Patents

Literature

129results about How to "Implement deep processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep treatment process of oily wastewater

ActiveCN102060350ASolving Deep Processing ChallengesImplement deep processingFatty/oily/floating substances removal devicesCombustible gas purificationActivated carbonSorbent

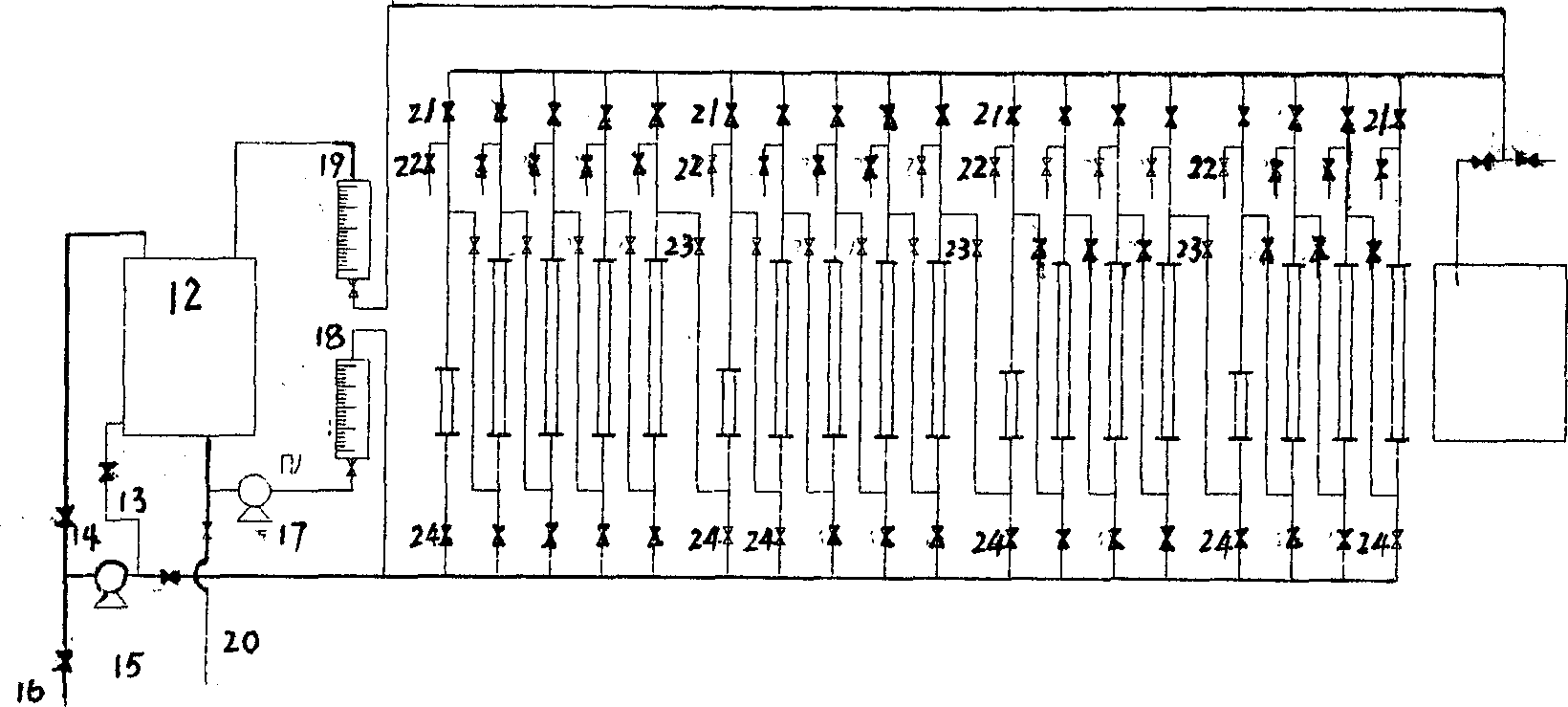

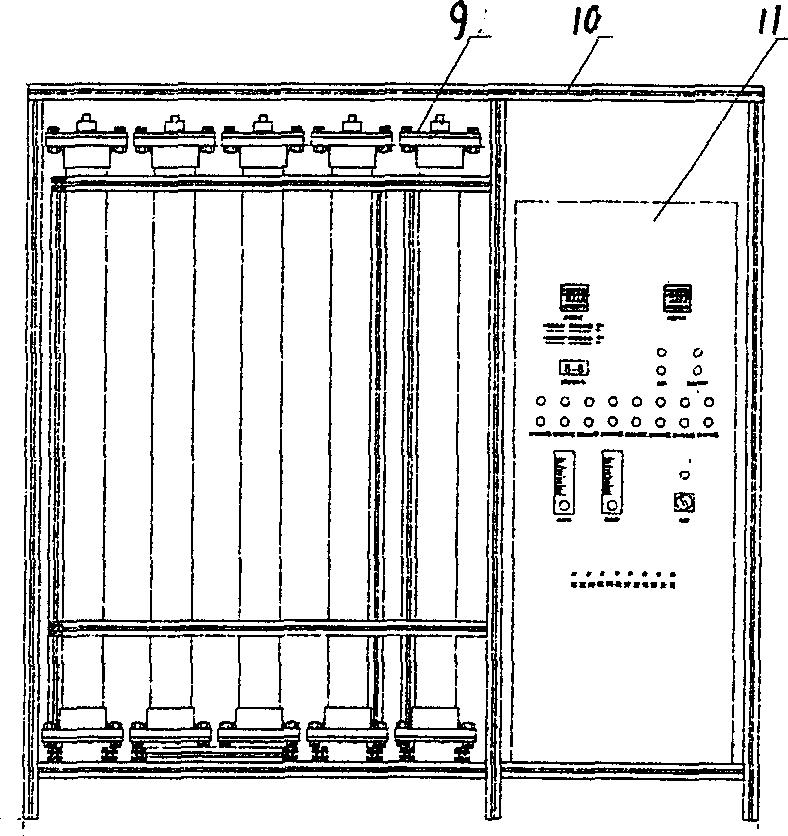

The invention relates to a deep treatment process of oily wastewater, which is characterized in that an absorption system and a regeneration system are provided in the process, wherein the absorption system is formed by a series of absorption tower groups with columns in series used for realizing parallel operation, the absorption tower groups are used for alternately performing deep treatment on oily yielding water with a low concentration of 30-50 mg / L of a traditional process, the absorption operation is carried out at normal temperature, the oil content in the yielding water is controlled to be lower than 1 mg / L through the treatment of a group of the absorption towers with columns in series, and an absorbing agent is made of modified fly ash, activated carbon and an expanded graphite absorbing material; when the yielding water in a group of the absorption towers exceeds a treatment requirement, the group of the absorption towers is switched to a biological regeneration system, and other absorption tower groups are simultaneously switched to the absorption system for continuous absorption; and saturated absorption towers are used for performing in-situ regeneration on the saturated absorbing agent by utilizing degradation ability of high temperature-resistant and efficient petroleum hydrocarbon for degrading bacteria.

Owner:CHINA NAT OFFSHORE OIL CORP +2

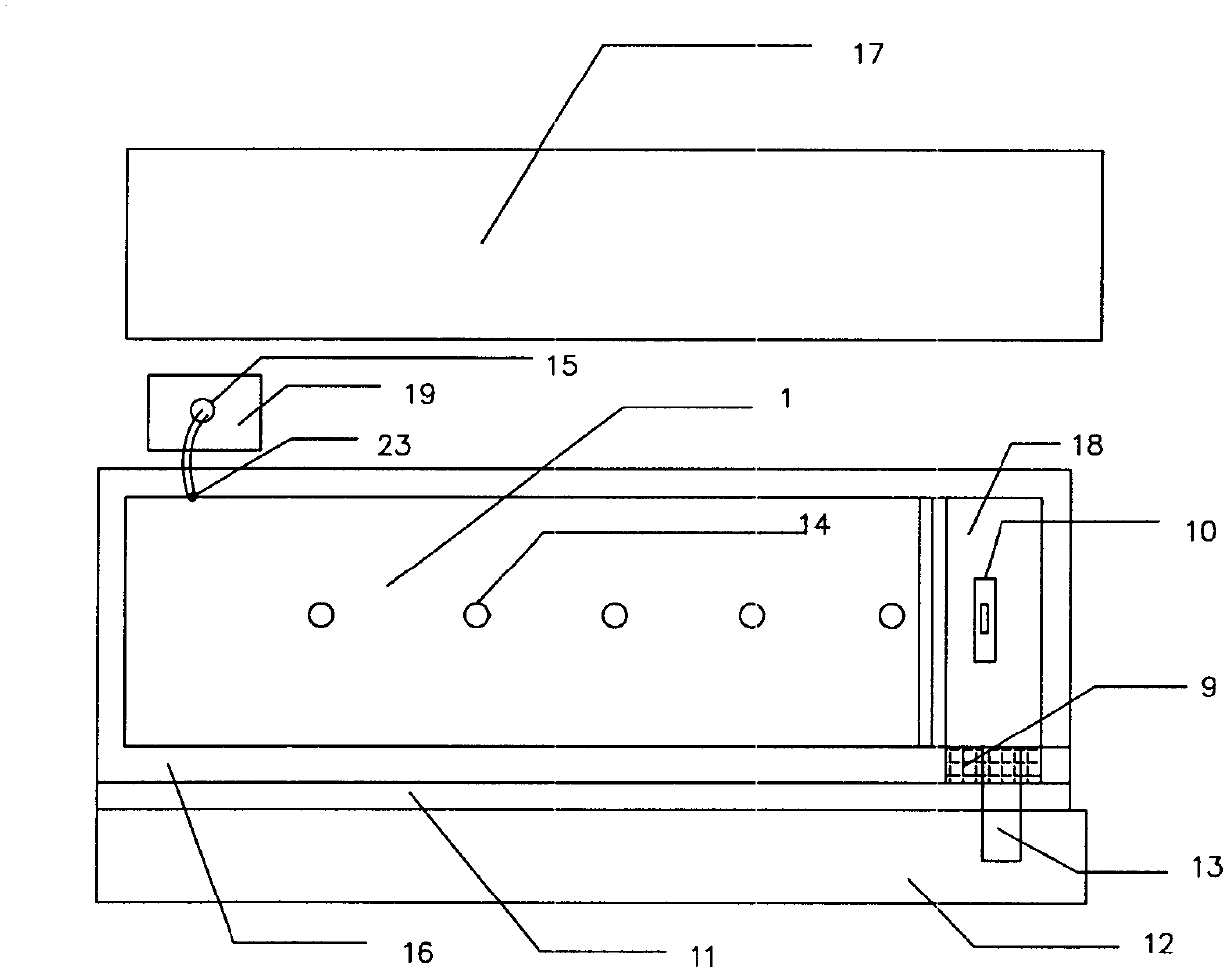

System and method integrating road surface runoff collection, purification, storage and utilization for plants

ActiveCN103374972AWidely used valueReduce capacity spaceFatty/oily/floating substances removal devicesSewerage structuresEngineeringHazardous materials transportation

The invention relates to a system and a method integrating road surface runoff collection, purification, storage and utilization for plants. A biological planting groove lower than a road surface is used for collecting and processing road surface runoff at an initial stage and formed by stacking a planting soil layer, an infiltration filtering layer, a supporting layer, a water storage layer, an impervious layer and the like from the top to the bottom. The road surface runoff at a later stage is collected in a level observing well separated in the groove through an overflowing groove on the side of the biological planting groove and can be discharged directly through a lateral wall water discharging pipe. The collected road surface runoff at the initial stage is calculated according to an area rainstorm intensity formula and collecting time, and on the basis of the calculated road surface runoff at the initial stage, filling material texture and thickness, soil infiltration capacity, a soil surface distance and an overflow distance are combined to distribute filling materials of the planting soil layer and the water storage layer. Storage water is extracted by an extraction device and utilized for road surface plants. The system and the method are applicable to collection, processing and comprehensive utilization of the road surface runoff which is at the initial stage and has a pollution effect and emergency management of a road environment under the condition of leakage of dangerous goods during transportation.

Owner:CHINA ACAD OF TRANSPORTATION SCI +1

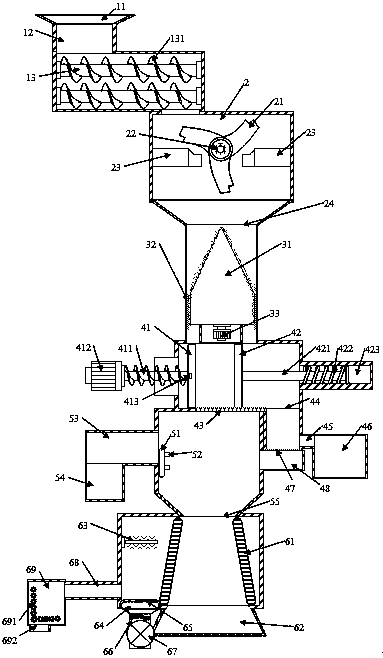

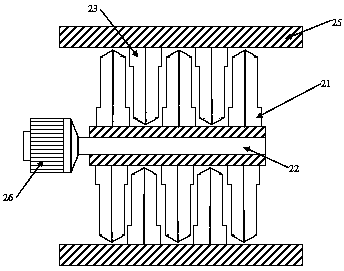

Kitchen waste treating device

ActiveCN110252483AImplement deep processingEasy to separateSolid waste disposalMultistage water/sewage treatmentLitterLiquid state

The invention relates to a kitchen waste treating device. The kitchen waste treating device comprises a conveying device, a crushing chamber, a grinding chamber, a compression separator, an oil-water separating device and a water treatment device. A kitchen waste main body is food residue which is divided into a liquid state and a solid state. By conveying for primary breaking, crushing and grinding, solid matters are granular; solid is separated from liquid by extrusion; solid particles are sufficiently dewatered and dried to serve as a fertilizer raw material; upper-layer oil is removed and collected according to the densities of oil and water, and water is filtered, foamed and sterilized to obtain treated water, and thereby the kitchen wastes are centrally and efficiently treated at waste producing places in a concentrated area of restaurants.

