Patents

Literature

55 results about "Iron plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

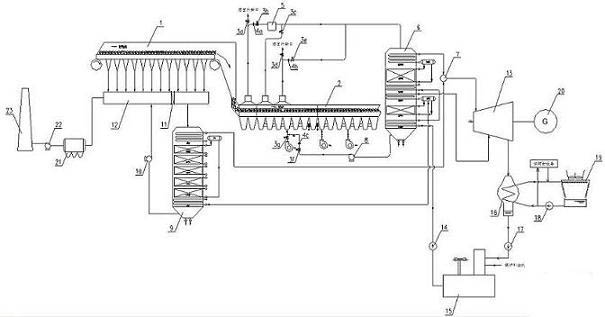

System and method for power generating by jointly recovering waste heat of flue gas of sintering machine and exhaust gas of cooling machine

ActiveCN102012167AImprove the efficiency of waste heat recovery and utilizationIncrease feed water temperatureEnergy industryIncreasing energy efficiencyWaste heat recovery unitIron plant

The invention discloses a system and method for power generating by jointly recovering the waste heat of a flue gas of a sintering machine and an exhaust gas of a cooling machine, belonging to the technical field of power generation by using waste sintering heat of a steel and iron plant. The power generating system comprises a sintering machine flue gas waste heat utilizing system, a cooling machine exhaust gas waste heat utilizing system, a turbine generating system and a relevant auxiliary system, wherein a main waste heat discharging boiler is utilized to recover the waste heat of the flue gas of a high-temperature segment of the tail part of the sintering machine; a cooling machine waste heat boiler is utilized to recover the waste heat of the high-temperature exhaust gas of the cooling machine; and a high-temperature electric butterfly valve is arranged between the high-temperature segment and a low-temperature segment of a large flue positioned on the tail part of the sintering machine to prevent the wind pickup temperature of the flue gas from being reduced because a low-temperature flue gas and a high-temperature flue gas are directly mixed so as to ensure the high-temperature flue gas to enter the main waste heat discharging boiler for waste heat recovery. The system and method effectively utilizes the waste heat resources of the high-temperature flue gas of the machine tail of the sintering machine and a hot gas of the high-temperature segment of the cooling machine, enhances the waste heat recovery and utilization efficiency of a sintering process and increases the power generation capacity of the waste heat power generating system.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

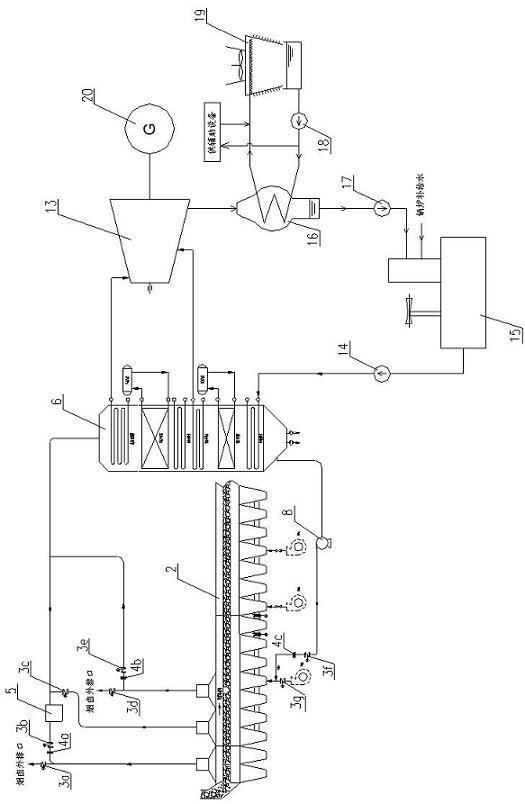

System for regulating and optimizing smoke by power generation and recycle of residual heat of sintering ring cold machine

ActiveCN101655319ATake advantage ofOptimize the operation modeEnergy industryIncreasing energy efficiencyIron plantEngineering

The invention discloses a system for regulating and optimizing smoke by power generation and recycle of residual heat of a sintering ring cold machine, which mainly comprises a ring cooling machine, a ring cooling machine wind box, a ring cooling machine wind chamber, a switching baffle door, a dual-pressure boiler without resisual heat and a steam filling and condensing type dual-pressure steam turbine, wherein the ring cooling machine wind chamber is divided into a high-temperature wind chamber and a low-temperature wind chamber which are respectively connected with the dual-pressure boilerwithout resisual heat through inlet flues, the steam outlet of the dual-pressure boiler without resisual heat is connected with the steam filling and condensing type dual-pressure steam turbine, and the outlet of a sediment chamber of the dual-pressure boiler without resisual heat is connected with a circulation fan through the flues and a wind complementing door. The invention has the highest efficiency in recovering residual heat, can use the resisual heat of sintering mineral materials at most, keeps stability, high efficiency and contineous operation for power generation by using the residual heat, and has important meaning for steal and iron plants.

Owner:ZHEJIANG XIZI UNITED ENG

Method for extracting iron particles and zinc powder from dust of steel and iron plant

ActiveCN102329909AImprove resource utilizationIncrease production costProcess efficiency improvementIron plantAdhesive

The invention relates to a method for extracting iron particles and zinc powder from dust of a steel and iron plant. The method for extracting the iron particles and the zinc powder from the dust of the steel and iron plant is characterized by comprising the following steps of: 1) pressing the dust of the steel and iron plant, dolomite and adhesive in a mass ratio of 1: (0.05-0.1): (0.03-0.06) bya ball press to form raw balls; 2) conveying the dried raw balls to a rotary hearth furnace, and performing high-temperature reduction; and 3) discharging the reduced cured balls out of the furnace through a spiral discharger arranged in the rotary hearth furnace, cooling, and screening to obtain the iron particles; preferentially reducing zinc in the raw balls into zinc steam in the rotary hearth furnace under the actions of reductive atmosphere and high temperature, and discharging the zinc steam from the rotary hearth furnace together with the flue gas generated in the rotary hearth furnace to form zinc-containing flue gas; introducing the zinc-containing flue gas to a bag-type dust collector, and catching and reclaiming the zinc oxide dust in the zinc-containing flue gas to obtain thezinc powder; and discharging the residual waste gas to the atmosphere through a chimney under the action of a draught fan. The method reduces the production energy consumption and the cost, and can realize comprehensive utilization of resources.

Owner:中国冶金科工股份有限公司

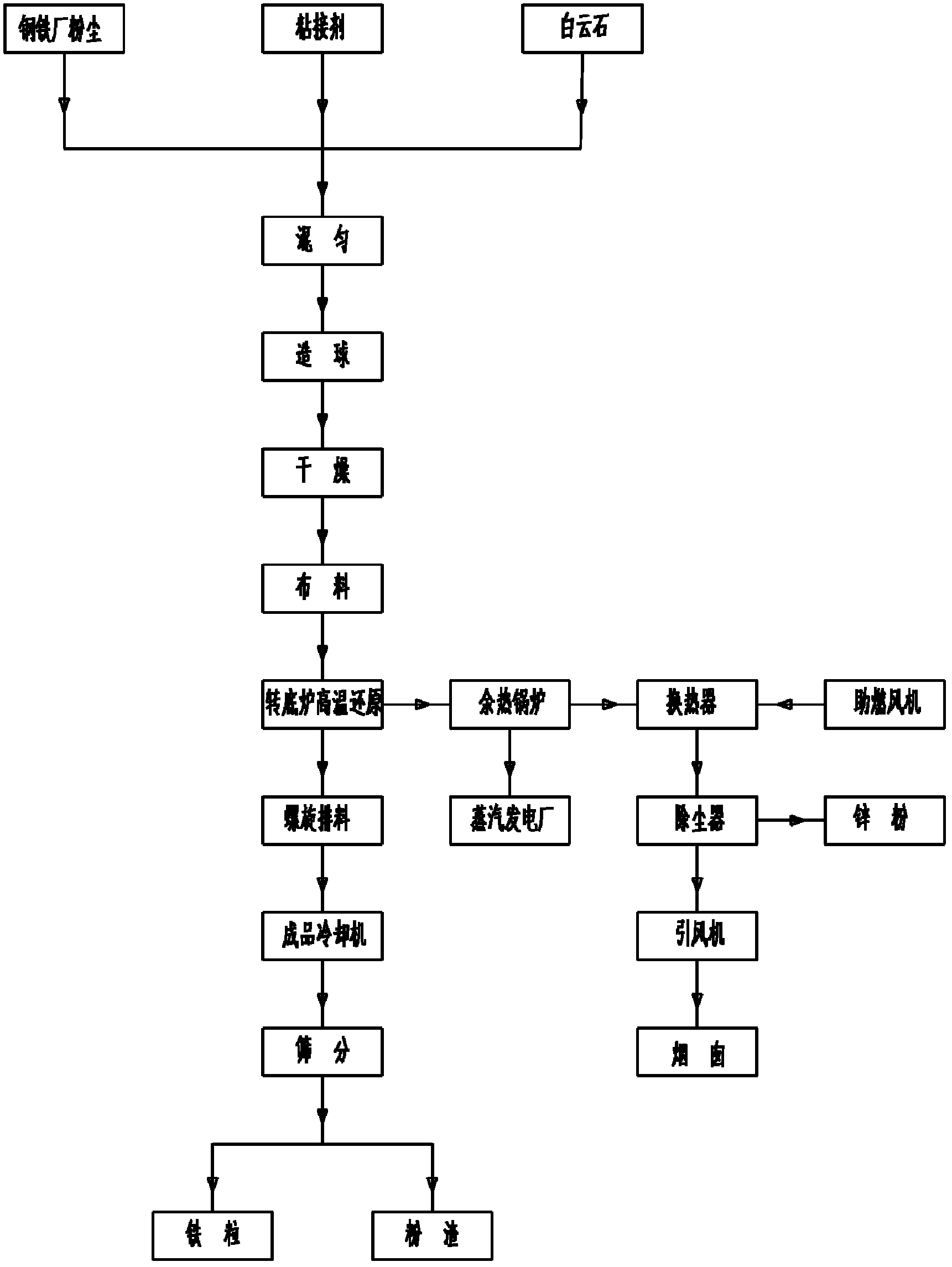

Method for directly preparing sulfate and ferric oxide by ferrous sulfate

InactiveCN103072953ASave on dehydration costsGas with low water contentChemical industrySulfur compoundsIron plantToxic industrial waste

The invention provides a method for directly preparing sulfate and ferric oxide by ferrous sulfate. The method comprises the following steps of firstly, carrying out primary heating on the ferrous sulfate with crystallizing water to form anhydrous ferrous sulfate or monohydrate ferrous sulfate; then, carrying out secondary heating on the anhydrous ferrous sulfate or the monohydrate ferrous sulfate, decomposing into a mixing gas of sulfur dioxide and sulfur trioxide and a ferric oxide solid, delivering the gas of sulfur dioxide and sulfur trioxide into a reformer to produce sulfate by a conventional catalyzing method, and directly using the ferric oxide solid as ferric smelting raw material of iron plants or for the production of ferric pigments, wherein the primary heating and the secondary heating are indirect heating, and a heat source of the indirect heating is a direct hot blast stove or residual heat recovered from a high-temperature combustion furnace or a high-temperature reaction furnace. The method has the advantages that the problem of treating wastes of ferrous sulfate is solved, the ferric and sulfur resources in the ferrous sulfate of industrial wastes are maximumly utilized, and a recycled and economic utilization mode is formed.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

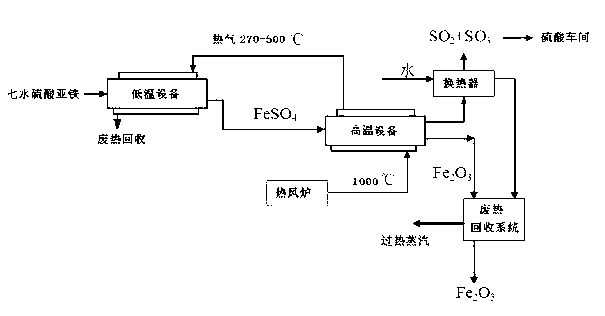

Method for preparing biofuel by using flue gases as raw materials

InactiveCN101525551APromote growthIncrease productionClimate change adaptationLiquid carbonaceous fuelsBiodieselIron plant

The invention belongs to the technical field of greenhouse gas emission reduction and biofuels and relates to a method for preparing a biofuel by using fuel gases as raw materials. Fuel gases emitted in large volume from power plants, steel plants and the like are used as the raw materials for producing the biofuel; in a specially designed bioreactor with light irradiation, rich carbon dioxide in the fuel gases are absorbed by seaweed through photosynthesis, and culture fluid is added at the same time to allow the seaweed to grow rapidly; and the produced seaweed can be converted to biodiesel and other fuels. The technology not only achieves the aims of dramatically reducing the carbon dioxide in the fuel gases and rapidly culturing a large amount of seaweed at low cost, but also solves the problems of greenhouse gas emission reduction and biofuel shortage. The method can be used as greenhouse gas emission reduction technology and used for producing biofuel oil containing seaweed as a by-product to obtain a biofuel for producing biodiesel at the same time in industries continuously emitting carbon dioxide containing flue gases, such as power plants, iron plants, and building material and cement industries.

