Method for increasing production and injection of flue gas desulfurization and denitrification coupled reservoir

A technology for desulfurization and denitrification, flue gas, applied in the direction of separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of fast reaction rate of acid rock, complicated construction, weak alkalinity of curing agent, etc., and achieve economic benefits and control Effects of air pollution and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for coupling reservoir production and injection with flue gas desulfurization and denitrification, comprising the following steps:

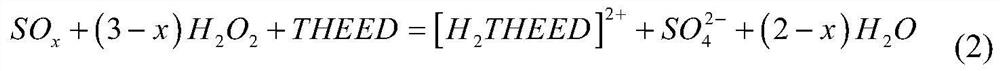

[0047] (1) Flue gas desulfurization and denitrification process: add THEED with a mass fraction of 0.015% to 15% H 2 o 2 The mixed solution is prepared in the solution, and the volume ratio is 75:1. The mixed solution is sprayed into the flue gas in the opposite direction of the flue gas flow. When the pH of the system reaches 6.5, the waste liquid generated by desulfurization and denitrification is collected, and the waste liquid is acid.

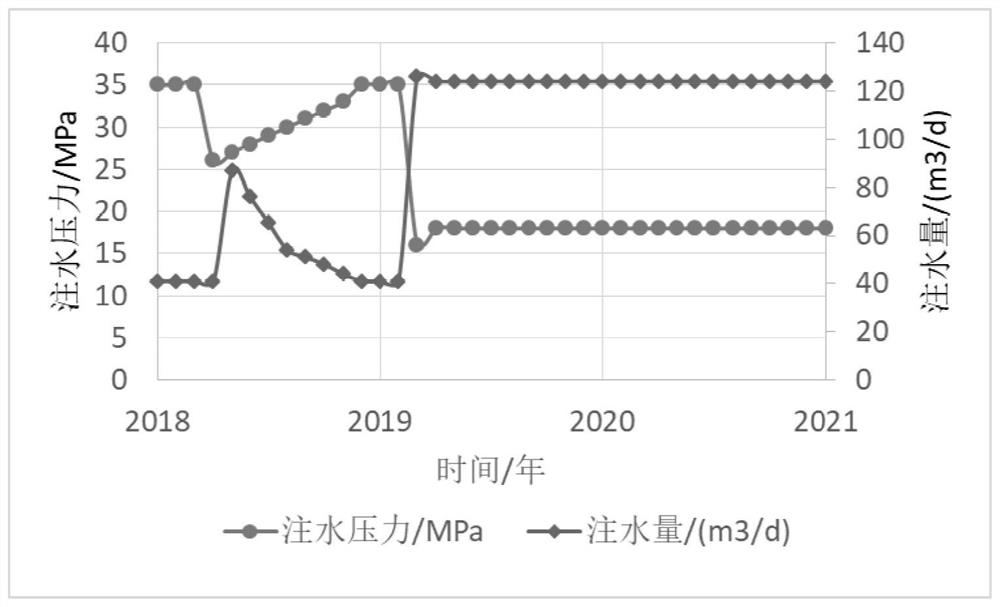

[0048] (2) The obtained acid solution can be directly injected into the formation to increase production and injection, and the acid solution contains about 0.015% [H 2 THEED] 2+ ; The dissolution rate and corrosion rate of the acid solution are detected, and the detection basis is SY / T 5358-2002 "Reservoir Sensitivity Flow Experimental Method", and the operation steps for testing the disso...

Embodiment 2

[0051] A method for coupling reservoir production and injection with flue gas desulfurization and denitrification, comprising the following steps:

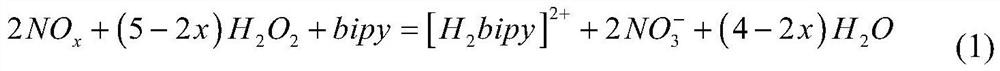

[0052] (1) Flue gas desulfurization and denitrification process: adding bipy with a mass fraction of 0.015% to 15% H 2 o 2 The mixed solution is prepared in the solution, and the volume ratio is 400:3. The mixed solution is sprayed into the flue gas in the opposite direction of the flue gas flow. When the pH of the system reaches 6.5, the waste liquid generated by desulfurization and denitrification is collected, and the waste liquid is acid.

[0053] (2) The obtained acid solution can be directly injected into the formation to increase production and injection, and the acid solution contains about 0.015% [H 2 bipy] 2+ ; According to the method in embodiment 1, the dissolution rate and corrosion rate of acid solution are detected, and the results are shown in Table 1.

Embodiment 3

[0055] A method for coupling reservoir production and injection with flue gas desulfurization and denitrification, comprising the following steps:

[0056] (1) Flue gas desulfurization and denitrification process: the O 3 Mix into the flue gas in the opposite direction of the flue gas flow, and spray 0.015% THEED, THEED and O at the same time 3 The volume ratio is 100:1. When the pH of the solution reaches 6.5, the waste liquid produced by desulfurization and denitrification is collected, which is the acid liquid.

[0057] (2) The obtained acid solution can be directly injected into the formation to increase production and injection, and the acid solution contains about 0.015% [H 2 THEED] 2+ ; According to the method in embodiment 1, the dissolution rate and corrosion rate of acid solution are detected, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com