Owner:蒋军欢

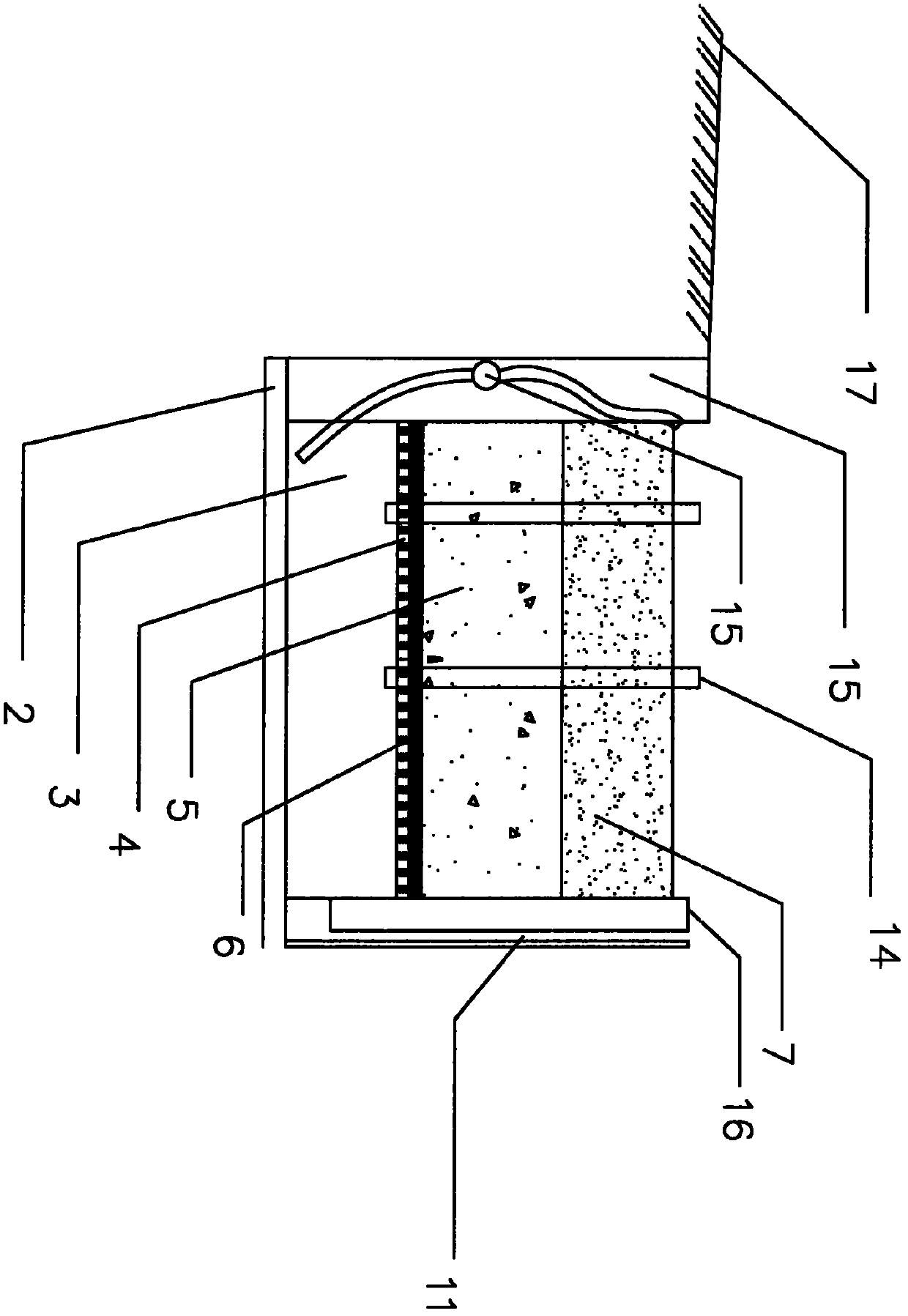

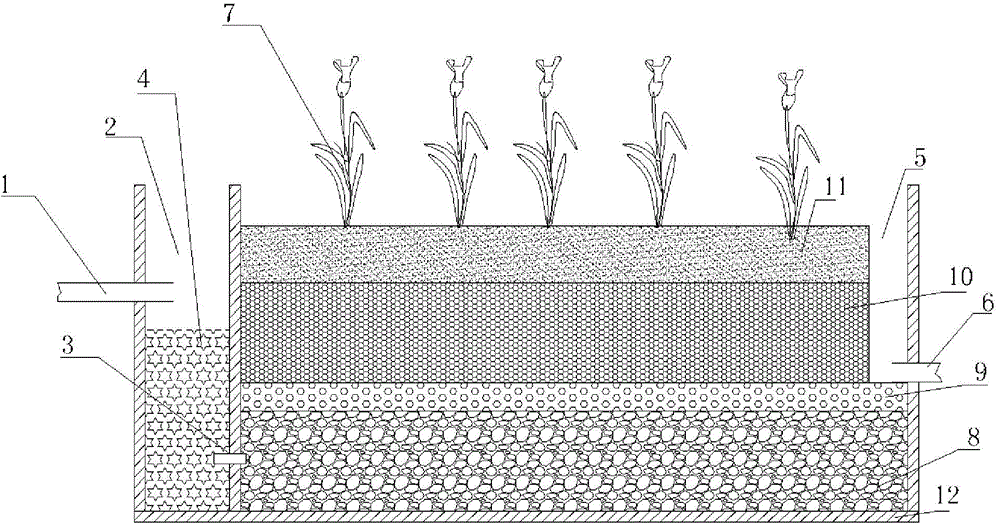

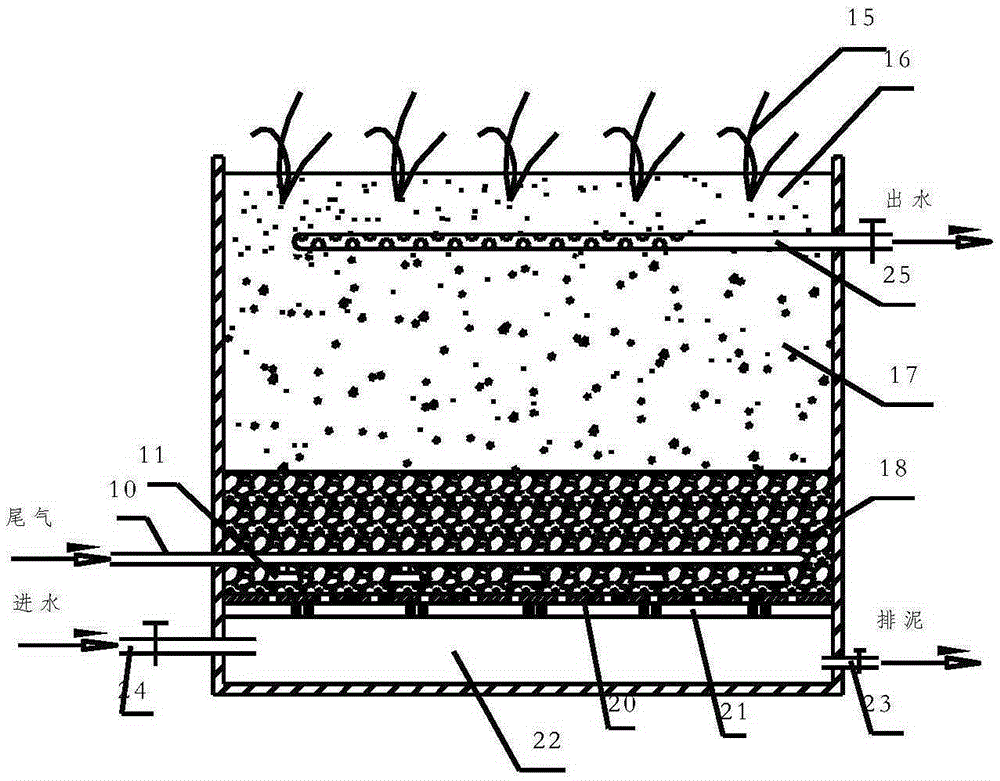

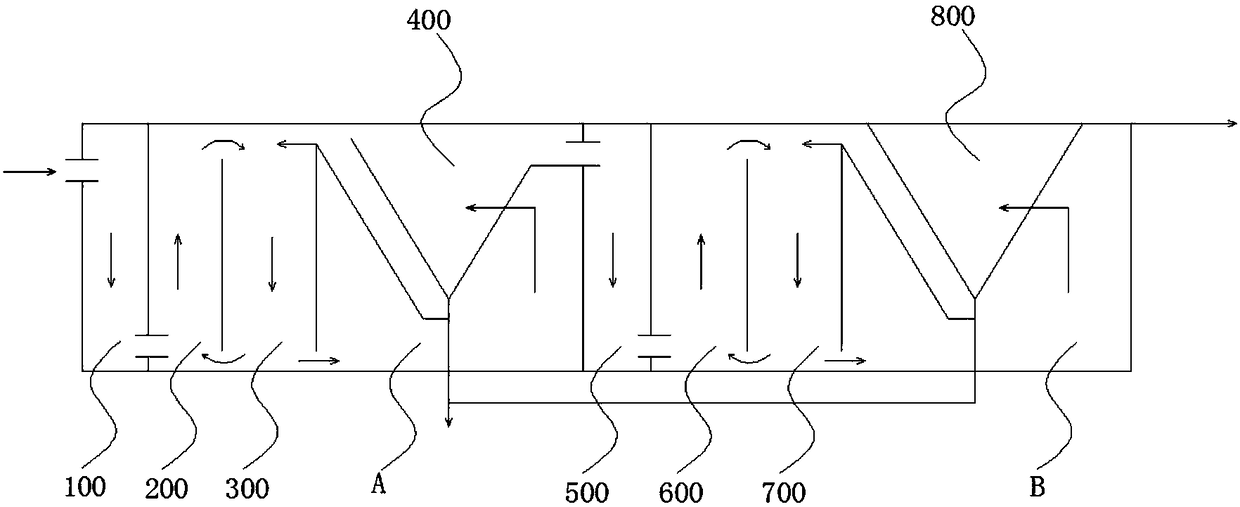

Multi-medium tidal flow artificial wetland device and method

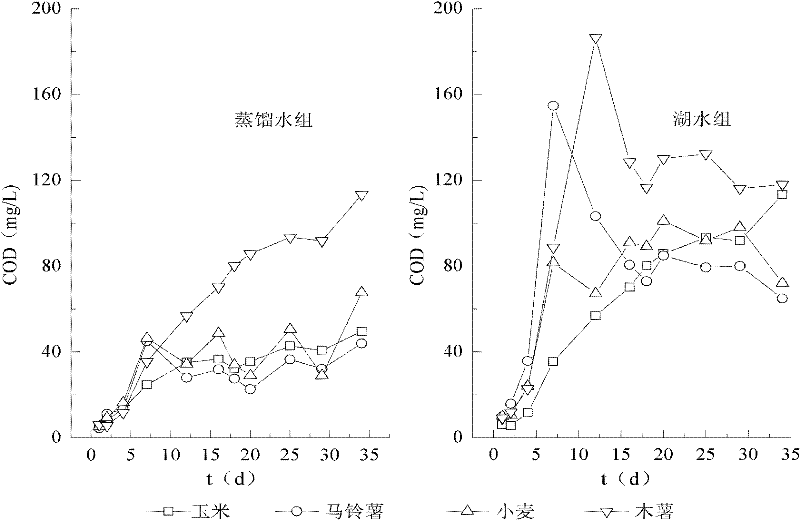

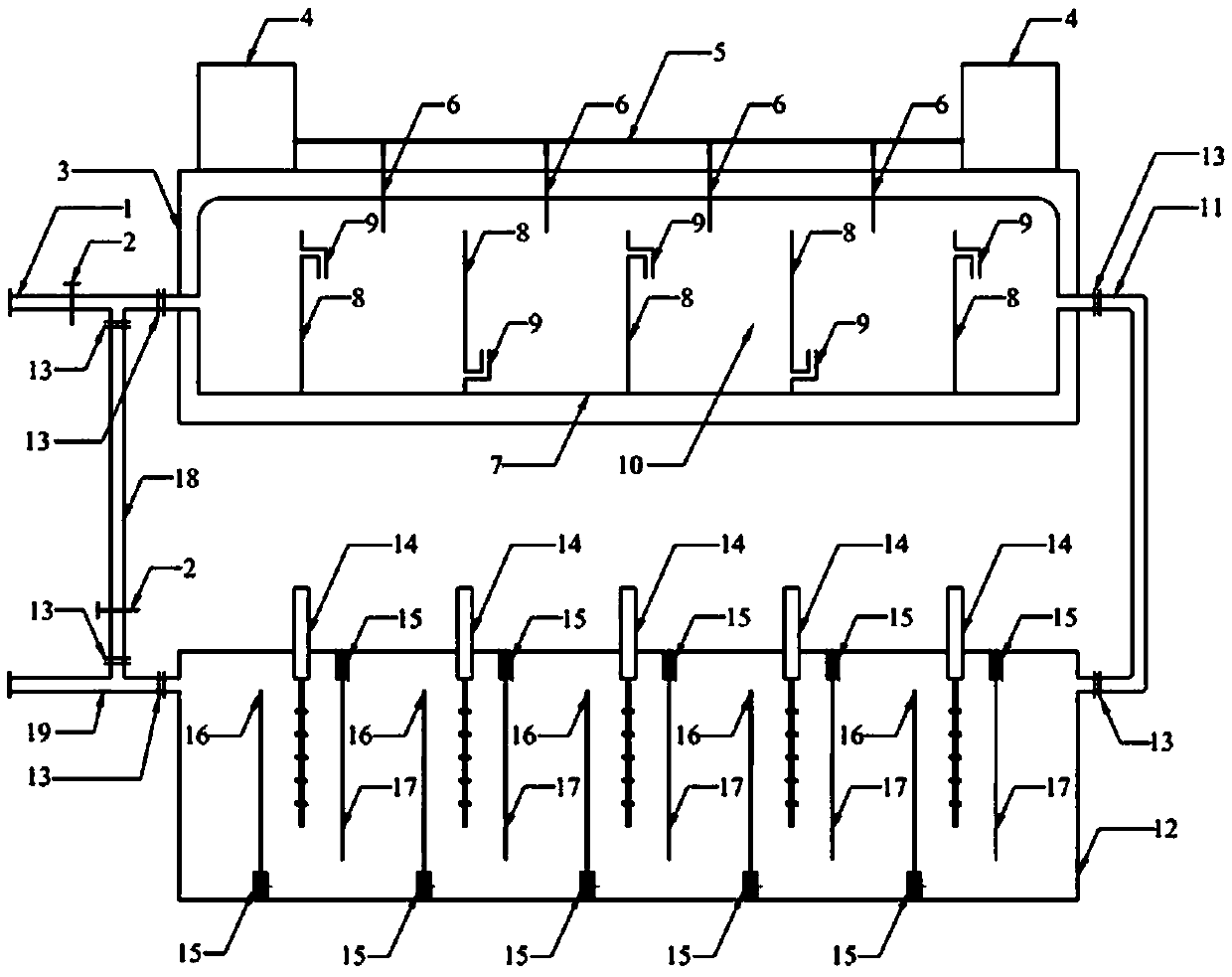

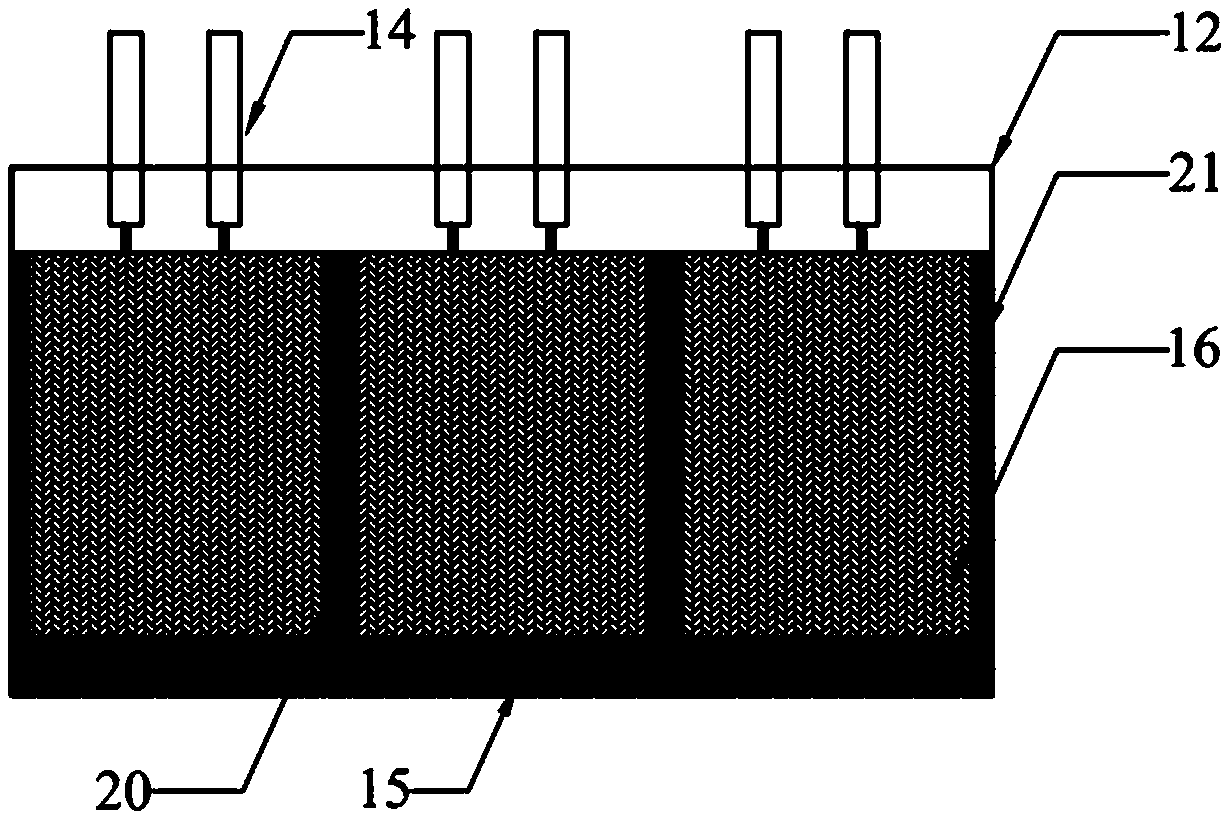

ActiveCN104591490AAvoid cloggingAdd a fixed amountMultistage water/sewage treatmentConstructed wetlandMicroorganism

The invention discloses a multi-medium tidal flow artificial wetland device and method. The artificial wetland device comprises anti-seepage layers, a water distribution tank and a filter tank, wherein the water distribution tank is formed by separating a tank body by virtue of the anti-seepage layers and internally provided with a porous polyurethane material and a water inlet pipe is arranged at the upstream side of the water distribution tank; the upstream side of the filter tank is communicated with the downstream side of the water distribution tank through a plurality of communication pipes, a multi-medium filtering material layer is arranged in the upstream space inside the filter tank and the downstream space inside the filter tank forms a water collecting tank. According to the multi-medium tidal flow artificial wetland device, by the inter-coordinated physical, chemical and biological actions of the multi-medium filtering material, wetland plants and efficient microbes, the media adsorption, ion exchange, co-precipitation, and efficient microbial adsorption reduction, fixed and biological extraction are organically combined so that the heavy metals in micro-polluted water are effectively removed and the secondary pollution of the heavy metals is prevented.

