Method for controlling titanium of pure steel

A pure steel and titanium removal technology, which is applied in the field of pure steel control, can solve the problems of complex titanium content process and high cost, and achieve the effects of reducing titanium control costs, increasing capital costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

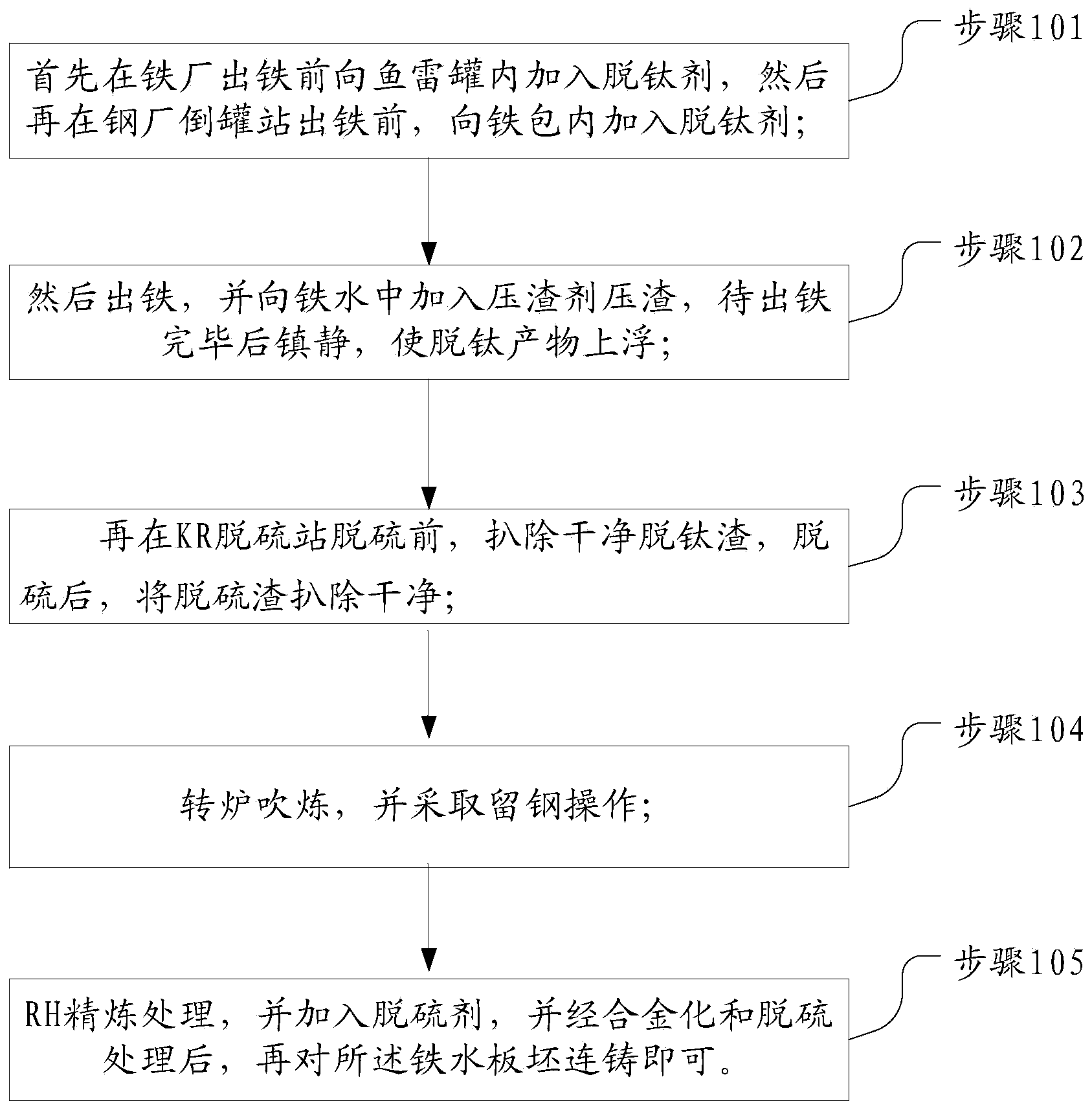

Image

Examples

Embodiment 1

[0029] Step 201: Detitanium removal from hot metal: Detitanium removal from hot metal is carried out in two steps. First, add titanium removal agent to the torpedo tank before tapping in the iron factory, add 15KG-30KG / T iron oxide scale to the torpedo tank, and then pour it in the steel factory. Add titanium removal agent into the iron ladle before tapping the iron at the tank station, among which, add 15KG-30KG / T iron oxide scale into the iron ladle;

[0030] Step 202: Then tap the iron, stir by using the impact effect in the tapping process to make it undergo sufficient detitanium reaction, and add a slag pressing agent to the molten iron to press the slag, and the slag pressing agent can be added in 3-4 times, To prevent the top slag from overflowing, in the embodiment of the present invention, the slag pressing agent is a wooden square of 70cm×70cm×10cm, and it is calmed down for 10-20 minutes after tapping is completed, so that the detitanium product is fully floated;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com