Soap-free emulsion polymerization method based on temperature responsive monomer

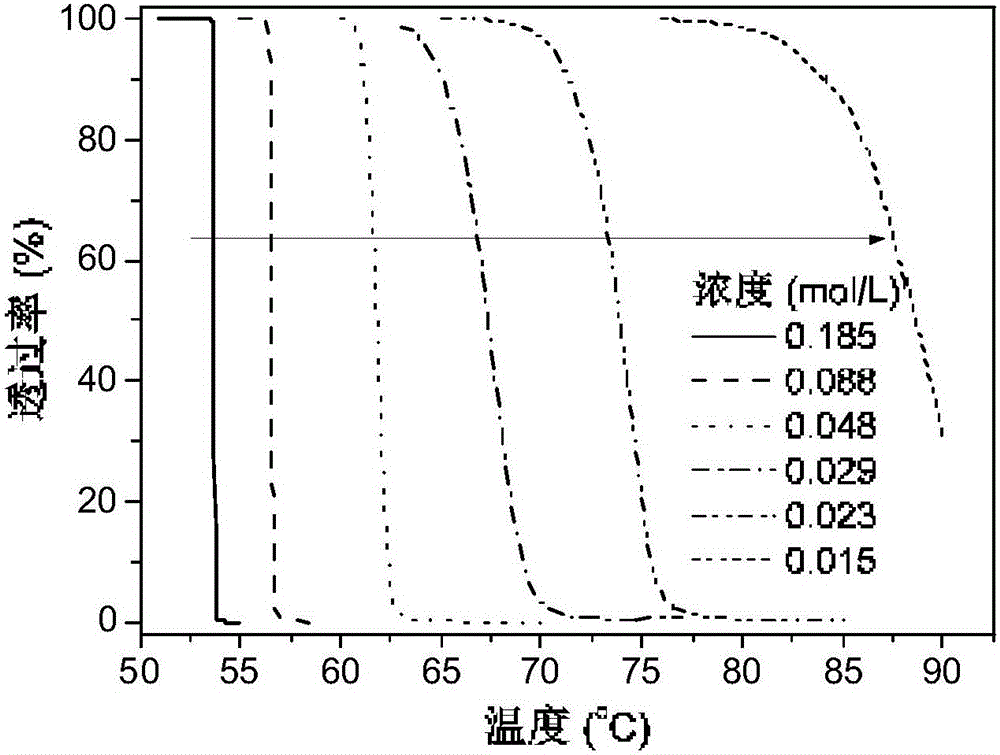

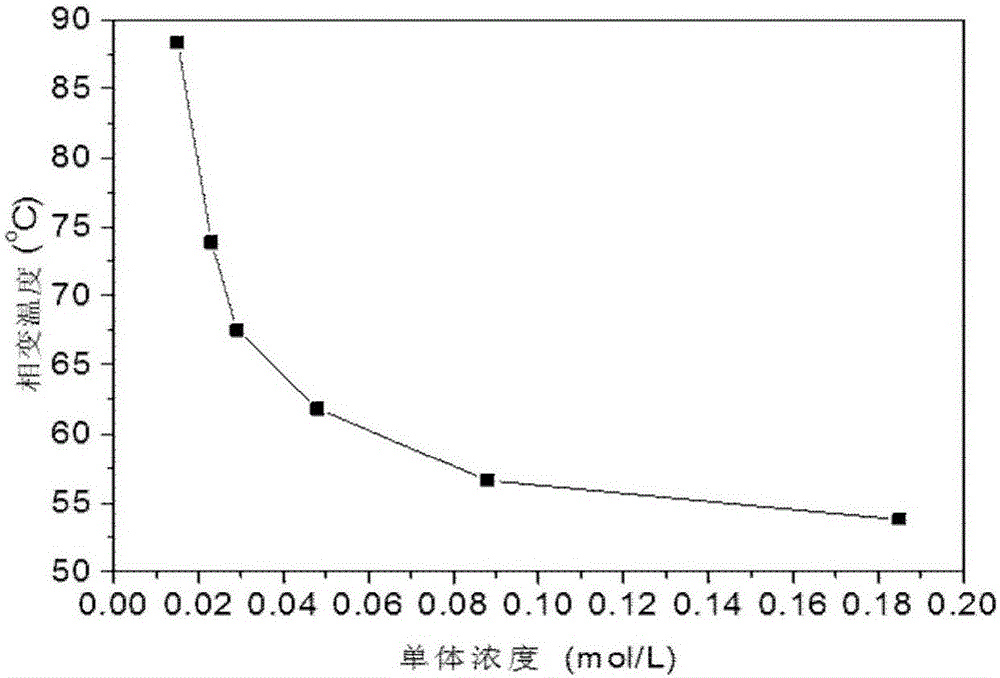

A temperature-responsive, soap-free emulsion technology, applied in the field of soap-free emulsion polymerization, achieves the effects of simple process, mild polymerization conditions and high molecular weight of the prepared polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

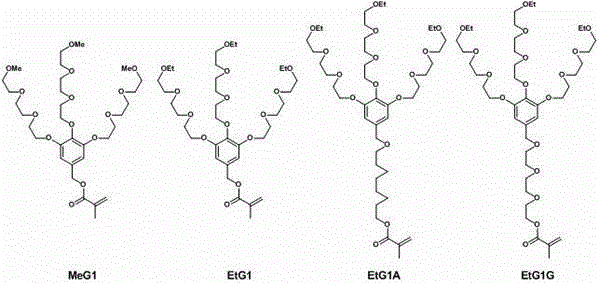

Embodiment 1

[0022] Example 1: The specific steps are as follows: put 0.5 g of temperature-responsive monomer MeG1 into a reaction tube, add 2.5 mg of 4,4'-azo(4-cyanovaleric acid) (AVCA) as a water-soluble free radical initiator, Then add 5 mL of distilled water. Add magnetic sub-stirring at normal temperature to make the mixture uniform, then seal the reaction tube, replace nitrogen, and then place the reaction tube at 65 o In the C oil bath, the system changed from clarification to milky white and reacted for 6 hours. Yield 82%. The polymer molecular weight (Mn) was 1,300,000. The product became a viscous oil.

Embodiment 2

[0023] Embodiment two: concrete steps are as follows:

[0024] Take 0.2 g of temperature-responsive monomer EtG1 into the reaction tube, add 1 mg of 4,4'-azo(4-cyanovaleric acid) (AVCA) as a water-soluble free radical initiator, and then add 2 mL of distilled water. Add magnetic sub-stirring at normal temperature to make the mixture uniform, then seal the reaction tube, replace nitrogen, and then place the reaction tube at 65 o In the C oil bath, the system changed from clarification to milky white and reacted for 4 hours. Yield 75%. The polymer molecular weight (Mn) was 2,200,000. The product became a viscous oil.

Embodiment 3

[0025] Embodiment three: concrete steps are as follows:

[0026] Take 0.5 g of temperature-responsive monomer EtG1 and 0.5 g of non-temperature-responsive styrene, add 2.5 mg of 4,4'-azo(4-cyanovaleric acid) (AVCA) as a water-soluble free radical initiator, and then add Distilled water 10 mL. Add magnetic sub-stirring at normal temperature to make the mixture uniform, then seal the reaction tube, replace nitrogen, and then place the reaction tube at 65 o In the C oil bath, the system changed from clarification to milky white and reacted for 4 hours. The product is in the form of a viscous emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com