Treatment method for textile industrial waste water

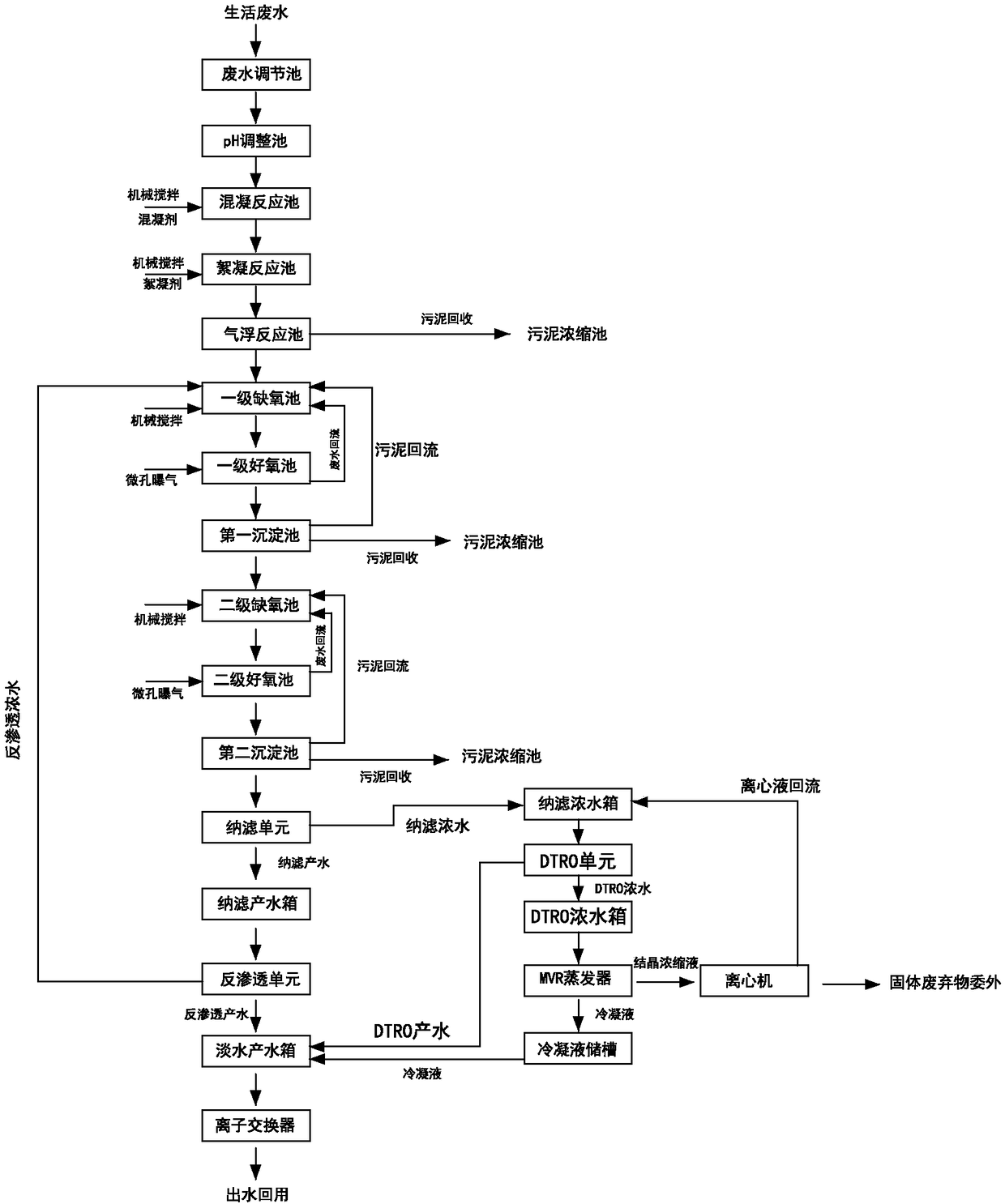

A technology of textile industry wastewater and treatment method, which is applied in the direction of textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as equipment shutdown, replacement of parts, equipment depreciation and wear, and negative effects of treatment processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Sampling and analysis of wastewater from a textile industry shows that the basic properties of the wastewater are: ammonia nitrogen: 100-160mg / L, total nitrogen: 120-180mg / L, COD cr : 2000~2600mg / L, Chromaticity: 200~400 times, PH: 6~8, SS: 120~400mg / L, Conductivity: 1500~2000us / cm, Wastewater generation: 240m 3 / d.

[0091] Follow the steps below to treat the waste water:

[0092] (1), adjust the pH value: pump the textile wastewater in the wastewater adjustment tank into the pH adjustment tank with a lift pump, then adjust the pH value of the wastewater to 8 according to the water quality characteristics of the wastewater;

[0093] (2), coagulation and air flotation treatment: after the waste water is treated in the step (1), it first enters the coagulation reaction tank, and a 10% polyaluminum chloride aqueous solution is added, and the dosage is 600 mg / L , stirred and reacted for 15 minutes, then entered the flocculation reaction tank, and added a polyacrylamide a...

Embodiment 2

[0107] Sampling and analysis of wastewater from a textile industry shows that the basic properties of the wastewater are: ammonia nitrogen: 80-130mg / L, total nitrogen: 90-150mg / L, COD cr : 1600~2200mg / L, chromaticity: 160~360 times, PH: 7~8, SS: 160~430mg / L, conductivity: 2500~4000us / cm, waste water generation: 1200m 3 / d.

[0108] Follow the steps below to treat the waste water:

[0109] (1), adjust the pH value: pump the textile wastewater in the wastewater adjustment tank into the pH adjustment tank with a lift pump, then adjust the pH value of the wastewater to 8 according to the water quality characteristics of the wastewater;

[0110] (2), coagulation and air flotation treatment: after the waste water is treated in the step (1), it first enters the coagulation reaction tank, and adds a polyaluminum chloride aqueous solution with a concentration of 12%, and the dosage is 700 mg / L , stirred and reacted for 20 minutes, then entered the flocculation reaction tank, and adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com