Owner:PEKING UNIV

Method for treating oil field produced waste water containing polymer

InactiveCN1631809AImplement deep processingImprove adaptabilityWater/sewage treatment by irradiationWater/sewage treatment by flocculation/precipitationChemistryPenetration rate

A processing method for oil producing waste water containing polymer, relates to a waste water processing technique, concretely to an oil producing waste water containing polymer processing technique. It processes the waste water by the following steps: deposit and separation to the oil producing waste water containing polymer; the second filtration to the water obtained; oxidation procession to the water after filtration; finally sotisphicated filtration to the water after oxidation. Having maintained the present processing steps, it bring the new high effective processing steps, making use of the ability of present technique as well as realizing deep procession to the waste water, increasing the adapting ability of the technique to water wave and assuring the water after procession can reach the standard of each penetration rate oil layer. The oil producing waste water containing polymer processed by the invention can reach the standard of each penetration rate oil layer, as well as has solved the problems that the procession effect of present technique is influenced by the HPAM content greatly and no assurance for the water quality.

Owner:HARBIN INST OF TECH

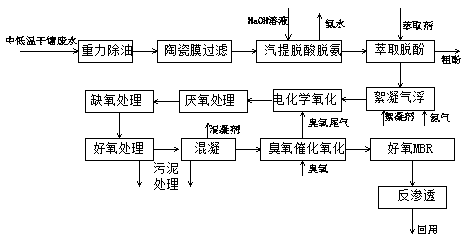

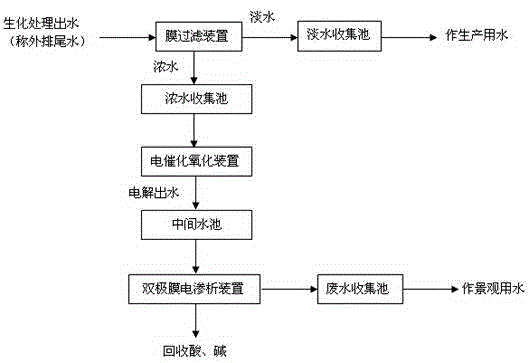

Method for treating and recycling wastewater produced by coal middle-low temperature dry distillation

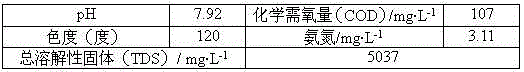

InactiveCN107746160AImprove processing economicsReduce loadFatty/oily/floating substances removal devicesGeneral water supply conservationChemical oxygen demandCatalytic oxidation

The invention discloses a method for treating and recycling wastewater produced by coal middle-low temperature dry distillation. The method comprises the steps of pretreatment, biochemical treatment as well as advanced treatment and recycling. The method concretely comprises the following steps: firstly, carrying out oil removal on the wastewater by means of gravity, filtering and then deacidifying and deaminizing by means of steam stripping; dephenolizing by means of extraction, and removing emulsified oil and suspended solids by means of flocculation-air flotation; reducing chemical oxygen demand (COD) by means of electrochemical oxidation, and then carrying out biochemical treatment including anaerobic treatment, anoxic treatment and aerobic treatment; finally, carrying out advanced treatment and recycling, i.e., coagulation treatment, ozone catalytic oxidation treatment, membrane bioreactor (MBR) treatment, reverse osmosis treatment, and recycling the effluent which reaches the standard. By adopting reasonable optimized combination configuration of all units, the high efficiency recovery of tar, ammonia and phenol in the wastewater as well as the advanced treatment of the wastewater produced by middle-low temperature dry distillation can be realized, and the wastewater is finally recycled by means of desalination, so that pollutant removal and water resource recycling are realized.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL TECH RES INST CO LTD

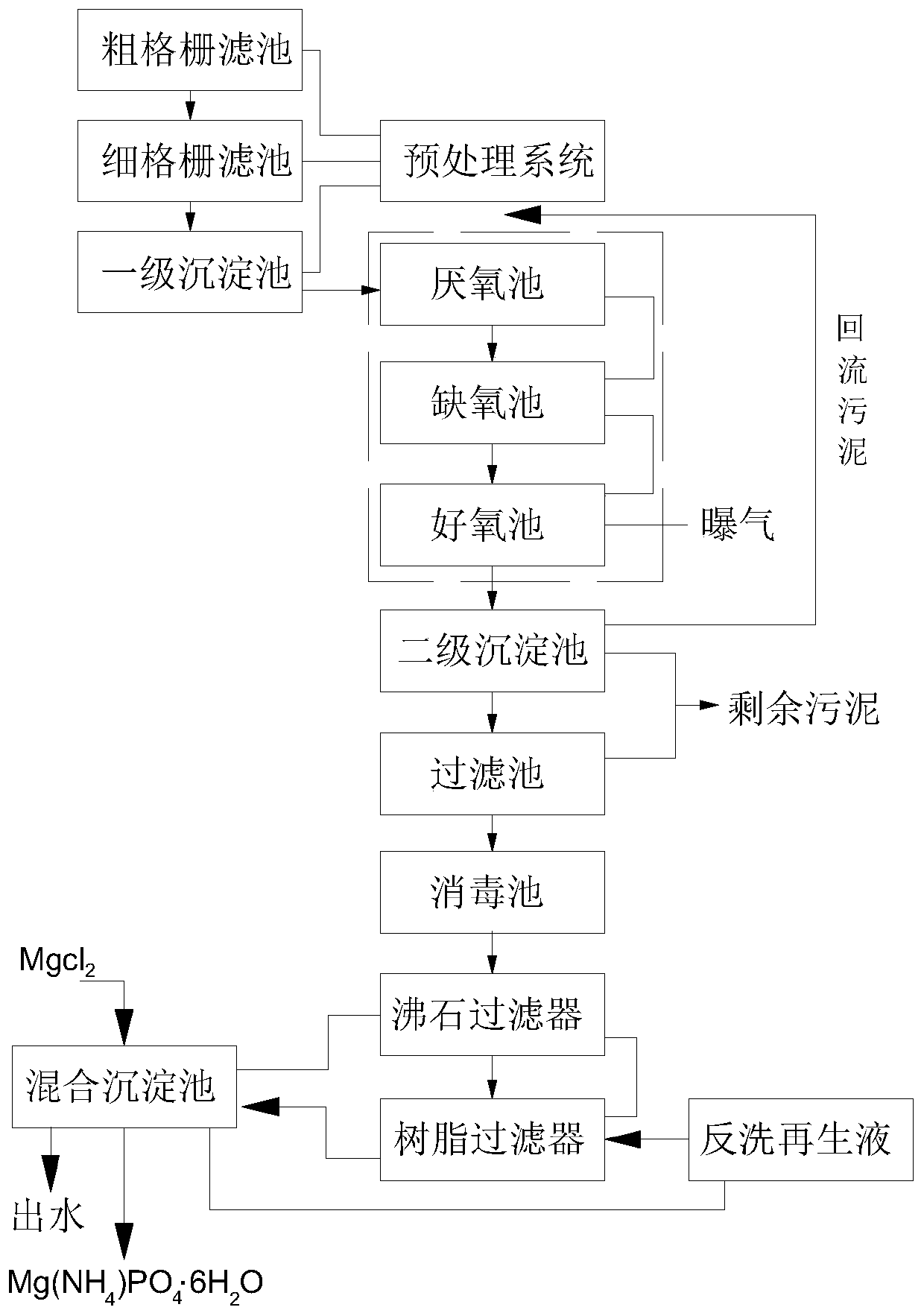

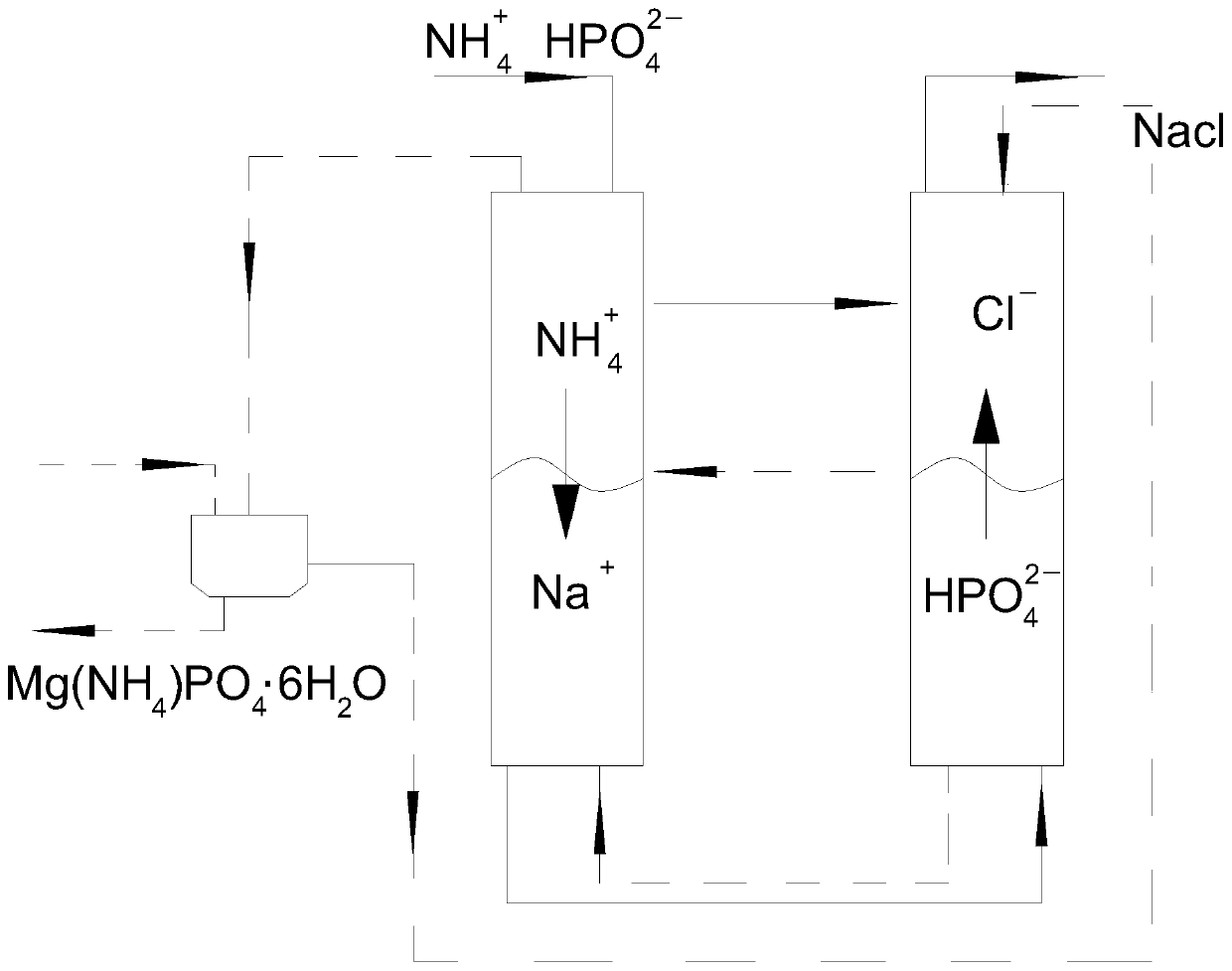

Nitrogen and phosphorus advanced treatment system and method for sewage treatment

InactiveCN110386736AGuaranteed uptimeLow costWater/sewage treatment by irradiationSpecific water treatment objectivesEutrophicationDisposal Technique

The invention relates to the technical field of water treatment, in particular to a nitrogen and phosphorus advanced treatment system for sewage treatment. The nitrogen and phosphorus advanced treatment system comprises a pretreatment system, a first-stage biological denitrification and phosphorus-removal system and a second-stage advanced denitrification and phosphorus-removal system, and the pretreatment system is composed of a coarse screen filtering tank, a fine screen filtering tank and a first stage sedimentation tank which are connected in turns through pipelines; the first biological denitrification and phosphorus-removal system is composed of an anaerobic tank, an anoxic tank and an aerobic tank which are connected in turns through pipelines; and the second-stage advanced denitrification and phosphorus-removal system is composed of a secondary sedimentation tank, a filtering tank, a disinfection tank, a zeolite filter, a resin filter and a mixed sedimentation tank which are connected in turns through pipelines. By combining the first-stage biological denitrification and phosphorus-removal system and the second-stage advanced denitrification and phosphorus-removal system, the advanced treatment of nitrogen and phosphorus in sewage is realized, the risk of eutrophication of water bodies is reduced, and by simultaneously adopting novel materials and a regeneration process, the selective adsorption and concentration of nitrogen and phosphorus are realized, and recycling of nitrogen and phosphorus is realized.

Owner:芜湖沃泰环保科技有限公司

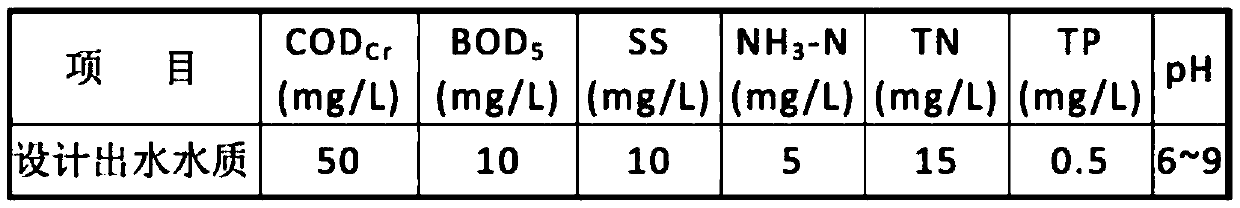

Catalytic ozonation treatment method for refining sewage

ActiveCN106256787AReduce dosageSave construction investmentMultistage water/sewage treatmentActivated carbonSewage

The invention provides a sewage treatment technology method achieved by combining biochemistry with catalytic ozonation. The method is characterized in that according to the technology, activated carbon of a biochemistry unit and a catalytic ozonation unit can be recycled, and the technical problems that in industry sewage treatment, large activated carbon dosage is needed, the operation cost is high, and the effect of a catalytic ozonation catalyst is reduced are solved. According to the technical scheme, the activated carbon catalyst of the catalytic ozonation unit is recycled through an activated carbon recycling WAR unit of a biochemical system, so that the activated carbon catalyst of which the catalytic activity is reduced can be recycled on the condition that no treatment unit is additionally arranged, the regenerated catalyst can be used as a catalyst again, and therefore the dosage of adsorption activated carbon and the catalyst activated carbon of an enterprise is decreased. The method can be applied to the field of refinery enterprise sewage treatment and is particularly suitable for upgrading and reconstruction conducted on a sewage treatment system.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for advanced purification of trace amount of thallium in water by using polymer-base nanometer manganese oxide

ActiveCN102173517ALarge amount of processingFast adsorptionMaterial nanotechnologyWater treatment compoundsDesorptionSafety control

The invention discloses a method for the advanced purification of a trace amount of thallium in water by using polymer-base nanometer manganese oxide, and belongs to the field of the crossing of water environmental management and a nanometer technology. The method comprises the following steps of: regulating the pH value of the water polluted by the trace amount of thallium to be between 5 and 8.5, and filtering; allowing the treated water to pass through a packed tower or a filter bed filled with the polymer-base nanometer manganese oxide, so that the thallium in the water is adsorbed onto ananometer composite material selectively; and stopping adsorbing until the adsorbed thallium in the water reaches a leakage point, performing desorption regeneration on the packing of the polymer-base nanometer manganese oxide by taking HCl and Ca(NO3)2 mixed solution as a desorption agent, wherein the regenerated packing can be used repeatedly. In the method, when the concentration of positive ions such as Ca<2+>, Mg<2+>, Na<+>, Si(IV) and the like which coexist in the water is far higher than that of the thallium, the advanced treatment of the trace amount of the thallium in the water and the safety control over water quality still can be realized, so that the thallium content in the water is reduced from the range of between 0.01 and 0.5 mg / L to less than 0.1 microgram / L. The nanometercomposite material has high operation adsorption capacity, and can be regenerated completely and recycled.

