Alkali dissolving device for thermal power station and control method of alkali dissolving device

A technology of alkali-dissolving and alkali-dissolving box, which is applied in the direction of chemical instruments and methods, dissolution, dissolution, etc., which can solve the problems of increased operating costs and achieve the effects of convenient operation and maintenance, cost saving and economical improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

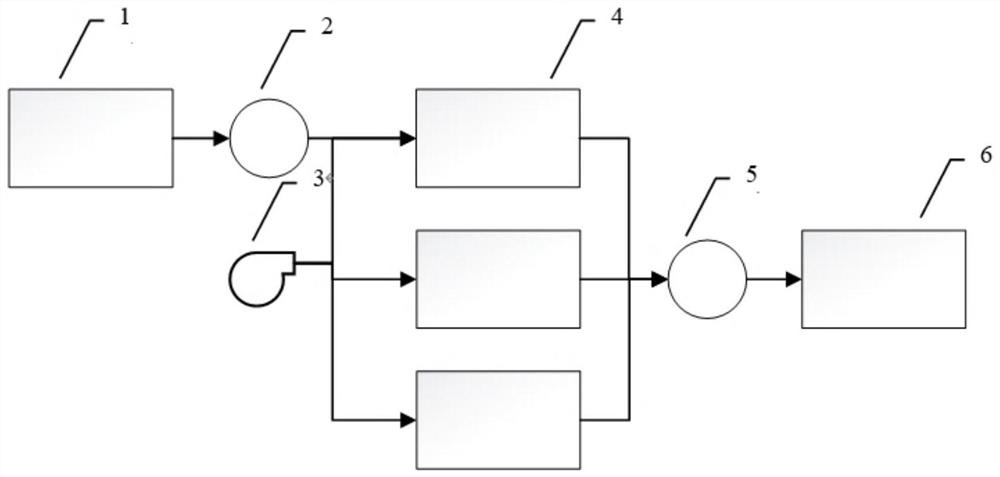

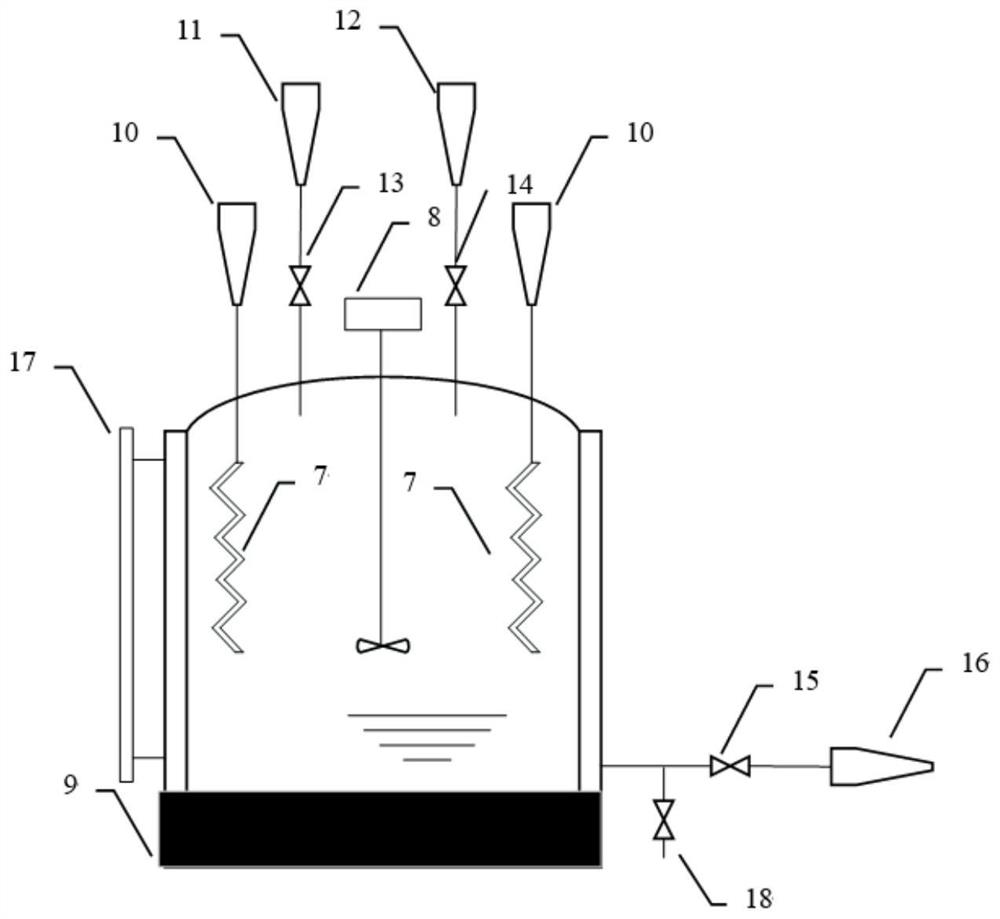

[0028] refer to figure 1 , The alkali-dissolving device of the thermal power station includes the transmission of solid alkali, the alkali-dissolving tank 4, the transportation of liquid alkali and the corresponding auxiliary equipment such as pipelines, valves, and pumps.

