Automatic control system and method for different material layers of stored materials of large-diameter silo

A technology of automatic control system and central control system, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of pressure increase, the unloading of the feeding port, and the material stacking out of the top of the warehouse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

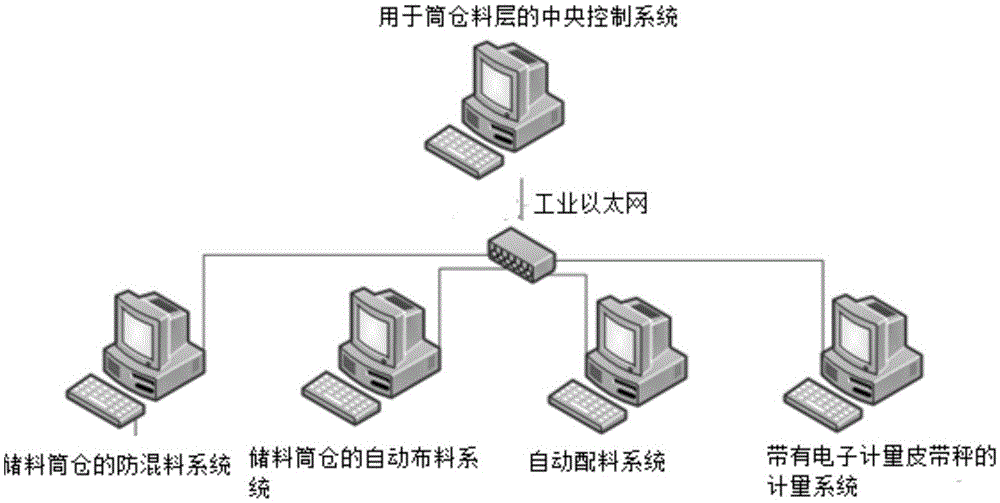

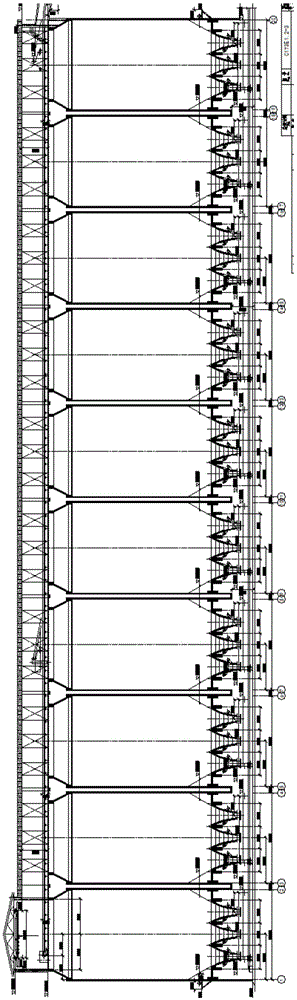

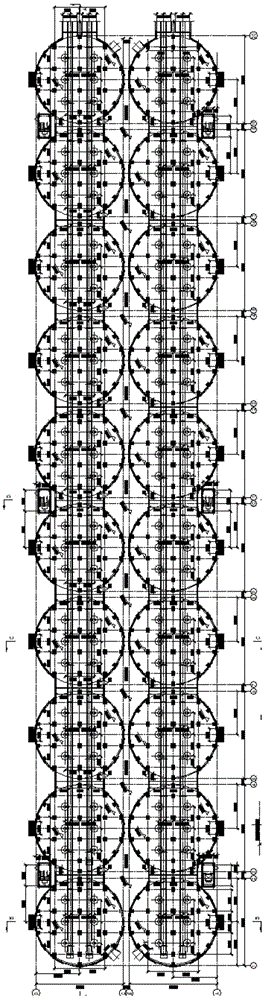

[0032] Such as figure 1 , figure 2 and image 3As shown, the automatic control system for different layers of materials stored in the large-diameter silo, the automatic control system for the material layer includes the anti-mixing system of the storage silo connected through the communication network, the automatic distribution of the material storage silo system, a metering system with an electronic metering belt scale, an automatic batching system and a central control system for the material layer of the silo. In addition, there is a dumper on the top of the silo, and the corresponding unloading machine The material trolley is provided with a position detection device, wherein the anti-mixing system of the storage silo is set on the roof of the silo to prevent the silo from mixing accidents during the loading process; the The automatic material distributing system of the storage silo is used to load the material evenly into the silo, and keep the upper plane of the mate...

Embodiment 2

[0036] like figure 1 , Figure 4 and Figure 5 As shown, the automatic control system for different layers of materials stored in the large-diameter silo, the automatic control system for the material layer includes the anti-mixing system of the storage silo connected through the communication network, the automatic distribution of the material storage silo system, a metering system with an electronic metering belt scale, an automatic batching system and a central control system for the material layer of the silo. In addition, there is a dumper on the top of the silo, and the corresponding unloading machine The material trolley is provided with a position detection device, wherein the anti-mixing system of the storage silo is set on the roof of the silo to prevent the silo from mixing accidents during the loading process; the The automatic material distributing system of the storage silo is used to load the material evenly into the silo, and keep the upper plane of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com