Method for cooperatively treating chromium-containing waste water by pelletizing process

A technology for synergistic treatment of chromium wastewater, applied in metallurgical wastewater treatment, chemical instruments and methods, reduced water/sewage treatment, etc., can solve problems such as increased transportation costs and risks, increased water treatment costs, and increased water treatment difficulty, achieving It has environmental and social benefits, reduces the risk of transshipment, and reduces the effect of procedures and treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Chromium (Cr 6+ ) Wastewater treatment.

[0055] S1, reduction, adding sulfuric acid with a mass fraction of 98% to the chromium-containing wastewater for acidification, adjusting the pH value to 2; then adding Na 2 S 2 o 5 Cr in chromium-containing wastewater 6+ reduced to Cr 3+ , where Na 2 S 2 o 5 Cr in chromium-containing wastewater 6+ The mass ratio of is 3.8; Add the NaOH solution that concentration is 40% again in the chromium-containing waste water, adjust pH value to 7.5, make Cr 3+ With Cr(OH) 3 Form precipitation, forming Cr-containing 3+ waste water;

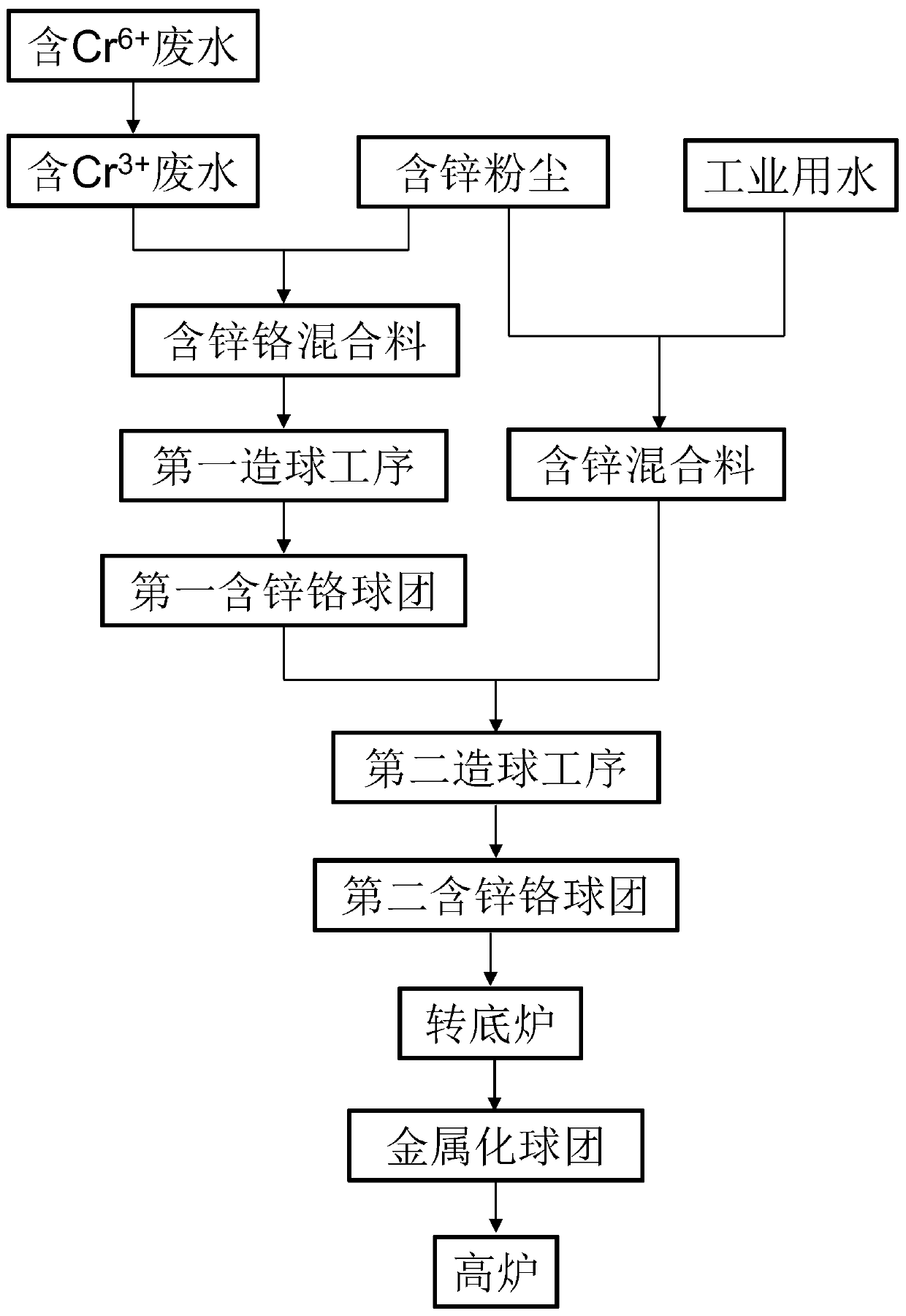

[0056] S2, the first pelletizing process, the reduced chromium-containing wastewater is sent into the mixer through the pipeline, partly replacing the industrial water in the original system, so that the various zinc-containing dusts in the mixer are fully mixed, and the zinc-containing waste water is obtained. Chromium mixture, and then the zinc-chromium mixture is sent to the disc pelletizer to o...

Embodiment 2

[0061] Chromium (Cr 6+ ) Wastewater treatment.

[0062] S1, reduction, acidification by adding phosphoric acid with a mass fraction of 97% to the chromium-containing wastewater, adjusting the pH value to 3; then adding Na 2 S 2 o 5 Cr in chromium-containing wastewater 6+ reduced to Cr 3+ , where Na 2 S 2 o 5 Cr in chromium-containing wastewater 6+ The mass ratio of is 3.7; Then add 40% NaOH solution to the chromium-containing wastewater, adjust the pH value to 7.8, make Cr 3+ With Cr(OH) 3 Form precipitation, forming Cr-containing 3+ waste water;

[0063] S2, the first pelletizing process, the reduced chromium-containing wastewater is sent into the mixer through the pipeline, partly replacing the industrial water in the original system, so that the various zinc-containing dusts in the mixer are fully mixed, and the zinc-containing waste water is obtained. Chromium mixture, and then the zinc-chromium mixture is sent to the disc pelletizer to obtain the first zinc-ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com