Method for extracting iron particles and zinc powder from dust of steel and iron plant

A technology for iron and steel plants and dust, applied in the direction of improving process efficiency, can solve problems such as failure to explore a good process control method, processing capacity, unsatisfactory reduction rate, and backward technology, so as to improve the comprehensive utilization level of resources and optimize components. The effect of controlling and streamlining the process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

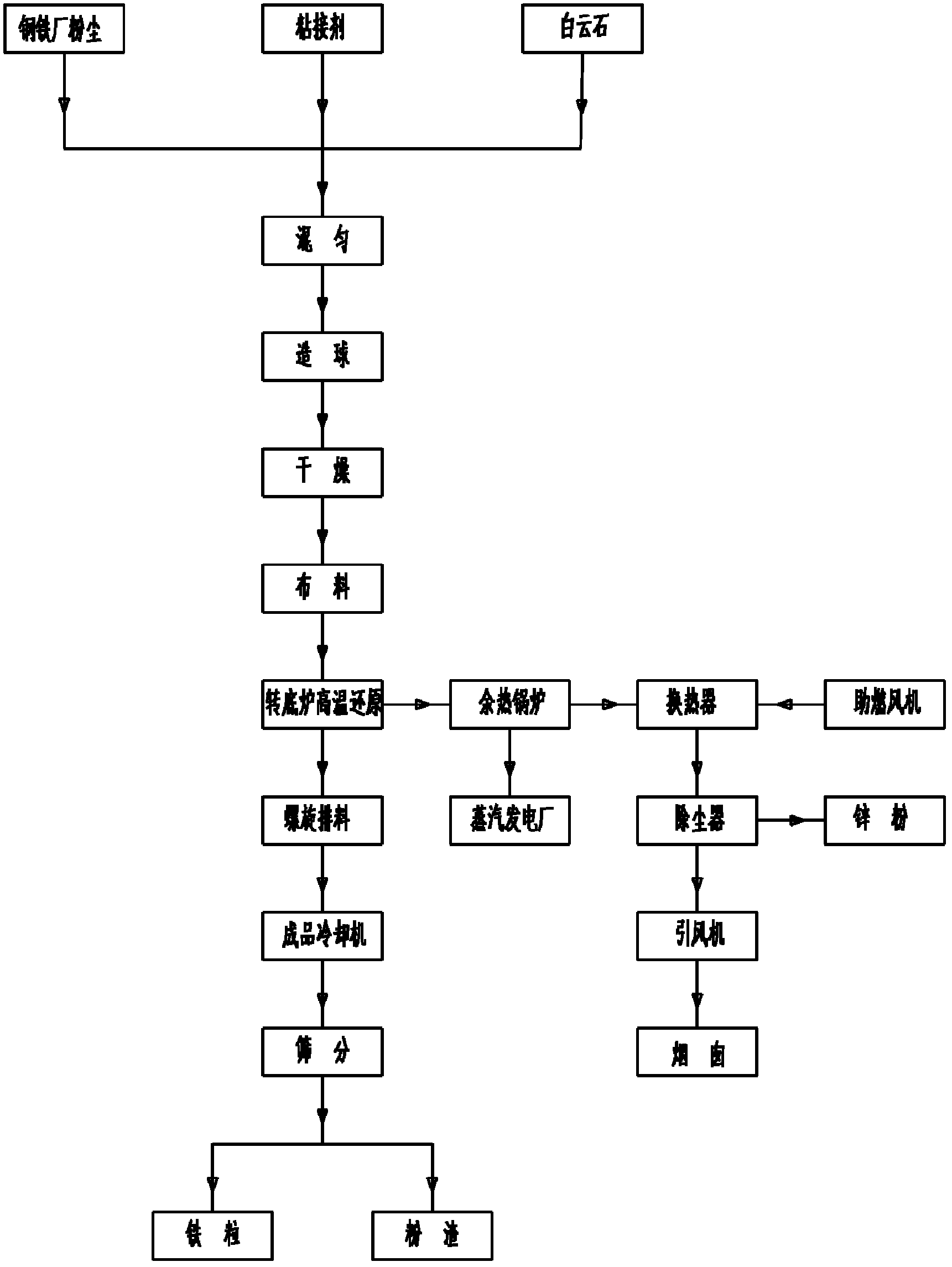

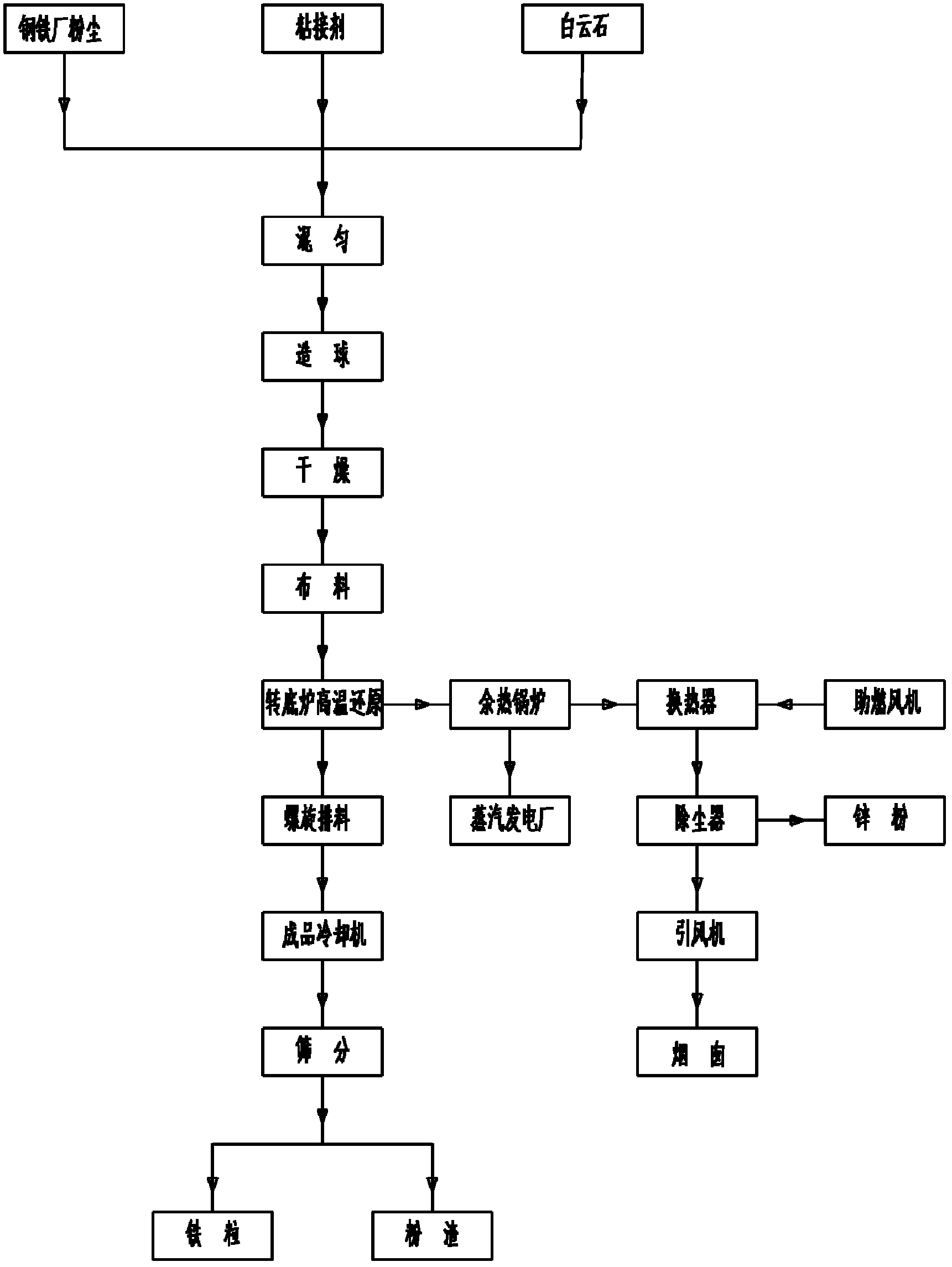

[0020] As shown in Figure 1, a kind of method extracting iron particle and zinc powder from iron and steel factory dust, it comprises the steps:

[0021] 1) According to the mass ratio of iron and steel plant dust, dolomite and adhesive as 1:0.08:0.04, select iron and steel plant dust, dolomite and adhesive, mix them on the mixer, and then send them to the ball press machine to form 7~ 13mm green balls, the made green balls are then dried in a dryer to reduce the moisture content of the green balls to below 2wt% to obtain dried green balls;

[0022] The iron and steel plant dust is all kinds of iron-containing dust produced in the production process of the iron and steel plant; after the iron-containing dust is prepared, the iron content is 50wt%, and the zinc is 2wt%;

[0023] Described bonding agent is diatomaceous earth;

[0024] 2) Send the dried raw pellets to the buffer bin of the rotary hearth furnace, and evenly distribute them into the rotary hearth furnace through t...

Embodiment 2

[0029] Basically the same as Example 1, the difference is: the mass ratio of iron and steel plant dust, dolomite, and bonding agent is 1: 0.05: 0.03;

[0030] The iron and steel plant dust is all kinds of iron-containing dust produced in the iron and steel plant production process (such as steelmaking); after the iron-containing dust is prepared, the iron content is 45wt%, and the zinc is 2wt%;

[0031] The binder is molasses.

Embodiment 3

[0033] Substantially the same as Example 1, the difference is that the mass ratio of iron and steel plant dust, dolomite, and binding agent is 1: 0.1: 0.06,

[0034] The iron and steel plant dust is all kinds of iron-containing dust produced in the iron and steel plant production process (such as hot rolling); after the iron-containing dust is prepared, the iron content is 50wt%, and the zinc content is 4wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com