Owner:饶文涛 +1

Intelligent plate welding device and method for end surface of steel bundle

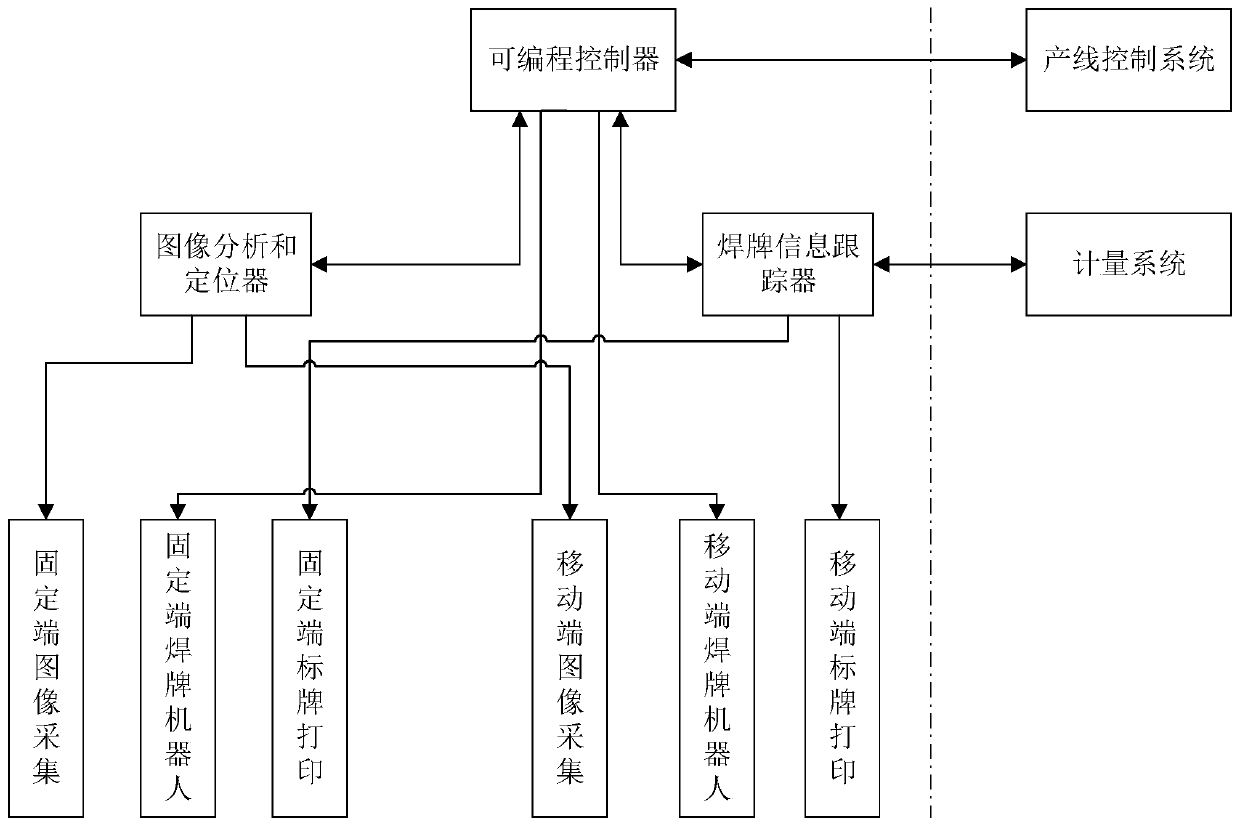

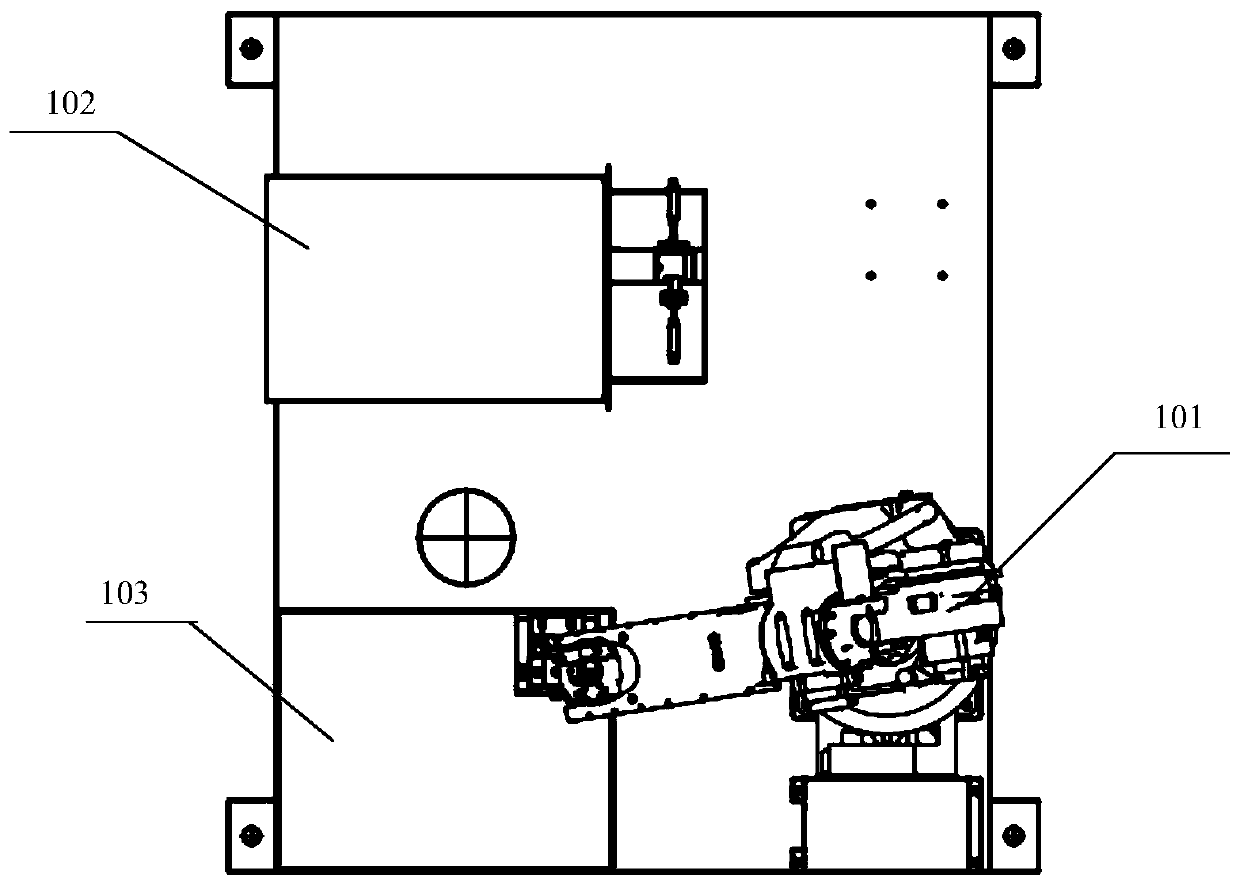

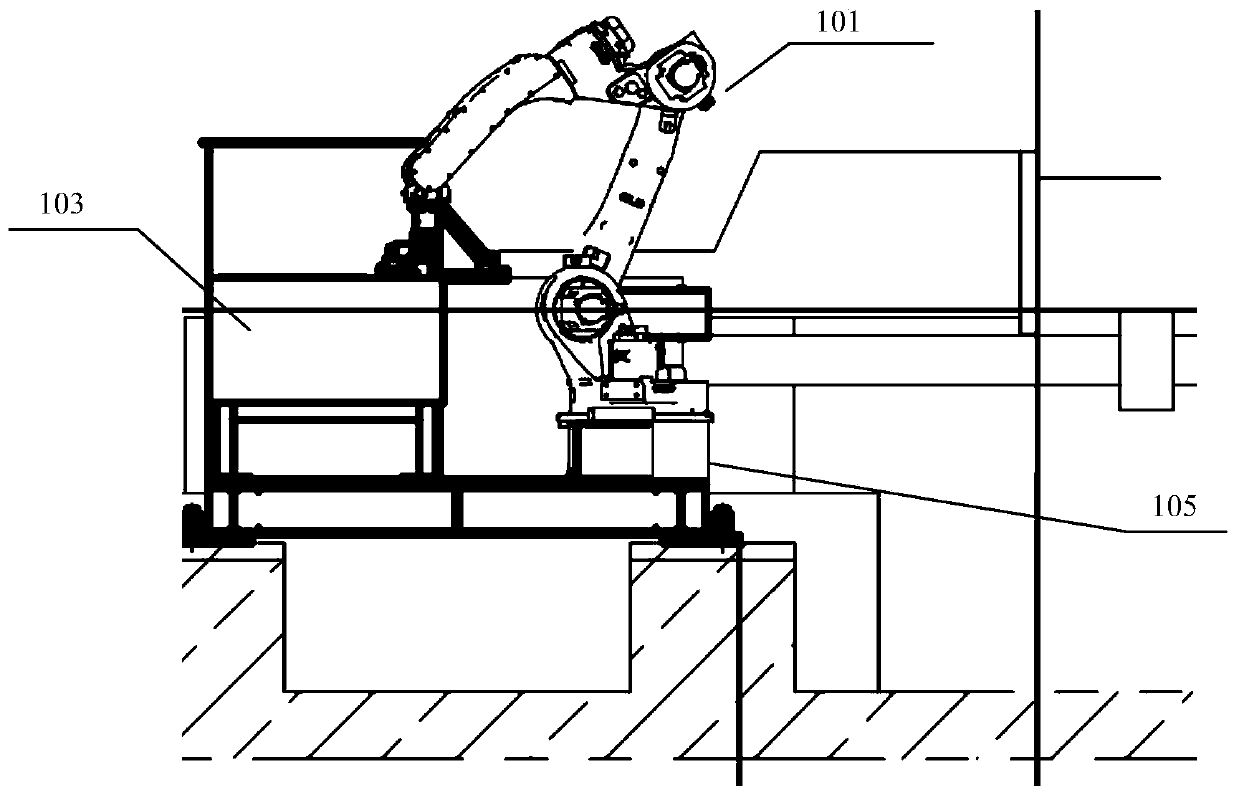

ActiveCN110614459AImplement automatic trackingRealize fully automatic unmanned operationProgramme-controlled manipulatorImage analysisMachine visionIron plant

The invention relates to an intelligent plate welding device and method for the end surface of a steel bundle, belongs to the field of intelligent plant intelligence equipment application, and solvesthe problems of high error rate, high labor intensity, high working area dangerousness and the like caused by manual operation of plate welding of the steel bundle in a steel and iron plant. Image analysis is carried out through a machine vision technology, the position of a steel rod in the steel bundle is positioned, an industrial robot is assisted by accurate coordinate information so as to runto the positioned position, and plate welding is carried out through a specially made machine head plate welding executing mechanism. The whole working process meets the production process rhythm requirement and completely replaces an on-site manual operation post, so that the production efficiency is improved, and the control level is improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH +1

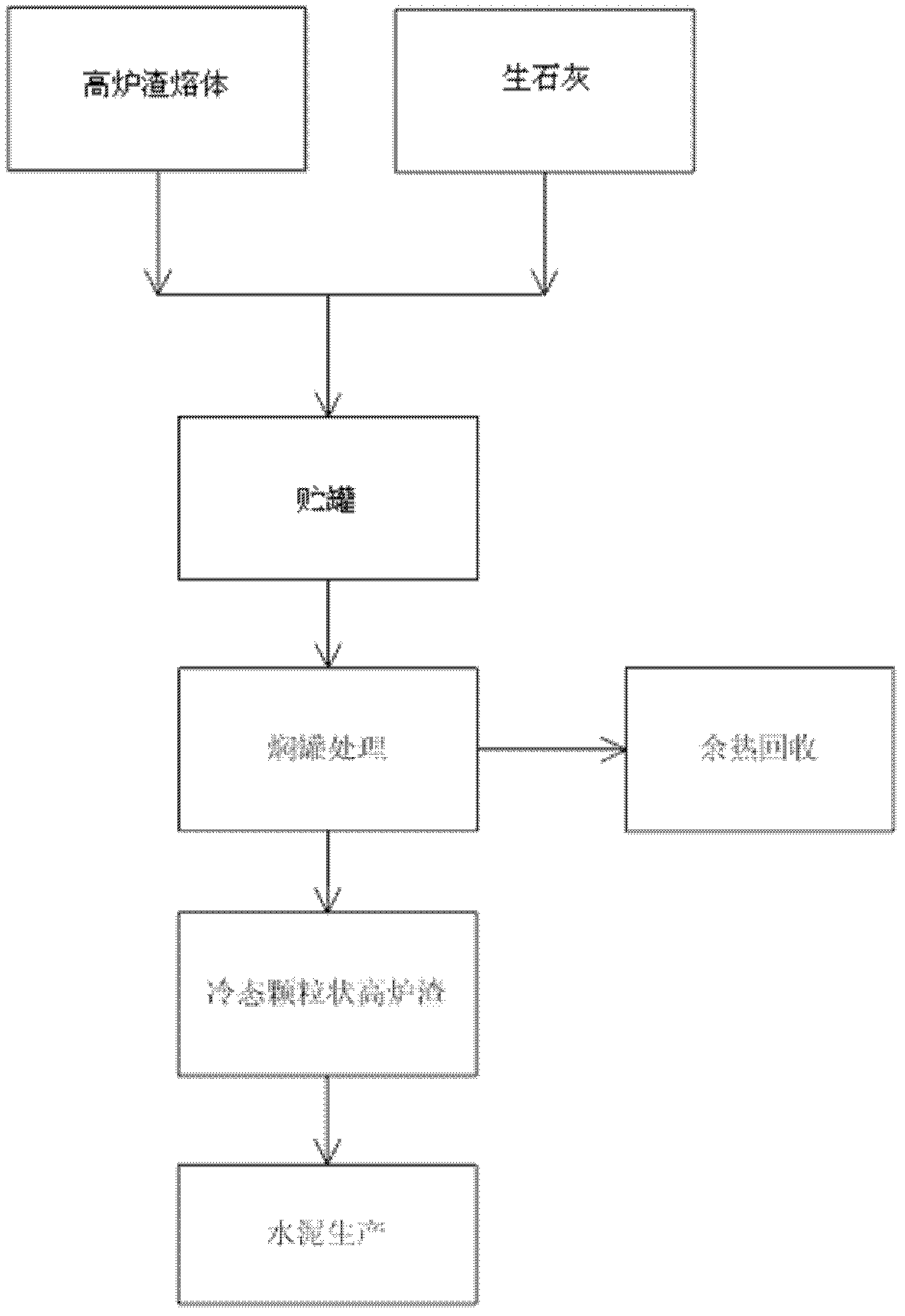

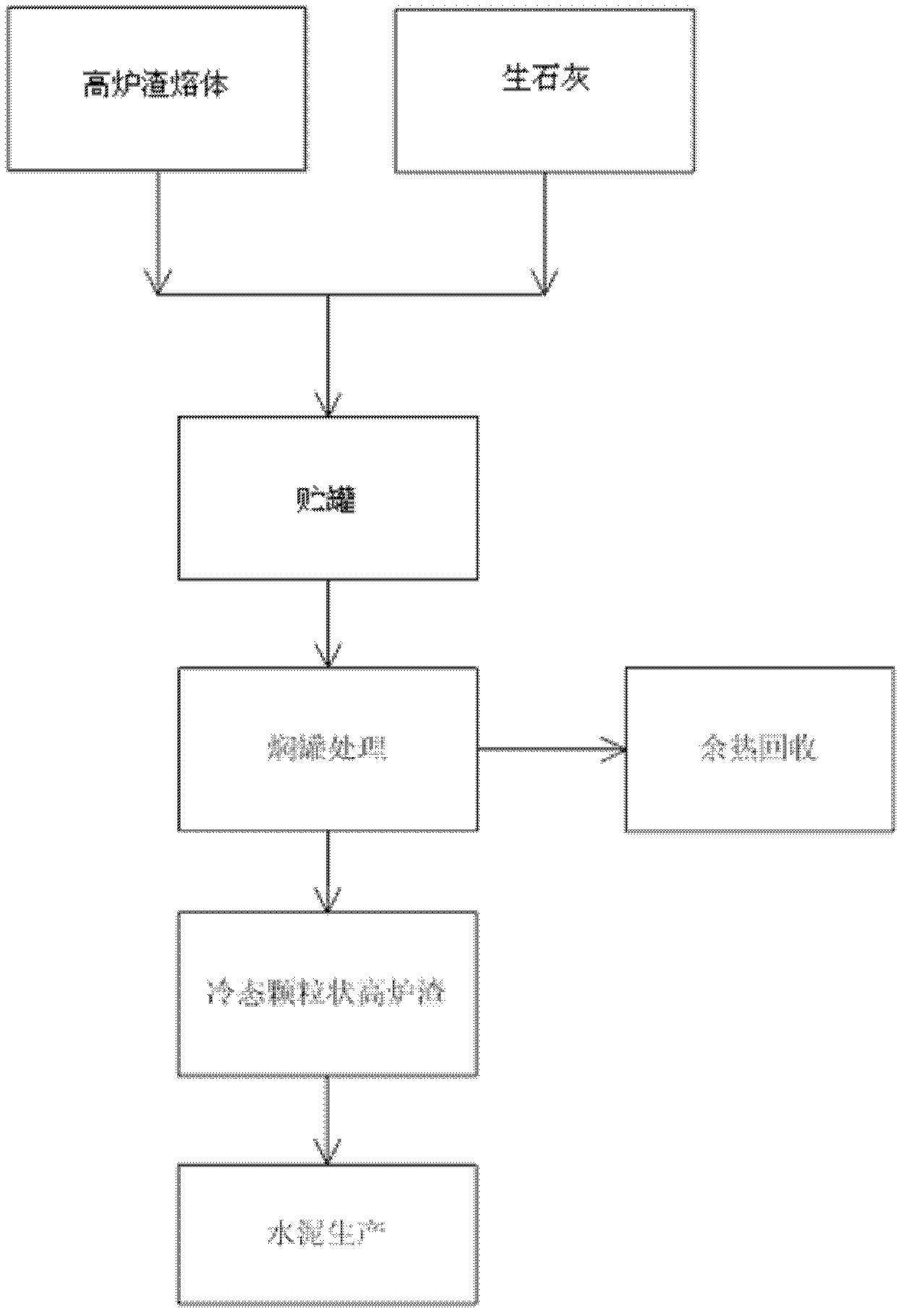

Method for treating blast furnace slag

InactiveCN102382912AAchieve natural pulverizationDoes not affect performanceRecycling and recovery technologiesProcess efficiency improvementIron plantSlag

The invention relates to a method for treating blast furnace slag in a steel and iron plant. The method comprises the following steps of: mixing blast furnace slag melt and calcined lime in a storage tank provided with a heat exchanger; keeping the temperature in the storage tank between 1,200 and 1,295 DEG C; keeping the alkalinity R of the mixed materials between 2.0 and 2.1; performing sealing treatment on the storage tank till the mixed materials are completely pulverized; reclaiming waste heat in the storage tank through the heat exchanger; and taking out the pulverized materials from which the heat is reclaimed. Because water quenching treatment is not needed in the method, the water slag drying cost of a cement plant is saved, the problem of equipment abrasion during flushing the slag with water is avoided, and the operating environment and the quality of air are affected little; because large blast furnace slag granulating equipment is not needed, the energy consumption is low, the process is simple, and performance and additional value of the blast furnace slag are not affected; and the method is energy-saving and environment-friendly, is favorable for improving the comprehensive utilization level of resources, and has good economic and social benefits.