Owner:NANJING UNIV +1

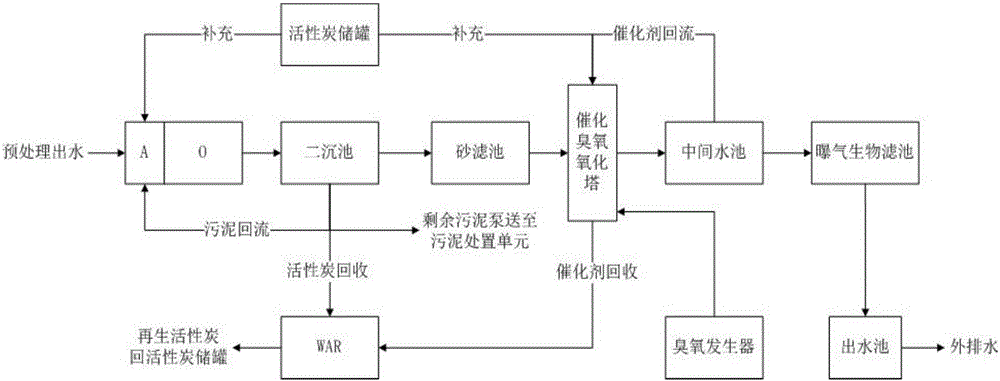

Wastewater advanced treatment method coupling membrane and electricity

ActiveCN104944646AImprove conductivityEmission reductionMultistage water/sewage treatmentWater useFiltration

A wastewater advanced treatment method coupling membrane and electricity belongs to the technical field of wastewater treatment. The treatment method comprises the following steps: discharged wastewater is filtered through a membrane filtration device to obtain fresh water and concentrated water; the fresh water is recycled, the concentrated water is conveyed into an electrocatalysis and electrooxidation device, and the organic pollutants and organisms in the concentrated water are treated and decomposed by electrocatalysis and electrooxidation; the obtained reclaimed water is conveyed into a bipolar membrane electrodialysis device, and the inorganic salt in the reclaimed water is transformed into acid and alkali, so that resource utilization is achieved; the wastewater with the inorganic salt separated by the bipolar membrane electrodialysis device is adopted as scenic environmental water. According to the treatment method, membrane and electricity are coupled, so that advanced treatment of wastewater, material recycling and emission reduction of pollutants are achieved; all water quality indexes of the fresh water and the concentrated water treated through the treatment method respectively meet the standards of GB / T 19923-2005 The Reuse of Urban Recycling Water-Water Quality Standard for Industrial Uses and GB / T 18921-2002 The Reuse of Urban Recycling Water-Water Quality Standard for Scenic Environment Use.

Owner:ZHEJIANG UNIV OF TECH

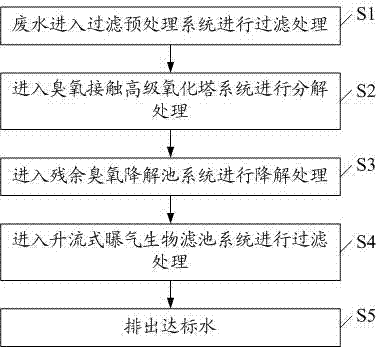

Deep papermaking wastewater treatment device and method

ActiveCN103896451AImprove biodegradabilityChromophore removalMultistage water/sewage treatmentWaste water treatment from plant processingPapermakingWastewater

The invention discloses a deep papermaking wastewater treatment device. The device comprises a filtering pretreatment system, an ozone generation system, an ozone contact advanced oxidation tower system, a residual ozone degradation pond system and an upflow biologic aerated filter system, wherein the filtering pretreatment system, the ozone contact advanced oxidation tower system, the residual ozone degradation pond system and the upflow biologic aerated filter system are connected in sequence, and the ozone generation system is connected with the ozone contact advanced oxidation tower system. The invention further discloses a deep papermaking wastewater treatment method. According to the device, the filtering pretreatment system, the ozone contact advanced oxidation tower system, the residual ozone degradation pond system and the upflow biologic aerated filter system are combined, so that papermaking wastewater can be deeply treated, and the treated wastewater meets the standards.

Owner:GUANGDONG XINTAILONG ENVIRONMENTAL PROTECTION GRP CO LTD

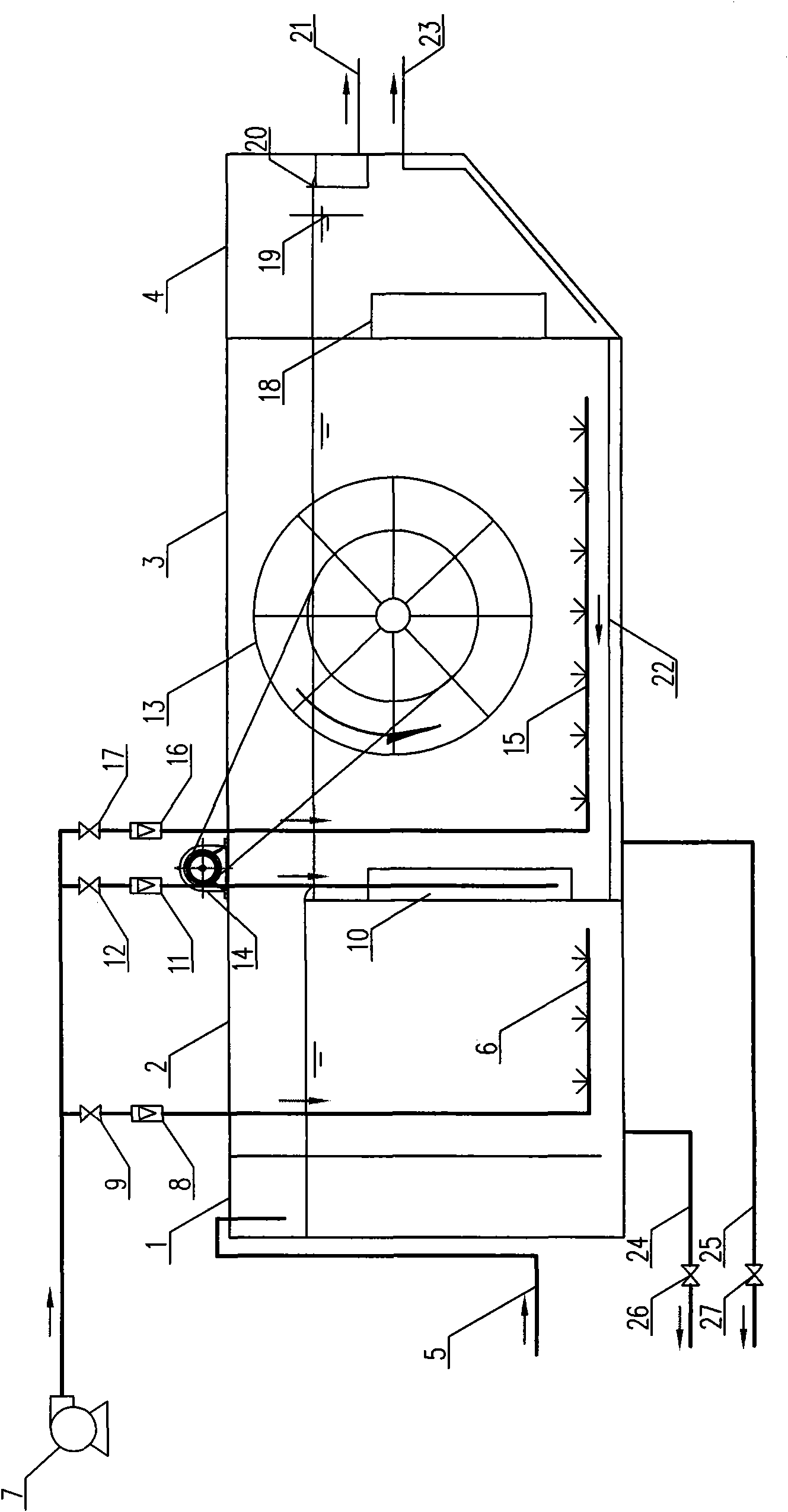

Combined sewage treatment device

InactiveCN101570380ATo achieve the purpose of phosphorus and nitrogen removalEasy to handleTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeSewage

The invention provides a combined sewage treatment device which integrates the activated sludge process and the biofilm process, organically combines the advantages of the suspension growth technology and the attached growth technology, combines anaerobic and aerobic properties in one device, leads the two to promote each other and improves the sewage treatment capacity and the treatment efficiency. The combined sewage treatment device is characterized in that the combined sewage treatment device comprises a biological phosphorus removal zone, a denitrification zone, a nitrification zone and a sludge-water separation zone positioned in a tank body structure, the biological phosphorus removal zone is connected with a sewage inlet pipe, the sludge-water separation zone is provided with a water outlet pipe, a residual sludge discharge pipe and a return sludge hole, and the return sludge hole leads to the biological phosphorus removal zone and / or the denitrification zone; and a rotating biological disk is arranged in the nitrification zone.

Owner:TAWA BEIJING

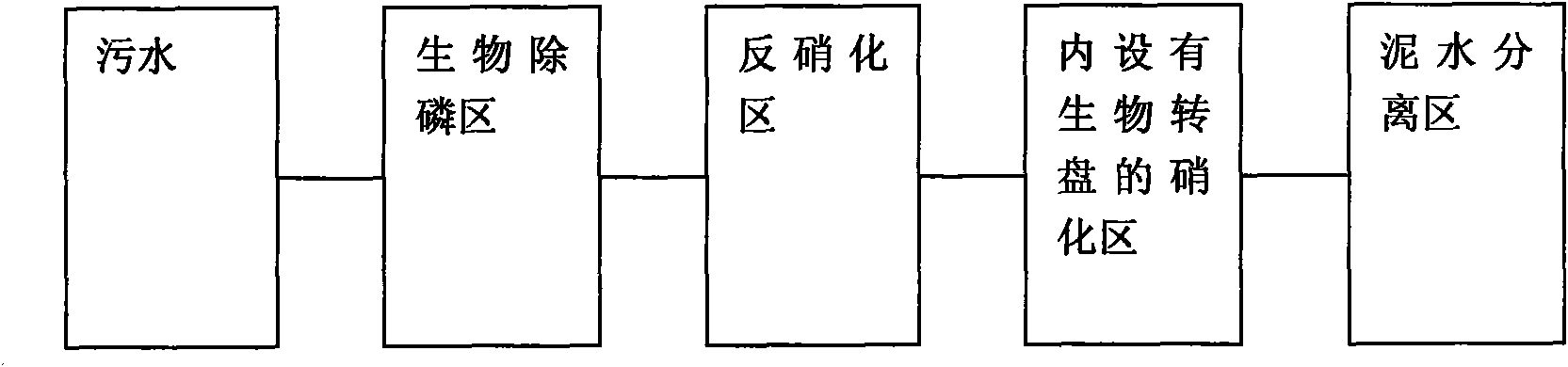

Deep nitrogen and phosphorus removal process for surface water body

ActiveCN102249478AImplement deep processingGuaranteed cleanlinessWater resource protectionTreatment with aerobic and anaerobic processesPhosphateFiltration

The invention provides a deep nitrogen and phosphorus removal process for a surface water body. The process mainly comprises six working sections, such as contact oxidation, rapid filtration, anaerobic denitrification, flocculation reaction, phosphorus sediment removal and phosphate removal through adsorption. The process is realized on the basis of improvement, strengthening and combination of the traditional treatment processes integrates a biological method, a chemical method and a physical method and is used for removing various pollutants in the water body effectively; the sewage purifying efficiency is remarkably increased; and an entire treatment device is free from odor and secondary noise pollution; a natural flow type combination mode is adopted in the design without any multistage elevating pump or reflux pump; a back washing system is arranged in a rapid filter and used for periodic back-washing, so that the problems of blocking and power consumption are solved; and the entire process has the advantages of full automation, no need of manual guard, and convenience for management and maintenance.

Owner:襄阳先创环保科技有限公司

Integration method for electroplating acid pickle recycling and advanced waste treatment

InactiveCN101723558ARealize resource utilizationReduce salt contentWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentLiquid wasteQuaternary ammonium cation

The invention provides an integration method for electroplating acid pickle recycling and advanced waste treatment, which comprises the following steps: filtering the acid pickle of plating products in a plating process, then adding an oxidizer to ensure that bivalent iron ions in the acid pickle are completely converted into trivalent iron ions; then removing the trivalent iron ions in the acid pickle through an adsorption plant which is filled with anion exchange resins of which the surfaces are bound with quaternary ammonium cation bound, adding appropriate amount of industrial concentrated hydrochloric acid into the processed acid pickle of the plating products to increase the concentration to over 20 percent, then, returning the acid pickle to the production processes for recycling; and carrying out conventional fabrication processing on the processed electroplating wastewater, allowing the electroplating wastewater to pass through a combination filter bed, stopping adsorption when the adsorption reaches a leak point, and carrying out desorption and regeneration on a compound adsorbent by a desorption agent. The integration method realizes the resource utilization of the electroplating acid pickle, remarkably reduces the using amount of acid pickle in the electroplating process, realizes the advanced removal of the cationic contaminants such as heavy metal and the like and the anionic contaminants such as phosphate radical and the like which is difficult to realize in the conventional treatment process.