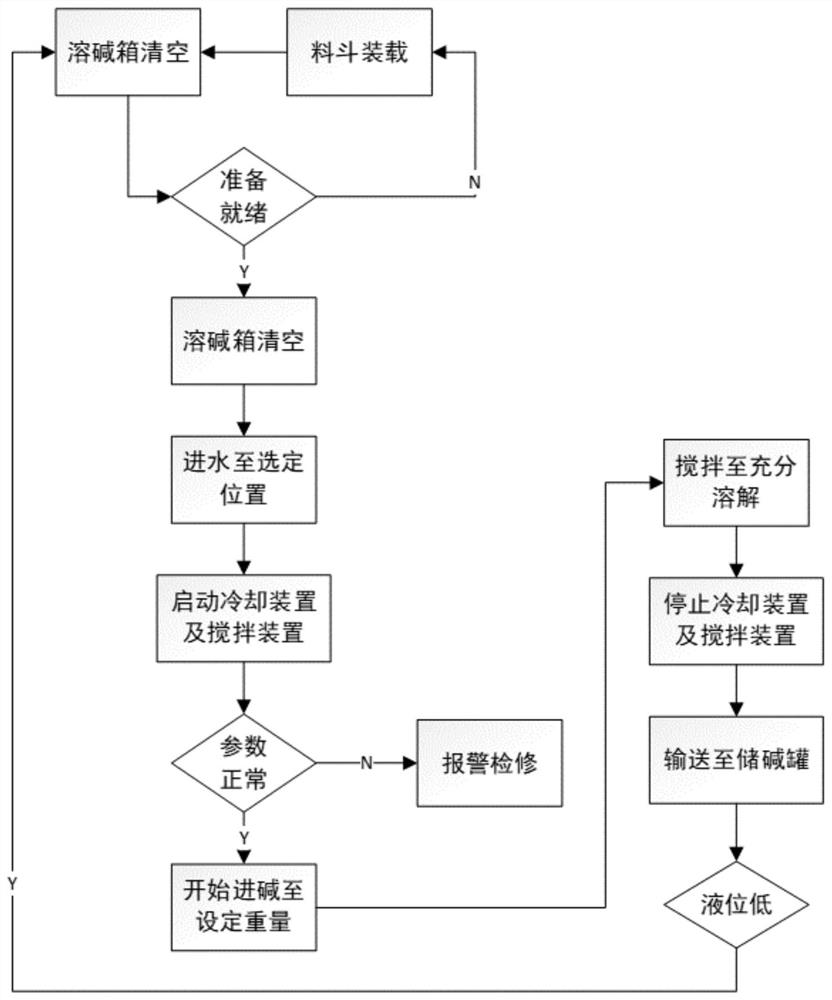

[0029] Among them, the alkali transmission process includes: first unpack the bagged solid alkali and pour it into the hopper 1, the host computer can start the screw pump 2 according to the signal feedback or manually, and at the same time start the blower device 3 in chains to keep the solid alkali continuously sent to the alkali-dissolving tank 4. After the configuration of the lye with a preset concentration is completed, it is determined whether to start the alkali delivery pump 5 according to the liquid level of the alkali storage tank 6, and if the remaining space of the storage t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com