Owner:WISDRI ENG & RES INC LTD

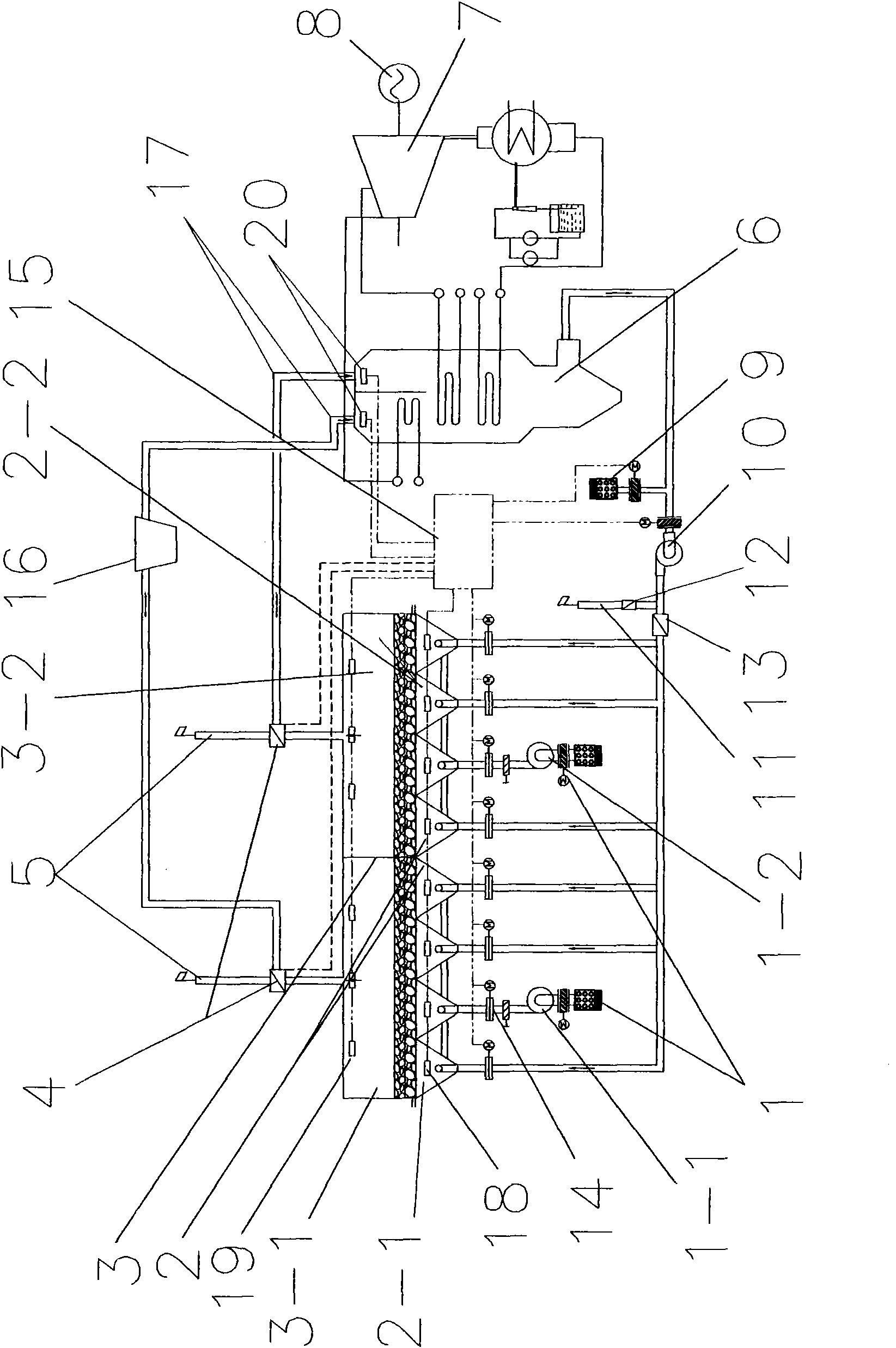

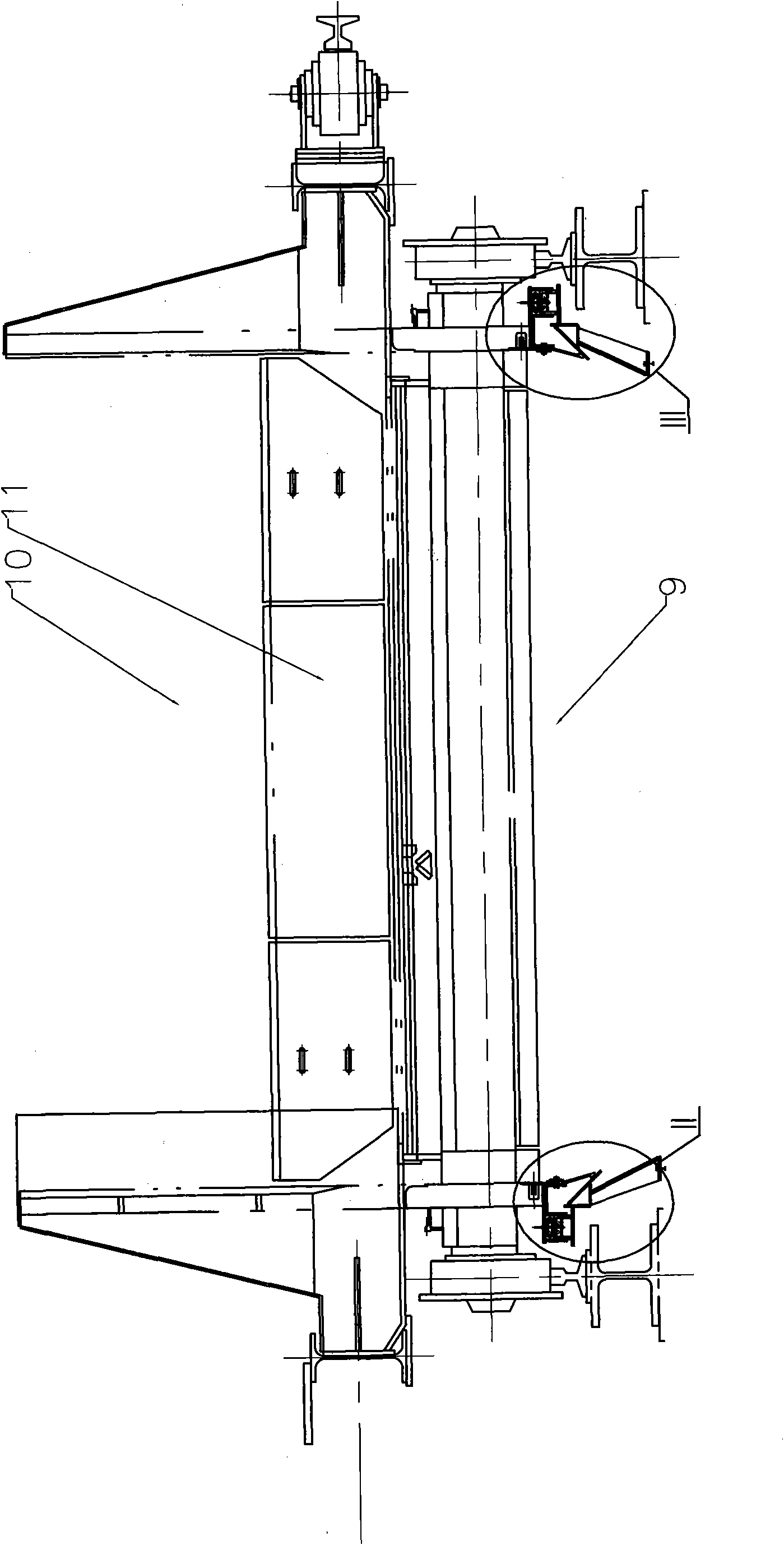

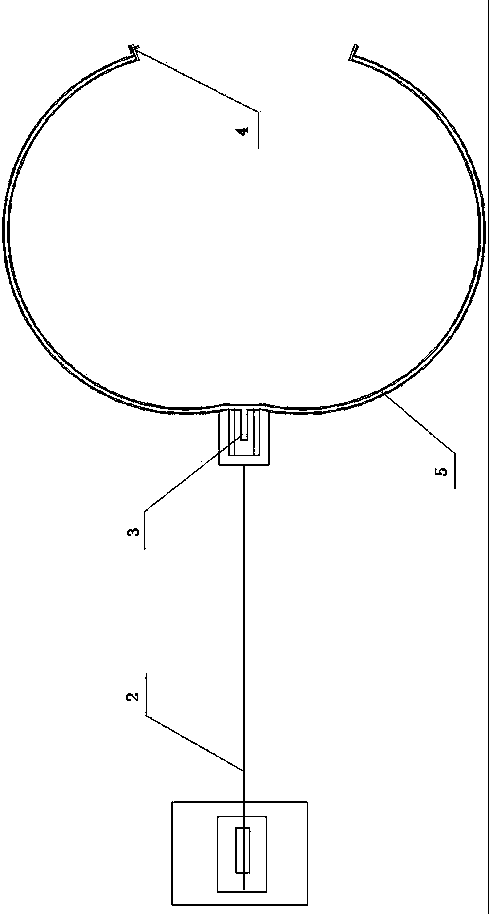

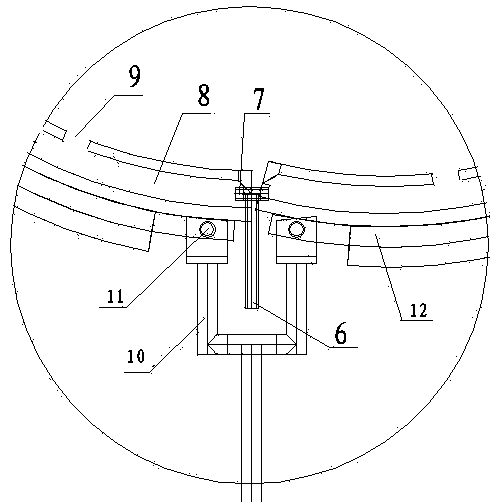

Seal structure between wind chamber and the lower part of sintering ring cold machine trolley of steel and iron plant

ActiveCN101655316AImprove the quality of useLow maintenanceFurnace typesHandling discharged materialIron plantEngineering

The invention discloses a seal structure between a wind chamber and the lower part of a sintering ring cold machine trolley of a steel and iron plant, which mainly comprises an outer seal piece, a seal contact plate and inner-side seal rubber, wherein the outer seal piece consists of a seal piece strut member, an outer limit plate, an inner limit plate, an elastic rubber cylinder, rubber in the shape of a seal groove, a support plate and an adjustable connection screw rod, the support plate is arranged in the rubber in the shape of a seal groove and is connected with the seal piece strut member through the adjustable connection screw rod in an adjustable way, outer seal is realized through the rubber in the shape of a seal groove and the seal contact plate, and inner seal is realized through the inner-side seal rubber. The invention improves the efficiency of smoke recycle and the quality of smoke utilization, fully recycles smoke, effeciently uses cold residual heat of sintering rings, decreases maintenance cost of the seal piece and shortens service life.

Owner:ZHEJIANG XIZI UNITED ENG

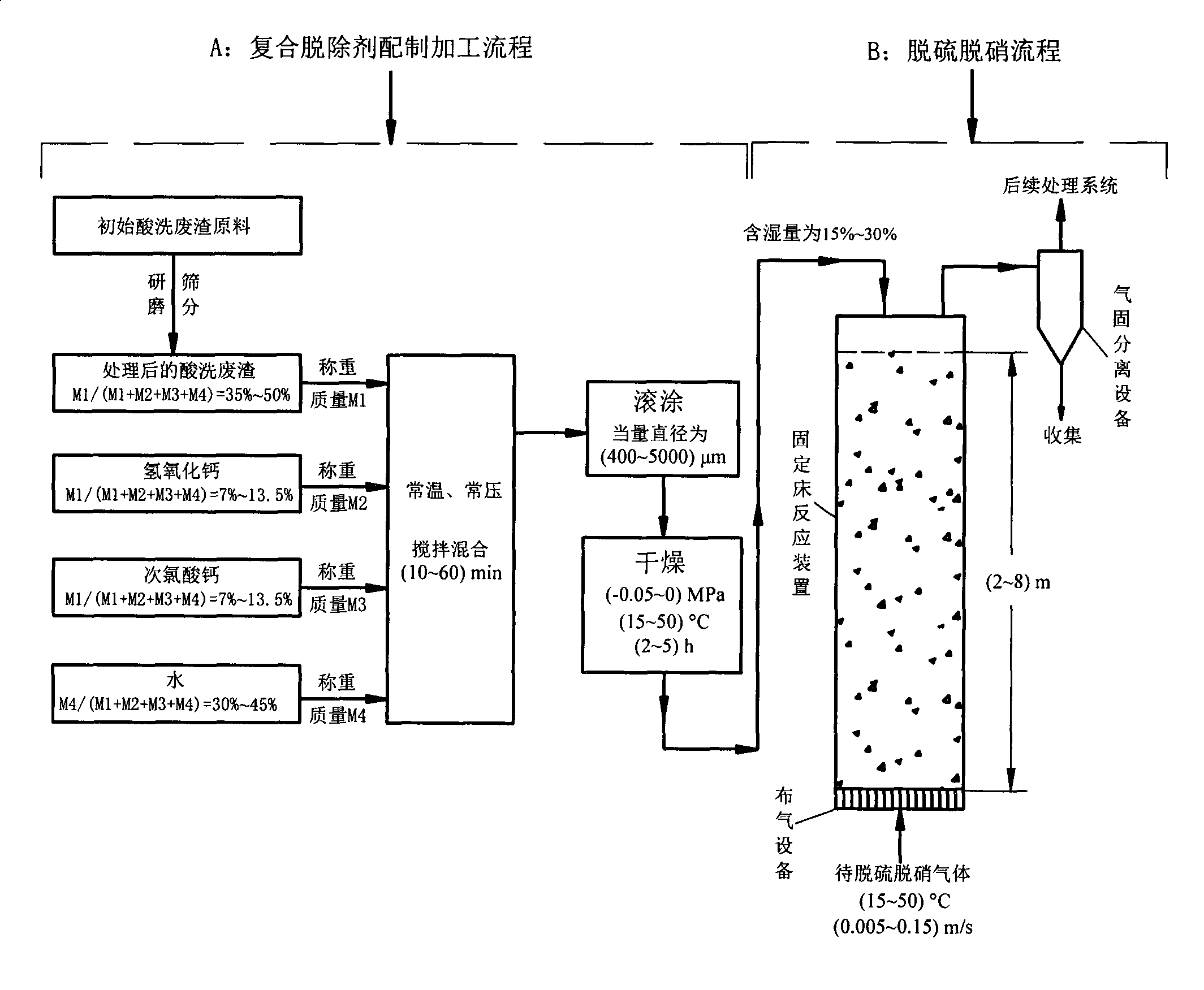

Method for preparing complex removal agent from steel and iron pickling waste residues to carry out desulfurization and denitrification

ActiveCN103537184ARealize secondary useTo achieve the purpose of flue gas dust removalSolid waste disposalDispersed particle separationCalcium hydroxideAfter treatment

The invention provides a method for preparing a complex removal agent from steel and iron pickling waste residues to carry out desulfurization and denitrification. The method is characterized by mixing 35-50% of pickling waste residues from steel and iron plants, 7-13.5% of calcium hydroxide, 7-13.5% of calcium hypochlorite and 30-45% of water by mass uniformly to prepare a paste-like complex removal agent, uniformly roll-coating the paste-like complex removal agent on inert particles, drying the particles with equivalent diameters of 400-5000mu m under certain conditions after roll coating, and filling the particles into a fixed bed reaction device when the moisture content is 15-30%, wherein the filling height is 2-8m; filling gases to be desulfurized and denitrified at 15-50 DEG C from the bottom of the device, wherein the apparent velocity of the gases based on the fixed bed section is 0.005-0.15m / s, and tail gases enter an after-treatment system. The method can be applied to the fields such as steel and iron, power, energy and environmental protection.

Owner:HEBEI UNIV OF TECH

Regeneration method for molten iron desulphurization slag

InactiveCN103981304AReduce manufacturing costEfficient use ofRecycling and recovery technologiesProcess efficiency improvementSteelmakingIron plant

The invention discloses a regeneration method for molten iron desulphurization slag. The regeneration method comprises the following steps of naturally cooling molten iron desulphurization slag generated by a steel and iron plant, breaking the molten iron desulphurization slag by using a heavy hammer, and then, carrying out ball-milling treatment, wherein a hard calcium sulfide shell on the surfaces of lime particles is broken in the ball-milling process; after ball-milling treatment is ended, sieving by using a 100-250-mesh sieve, deironing oversize products, then, returning the oversize products to carry out secondary levigation, enabling fine screen underflow particles to enter a dry magnetic separator to carry out magnetic separation at the magnetic field strength of 100-150kA / m, returning and sintering the obtained an iron-contained substance or steelmaking and recycling; adding 10-30% of lime into magnetic separation tailings, pressing a spherical desulfurizer on a dry ball pressing machine after uniformly mixing, and returning to a metallurgy process for secondary desulphurization. The regeneration method is capable of recycling a great number of unreacted lime particles in the molten iron desulphurization slag, simple in operation, economic, practical and particularly suitable for treating molten iron desulphurization slag in which lime powder is sprayed and blown.