Owner:NANJING UNIV

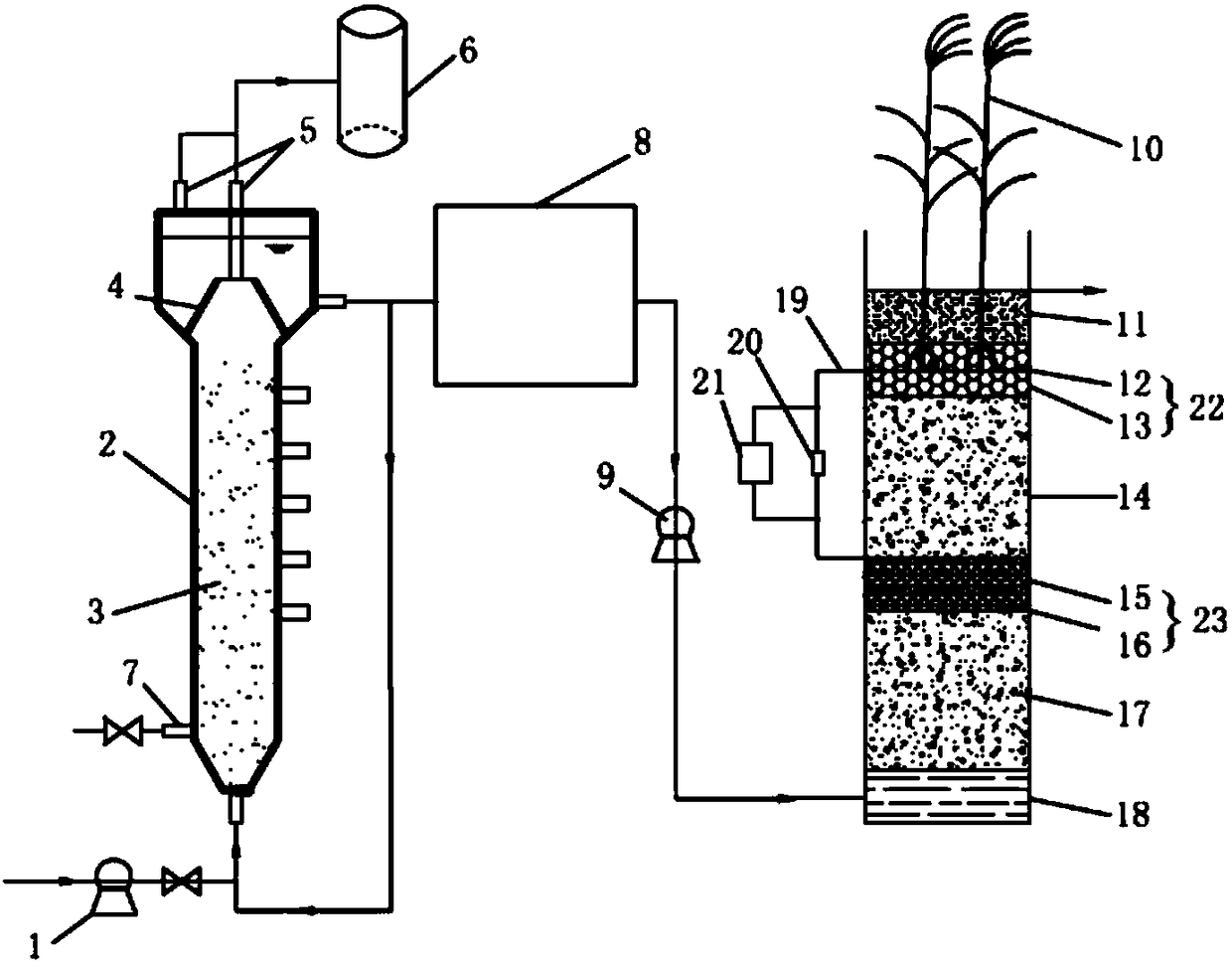

Anaerobic fluidized bed series constructed wetland type microbial fuel cell device and method

PendingCN108275776AStart fastRealize processingTreatment by combined electrochemical biological processesBiological treatment apparatusMicrobial fuel cellActivated sludge

The invention discloses an anaerobic fluidized bed series constructed wetland type microbial fuel cell device and method. The anaerobic fluidized bed series constructed wetland type microbial fuel cell device comprises an anaerobic fluidized bed and a constructed wetland type microbial fuel cell which are connected in series; the anaerobic fluidized bed cultures a carrier to which a biofilm is attached as an anode of the constructed wetland type microbial fuel cell. Compared with a traditional active sludge method, a novel sewage treatment system of the anaerobic fluidized bed and the constructed wetland type microbial fuel cell, provided by the scheme, has the advantages that two devices are connected in series to realize deep treatment of sewage and improve the treatment effect of waterquality; the anaerobic fluidized bed can culture the carrier to which the biofilm is attached, and the carrier is used for the anode of the constructed wetland type microbial fuel cell, so that startof the microbial fuel cell can be accelerated.

Owner:SHANDONG NORMAL UNIV

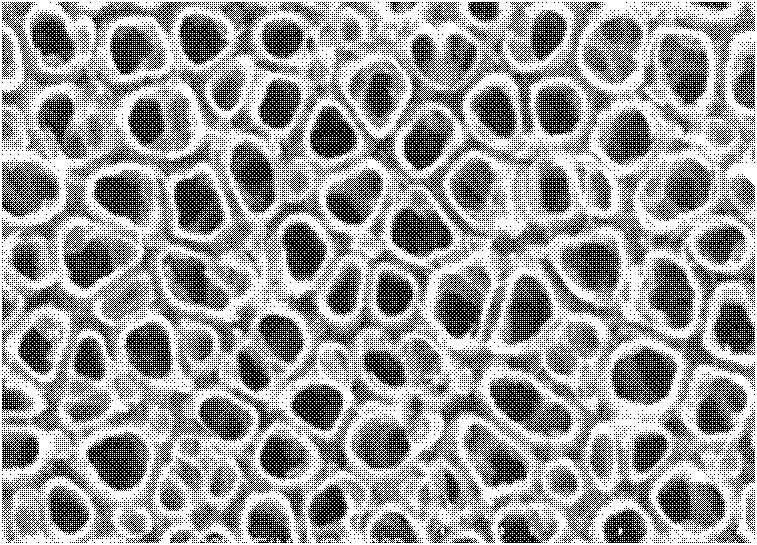

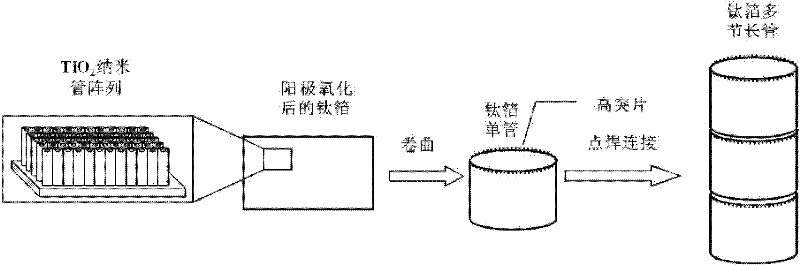

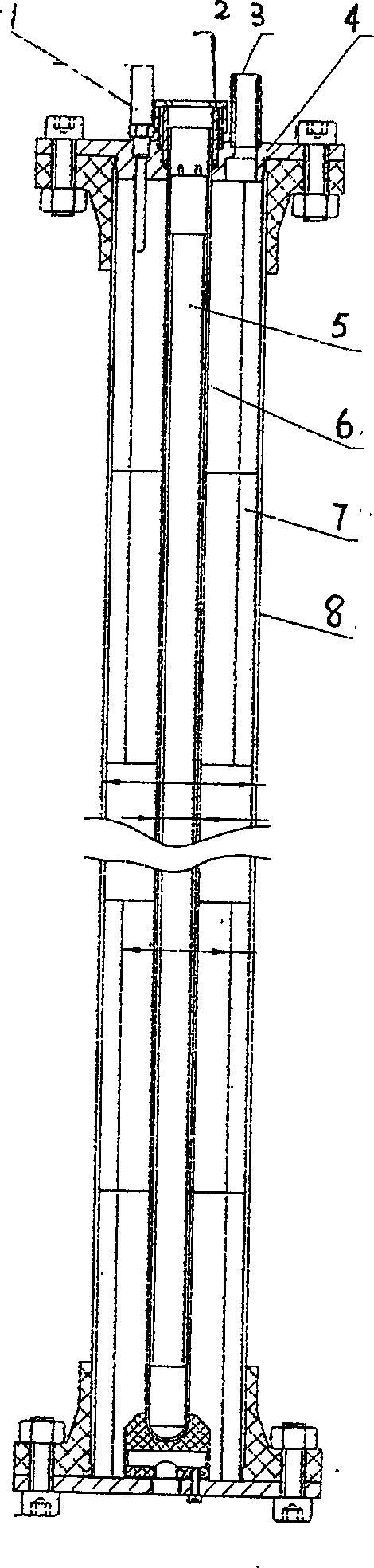

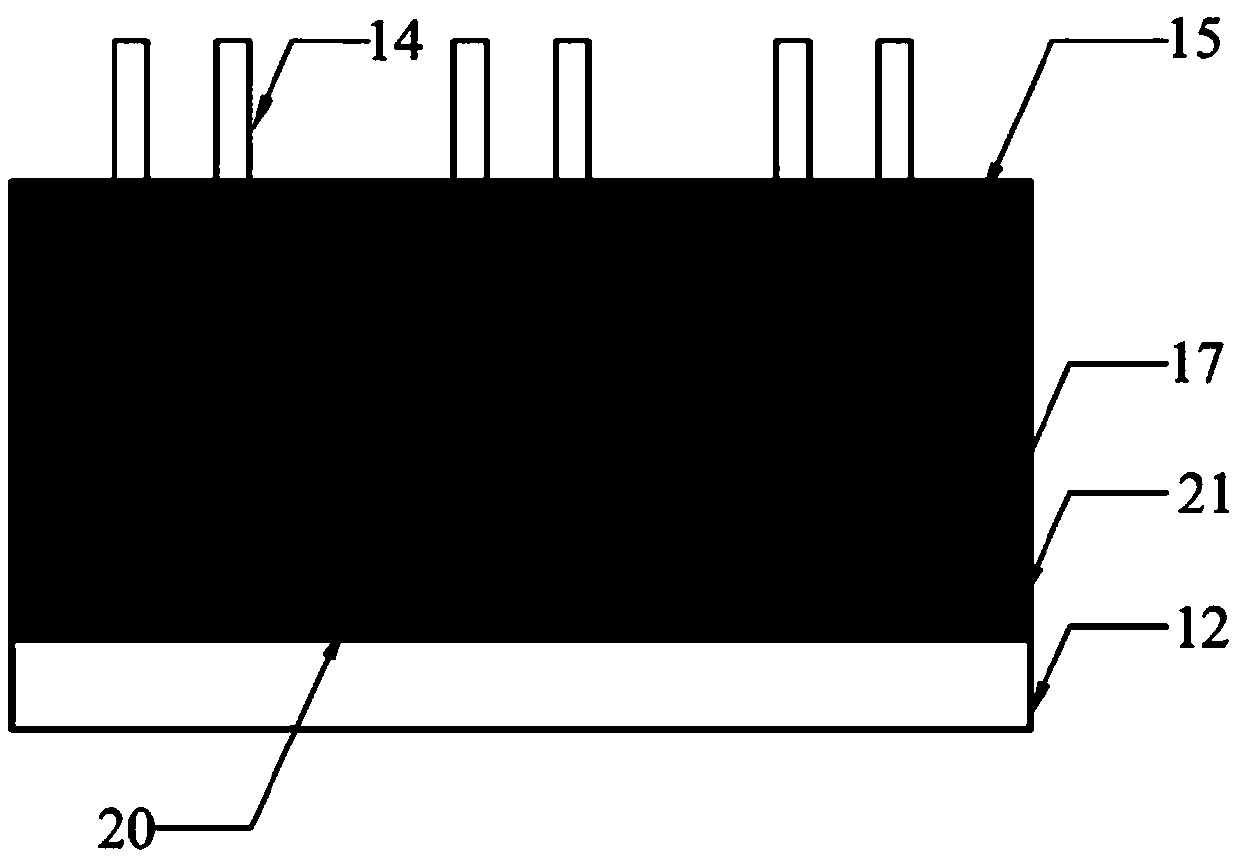

A tube-and-tube nano-titanium dioxide tube array photocatalytic reactor and preparation method thereof

InactiveCN102258971AGood technical effectImprove bindingWater/sewage treatment by irradiationEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionSewage

The invention provides a tubular nano titanium dioxide pipe array photocatalysis reactor and a preparation method, relating to a photocatalysis reactor. The tubular nano titanium dioxide pipe array photocatalysis reactor and the preparation method provided by the invention are simple to operate and easy to realize industrial application. The photocatalysis reactor is provided with an ultraviolet lamp, a photocatalyst, 1-6 photocatalysis reaction zone channels, a submersible pump, a sewage input channel, a booster pump, a first sewage recycling channel, a first three-way switch, an air booster pump, a gas-conveying channel, a second three-way switch and a second sewage recycling channel. The preparation method comprises the following steps of: firstly preparing a vertically growing titanium dioxide nano pipe array as the photocatalyst; connecting the pieces one by one by using spot welding, and then rolling into a cylinder; constructing the titanium dioxide nano pipe array as the photocatalyst on the surface of a titanium foil rolled into the cylinder shape; and forming the tubular photocatalysis reactor, and finally assembling to obtain the tubular nano titanium dioxide pipe array photocatalysis reactor.

Owner:XIAMEN UNIV

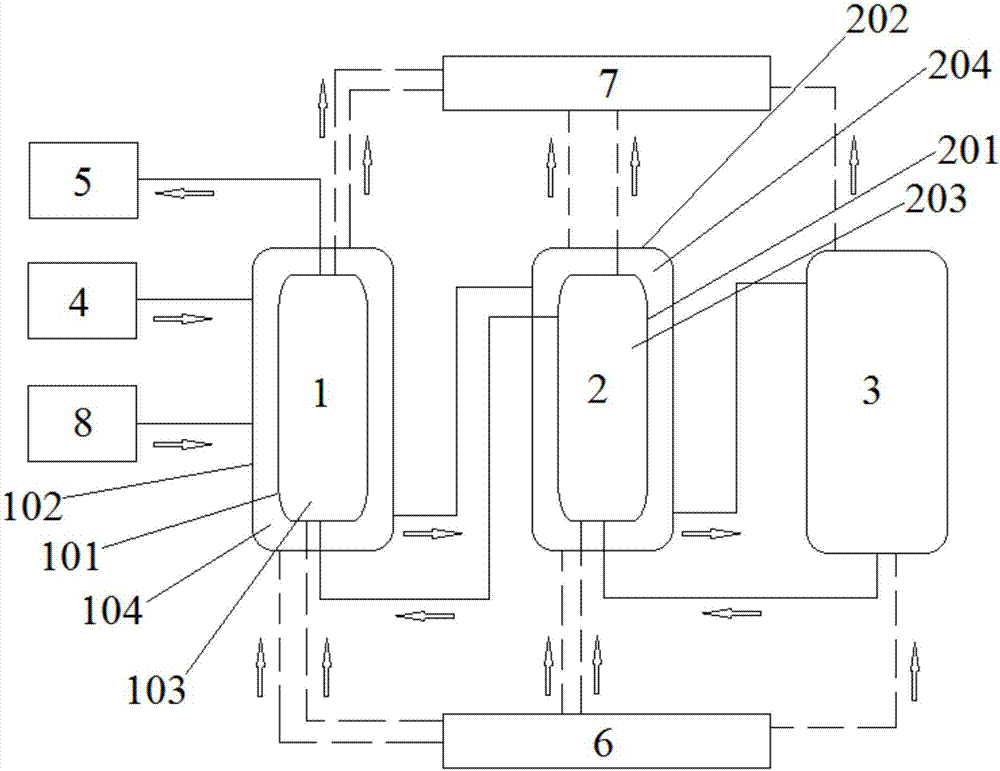

Method and device for treating industrial wastewater by multi-stage wet oxidation

ActiveCN107572651AImprove processing efficiencyReduce processing costsWater contaminantsWater/sewage treatment by oxidationIndustrial waste waterWater storage tank

The invention relates to a method and a device for treating industrial wastewater by multi-stage wet oxidation. The method comprises the steps: industrial wastewater sequentially undergoes first-stageoxidation, second-stage oxidation and third-stage oxidation, the temperature of first-stage oxidation is lower than the temperature of second-stage oxidation, the temperature of second-stage oxidation is lower than the temperature of third-stage oxidation, and moreover, third-stage oxidation sequentially supplies heat to second-stage oxidation and first-stage oxidation. The device comprises an influent water storage tank communicating with a second reaction chamber of a first-stage oxidation reactor and an effluent water storage tank communicating with a first reaction chamber of the first-stage oxidation reactor. Compared with the prior art, the method and the device disclosed by the invention adopt the three stages of oxidation processes sequentially connected in series, consequently, organic pollutants in industrial wastewater can be treated step by step and stage by stage, the efficiency of industrial wastewater treatment is greatly increased, moreover, heat which is emitted in the process of reaction is sufficiently utilized, the high-efficiency operation of the whole system is maintained, energy consumption and industrial wastewater treatment cost are reduced, and the efficiency of treatment is increased.

