Wastewater advanced treatment method coupling membrane and electricity

A technology of advanced treatment and electrical coupling, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effect of reducing cell voltage, saving energy consumption, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

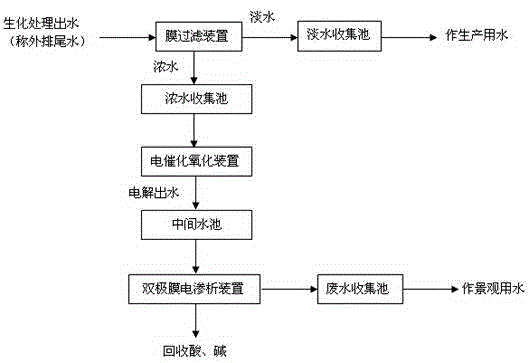

Image

Examples

Embodiment 1

[0030] (1) Raw water

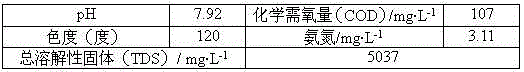

[0031] The biochemical tail water discharged from a sewage treatment plant is used as the raw water. The water quality is shown in Table 1-1:

[0032] Table 1-1 Raw water quality

[0033]

[0034] (2) Membrane filtration treatment

[0035] The membrane module in the membrane filtration unit uses nanofiltration membrane (its molecular weight cut-off is 150~300), the operating pressure is 0.5~1.0MPa, the operating temperature is 25°C, the fresh water production rate of nanofiltration membrane is 70%, and the water quality is shown in Table 1- 2:

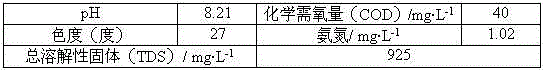

[0036] Table 1-2 Freshwater quality after membrane filtration

[0037]

[0038] The test results show that the quality of fresh water after membrane filtration meets the standards for cooling water, washing water, process and product water in GB / T 19923-2005 "Water Quality for Industrial Water Quality for Urban Sewage Reuse and Utilization".

[0039] (3) Electrocatalytic oxidation treatment

[0040] Th...

Embodiment 2

[0052] The biochemical effluent tail water is the same as the example, and the water quality is shown in Table 2-1:

[0053] Table 2-1 Raw water quality

[0054]

[0055] (2) Membrane filtration treatment

[0056] The membrane components in the membrane filtration unit are reverse osmosis membranes (the molecular weight cut-off is greater than 100), the operating pressure is 1.0~1.5MPa, the operating temperature is 10°C, the fresh water production rate of the nanofiltration membrane is 70%, and the water quality is shown in Table 2-2 :

[0057] Table 2-2 Freshwater quality after membrane filtration

[0058]

[0059] The test results show that the quality of fresh water after membrane filtration meets the standards for cooling water, washing water, process and product water in GB / T 19923-2005 "Water Quality for Industrial Water Quality for Urban Sewage Reuse and Utilization".

[0060] (3) Electrocatalytic oxidation treatment

[0061] The yield of concentrated water af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com