Owner:SUZHOU UNIV

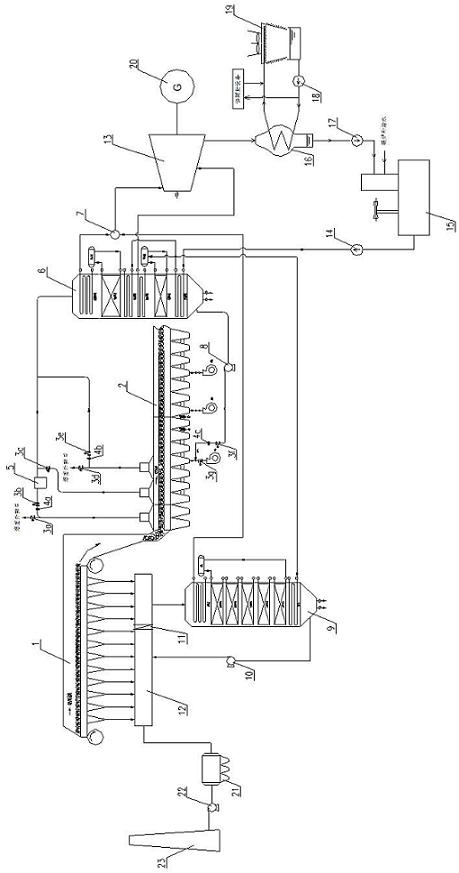

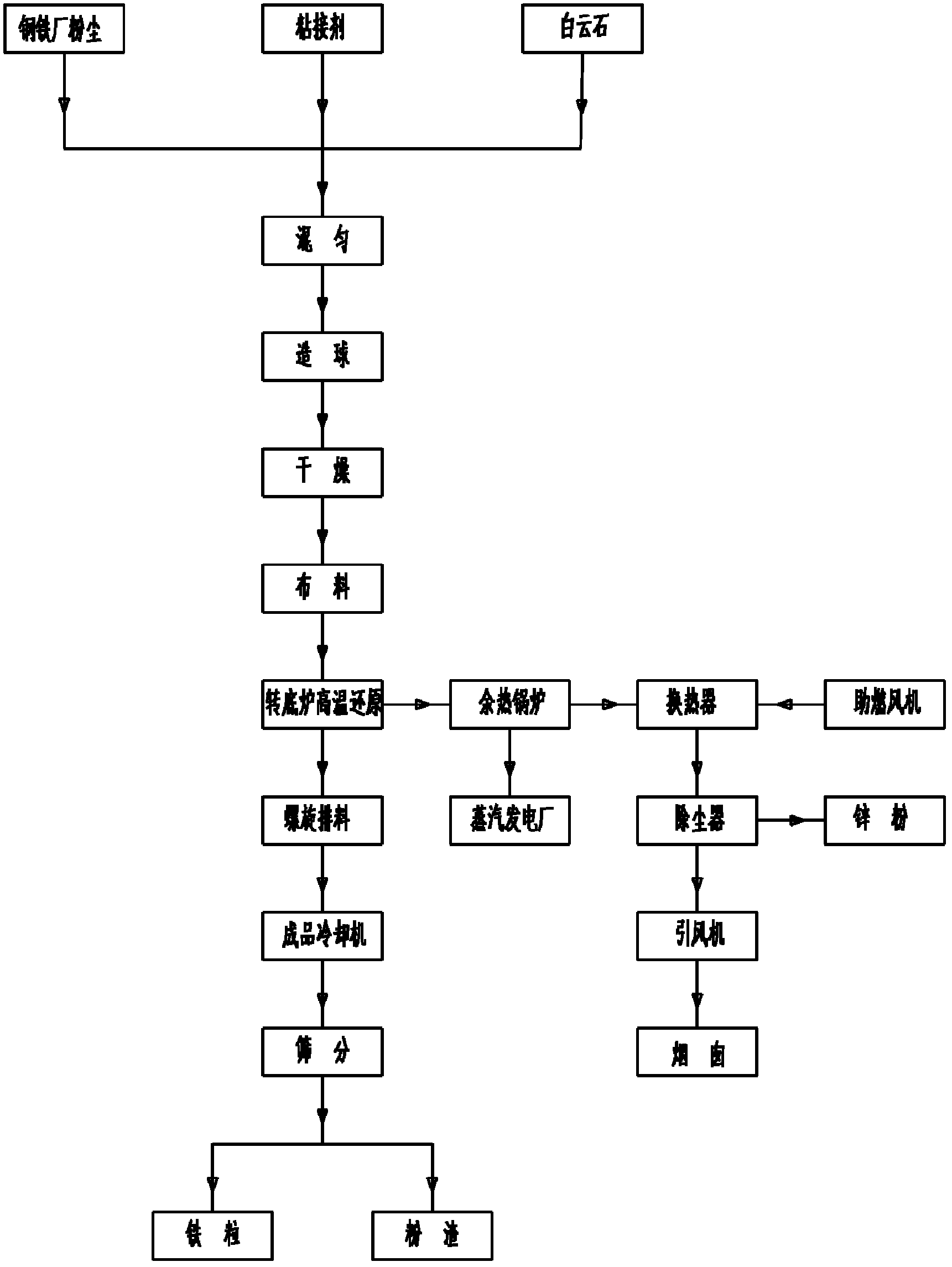

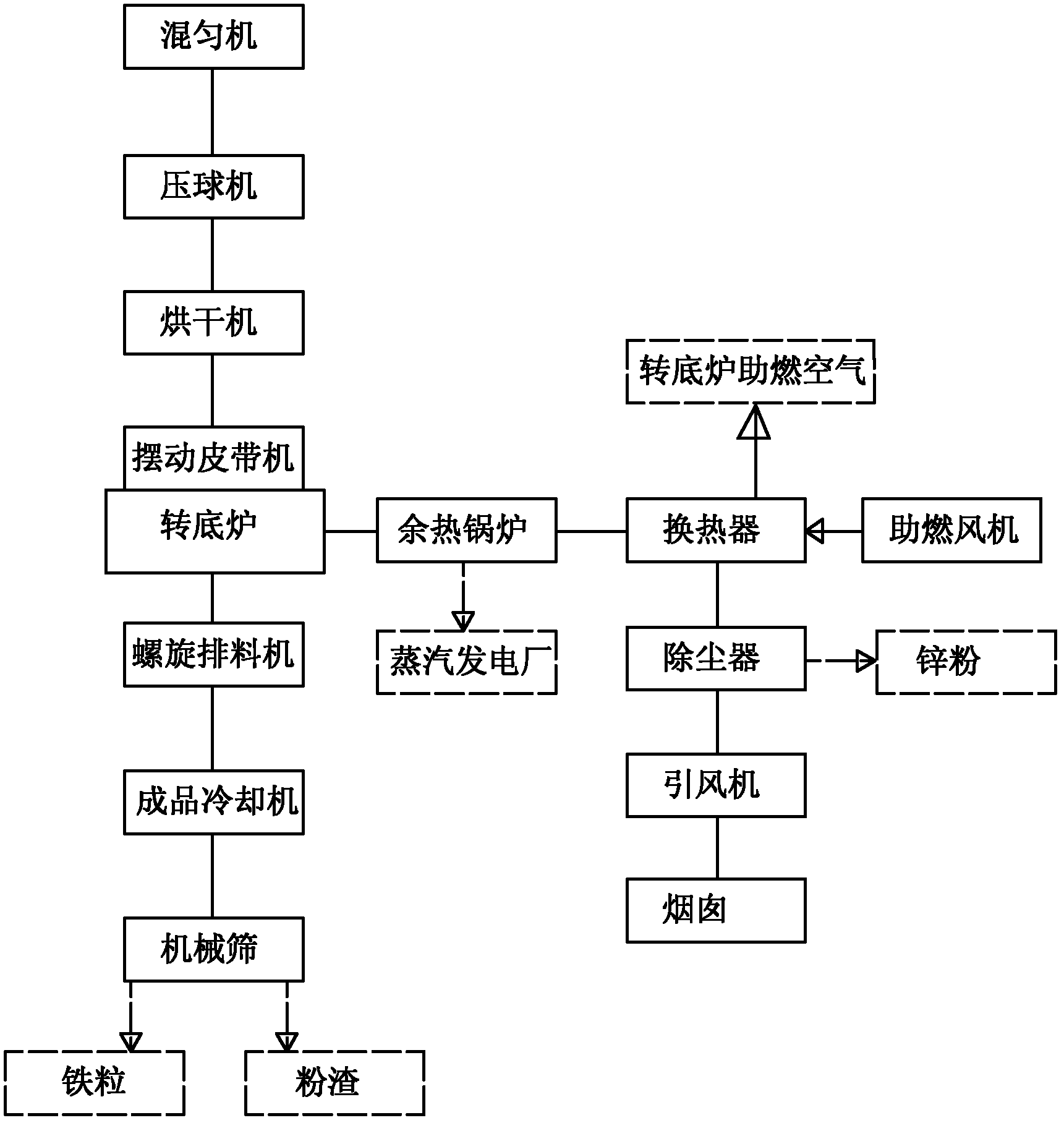

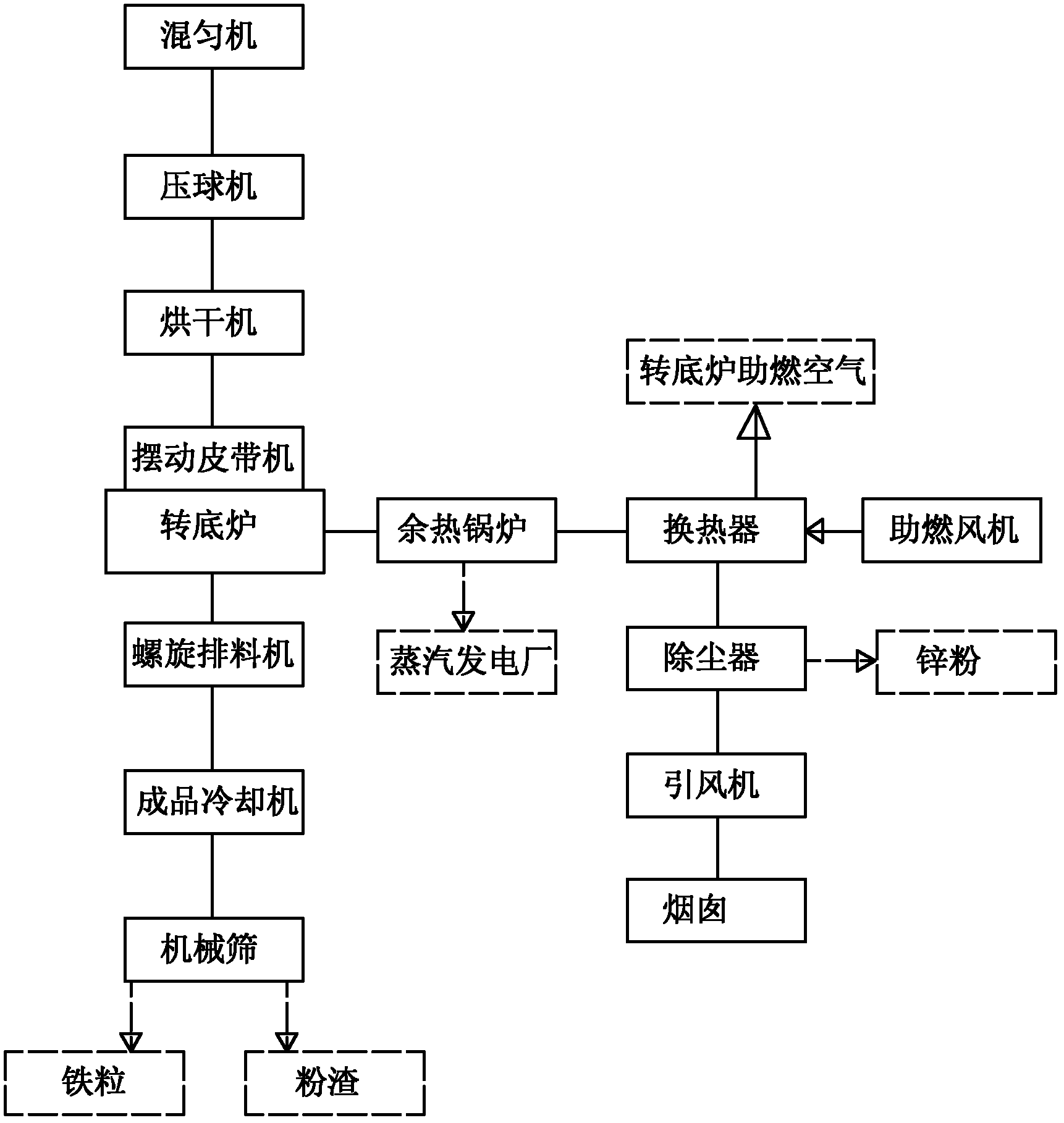

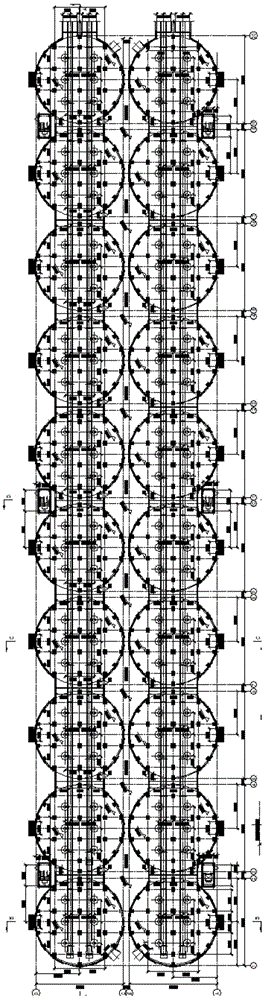

System for extracting iron particles and zinc powder from dust of steel and iron plant

InactiveCN102329908ARealize comprehensive utilizationSimple process routeProcess efficiency improvementIron plantCombustion

The invention relates to a system for extracting iron particles and zinc powder from dust of a steel and iron plant. The system for extracting the iron particles and the zinc powder from the dust of the steel and iron plant is characterized by comprising a mixer, a ball press, a dryer, a swinging belt machine, a rotary hearth furnace, a spiral discharger, a finished product cooler, a mechanical sieve, a waste heat boiler, a heat exchanger, a combustion fan, a dust remover, a draught fan and a chimney; and the output port of the mixer is communicated with the input port of the ball press through conveying equipment, the output port of the ball press is communicated with the input port of the dryer through the conveying equipment, the output port of the dryer is communicated with the input end of the swinging belt machine through the conveying equipment, the swinging belt machine is arranged in a buffer bin of the rotary hearth furnace, the material output port of the rotary hearth furnace is communicated with the finished product cooler through the spiral discharger, and the output port of the finished product cooler is communicated with the input port of the mechanical sieve through the conveying equipment. The system reduces the production energy consumption and the cost, and can realize comprehensive utilization of resources.

Owner:WISDRI ENG & RES INC LTD

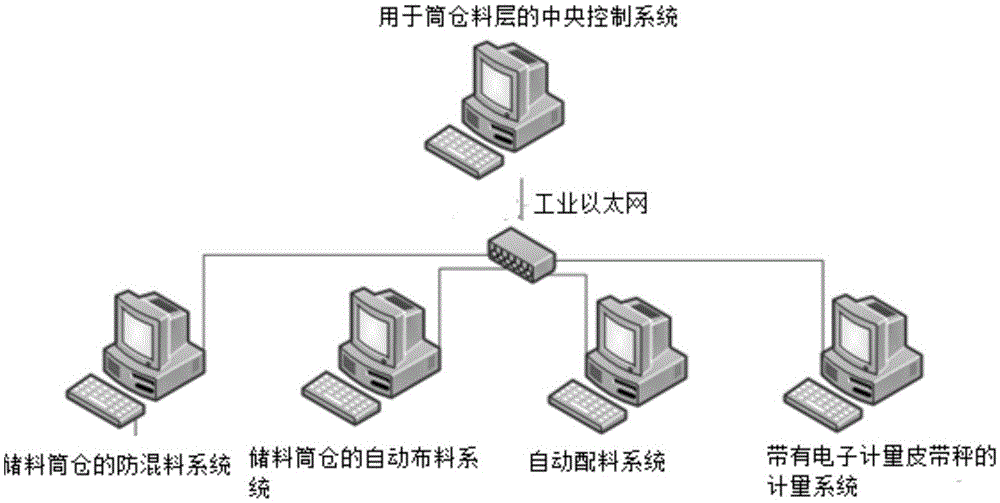

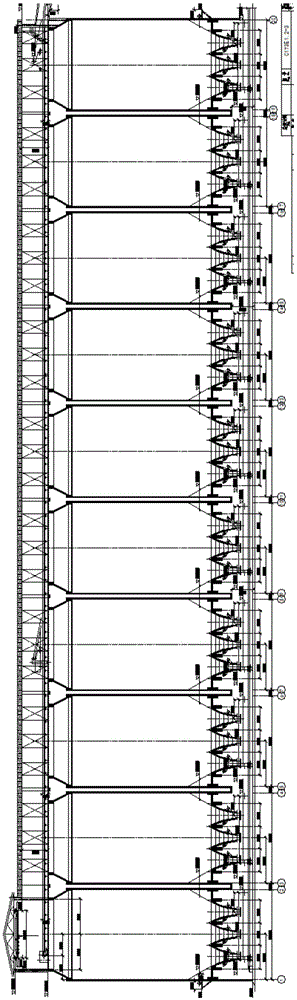

Automatic control system and method for different material layers of stored materials of large-diameter silo

InactiveCN105584852AEasy to controlReduce manufacturing costLoading/unloadingAutomatic controlIron plant

Owner:北京金日新事业技术有限公司

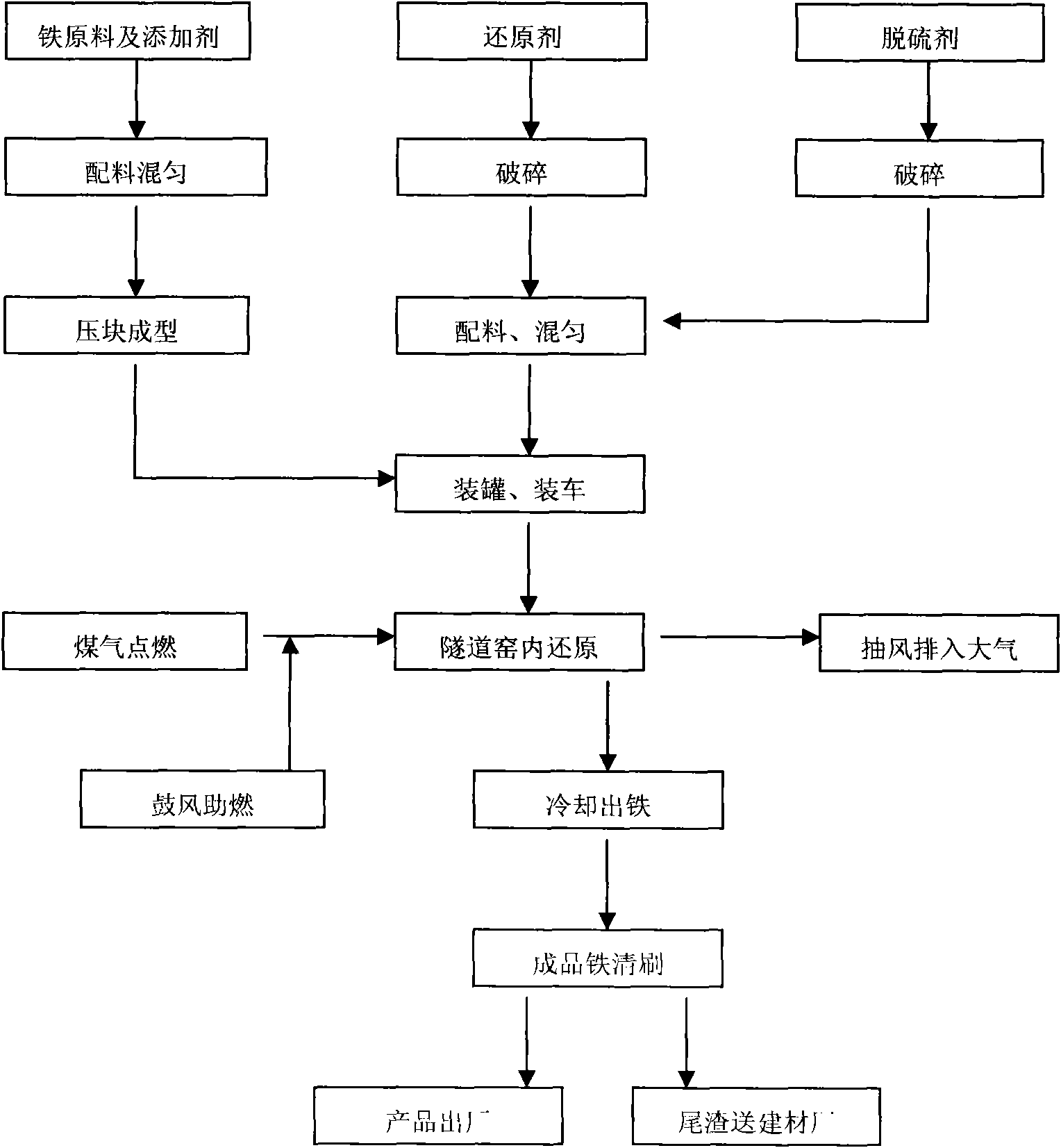

Method for increasing direct reduced iron metallization rate by industrial wastes containing iron and carbon

The invention provides a method for increasing direct reduced iron metallization rate by industrial wastes containing iron and carbon. The method is to mix the industrial wastes containing iron and carbon with the mass ratio of 95 to 99 percent and vegetable powder with the weight ratio of 1 to 5 percent into additive, mix 7 to 20 percent of the additive, 50 to 70 percent of iron raw material, 18 to 25 percent of reducing agent, and 5 to 8 percent of fusing agent by mass ratio, charge, heat and reduce the mixture according to the process of conventional direct reduced iron to obtain an iron product. The method can obviously improve the metallization ratio of direct reduced iron so as to improve the yield of reduced iron, reduce energy consumption, comprehensively utilize the industrial wastes containing iron and carbon, reduce pollution of the industrial wastes on the environment and harm on the main production process of steel and iron plants, and find a perfect approach for the industrial wastes containing iron and carbon.