Owner:TONGJI UNIV

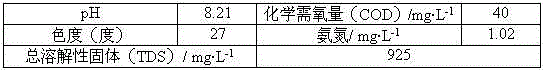

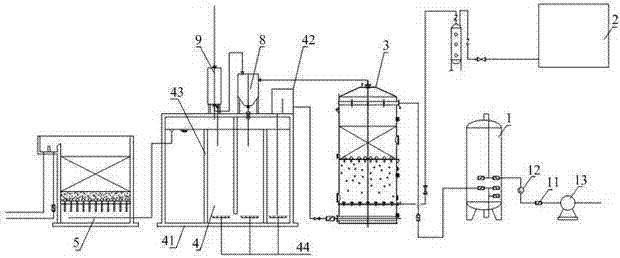

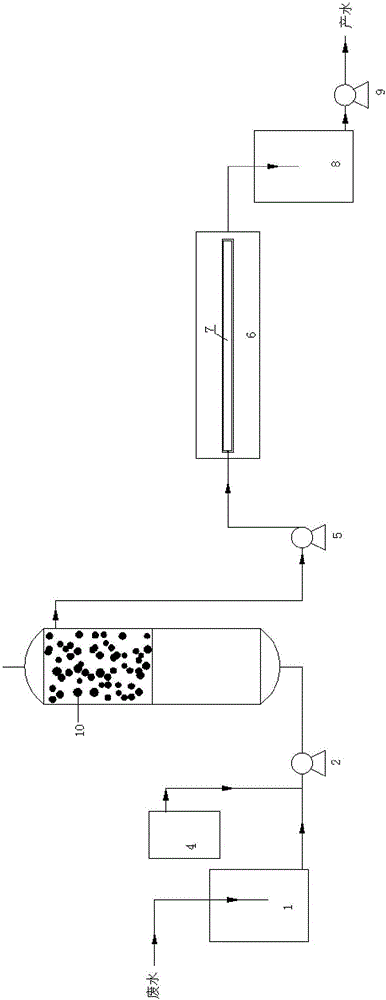

Method and device for deeply treating oil refinery wastewater through ultraviolet and catalytic ozonation

InactiveCN105000728AImprove dissolution efficiencyEfficient use ofMultistage water/sewage treatmentMicrobubblesUltraviolet

The invention provides a method and device for deeply treating oil refinery wastewater through ultraviolet and catalytic ozonation. The method comprises the steps that the oil refinery wastewater and ozone are mixed through a gas-liquid mixing pump to obtain milky gas-liquid mixing pump yielding water which is rich in ozone microbubbles; the gas-liquid mixing pump yielding water enters a reaction tower of which the upper portion is loaded with an ozone catalyst to react, the reaction tower achieves upper input and lower output, a oxidative degradation reaction is firstly performed on the lower portion of the reaction tower, then a catalytic oxidation is performed on the upper portion of the reaction tower to degrade organic pollutants in the wastewater, reaction tower yielding water is conveyed into an enhancement reactor with a high intensity ultraviolet lamp to perform an ultraviolet-ozone co-oxidation reaction to degrade the pollutants, and yielding water meeting the standard is obtained. According to the method, the dissolving efficiency of the ozone in the wastewater can be improved, the oxidation performance of the ozone is enhanced, the energy of the high intensity ultraviolet lamp can be efficiently utilized, and therefore the oil refinery wastewater can meet the standard and then be drained after being deep treated; the device has the advantages of being low in investment and operation cost.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

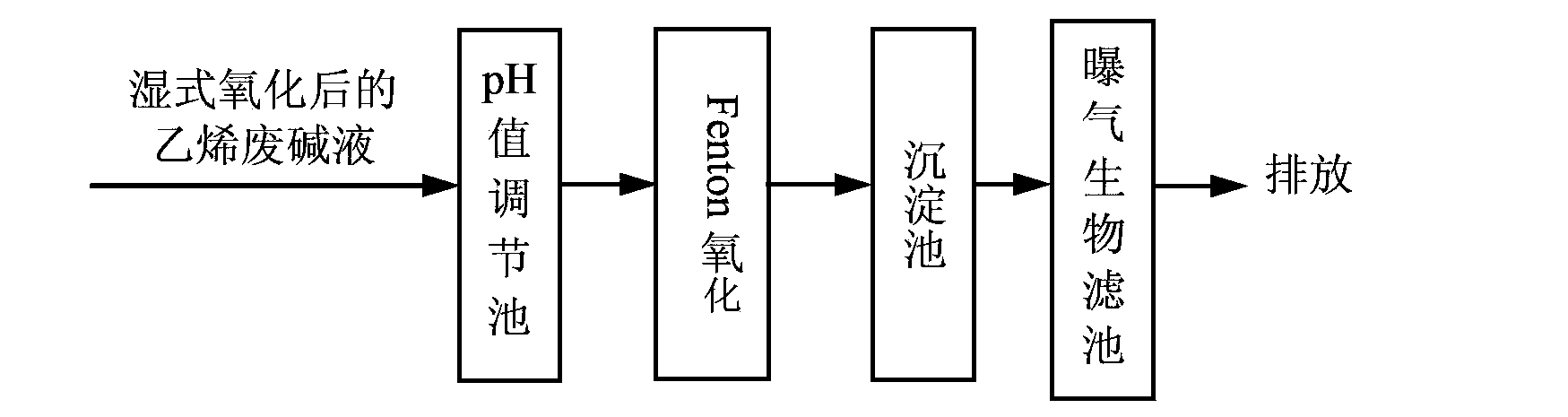

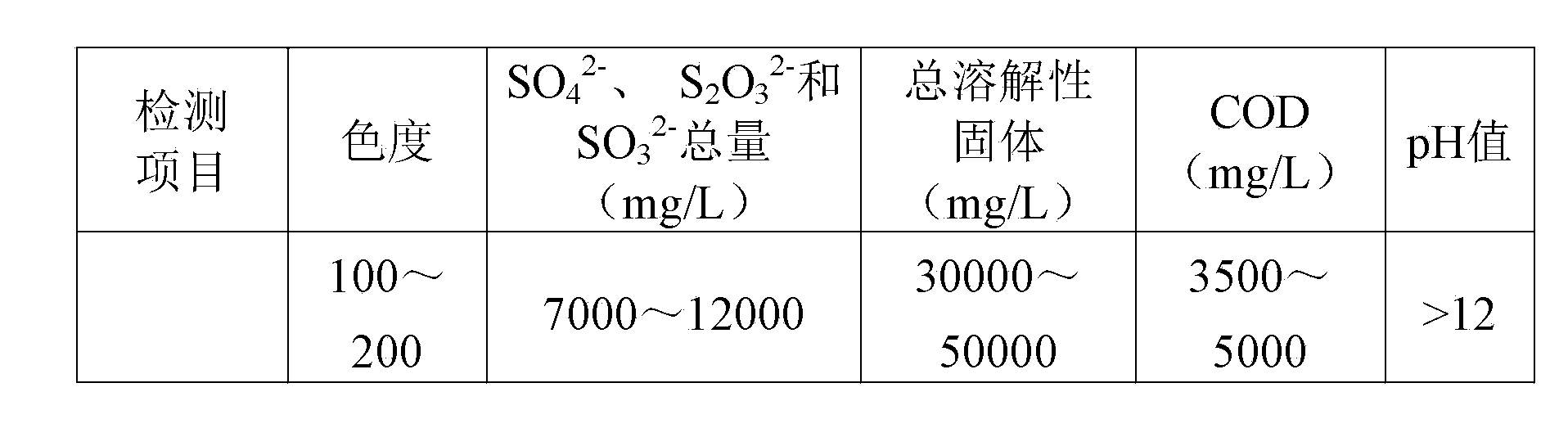

Deep treatment method of ethylene waste lye

ActiveCN103663842AEasy to process in depthImprove oxidation efficiencyMultistage water/sewage treatmentChemical oxygen demandAfter treatment

The invention relates to a deep treatment method of ethylene waste lye, and particularly relates to a deep treatment method of ethylene waste lye after wet oxidation pretreatment. The ethylene waste lye after wet oxidation pretreatment is deeply treated by adopting a Fenton oxidation-biological aerated filter (BAF) technology, the chemical oxygen demand (COD) of effluent after treatment is smaller than 200mg / L, the chromaticity is smaller than 1, the ethylene waste lye is clear and transparent, and deep treatment of the ethylene waste lye is achieved. The treatment method is simple and convenient in operation, stable to run, high in COD removal efficiency, and good in decoloration effect, and can be directly discharged to a municipal sewage plant and receiving water or merged into other treatment systems.

Owner:CHINA PETROLEUM & CHEM CORP +1

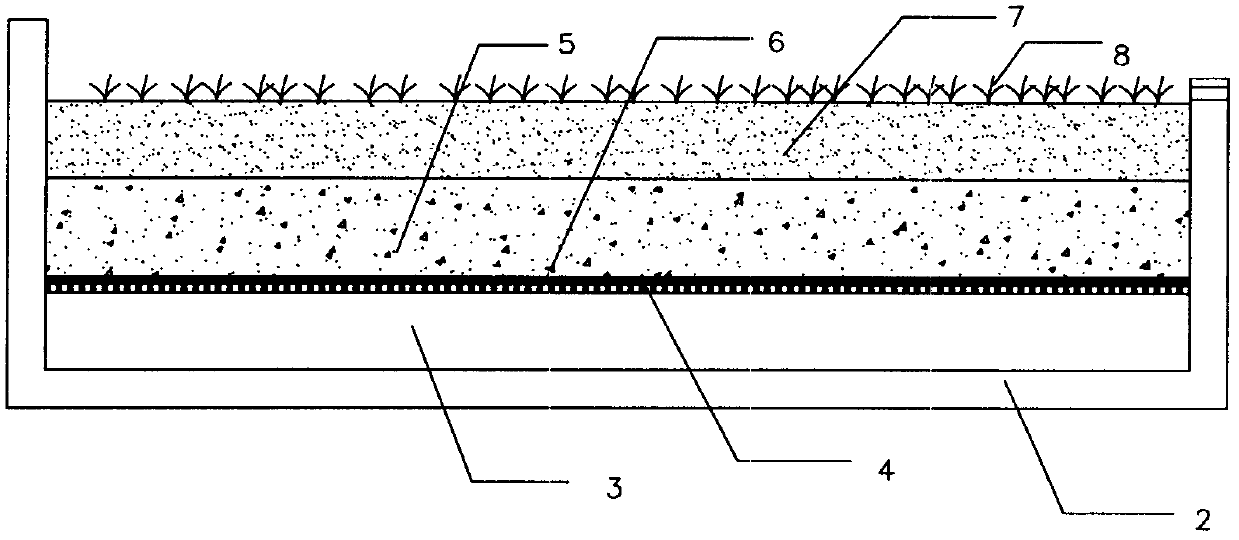

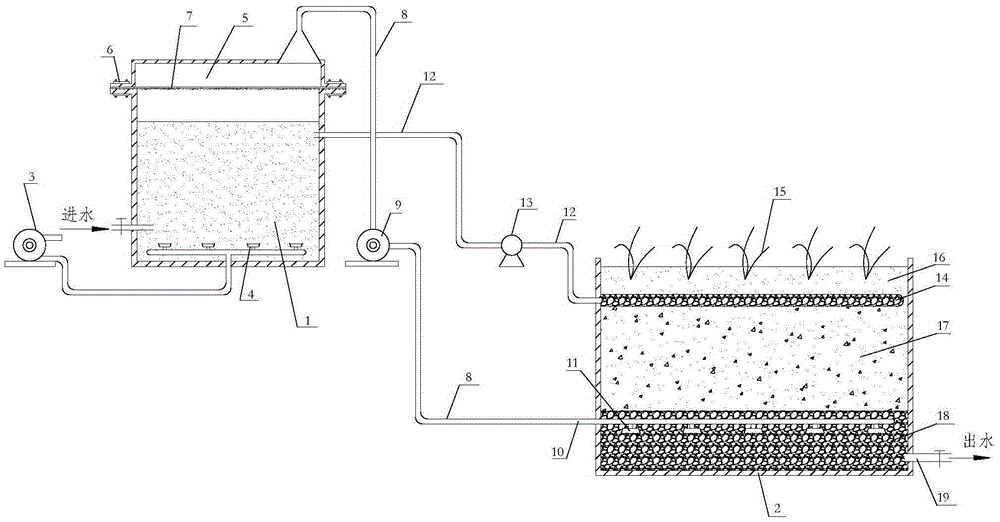

Soil fast-filter bed system for purifying bioreactor tail gas

ActiveCN105236551AReduce running timeSimple structureTreatment using aerobic processesDispersed particle separationFluidized bedWater quality

The invention relates to a soil fast-filter bed system for purifying bioreactor tail gas and deeply processing sewage. The system comprises a bioreactor (such as biological fluidized bed reactor, membrane bioreactor, etc.) and a soil fast-filter bed. The tail gas is collected by a gas collecting hood; then the tail gas enters the soil fast-filter bed after going through a gas pipeline, a wind turbine, a gas distribution pipe, and a micropore aerator; the effluent from the bioreactor goes through a water pipeline, a water pump, and a water distribution tank and enters the soil fast-filter bed; thus the comprehensive effect of soil, microbes, and plants in the soil fast-filter bed can be used to purify the effluent and tail gas, the operation time of the reactor is shortened, and the operation cost is reduced. The provided system can utilize and purify tail gas, can also deeply process sewage, and has the advantages of high purification efficiency and good quality of processed water.

Owner:SHANDONG UNIV

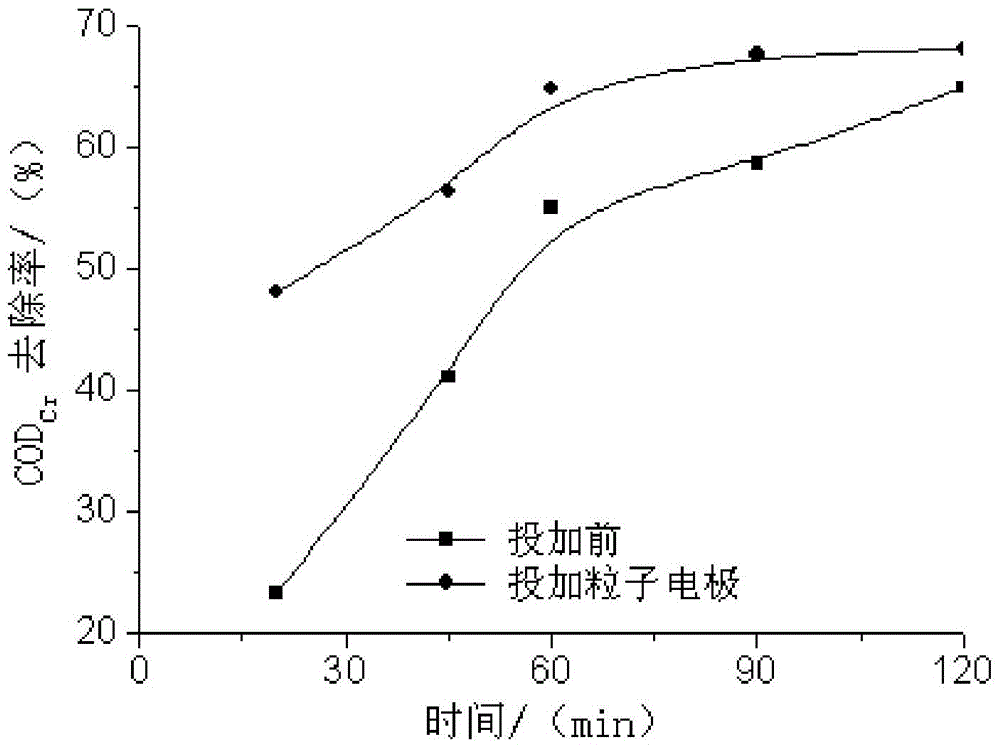

Blast furnace dust recycling utilization method

ActiveCN104402097ALoose structureLarge specific surface areaWater treatment parameter controlWater contaminantsElectrolysisSlag

The invention discloses a blast furnace dust recycling utilization method, which comprises the following steps: 1) screening out blast furnace dust with the diameter of 200-400 mesh; 2) mixing the blast furnace dust and ammonium salt in the ratio of 6-10:1, then adding water and tar slag for granulate into particles with the particle size of 1.5-3.0mm; 3) after drying the particles at 60 to 80 DEG C for 25-40min, transferring into a muffle furnace, heating to 400 to 700 DEG C in 10 to 15 DEG C / min speed for roasting for 30min-1H to prepare iron carbon micro electrolysis particles; and 4) pouring the iron carbon micro electrolysis particles into coking biochemical efflux water, adjusting the PH value to 3-5 for fully degrading organic matters, then adjusting the pH value to 6-9 for the removal of precipitate to complete advanced treatment; or putting the iron carbon micro electrolysis particles into a three-dimensional electrode reactor to be used as a particle electrode for treatment of the coking biochemical efflux water. The blast furnace dust recycling utilization method not only solves the problems of blast furnace dust environmental pollution and land occupation, also realizes the advanced treatment of the coking biochemical efflux water, and greatly reduces the processing cost.

