Treatment method of chemical nickel-plating wastewater

A technology for electroless nickel plating and wastewater treatment, which is applied in metallurgical wastewater treatment, chemical instruments and methods, oxidized water/sewage treatment, etc. The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

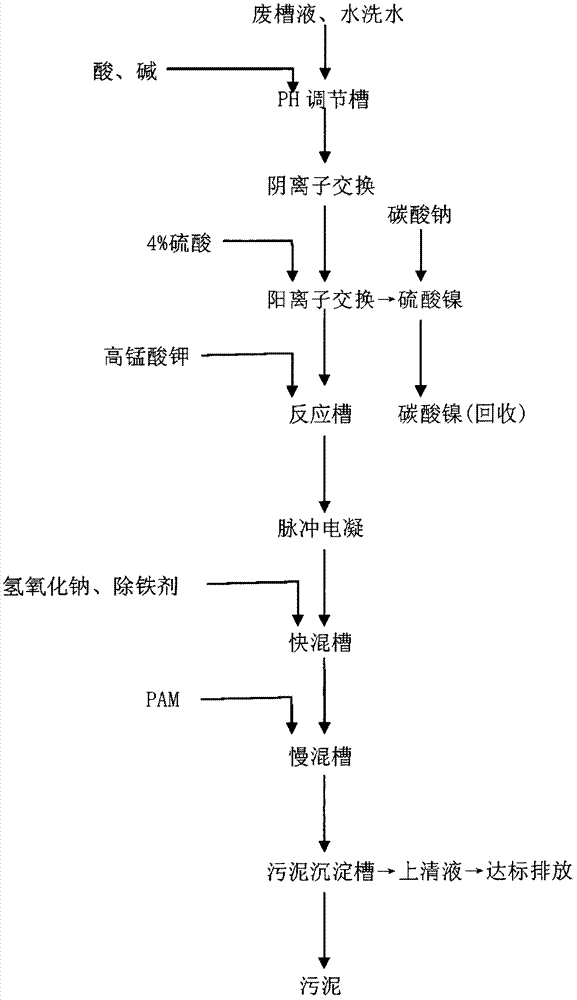

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Before the present invention, Nanya Copper Foil (Kunshan) Co., Ltd. used physicochemical, flocculation, and precipitation treatment methods to treat copper-plated nickel-containing waste water, with a daily treatment capacity of 25m 3 , the water quality after treatment is shown in Table 1 below, which did not reach the standard.

[0039] Table 1 Water quality data after the traditional method of treating nickel-containing wastewater

[0040] Project (PPM)

pH value

Conductivityμs / cm 2

Ni

COD

7~9

>6000

≤10

≤1000

[0041] Afterwards, this factory adopts process of the present invention to carry out pilot test to aforementioned nickel-containing waste water, and this process comprises five steps:

[0042] (1) Electroless nickel plating waste bath liquid or electroless nickel plating washing water is treated separately, or the two waste liquids are mixed, and then enter the strong alkali...

Embodiment 2

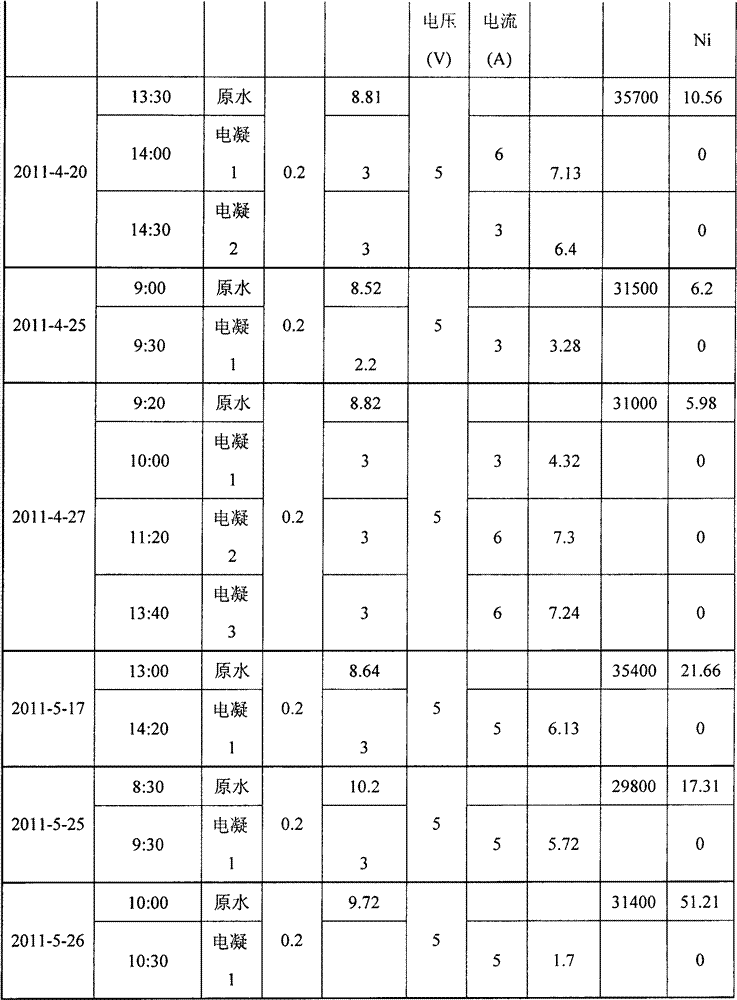

[0051] Xinxing Tongtai Technology (Kunshan) Co., Ltd. also adopts the process of the present invention to process the scrap electroless nickel plating bath and washing water, and its process is basically the same as that of Example 1.

[0052] The quality and quantity of wastewater before treatment are as follows:

[0053] The amount of waste water is 250 tons / month (including bath liquid and washing water)

[0054] Water quality profile:

[0055] Scrap tank solution Nickel ion concentration 2429ppm

[0056] Washing water Nickel ion concentration 16ppm

[0057] 1 part of waste bath liquid mixed with 40 parts of washing water for analysis

[0058] Ni: 80ppm PH value: 1.86

[0059] Pilot test treatment capacity 0.2m 3 / h.

[0060] During this process, the content of nickel ions in the wastewater in each process was monitored by ICP, and the data are shown in Table 3 below.

[0061] Table 3 Data of nickel content in each process wastewater in nickel-containing wastewater tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com