Owner:WUKUN STEEL

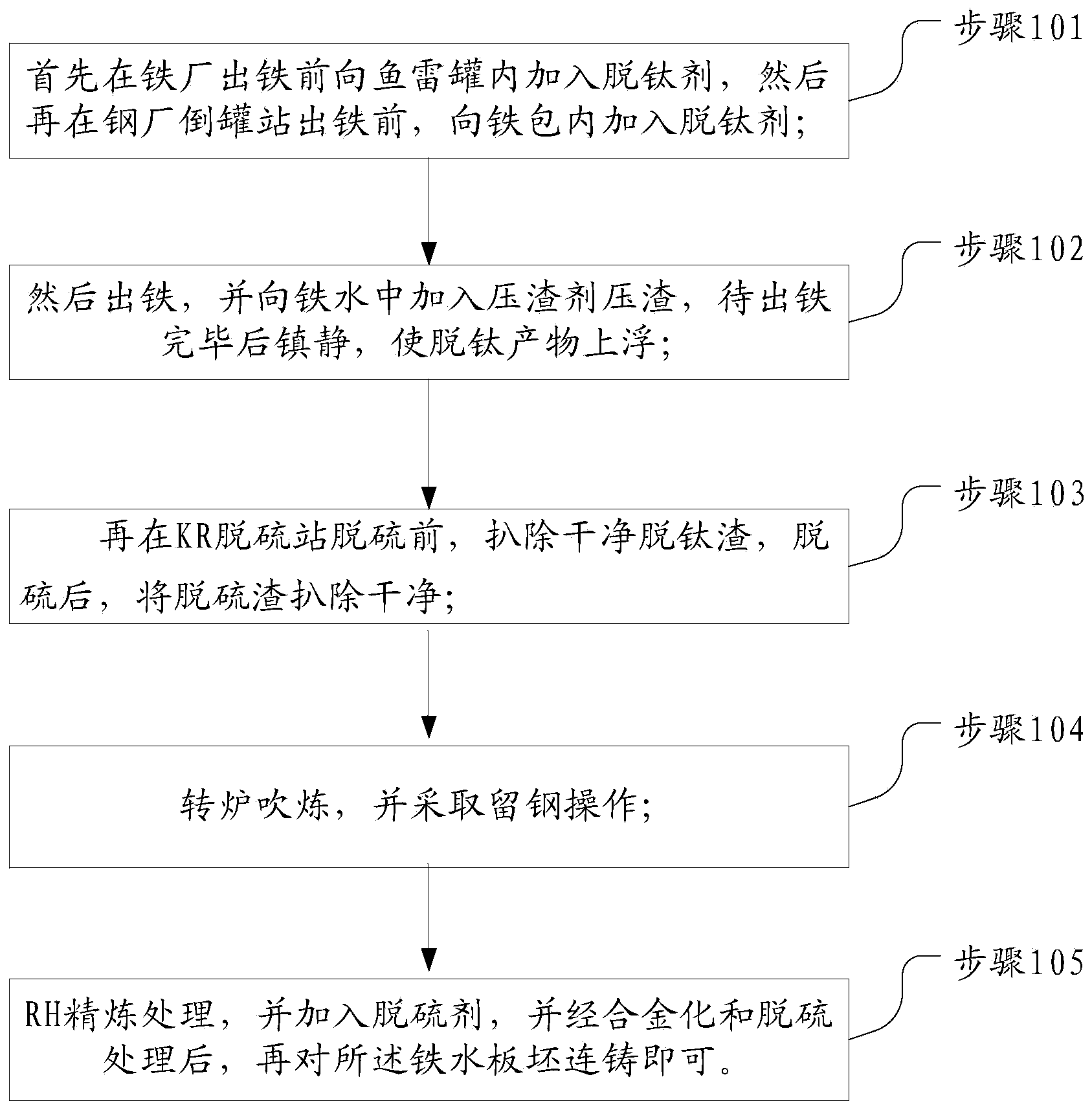

Method for controlling titanium of pure steel

The invention discloses a method for controlling titanium of pure steel and belongs to the technical field of pure steel control. The method for controlling titanium comprises the following steps: adding a titanium removing agent into a torpedo ladle before tapping of an iron plant, and adding a titanium removing agent into an iron ladle before tapping of a reladling station of a steel plant; tapping and adding a slag pressing agent into molten iron in the tapping process to press slag; completely removing titanium removing slag before desulfurization of a KR desulfurization station, and completely removing desulfurization slag after desulfurization is finished; blowing by using a converter and performing steel retaining operation; performing RH refining treatment, adding a desulfurizing agent, performing alloying and desulfurization treatment, and performing continuous casting on molten steel plate blanks. According to the method for controlling titanium disclosed by the invention, iron scale is added into the torpedo ladle and the iron ladle, and reaction is finished by utilizing iron flow impact, so high titanium removing ratio is achieved; during RH refining, high TFe and low alkalinity of top slag are controlled, so that the thermodynamic condition of titanium return reaction among steel slag can be reduced and the titanium return amount can be reduced.

Owner:BEIJING SHOUGANG CO LTD

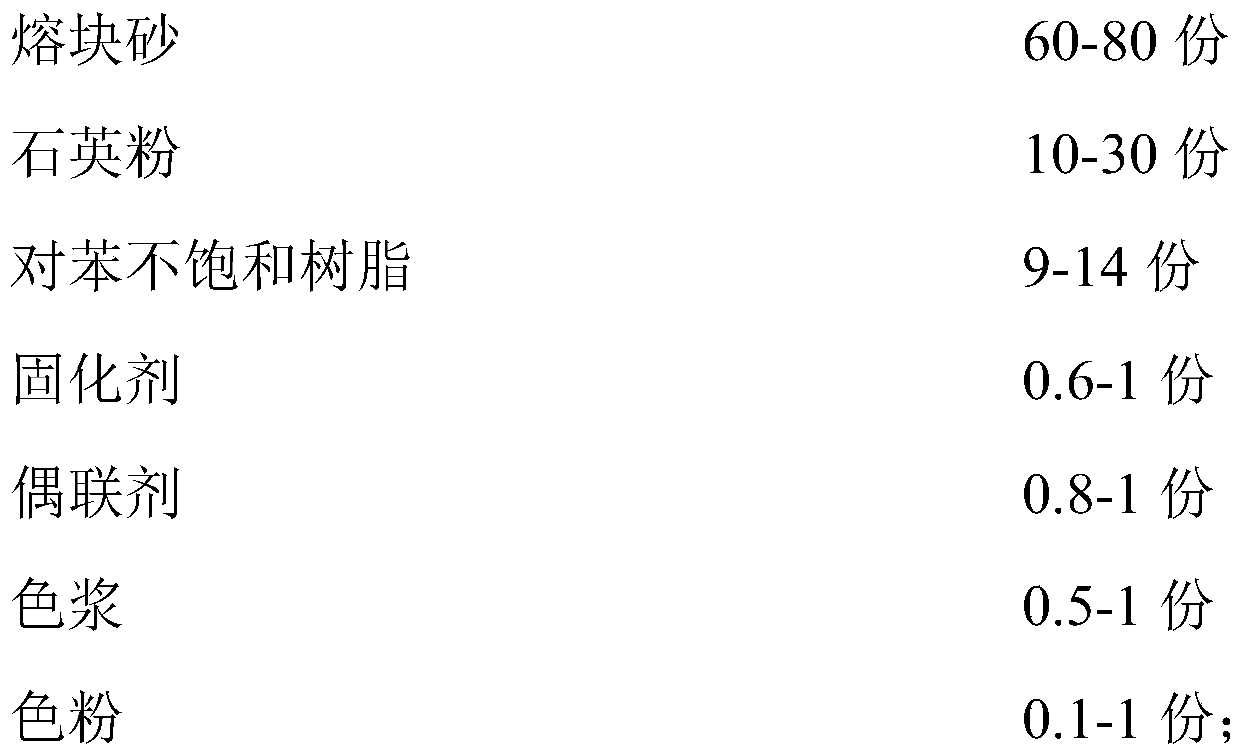

Environment-friendly, low-cost and high-strength artificial stone and method for preparing same

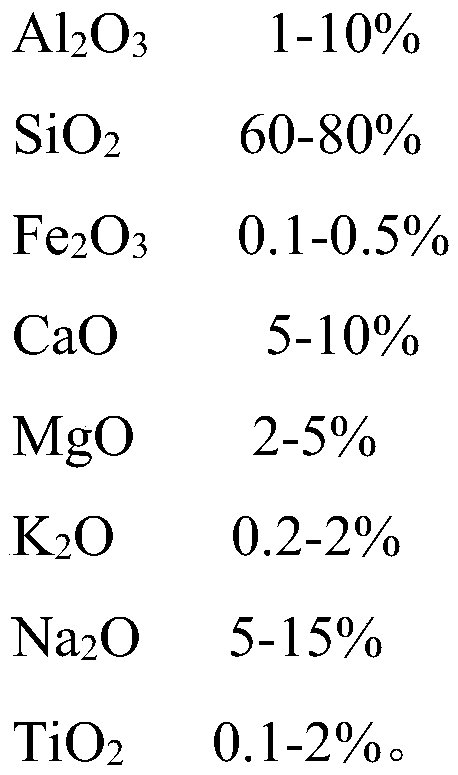

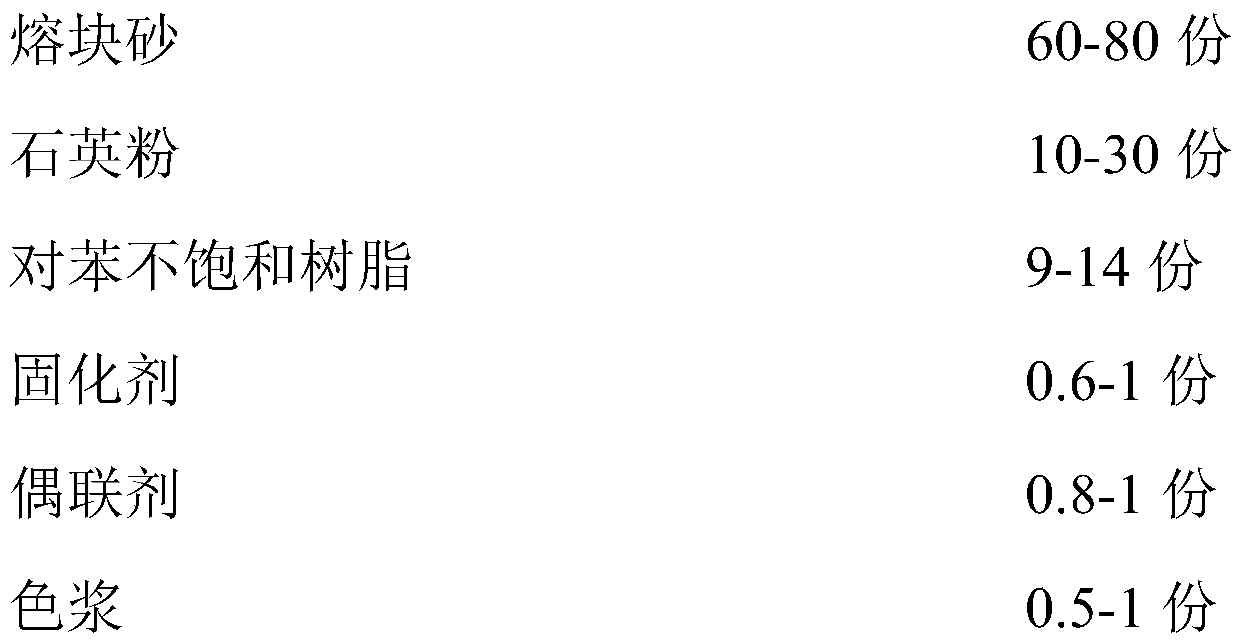

InactiveCN109734356ALess impuritiesUniform particle sizeGlass shaping apparatusIron plantInternational market

The invention relates to environment-friendly, low-cost and high-strength artificial stone and a method for preparing the same. The environment-friendly, low-cost and high-strength artificial stone comprises, by weight, 60-80 parts of fritted sand, 10-30 parts of quartz powder, 9-14 parts of terephthalic unsaturated resin, 0.6-1 part of curing agents, 0.8-1 part of coupling agents, 0.5-1 part of color paste and 0.1-1 part of toner. The environment-friendly, low-cost and high-strength artificial stone and the method have the advantages that mine solid waste materials or discarded materials canbe used as production raw materials, blast furnace gas and coke oven gas which are recycled and purified in steel and iron plants and coking coal plants in production procedures can be used as fuel inproduction procedures, accordingly, the production procedures are green and environmentally friendly, and waste can be recycled; the environment-friendly, low-cost and high-strength artificial stoneis high in strength, has natural streaks, is attractive, elegant, green and environmentally friendly and can be accepted by domestic and foreign clients, and accordingly the environment-friendly, low-cost and high-strength artificial stone and the method have broad prospects on domestic and international markets.