Owner:武汉钢铁有限公司

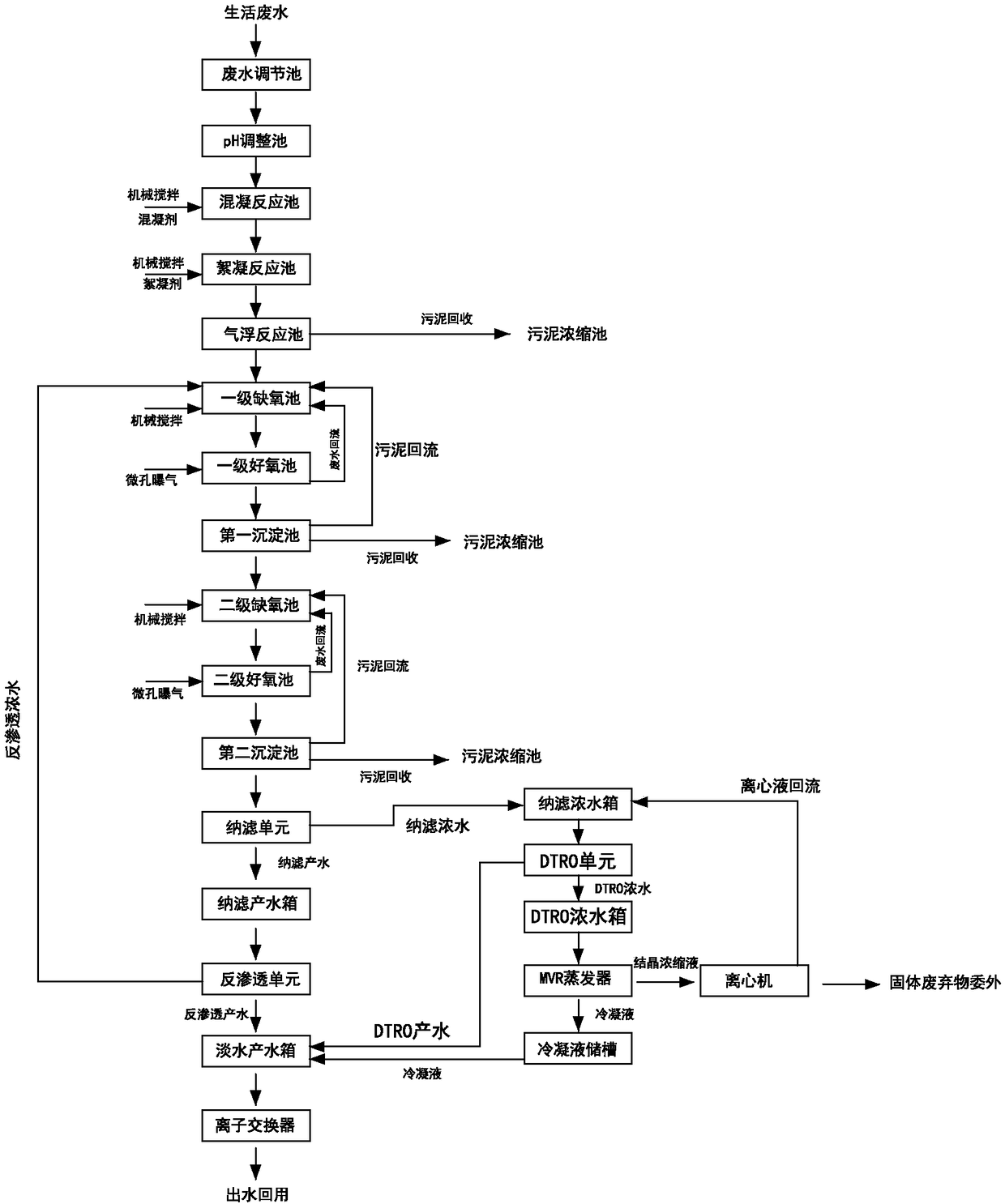

Treatment method for textile industrial waste water

ActiveCN108083552ASolve processing problemsReduce chromaTreatment involving filtrationTreatment with aerobic and anaerobic processesOxygen deficitNanofiltration

The invention discloses a treatment method for textile industrial waste water. The treatment method for textile industrial waste water comprises the following steps: (1) regulating a pH value; (2) carrying out coagulation air floatation treatment on the waste water obtained in step (1); (3) carrying out primary oxygen deficit / primary aerobiotic biological treatment on the waste water obtained by treatment in step (2); (4) carrying out secondary oxygen deficit / secondary aerobiotic biological treatment on the waste water obtained by treatment in step (3); (5) carrying out reverse osmosis treatment on nano-filtration produced water obtained by treatment in step (5), and enabling reverse osmosis concentrated water to enter a primary anoxic pond; (7) carrying out DTRO disc tube type reverse osmosis treatment on nano-filtration concentrated water obtained by treatment of step (5); and (8) carrying out evaporation treatment on the DTRO disc tube type reverse osmosis concentrated water obtained by treatment in step (7). By the method, the problem of dispersed treatment of salt in the waste water is solved, the treatment efficiency and effect are improved, the treatment cost is reduced, andzero emission of treatment of the waste water is further implemented.

Owner:SUZHOU SUJING ENVIRONMENTAL ENG

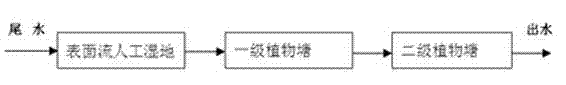

Constructed wetland and plant pond joint treatment system for tail water advanced treatment

ActiveCN104261618AImplement deep processingEfficient removalMultistage water/sewage treatmentBiological water/sewage treatmentConstructed wetlandEngineering

The invention discloses a constructed wetland and plant pond joint treatment system for tail water advanced treatment. The constructed wetland and plant pond joint treatment system comprises a surface flow constructed wetland, a first-stage plant pond and a second-stage plant pond, which are arranged in a stepped manner from top to bottom, wherein water-distributing water level adjusters are respectively arranged between the surface flow constructed wetland and the first-stage plant pond, and between the first-stage plant pond and the second-stage plant pond; an aquatic plant is planted into the surface flow constructed wetland; and water surface plants and riparian plants are planted into the first-stage plant pond and the second-stage plant pond. The constructed wetland and plant pond joint treatment system runs by completely utilizing an automatic-flow manner, does not generate the operating cost, is simple in management and maintenance, and has high application value.

Owner:FUDAN UNIV

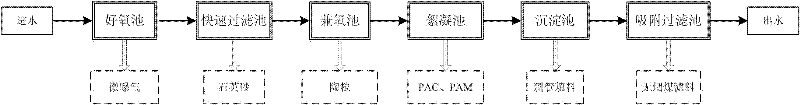

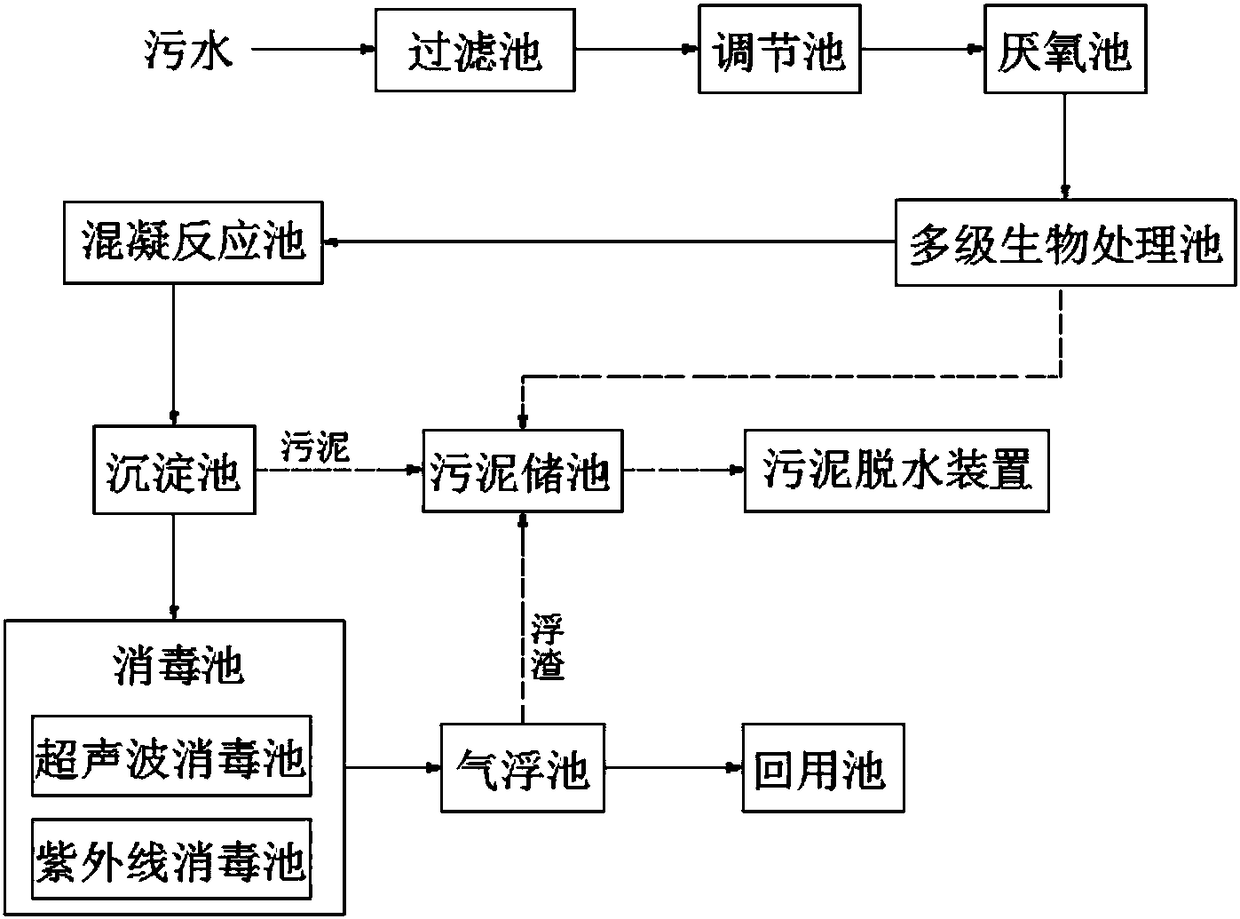

Water circulating device and system for fiber production

PendingCN108218145AImprove biodegradabilityReduce concentrationWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsFiberWater quality

The invention provides a water circulating device and a water circulating system for fiber production, relates to the technical field of sewage treatment, and aims to solve the technical problem thata desired treatment effect cannot be achieved by the conventional treatment method because a large amount of sewage produced during cotton processing has the characteristics of large volume, high organic pollutant content, deep color, large water quality change and the like. The invention relates to the water circulating device for the fiber production. The water circulating device for the fiber production comprises a filter tank, wherein a grid assembly is arranged inside the filter tank; the filter tank is sequentially communicated with an adjusting tank, an anaerobic tank, a multi-stage biological treatment tank, a coagulation reaction tank, a sedimentation tank, a disinfecting tank, a floatation tank and a recycling tank. The invention further relates to the water circulating system for the fiber production. The water circulating system for the fiber production comprises the water circulating device for the fiber production. The water circulating device for the fiber production andthe water circulating system for the fiber production can treat the sewage better, so that the sewage can meet recycling and discharge standards.

Owner:哈密绿天使纤维科技有限公司

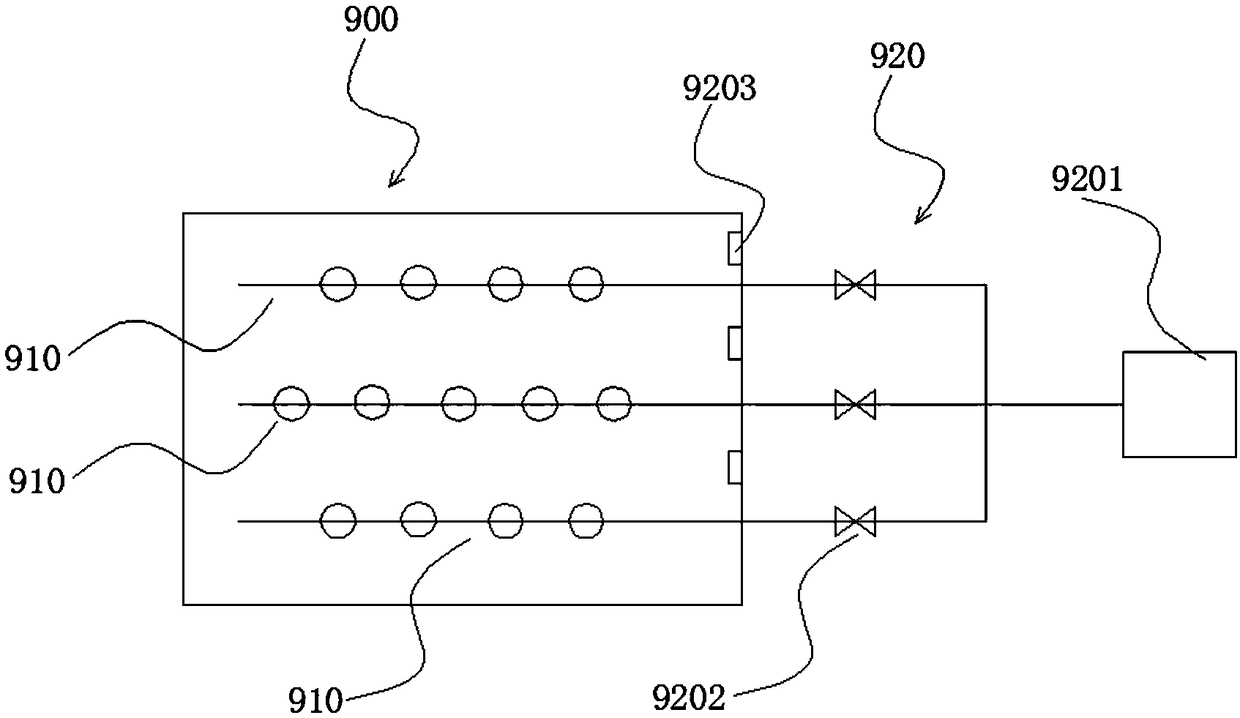

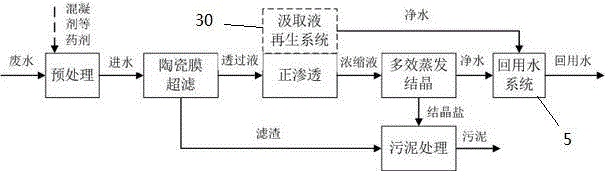

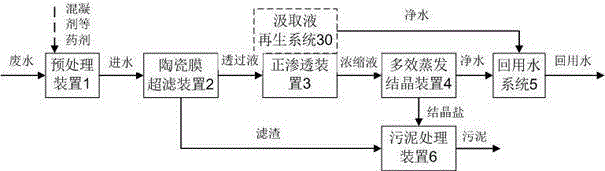

Zero-discharge treatment process and device for high-salt-content industrial wastewater

InactiveCN105174585AEfficient ConcentrationImplement deep processingMultistage water/sewage treatmentEvaporationImpurity

The invention provides a zero-discharge treatment process for high-salt-content industrial wastewater. The process includes the steps that S1, in pretreatment, through adding chemicals, ions and impurities in the wastewater are settled; S2, in ceramic membrane filtering, a ceramic membrane is utilized for separating the settled ions and impurities in the wastewater to serve as pretreatment of a forward osmosis technology; S3, in forward osmosis concentration, based on a forward osmosis principle, the wastewater is concentrated efficiently, and purified water is separated from the wastewater to be recycled; S4, in multi-effect evaporation crystallization, a multi-effect evaporation crystallization technology is utilized for performing advanced treatment on forward osmosis concentrate to achieve zero discharge of the wastewater. The invention further provides a zero-discharge treatment device for the high-salt-content industrial wastewater. The zero-discharge treatment process and device have the advantages that the multiple technologies of the ceramic membrane, forward osmosis and evaporation crystallization are coupled, the high-quality purified water can be recycled from the industrial wastewater, zero discharge of the wastewater can be achieved, energy consumption is low, the production cost is low, and the process is advanced.

