Device and method for advanced treatment of oily sludge by E<+>-micro-nano bubble ozone

A technology of micro-nano bubbles and advanced treatment, which is applied in the direction of oxidation treatment of sludge, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of poor ozone utilization rate and mass transfer efficiency, and achieve advanced treatment, The effect of improving separation efficiency and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

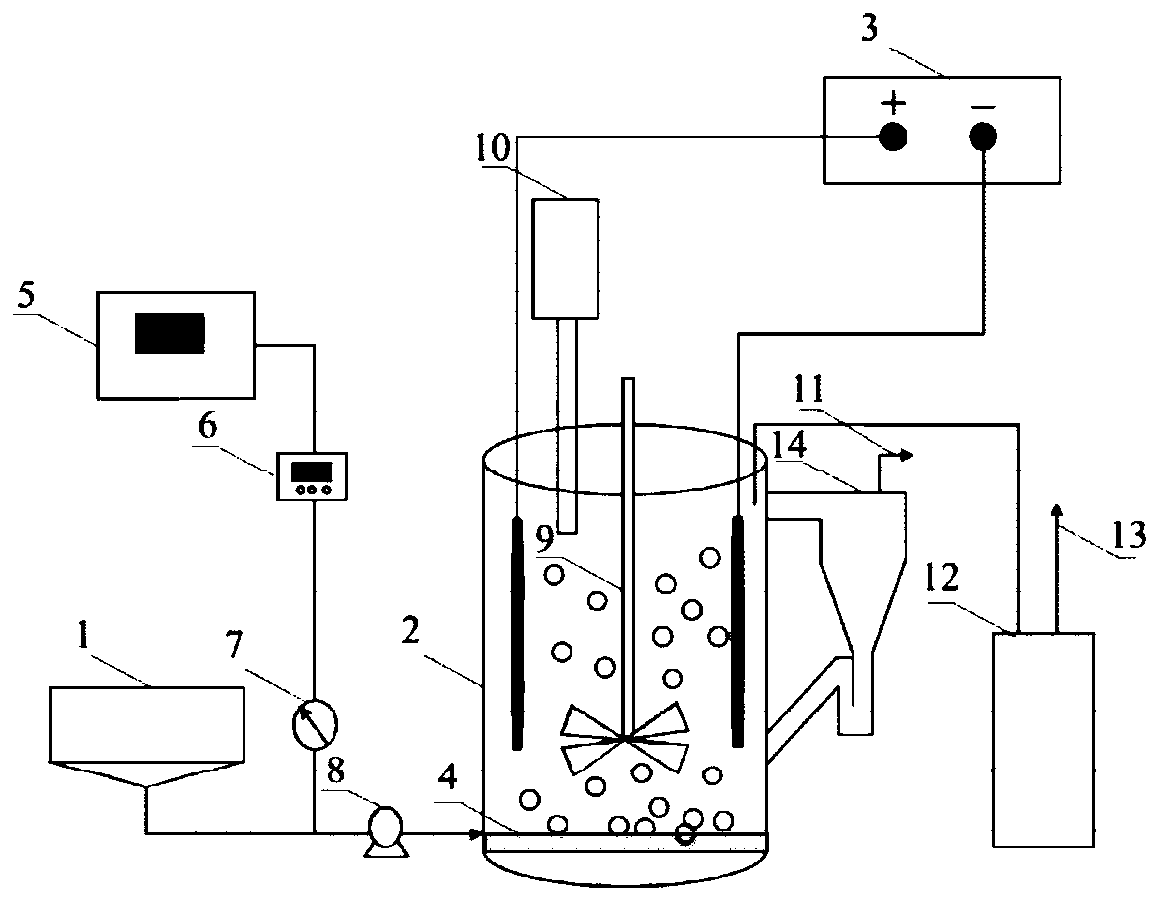

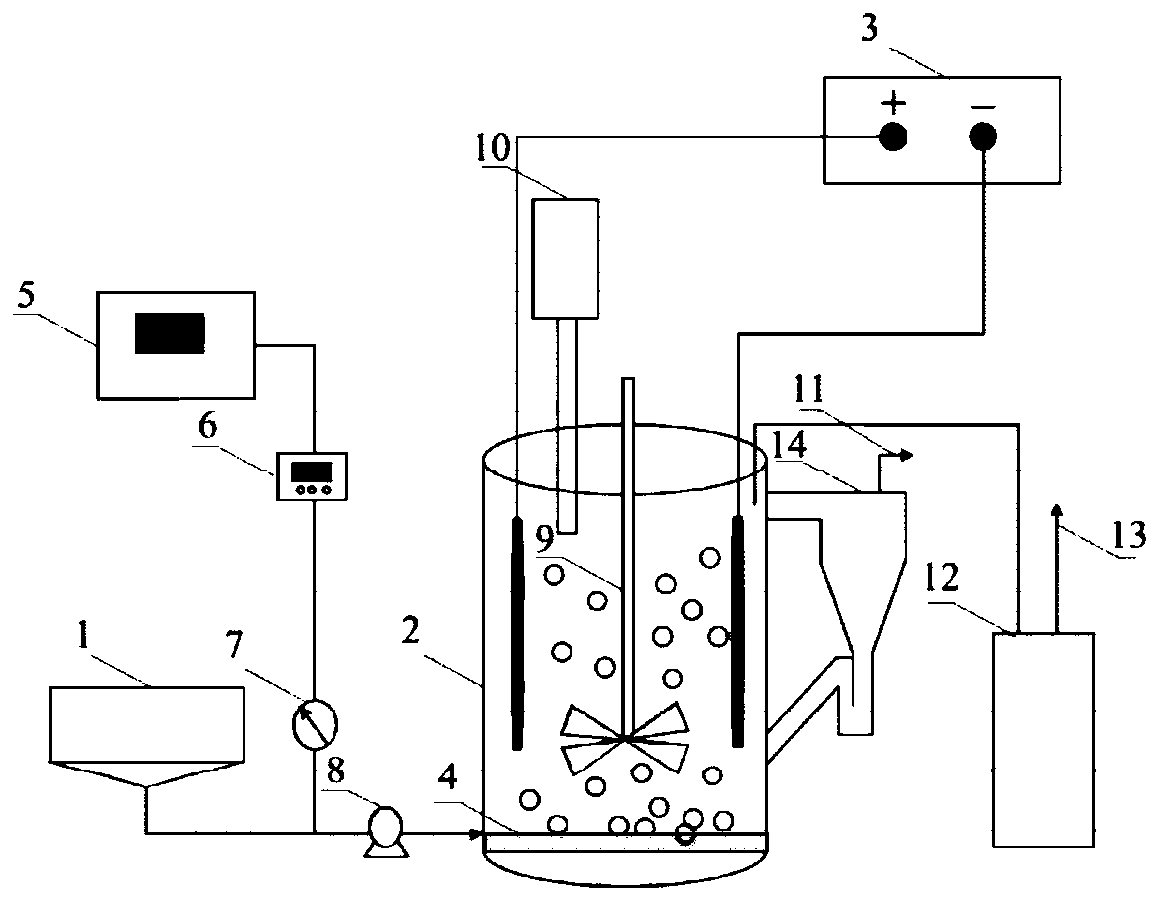

[0050] Specific implementation mode one: a kind of E of this implementation mode + -Micro-nano bubble ozone coupling oily sludge advanced treatment device, such as figure 1 Shown; Mainly include: vibrating screen 1, E + -Micro-nano bubble ozone device 2, power supply 3;

[0051] The vibrating screen 1 and E + - The oily sludge inlet of the micro-nano bubble ozone device is connected;

[0052] The E + - The bottom of the micro-nano bubble ozone device 2 is provided with an aeration pan 4, and the ozone generator 5 is connected to the aeration pan 4 through an ozone concentration meter 6, a flow meter 7, and a fluid pump 8;

[0053] The E + -The inside of the micro-nano bubble ozone device 2 is provided with an agitator 9, and an oil scraper 10 is provided at the upper end;

[0054] The E + - Electrodes are respectively arranged on both sides inside the micro-nano bubble ozone device 2, and the electrodes are respectively connected to the positive and negative poles of th...

specific Embodiment approach 2

[0059] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the water content of the oily sludge is controlled at 75%-95%, the oil content is controlled at 5%-20%, the actual action intensity of the control current, The control voltage is 1V-15V, and the control current is 2A-10A.

[0060] Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0061] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the diameter of the oily sludge is less than or equal to 28 mm after the oily sludge is sifted through a vibrating screen.

[0062] Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com