Owner:FOSHAN MONICA QUARTZ STONE CO LTD

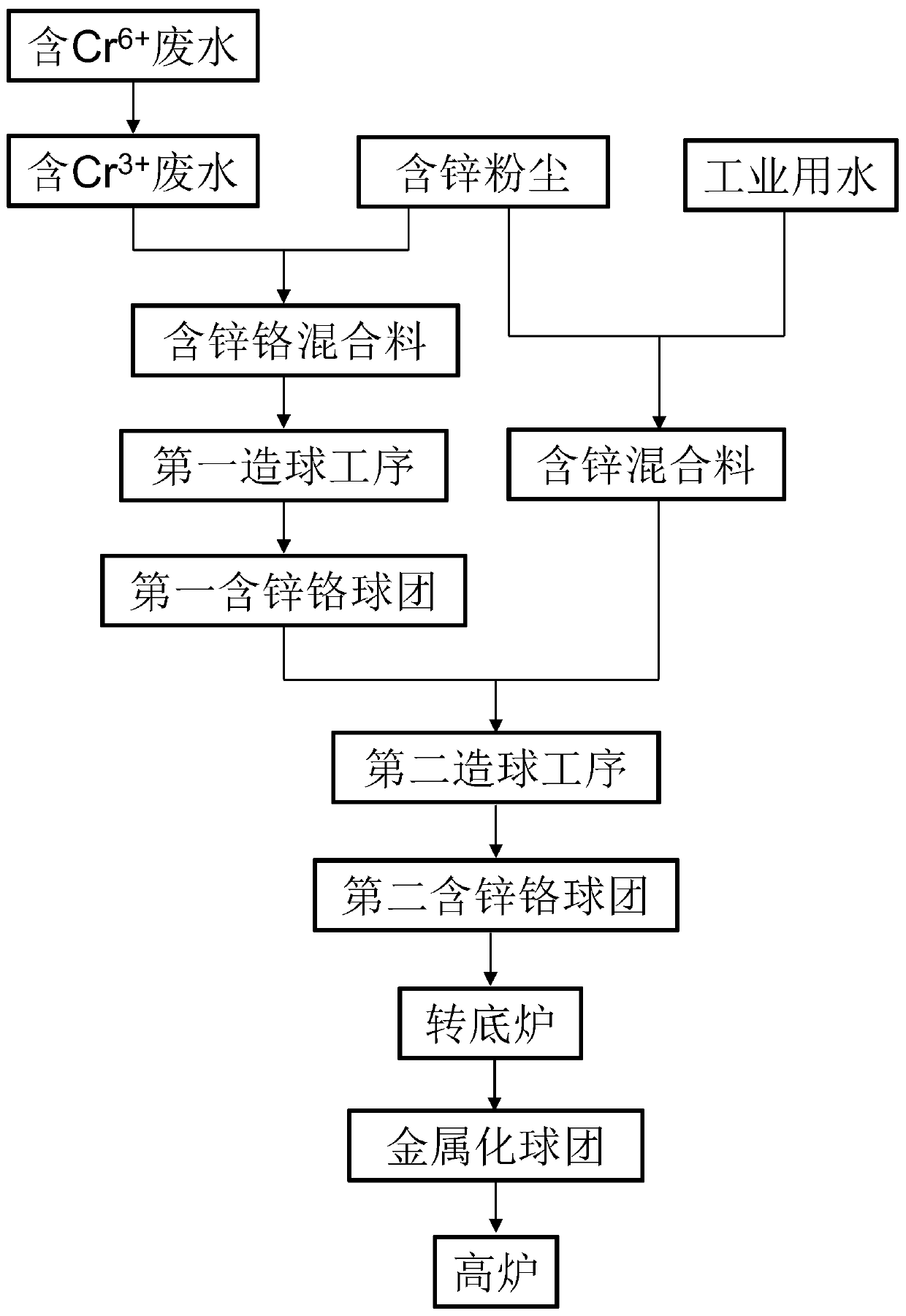

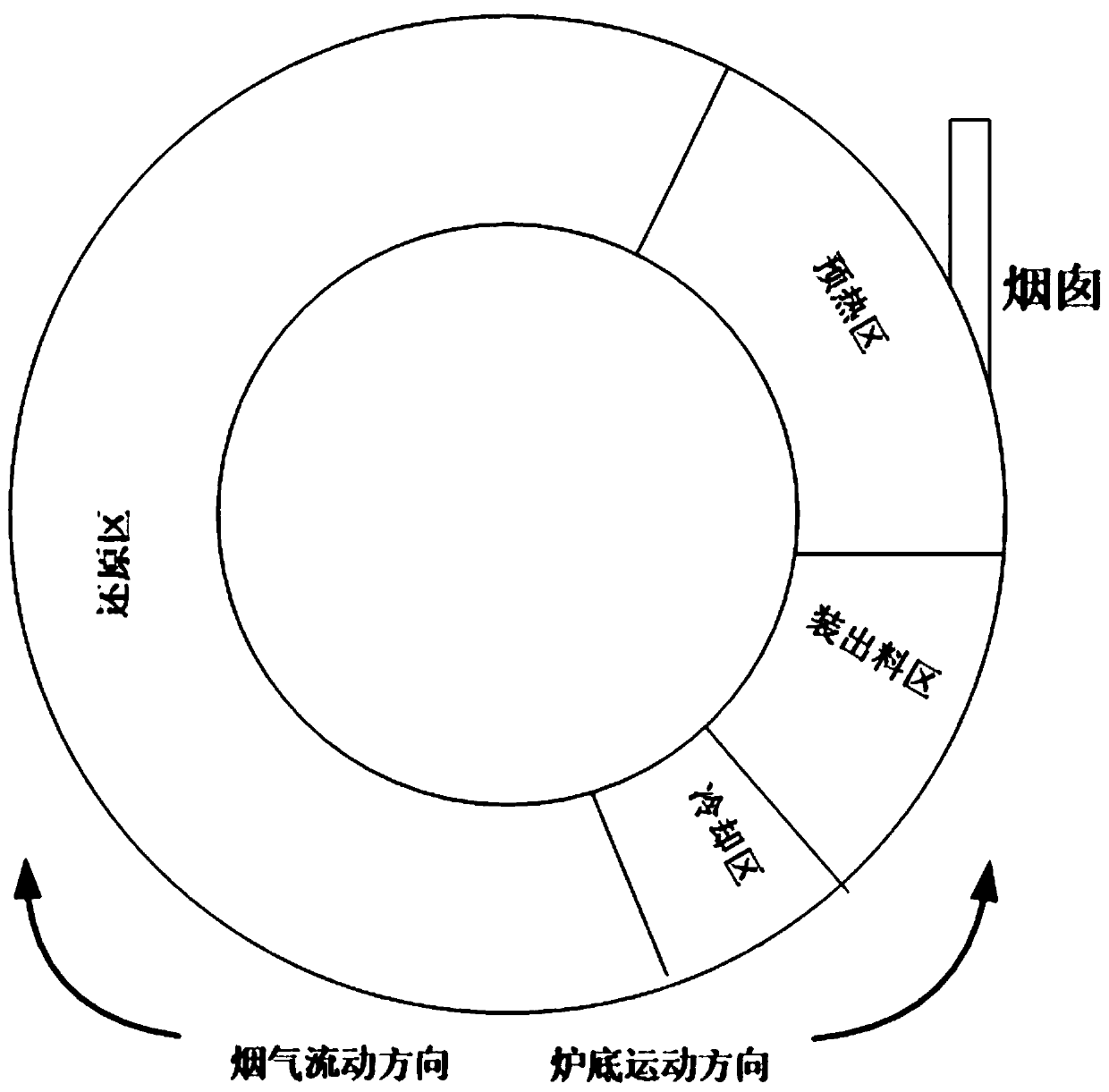

Method for cooperatively treating chromium-containing waste water by pelletizing process

ActiveCN111394572AReduce processing costsReduce usageWater contaminantsWaste water treatment from metallurgical processIron plantWastewater

The invention discloses a method for cooperatively treating chromium-containing waste water by a pelletizing process. The method comprises steps as follows: Cr<6+> in the chromium-containing waste water is reduced into Cr<3+>, and Cr(OH)3 precipitate is formed; the reduced chromium-containing waste water is mixed with zinc-containing dust, and a zinc and chromium contained mixture is obtained, andfirst zinc and chromium contained pellet is prepared by a first pelletizing process; the zinc-containing dust is mixed uniformly with industrial water, a zinc-containing mixture is obtained, the first zinc and chromium contained pellet coated with the zinc-containing mixture is prepared by a second pelletizing process, a zinc-containing coating layer is formed, and a second zinc and chromium contained pellet is prepared; the second zinc and chromium contained pellet is sent to a rotary hearth furnace for reduction, and a metallized pellet is prepared; and the metallized pellet is added to blast furnace ironmaking components for smelting, and chromium in the metallized pellet is completely melted into molten iron. According to the method for cooperatively treating the chromium-containing waste water by the pelletizing process, the chromium-containing waste water produced in a steel and iron plant can be 100% consumed in the plant, outsourcing treatment is not needed, and the method hasenvironment-friendly and social benefits while realizing reducing and harmless treatment.

Owner:宝武集团环境资源科技有限公司

Method for treating iron slag at dead angles of iron plant

InactiveCN101914638ASolve processing problemsGuarantee normal tappingRecycling and recovery technologiesIron plantSlag

The invention discloses a method for treating iron slag at dead angles of an iron plant. In the method, a stokehold crane is provided with a suspension crane and the suspension crane is used for treating the iron slag at the dead angles. The method has the advantages of solving the problem of difficult treatment of the iron slag at the dead angles well, ensuring normal iron discharge of a blast furnace, greatly reducing labor intensity in the stokehold of the blast furnace and improving working conditions of workers and labor efficiency.

Owner:PANGANG GRP ENG TECH +2

Method for filtering and washing raw red mud

InactiveCN1730417AReduce moisture contentReduce the amount of washing waterSludge treatmentProcess efficiency improvementIron plantRed mud

The invention discloses a crude red mud filtrating and washing process, which consists of loading crude red mud slip from the red mud grading procedure into horizontal band filters or flat disc type filters for filtrating and washing, wherein the distribution head on the filters divides the whole filter into a separation zone and a washing zone, loading the crude liquor obtained in the seperation zone into a desiliconisation procedure, entering the filter cakes of seperaton area into the washing zone, proceed reversal washing for two to three times, loading the washed red mud cleaning solution to a dissolving procedure, loading the washed crude red mud to sponge iron plant for reclamation of iron.

Owner:GUIYANG AL-MG DESIGN & RES INST

Energy-saving environment-protecting method for steel and iron plant sintering

The invention discloses an energy-saving environment-protecting method for steel and iron plant sintering. The energy-saving environment-protecting method for steel and iron plant sintering comprises the following steps that (1) solid fuel consumption is reduced by adopting thick bed sintering; (2) solid fuel consumption is reduced through recycling production and the burning effect and performance of solid fuels improvement; (3) the burning effect and performance of solid fuels are improved; (4) the temperature of a sintering material can be improved through hot returning ores and quick lime and hot gas sintering and by injecting steam through a drum mixer before the fuels are mixed, and thus waste heat can be utilized; (5) energy consumption of ignition is reduced by applying an energy-saving type igniter and by means of the method of preheating combustion air; (6) electricity consumption is reduced by reducing air leakage and by adopting a frequency conversion technology; and (7) waste heat is recycled by applying a waste heat boiler and by adopting a waste heat boiler and a waste gas sintering technology. Energy saving and environment protection of the sintering process is actually achieved through the energy-saving environment-protecting method for steel and iron plant sintering provided by the invention.

Owner:HARBIN HONGTIAN RUIDA TECH

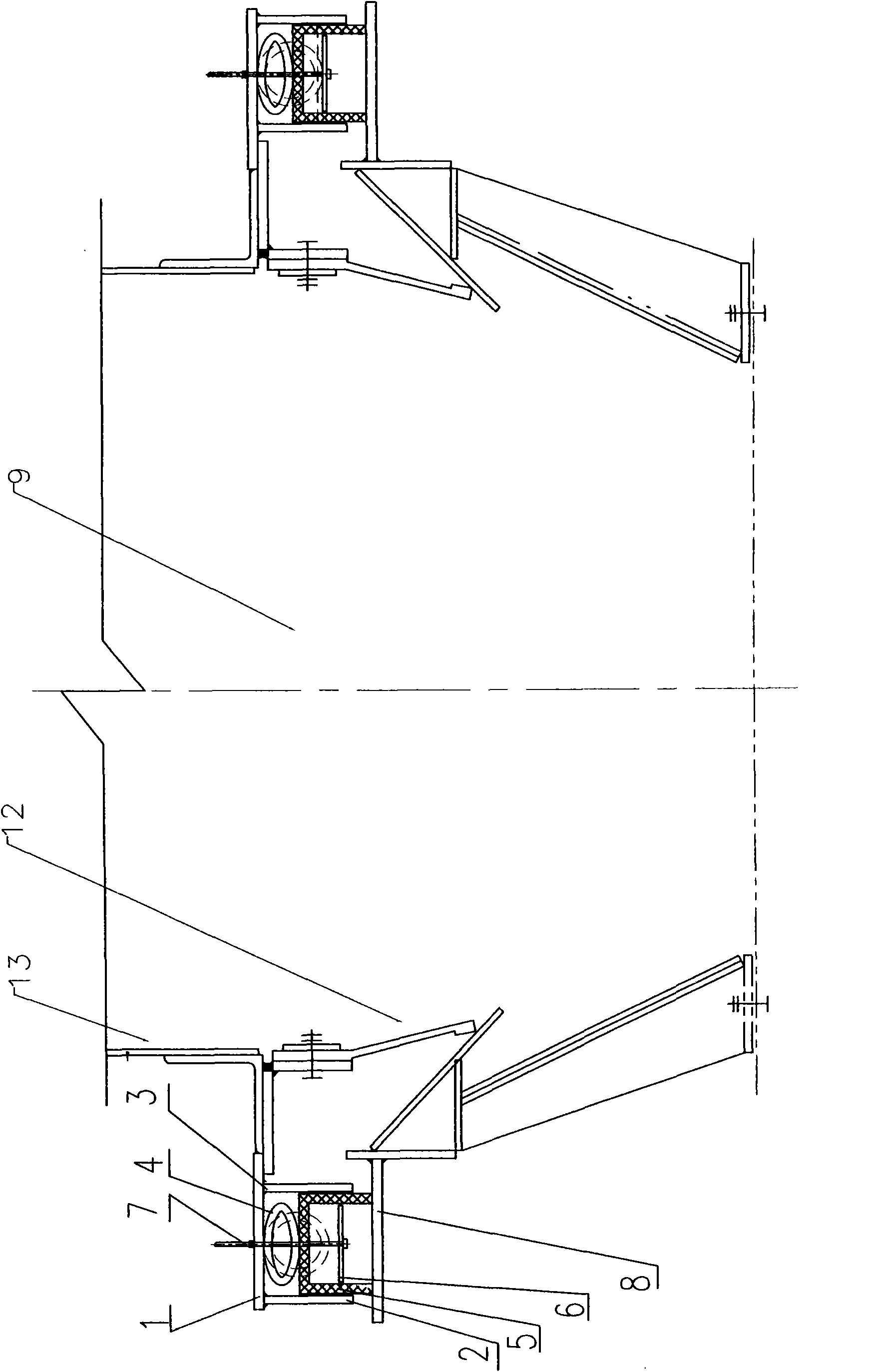

Seal structure at sintering ring cold machine air chamber terminal of steel and iron plant

ActiveCN101655317AImprove recycling ratesImprove the quality of useFurnace typesHandling discharged materialSheet steelIron plant

The invention discloses a seal structure at the sintering ring cold machine wind chamber terminal of a steel and iron plant, which comprises a seal structure at a high-temperature smoke using section, a seal structure at a low-temperature smoke using section, a trolley and seal rubber at the bottom of the trolley, wherein the seal structure at the high-temperature smoke using section mainly comprises a first seal steel plate, a second seal steel plate, a vertical steel windproof plate and a tripod, the near-edge distance between the first seal steel plate and the second seal steel plate is shorter than the length between two sections of the trolley, and the far-edge distance between the first seal steel plate and the second seal steel plate is longer than the length between two sections of the trolley; and the invention prevents wind leaking from two terminals of a residual heat using phase in an air chamber of a smoke recycling phase so as to improve the efficiency of smoke recycle and the quality of smoke utilization, and further ensures that the whole power generating system using residual heat operates stably and effectively.

