgear, the setting of switchgear with metal shell, the switchgear and other directions, can solve the problems of high cost and material consumption of switchgear, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

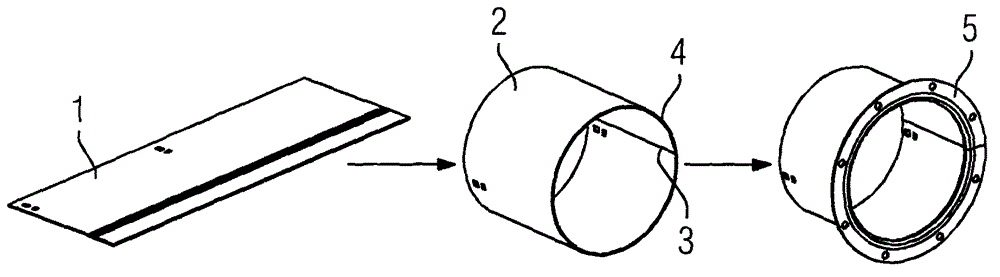

[0016] figure 1 Shown is a sheet metal 1 for the production of a container part of a sealed switchgear, which is rolled into a cylindrical tube 2 in a first method step, which is welded at butt edges 3 . At the first end 4 a flange 5 is then formed by deflection. For this, the cylindrical tube 2 is fixed in a rotating device and rotated about its central axis. Two rollers, which likewise rotate about their axes, are arranged on the cylindrical tube 2 in such a way that one of the two rollers rests against the outside and the other against the inside of the cylindrical tube 2 . The two rollers are arranged so as to be pivotable about a common point of rotation and are then pivoted outwards by 90°, so that a bead 5 is formed on the first end 4 of the cylindrical tube 2 . The thickness and the contour of the flange 5 can be varied here by repeated repetitions or by correspondingly changing the contours of the two rollers, so that a material-reinforced flange can also be formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com