Owner:乔铁军

Efficient photocatalytic water-treating process and apparatus

InactiveCN1810665AStrong loadLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationDouble tubeIndustrial waste water

The present invention relates to one kind of efficient photcatalytic water-treating process and apparatus. Inside a ceramic or stoneware tube with TiO2 coated to the inner wall, a transparent tube is set coaxially and an ultraviolet light source is set inside the double tube to constitute a membrane reaction tube. The membrane reaction tube is mounted vertically, the water to be treated inflows from the lower end of the membrane reaction tube and the treated water outflows from the upper end of the membrane reaction tube. The water flow rate is controlled so that the water settling time or photcatalytic reaction time is controlled. The apparatus is suitable for degrading organic matter and sterilizing of slightly contaminated industrial waste water, domestic waste water and natural water. The apparatus has jetting device to ventilate the solution, reflux device to reinforce the mass transfer effect of the reaction system, and control system including power source and light source controller.

Owner:NANJING UNIV

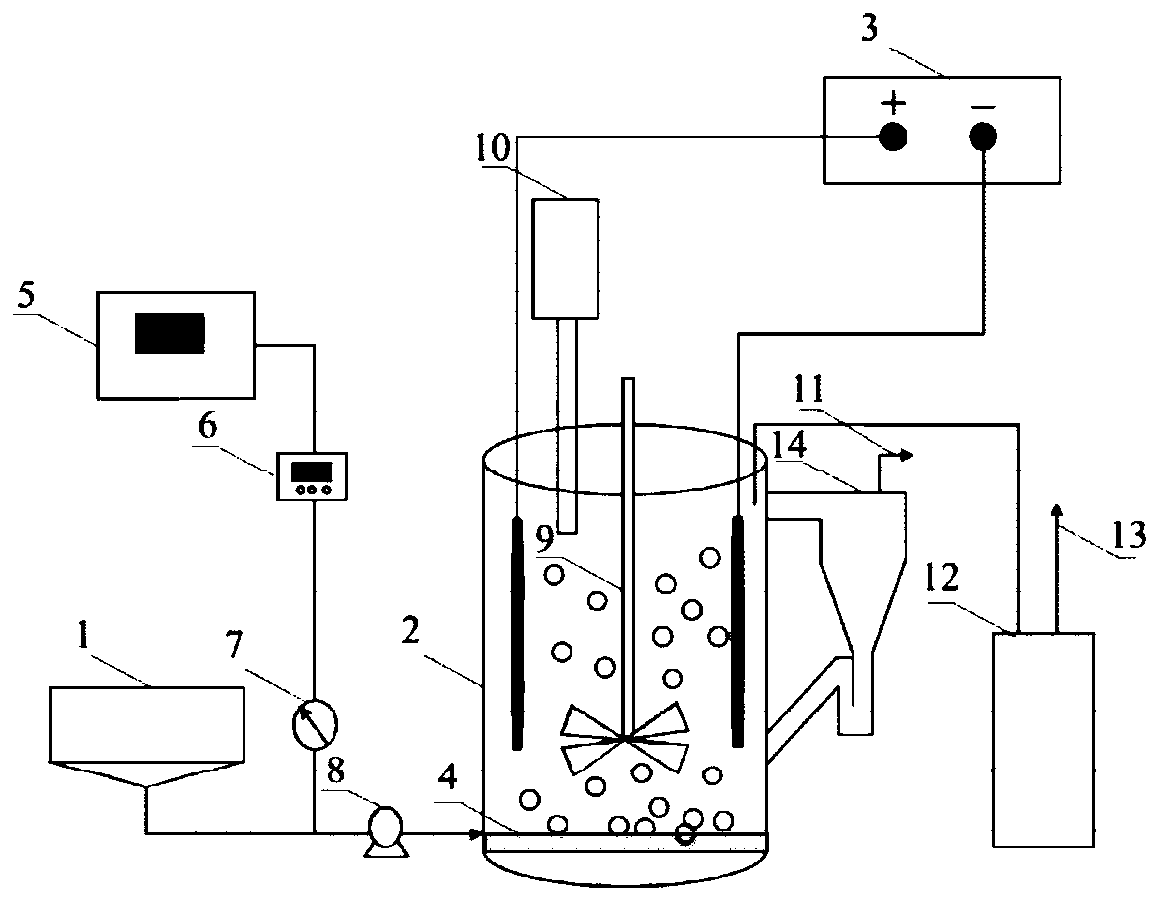

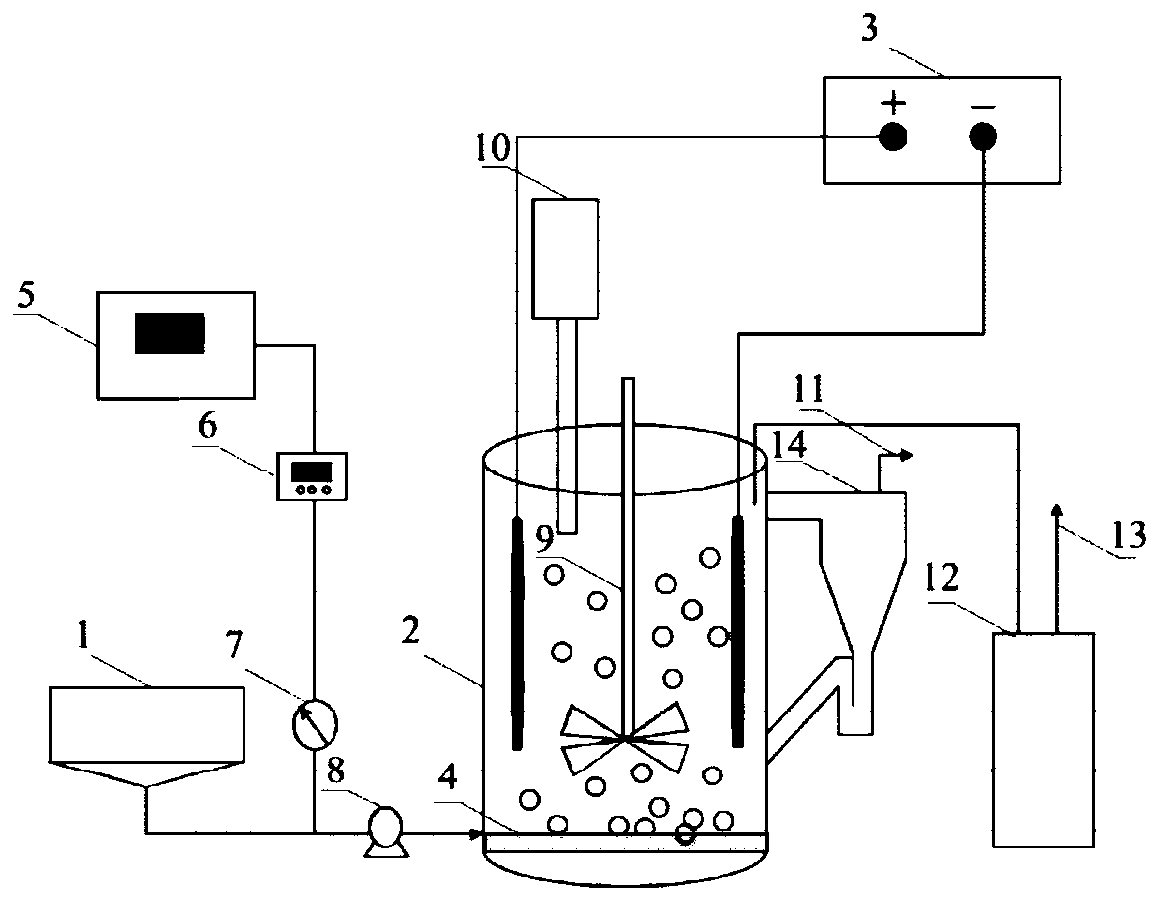

Synergistic treatment device for degradation-resistant organic waste water and method thereof

InactiveCN105502772AImplement deep processingMeet the requirements of effluent water qualityWater/sewage treatment with mechanical oscillationsWater contaminantsChemical reactionElectrolysis

The invention discloses a synergistic treatment device for degradation-resistant organic waste water and a method thereof, and belongs to the field of waste water treatment. The synergistic treatment device comprises a primary microwave waste water treatment unit and a secondary ultrasonic wave and electrocatalytic oxidation synergistic waste water treatment unit. In the microwave waste water treatment unit, primary waste water treatment is realized through physical and chemical reactions between microwaves and pollutants, the waste water obtained after microwave treatment enters the ultrasonic wave and electrocatalytic oxidation synergistic waste water treatment unit, on the premise that the waste water quality is improved by microwaves and conditions suitable for secondary treatment are created, secondary treatment on the waste water pollutants is achieved by means of strong-oxidizing free radicals synergistically generated by ultrasonic waves and electrocatalytic oxidation, and continuity of secondary treatment and high efficiency of electric energy utilization are ensured through an electrode surface layer clearing function of the ultrasonic waves. Secondary pollution is avoided in the whole waste water treatment process.

Owner:杭州科瑞特环境技术有限公司

Device and method for advanced treatment of oily sludge by E<+>-micro-nano bubble ozone

ActiveCN111138057AAchieve demulsificationImprove adhesion efficiencySludge treatment by oxidationWater contaminantsMicro nanoElectrolysis

The invention discloses a device and a method for advanced treatment of oily sludge by E<+>-micro-nano bubble ozone. The device comprises a vibrating screen, an E<+>-micro-nano bubble ozone device anda power supply, the oily sludge treated by the vibrating screen enters an E<+>-micro-nano bubble ozone device, the emulsification structure of the oily sludge is destroyed through ozone oxidation, and demulsification is further conducted through E<+> electrolysis at the upper end of the device; the O2 entrained by the aeration process and O3 which cannot be consumed by organic matters in time areconverted into H2O2, .OH and the like under the coupling action of E<+>-micro-nano bubble ozone, so that deep oxidation of oil substances is realized, and the oil substances are converted into carbondioxide and water; the micro-nano ozone floating bubbles bring demulsified oil drops to the liquid level, and the demulsified oil drops are recycled through an oil scraper. According to the method, an E<+>-micro-nano bubble ozone coupling method is adopted, air floatation, ozone and electrochemical synergistic oxidation is achieved, and meanwhile the multiple effects of oily sludge recycling, reduction, harmlessness and the like are achieved.

Owner:SHANGHAI JIAO TONG UNIV

Method for treating fiber ethanol production wastewater

ActiveCN106746162AEfficient removalEasy to handleWater contaminantsMultistage water/sewage treatmentFiberChemical oxygen demand

The invention relates to a method for treating fiber ethanol production wastewater. The method comprises the following steps: (1) adjusting the concentration of a sulfate radical in fiber ethanol production wastewater with epoxy chloropropane production wastewater so as to control the content of the sulfate radical in mixed wastewater to be within 3000 mg / L, and removing precipitates; (2) adjusting the pH value of the mixed wastewater to be 7.6-9.0, and keeping the temperature of the mixed wastewater to be higher than 60 DEG C; (3) after the reaction is completed, removing the precipitates, and performing anaerobic biochemical treatment on effluent; and (4) performing aerobiotic biochemical treatment on anaerobic effluent, thereby enabling treated wastewater to meet emission requirements. According to the method, the concentration of the sulfate radical in the fiber ethanol production wastewater is adjusted with the epoxy chloropropane production wastewater, and the mixed wastewater is treated by using anaerobic-aerobiotic processes, so that efficient removal of the sulfate radical and COD (Chemical Oxygen Demand) in the wastewater can be achieved, and the method has the characteristics of being simple in treatment process, good in treatment effect and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

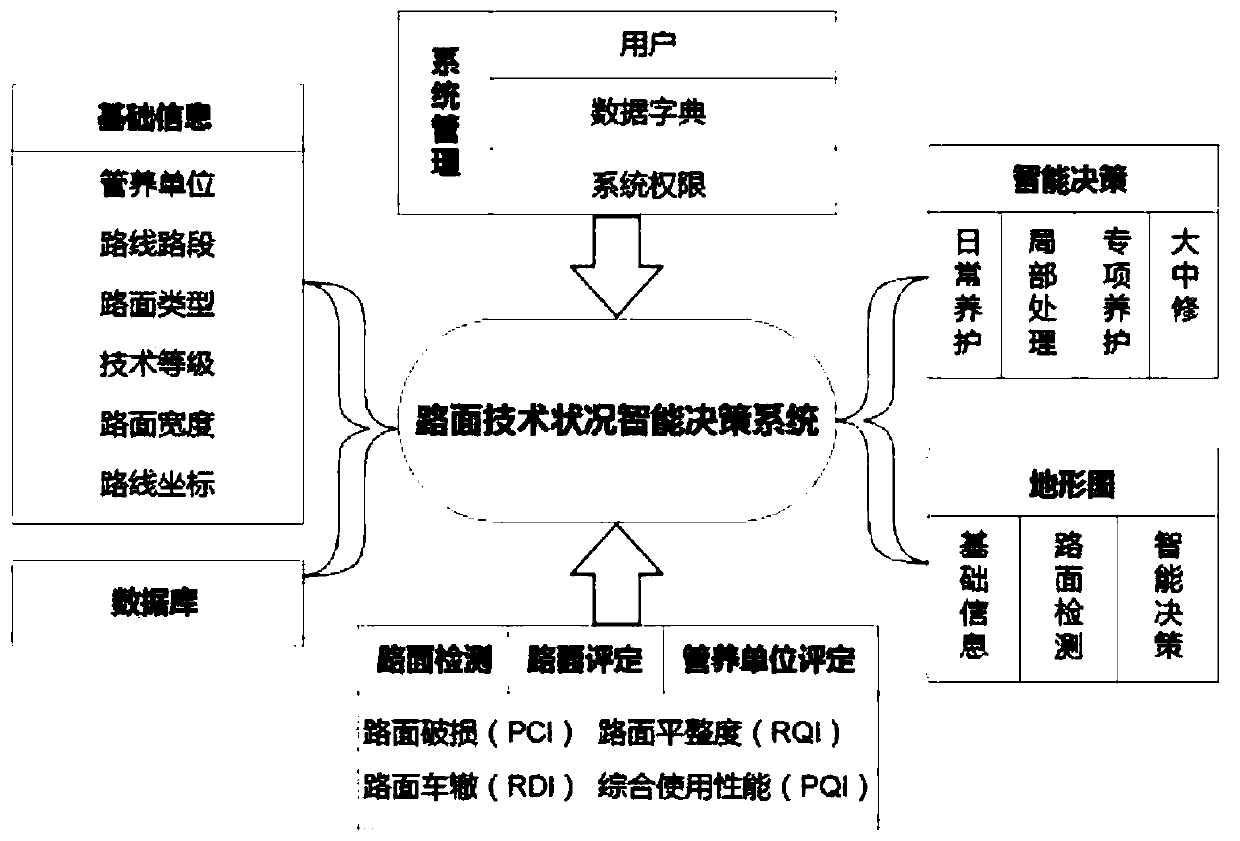

A national province trunk road pavement technical condition intelligent decision-making system

InactiveCN109767086AEasy data flowShortcut effectDigital data information retrievalResourcesHighway maintenanceManagement level

The invention discloses a national province trunk road pavement technical condition intelligent decision-making system, which comprises a basic data management module, and the basic data management module comprises a management and maintenance unit module and a route management module. The management and maintenance unit module is used for creating a management and maintenance unit model, and themanagement and maintenance unit model comprises a management and maintenance unit model and a route management model, and the route management module is used for creating a route management task and importing the created route management task into the route menu module. According to the invention, deep processing of pavement detection data is realized, road maintenance is assisted to make a decision better, and the road management level is improved.

Owner:江西秀川科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com