Owner:ZHEJIANG XIZI UNITED ENG

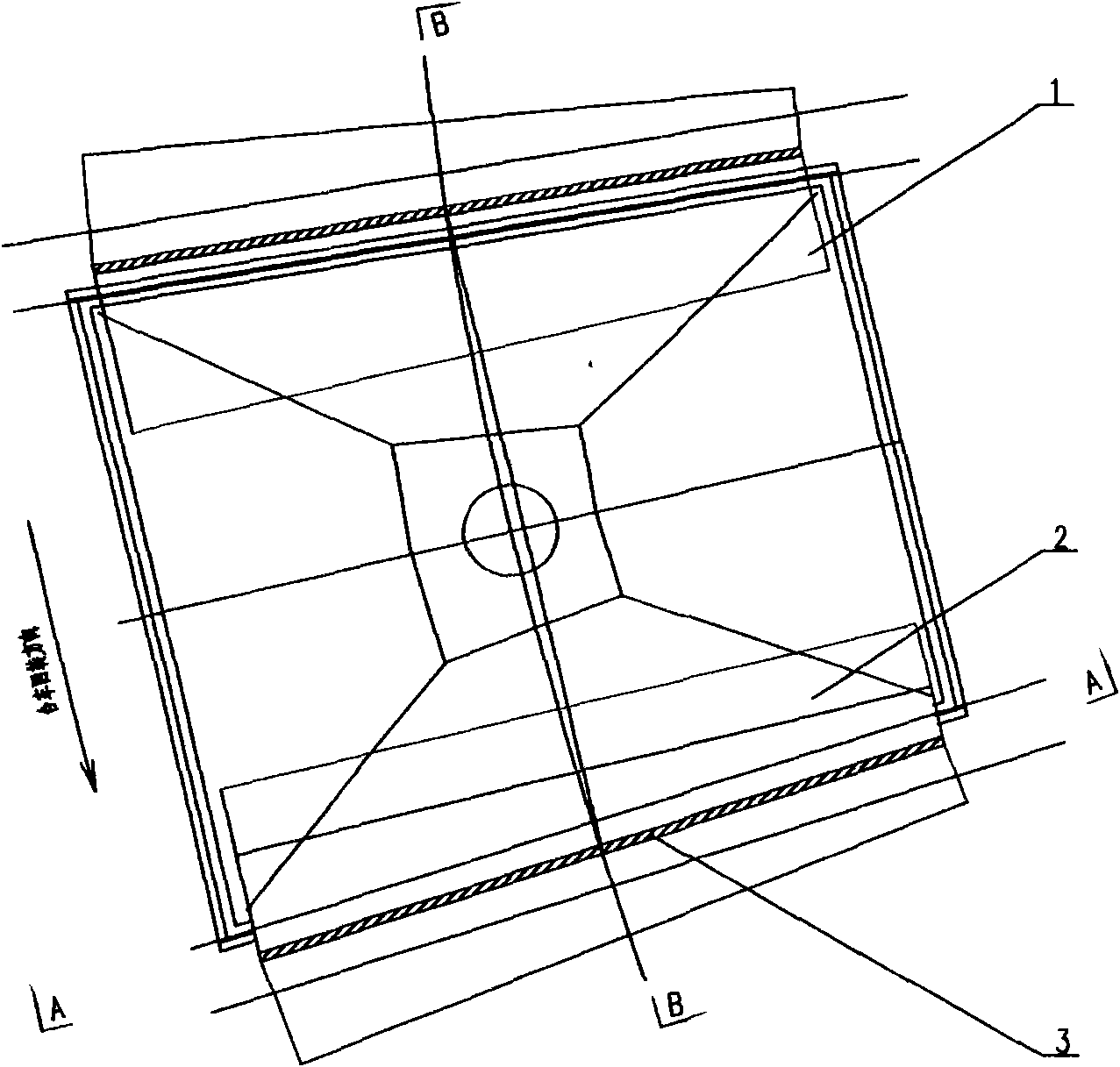

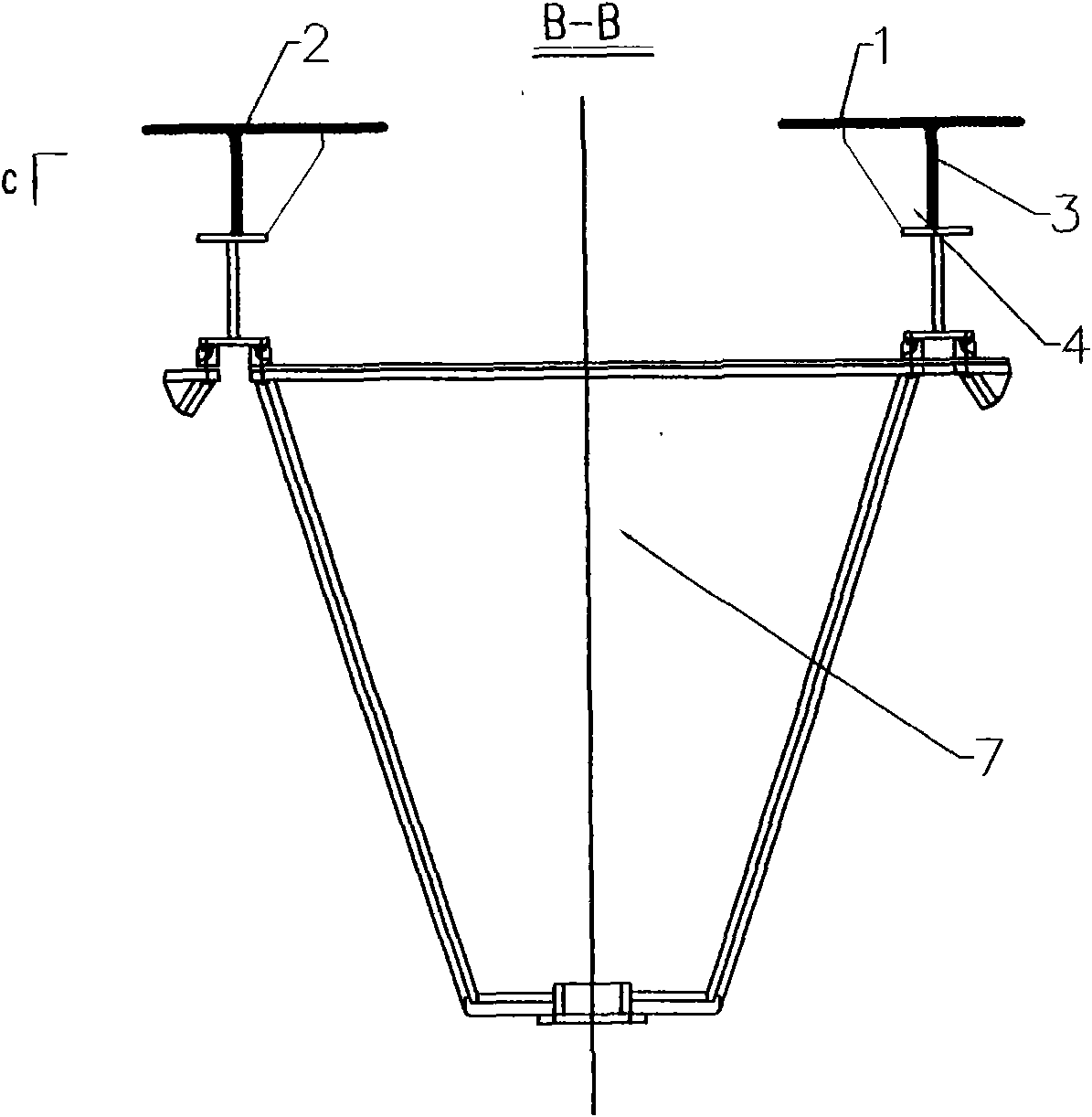

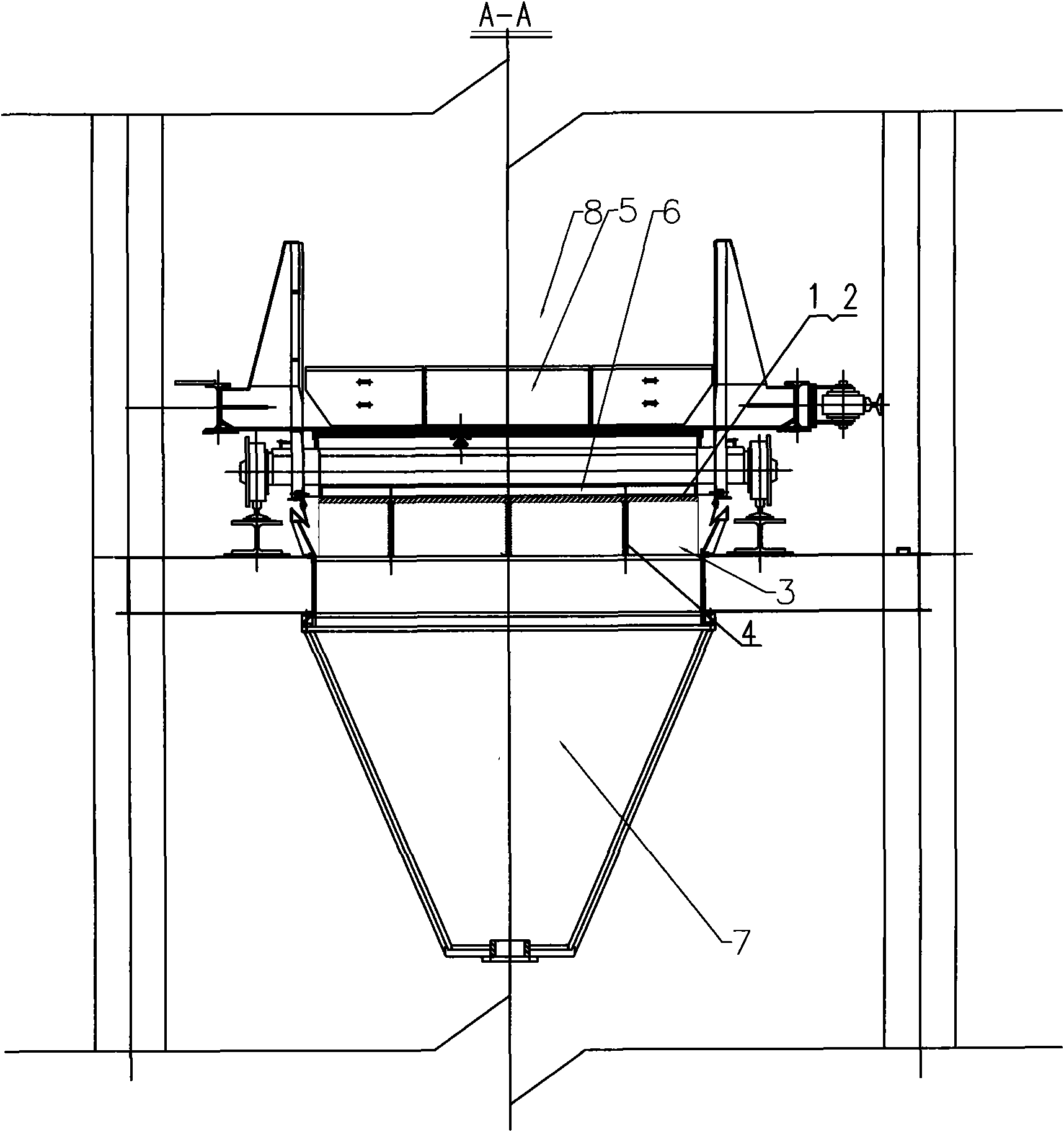

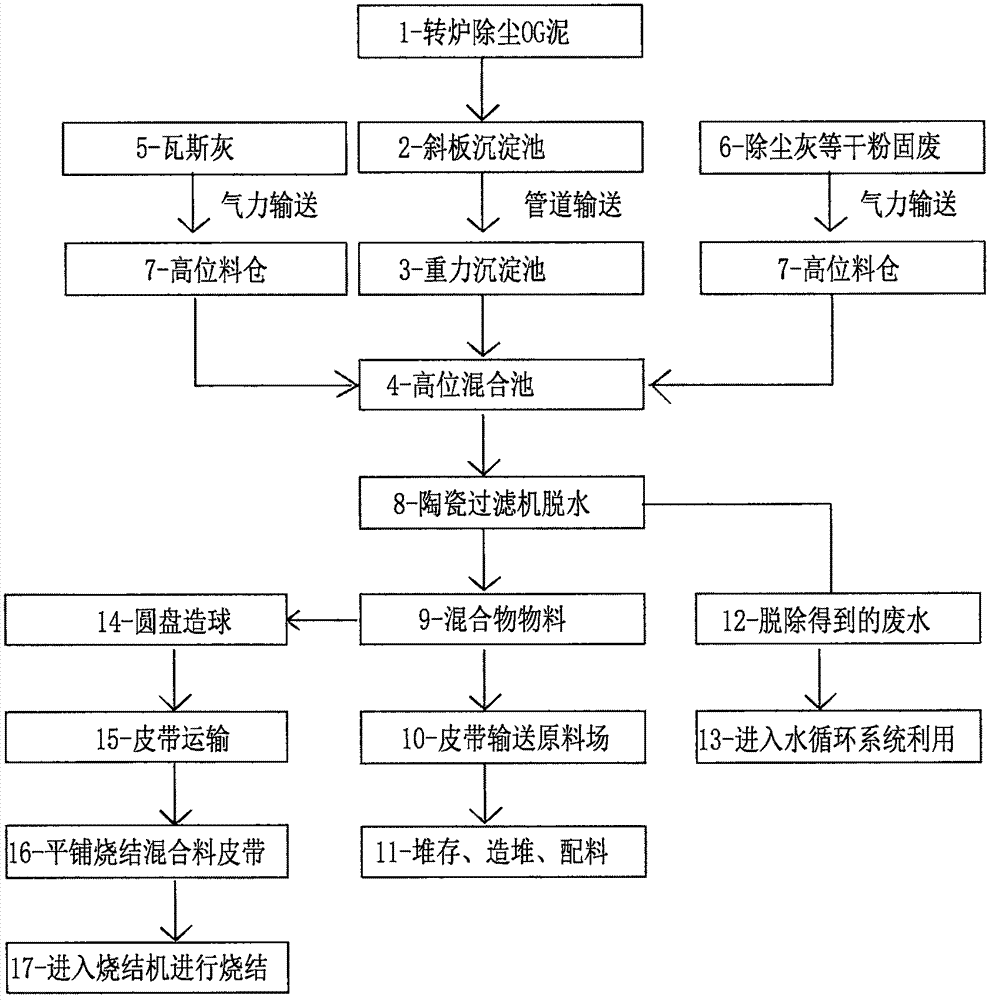

Method for recycling dedusting sludge of steel smelting converter and solid waste resources of steel and iron plant

ActiveCN107099629AAddress and improve the regional environmentReduce wasteRecycling and recovery technologiesSteelmakingSocial benefits

The invention relates to a method for recycling dedusting sludge of a steel smelting converter and solid waste resources of a steel and iron plant. The method comprises the following steps of (1) precipitating the sludge by an inclined plate precipitation tank, so as to obtain OG mud with concentration of 25% to 30%, and conveying into a gravity precipitating tank by a pipeline to perform precipitating and collecting; (2) respectively conveying gas ash and dedusting ash into a high-level material bin; (3) adding the gas ash, the dedusting ash and an additive into a high-level mixing tank, and stirring and uniformly mixing with the OG mud, so as to obtain the mud with concentration of 35% to 55%; (4) dewatering the mud obtained in step (3) by a ceramic filtering machine, so as to obtain a dry mixture filtrate cake; scraping by a scraping knife, so as to obtain the mixture material. The method has the advantages that the property and characteristic of the mixture are effectively changed; the problem of dewatering of the mixture is conveniently solved, the problems of high water content, difficulty in transportation, high stacking and airing cost, serious pollution to environment, undesired use effect and the like in the existing OG mud are solved, and the stable economic benefit and good social benefit are brought for enterprises.

Owner:浙江源程冶金科技发展有限公司

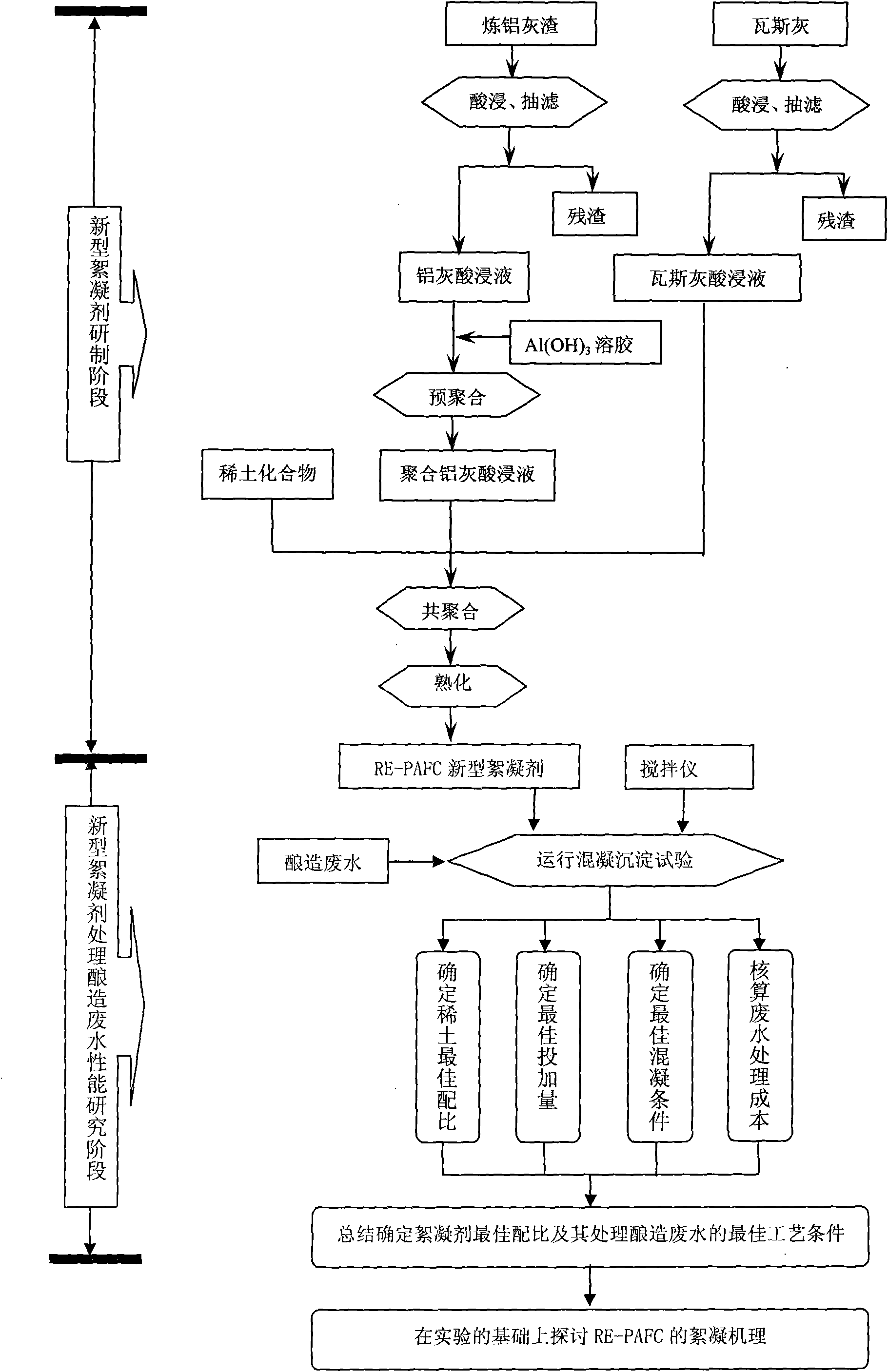

Method for preparing rare earth ceria modified inorganic polymeric flocculant by using industrial waste

InactiveCN101575130AReduce manufacturing costRealize resourcesWater/sewage treatment by flocculation/precipitationIron plantIron salts

The invention discloses a method for preparing a rare earth ceria modified inorganic polymeric flocculant by using industrial waste. In the method, blast furnace dust and aluminum-making cinder which contain iron salt and aluminum salt materials are used as main raw materials and are added with rare earth compounds to form the rare earth ceria modified inorganic polymeric flocculant through the thermosynthesis. The product synthesized by the method is a rare earth modified composite iron-aluminum polymer which has the combined properties of aluminum salt flocculants and iron salt flocculants as well as excellent water purifying property and a wide application range. The method provides a feasible way for comprehensively using wastes from iron plants and aluminum plants and provides a process route for producing flocculants with a cheap raw material, thereby realizing treating waste with waste and creating excellent economic, social and environmental benefits.

Owner:SHANDONG UNIV

Making technology of novel steel structure door

The invention provides a making technology of a novel steel structure door. The technology is characterized in that a production line mainly includes a sintering furnace from a sintering plant, a iron making blast furnace from an iron making plant, a steel making furnace from a steel making plant, and casting and steel rolling devices from a casting and steel rolling workshop; and the technology comprises the following steps: screening iron ores and iron sand ores, sintering high quality raw materials in the sintering furnace from the sintering plant until the raw materials are spherical in shape, mixing the obtained spheres with coke, putting the obtained mixture in the iron making blast furnace from the iron making plant, burning to form molten iron, sending the molten iron to the steel making plant, smelting to make steel, sending molten steel from the steel making plant to the casting and steel rolling workshop, carrying out steel forming, and cooling. Compared with the prior art, the technology has the advantages of simple operation, and realization of light weight, high strength, good ductility, good shock resistance, fire resistance and sound insulation of the novel steel structure door.

Owner:天津市耀强钢结构安装有限公司

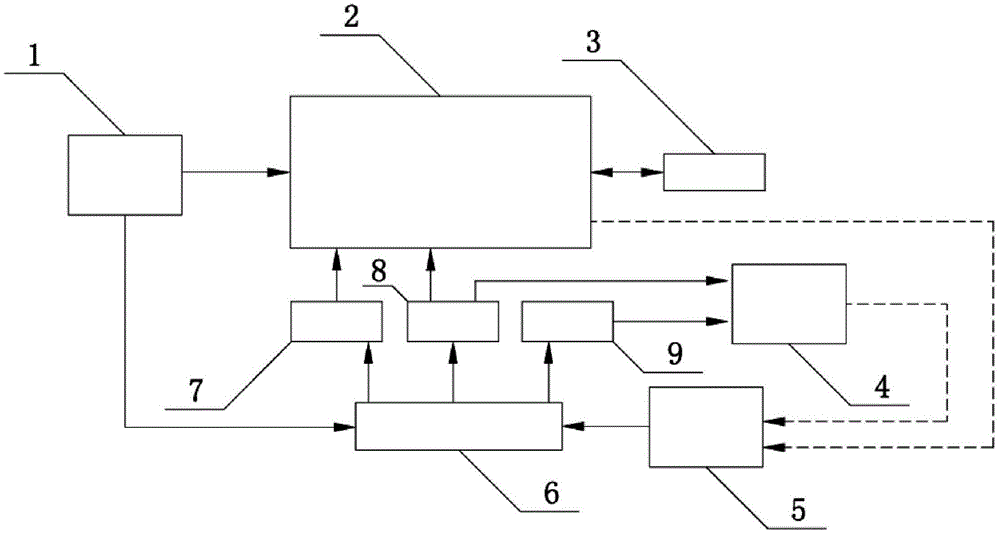

Method and system for reducing operation of clean circulating water system

ActiveCN106884459AReduce the cost of purchasing waterReduce energy consumptionIndustrial water supply conservationService pipe systemsIron plantBuffer tank

The invention provides a method and a system for reducing operation of a clean circulating water system. A clean circulating water circulating system, in accordance with actual demands of production, is divided into the normal-pressure clean circulating water system and a high-pressure circulating system, so that overall operating pressure of the circulating system is reduced; effluent of a sewage treatment station is directly supplied to the normal-pressure clean circulating water system, and rest part is conveyed to a large-capacity reservoir; meanwhile, in order to guarantee steady operation, the normal-pressure clean circulating water system is provided with a buffer tank, so that sudden change in pressure or a flow rate is prevented; the large-capacity reservoir can supply water to the normal-pressure clean circulating water system and the high-pressure circulating system by virtue of a water station, and meanwhile, the large-capacity reservoir is provided with a standby water station so as to avoid accidents; and rest parts, which are directly available, of the normal-pressure clean circulating water system and the high-pressure circulating system are directly returned to the large-capacity reservoir. According to the method and the system for reducing operation of the clean circulating water system provided by the invention, by regulating operating parameters and an operating mode of a clean circulating water system of a large integrated steel & iron plant, a circulating water quantity and circulating pressure can be reduced, so that purposes of energy conservation and emission reduction are achieved.

