Nozzle slag line erosion resistant device and method for protecting pouring by using same

A technology for protection pouring and corrosion resistance, applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve problems such as continuous casting nozzle slag line erosion, troublesome operation process, etc., to save replacement time, improve solidification quality, The effect of improving flow field stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

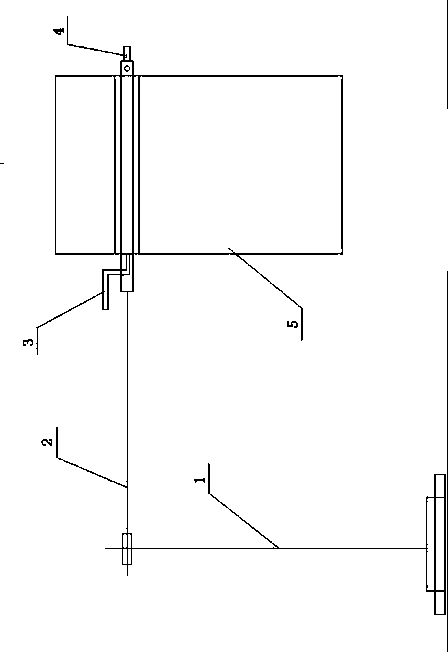

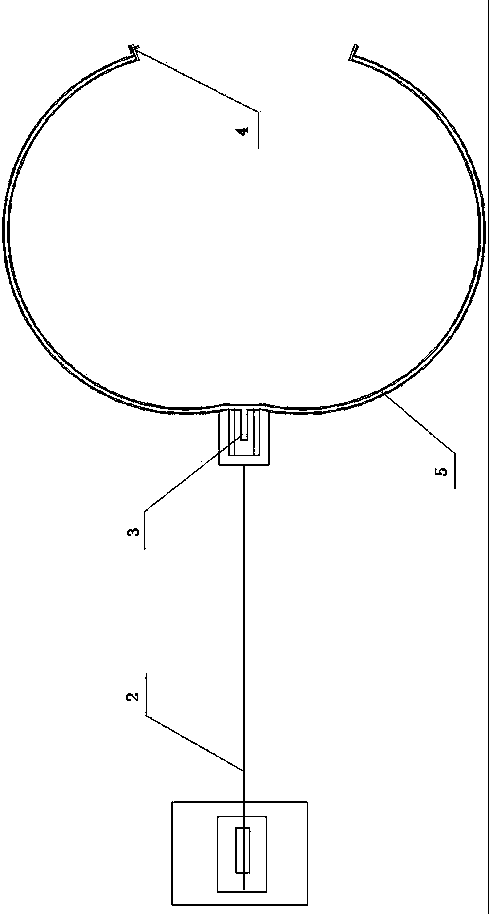

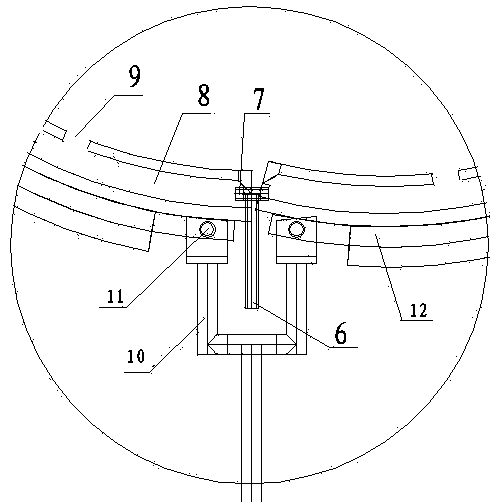

[0046] See Figure 1-Figure 6, water port slag line erosion resistance device, which is composed of motor-driven vertical lifting frame 1, horizontal holder 2, argon gas pipeline 3, corrosion-resistant casing 5, etc. The frame body of vertical lifting frame 1 is a tubular structure, and the bottom end and The bracket is welded and stands upright on the ground. The upper end of the vertical lifting frame 1 is equipped with a gear lifting system, and the lifting of the vertical lifting frame 1 is adjusted by the gear lifting system. The horizontal clamper 2 is composed of a horizontal support rod and a movable ring. One end of the horizontal support rod is slidingly connected with the vertical lifting frame 1 through gears. The other end of the horizontal support rod is equipped with a fork-shaped movable handle 10. The arm ends are respectively equipped with movable shafts 11, and the two movable shafts 11 are respectively connected to the semi-circular rings 12; the other ends...

Embodiment 2

[0062] See Figure 5 , the corrosion-resistant casing 5 suitable for the submerged nozzle 17 of billet continuous casting was made, the upper and lower parts are cylindrical, the inner diameter of the cylinder is 90mm, the wall thickness is 12mm, the length is 200mm, and the material is ZrO 2 -C quality, ZrO 2 The content is 70-80%, the C content is 12-17%, and the rest is a small amount of phenolic resin, silicon carbide, boron carbide, etc. The technical indicators are apparent porosity of 15%, and bulk density of 3.55g / cm 3 , Compressive strength 25MPa, flexural strength 8MPa.

[0063] Before the tundish 16 is poured, open the bolt lock 4 of the horizontal holder 2, hang the two semicircular casings on the two semicircular rings of the horizontal holder 2; place the vertical lifting frame 1 in the submerged Next to the nozzle 17, adjust the length of the horizontal holder 2, and after aligning the submerged nozzle 17, put the two semicircular casings together, tighten the...

Embodiment 3

[0065] To make a corrosion-resistant casing suitable for the submerged nozzle of a rectangular billet, the upper part is cylindrical, the lower part is oblate, the inner diameter of the upper part of the cylinder is 72mm, the wall thickness is 12mm, the length is 130mm, the inner diameter of the lower arc is 85mm, the flat width is 60mm, and the wall thickness 12mm, length 170mm, made of ZrO 2 -C quality, ZrO 2 The content is 70-80%, the C content is 12-17%, and the rest is a small amount of phenolic resin, silicon carbide, boron carbide, etc. The technical indicators are apparent porosity of 17%, and bulk density of 3.62g / cm 3 , Compressive strength 24MPa, flexural strength 7MPa.

[0066] Before the tundish 16 is poured, open the bolt lock 4 of the horizontal holder 2, hang the two semicircular casings on the two semicircular rings of the horizontal holder 2; place the vertical lifting frame 1 in the submerged Next to the nozzle 17, adjust the length of the horizontal holde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com