Method for treating and recycling wastewater produced by coal middle-low temperature dry distillation

A wastewater, low temperature technology, applied in multi-stage water treatment, water/sewage treatment, natural water treatment and other directions, can solve the problems of low extraction and dephenolization efficiency, no measures to improve the biochemical properties of wastewater, and high gas-liquid ratio, and achieve guaranteed removal. effect and stability, improving the biodegradability of wastewater, and reducing the load of the biochemical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

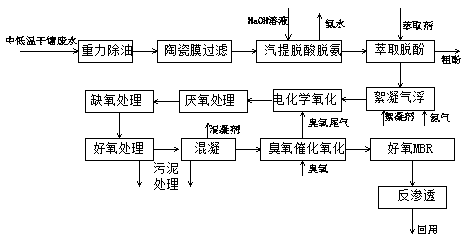

Image

Examples

Embodiment 1

[0050] The wastewater of a medium-temperature dry distillation enterprise of coal, the main indicators of water quality are: COD: 20000mg / L, total phenols: 4000mg / L, oil: 1000mg / L, NH 4 -N: 2000mg / L, CO 2 : 1500mg / L, H 2 S: 100 mg / L, pH 8.1.

[0051] Wastewater treatment and reuse methods are as follows:

[0052] Gravity oil separation unit: remove most of the slick oil and heavy oil in the wastewater, recover tar, reduce the oil content in the wastewater, adopt an advection degreasing tank, and stay for 4 hours. The heavy oil in the oil collection bucket is heated indirectly by steam, and the oil is heated The temperature is above 70°C;

[0053] Ceramic membrane filtration unit: remove suspended oil and coal ash in wastewater to prevent blockage of trays and heat exchangers in the process of stripping, deacidification and deamination; After gravity oil separation unit and ceramic membrane filtration, the oil content of wastewater is reduced to below 150mg / L;

[0054] Str...

Embodiment 2

[0066] The main water quality indicators of a coal medium-temperature dry distillation enterprise wastewater are: COD 32000mg / L, total phenols: 7000mg / L, oil: 1500mg / L, NH4-N: 2500mg / L, CO 2 : 2500mg / L, H 2 S: 120 mg / L, pH 8.3.

[0067] Wastewater treatment and reuse methods are as follows:

[0068] Gravity oil separation unit: remove most of the slick oil and heavy oil in the wastewater, recover tar, reduce the oil content in the wastewater, adopt an advection degreasing tank, and stay for 3 hours. The heavy oil in the oil collection bucket is heated indirectly by steam, and the oil is heated The temperature is above 70°C;

[0069] Ceramic membrane filtration unit: remove suspended oil and coal ash in wastewater to prevent blockage of trays and heat exchangers in the process of stripping, deacidification and deamination; After the gravity oil separation unit and the ceramic membrane filter, the oil content of the wastewater is reduced to below 200mg / L;

[0070] Stripping ...

Embodiment 3

[0082] The wastewater from a coal low-temperature dry distillation enterprise, the main indicators of water quality are: COD: 52000mg / L, total phenols: 12000mg / L, oil: 1800mg / L, NH 4 -N: 3000mg / L, CO 2 : 3500mg / L, H 2 S: 150 mg / L, pH 8.5.

[0083] Wastewater treatment and reuse methods are as follows:

[0084] Gravity oil separation unit: remove most of the slick oil and heavy oil in the wastewater, recover tar, reduce the oil content in the wastewater, adopt a flat flow degreasing tank, and stay for 5 hours. The heavy oil in the oil collection bucket is heated indirectly by steam, and the oil is heated The temperature is above 70°C;

[0085] Ceramic membrane filtration unit: remove suspended oil and coal ash in wastewater to prevent blockage of trays and heat exchangers in the process of stripping, deacidification and deamination; After the gravity oil separation unit and the ceramic membrane filter, the oil content of the wastewater is reduced to below 200mg / L;

[0086]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com