Owner:ANGANG STEEL CO LTD

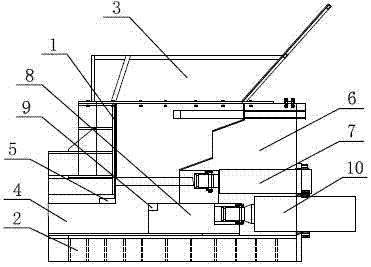

Box-type shearing machine with adjustable shearing height and shearing method

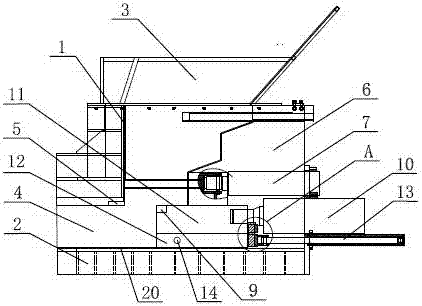

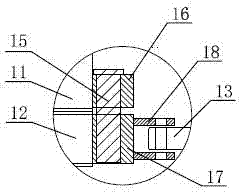

PendingCN107876852AMeet size requirementsLower acquisition costsMetal-working feeding devicesShearing machinesIron plantEngineering

A b ox-type shearing machine with the adjustable shearing height comprises a box body composed of an upper main box body and a lower main box body. A feeding hopper is installed at an opening in the upper portion of the upper main box body. A discharging outlet is formed between the lower portion of the left side of the upper main box body and the lower main box body. A pushing head is installed on the right side of the upper main box body. The outer side of the pushing head is connected with a pushing cylinder. A main tool apron and at least one cushion block are installed below the pushing head from top to bottom. The rear end of the main tool apron is connected with a piston rod of a main cylinder. The pushing cylinder and a cylinder body of the main cylinder are fixed to the box body.The main tool apron and the cushion blocks are connected through a detachable structure. By adjusting the connection state of the main tool apron, the cushion blocks and an auxiliary cylinder and adjusting the position of the cushion blocks in the box body, different combination states can be achieved, for different shearing heights, small wastes of different heights can be obtained in a shearingmode under different combination states only through a set of blades, the requirements of different iron plants are met, and the equipment cost is reduced. Besides, the working states can be quickly switched, and the equipment using efficiency is effectively ensured.

Owner:江苏大隆凯科技有限公司

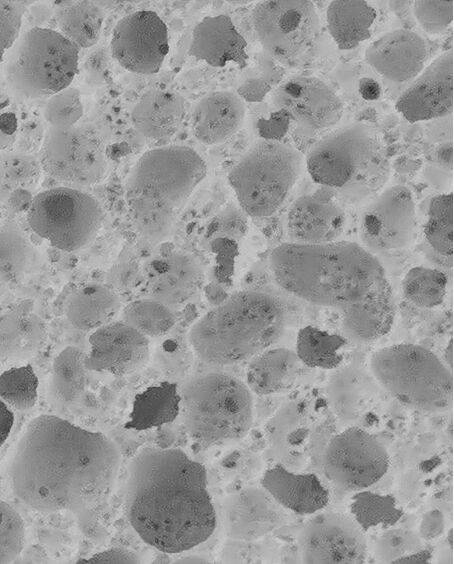

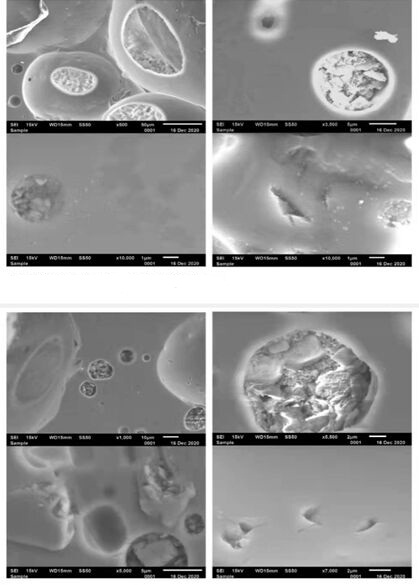

Micro-crystallized porous ceramic plate and preparation method thereof

The invention relates to a micro-crystallized porous ceramic plate and a preparation method thereof, and belongs to the technical field of porous ceramic production. According to the micro-crystallized porous ceramic plate and preparation method thereof of the invention, iron plant high-calcium water granulated slag and diatomite are used as main raw materials, and a product with low production cost, high open porosity, high strength and wide application range is obtained through twice foaming and high-temperature sintering. The preparation method of the micro-crystallized porous ceramic plate comprises the following steps of: 1) mixing raw materials, and carrying out wet ball milling to prepare slurry; (2) drying the slurry into powder; (3) adding the powder into a fire-resistant mold, and putting the mold into a tunnel kiln for sintering the mold to prepare a micro-crystallized porous ceramic blank; and (4) carrying out dry-method abrasive cutting on the micro-crystallized porous ceramic blank to obtain a plate with holes distributed all over the surface.

Owner:辽宁罕王环保科技有限公司

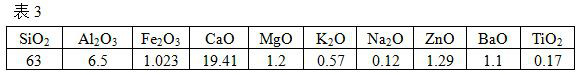

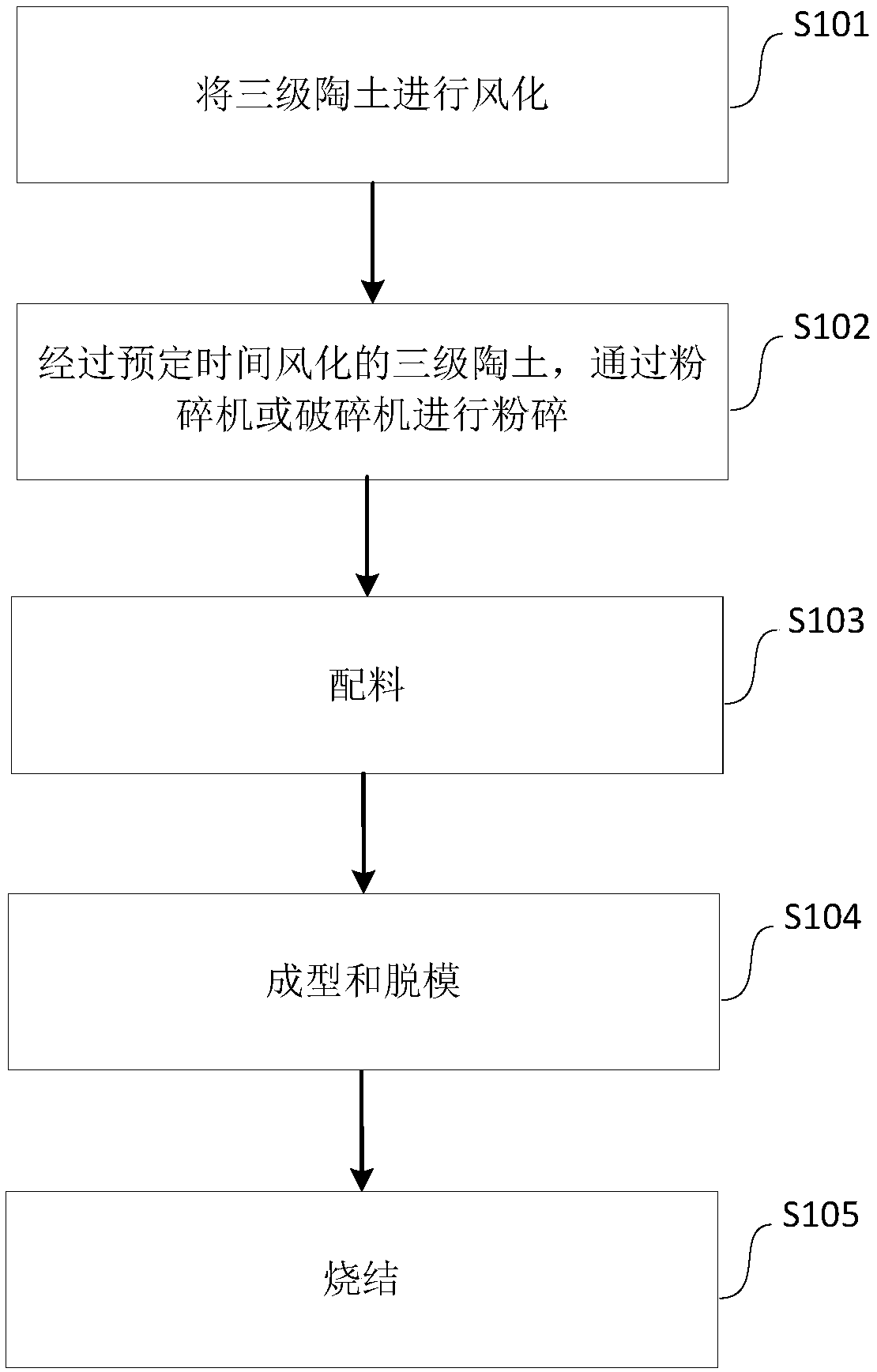

Pottery clay sintered water permeable brick

InactiveCN111434638ASolve the problem of green environmental protectionImprove sintered densityCeramic materials productionCeramicwareFreeze thawingIron plant

The invention provides a pottery clay sintered water permeable brick which is composed of the following components in percentage by weight: 50%-55% of pottery clay, 20%-25% of coal gangue, 10%-15% ofshale, 10%-15% of iron plant waste residues and 0.5%-1% of barium titanate. The main component of the iron plant waste residues is ferric oxide. The pottery clay sintered water permeable brick provided by the invention can effectively overcome one or more technical defects of the existing bricks for municipal pavements, for example, the pottery clay sintered water permeable brick provided by the invention can effectively improve the frost resistance in the aspect of freeze thawing resistance.

Owner:吉林市三路陶业有限公司

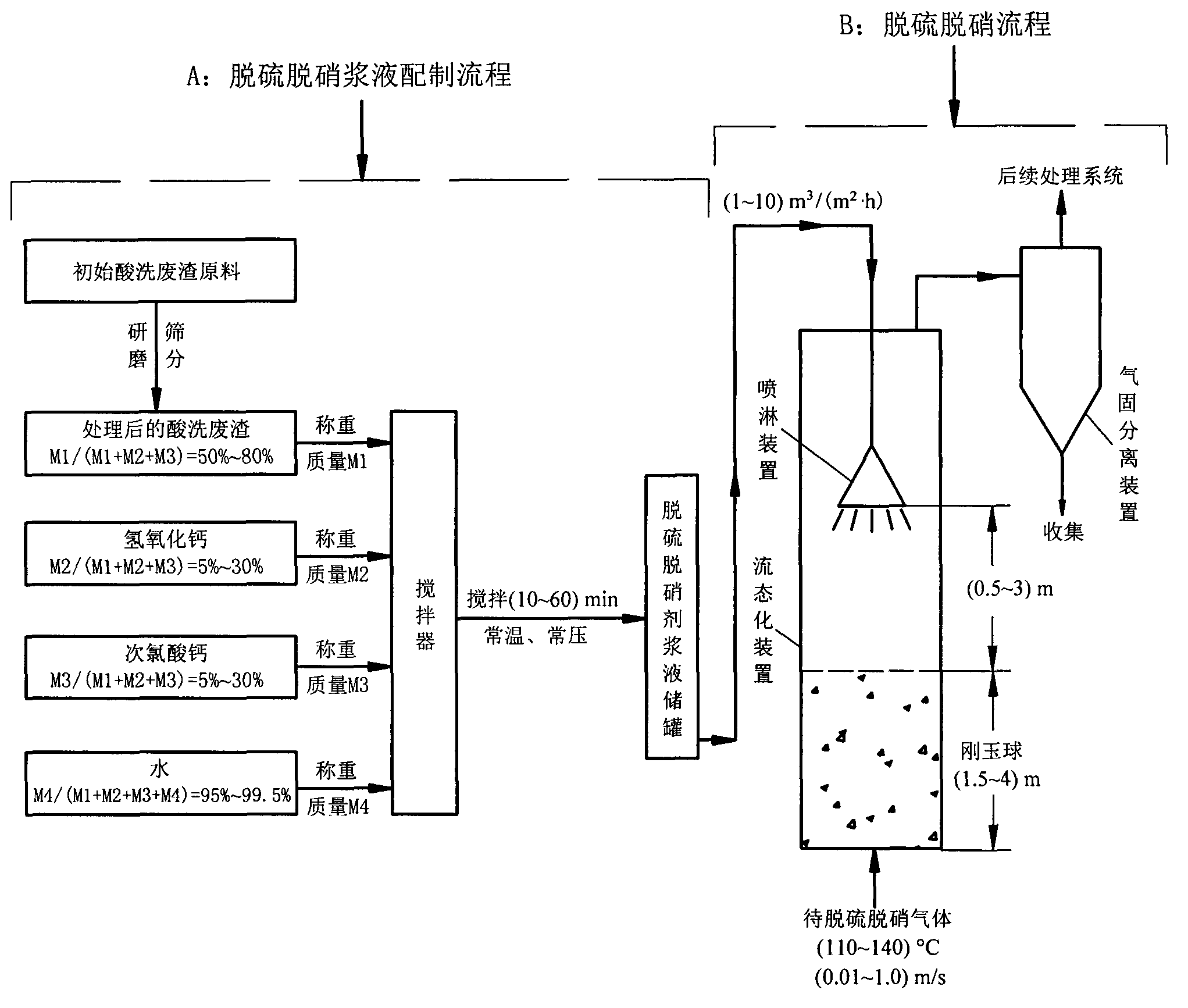

Desulfurization and denitrification agent with pickling waste residues from steel and iron plants as main materials and removal method

ActiveCN103537185ARealize secondary useTo achieve the purpose of flue gas dust removalSolid waste disposalDispersed particle separationCalcium hydroxideIron plant

The invention provides a desulfurization and denitrification agent with pickling waste residues from steel and iron plants as main materials and a removal method. The removal method is characterized by mixing 50-80% of pickling waste residue fine powder, 5-30% of calcium hydroxide fine powder and 5-30% of calcium hypochlorite fine powder by mass, then adding water to the mixture according to a mass ratio of 1 / (95-99.5), and stirring the mixture for 10-60 minutes, thus preparing desulfurization and denitrification agent slurry; enabling gases to be removed at 110-140 DEG C to enter a fluidization device with corundum sphere filling height of 1.5-4m from the bottom, wherein the apparent velocity of the gases based on the bed cross section is 0.01-1.0m / s; uniformly spraying the slurry onto the surfaces of the corundum spheres by a spray device arranged 0.5-3m above the charge level of a bed of the fluidization device, wherein the spray density is (1-10)m<3> / (m<2>.h). The desulfurization and denitrification agent and the removal method can be applied to the fields such as steel and iron, power, energy and environmental protection.

Owner:HEBEI UNIV OF TECH

Method for treating bottom mud of rolling oil

InactiveCN107129846AHigh calorific valueImplement deep processingCoke ovensSolid fuelsCoal briquetteIron plant

The invention belongs to the technical field of recycling of waste resources, in particular to a method for treating bottom mud of rolling oil. The method comprises the following steps of mixing the following raw materials in percentage by weight: 10 to 20% of bottom mud of rolling oil, 10 to 20% of coke breeze, 60 to 76% of coking coal, 0.5 to 5% of quick lime, and 3 to 10% of adhesive, uniformly mixing, extruding, and forming, so as to obtain coal briquette for coking. Compared with the prior art, the method has the advantages that the bottom mud of rolling oil is used as the raw material, and is mixed with the coke breeze, the coking coal, the quick lime and the adhesive to prepare the coal briquette for coking; the coke breeze in a coking plant is utilized at high efficiency, so that the coal resource is saved; the problem of bottom mud of rolling oil in a steel and iron plant is properly solved; while the caloric heat of the oil mud is recycled, the hazard to environment by pollutants is furthest eliminated.

Owner:SHANGHAI INST OF TECH

Nozzle slag line erosion resistant device and method for protecting pouring by using same

The invention provides a nozzle slag line erosion resistant device and a method for protecting pouring by using the same and belongs to the field of manufacturing and application of continuous casting nozzles. A vertical lifting frame of the device is connected with a horizontal clamper; the height of the horizontal clamper is adjusted through the vertical lifting frame; the horizontal clamper comprises a horizontal supporting rod and a movable ring; one end of the horizontal clamper is connected with the lifting frame; the other end of the horizontal clamper is connected with the movable ring; the movable ring is sleeved and encircled outside an erosion resistant protective cylinder and tightened by a bolt; the erosion resistant protective cylinder comprises two closed symmetric half cylinders; half-ring ventilating inner annular passages are formed in the upper part in the half cylinders; gas outlets for blowing argon are formed in the ventilating inner annular passages; and angular bosses are arranged outside the half cylinders. The method for protecting the pouring by using the nozzle slag line erosion resistant device comprises the steps of suspending, centering, cohesion, argon sealing, positioning and transposition. The nozzle slag line erosion resistant device provided by the invention has the advantages as follows: the operation process is simple and practical, the problem of serious nozzle slag line erosion is solved, the economic cost of continuous casting refractory material is reduced and the quality of a casting blank is improved. The nozzle slag line erosion resistant device provided by the invention is especially suitable for upgrading and remodeling continuous casting nozzle protective and erosion resistant technical measures in steel and iron plants.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com