Method for preparing sulfur and/or selenium-containing sequence controllable polymer through one-pot method and product thereof

A polymer and sequence technology, applied in the fields of polymer chemistry and materials science, can solve problems such as big challenges, and achieve the effects of low price, mild polymerization conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A sequence-controllable polythiourea, the structural formula of which is shown in P1:

[0059]

[0060] The sequence-controllable polythiourea is prepared by one-pot two-step multi-component polymerization of elemental sulfur, asymmetric amine, and isonitrile, and the reaction equation is shown in formula (1):

[0061]

[0062] Wherein, monomer 1 is sublimated sulfur, which can be purchased from the market, and isonitrile monomer 2 is 1,4-diisocyanobenzene, according to the literature (TianTian, Rongrong Hu, and Ben Zhong Tang, Room Temperature One-Step Conversion from Elemental Sulfur to Functional Polythioureas through Catalyst-FreeMulticomponent Polymerizations.J.Am.Chem.Soc., 2018,140,6156-6163.) prepared by the disclosed method, asymmetric amine monomer 3 is 2-(4-aminophenyl)ethylamine, It can be purchased from the market, and in this example, it was purchased from Anaiji Company, K 2 CO 3 Purchased from TCI Corporation.

[0063] The preparation steps of t...

Embodiment 2

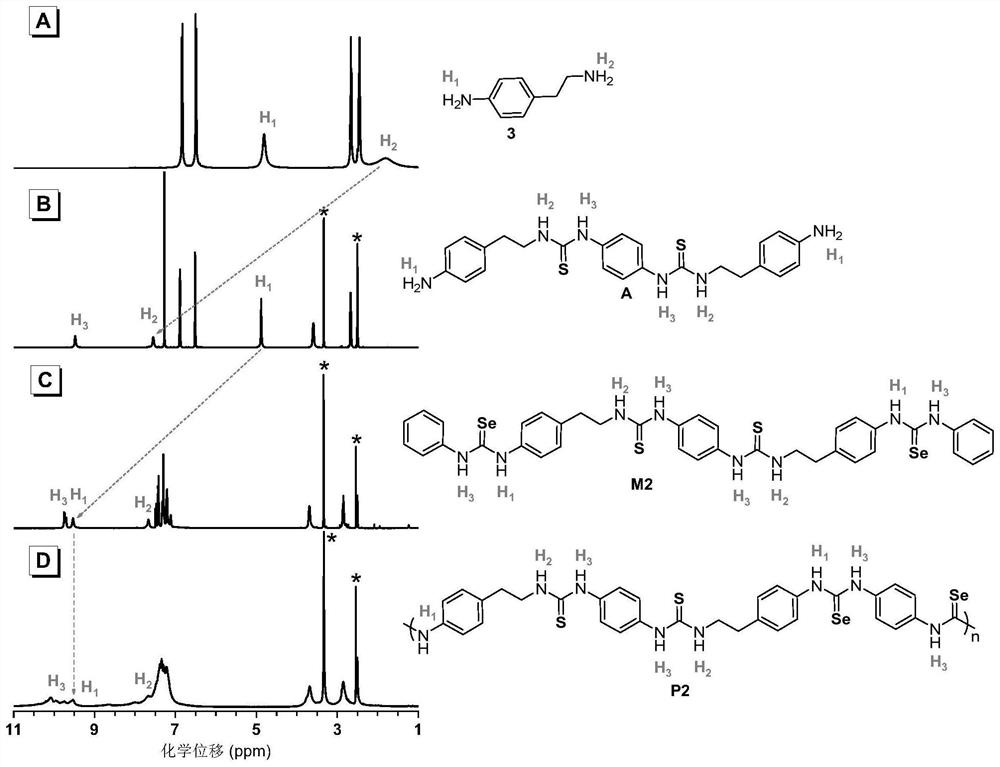

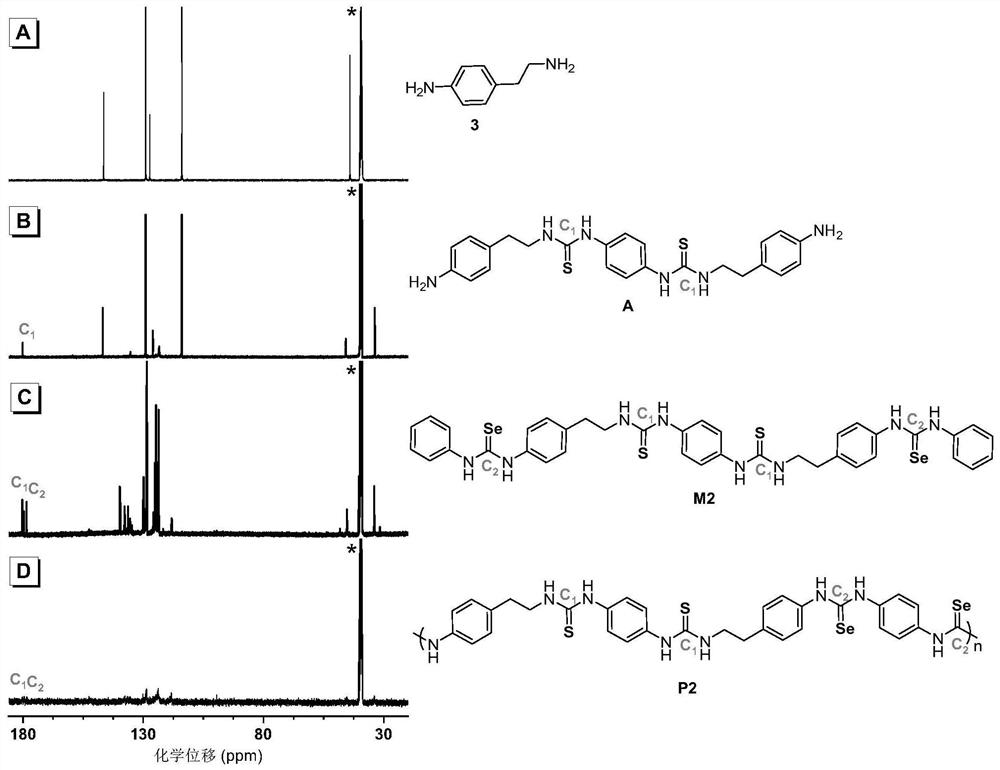

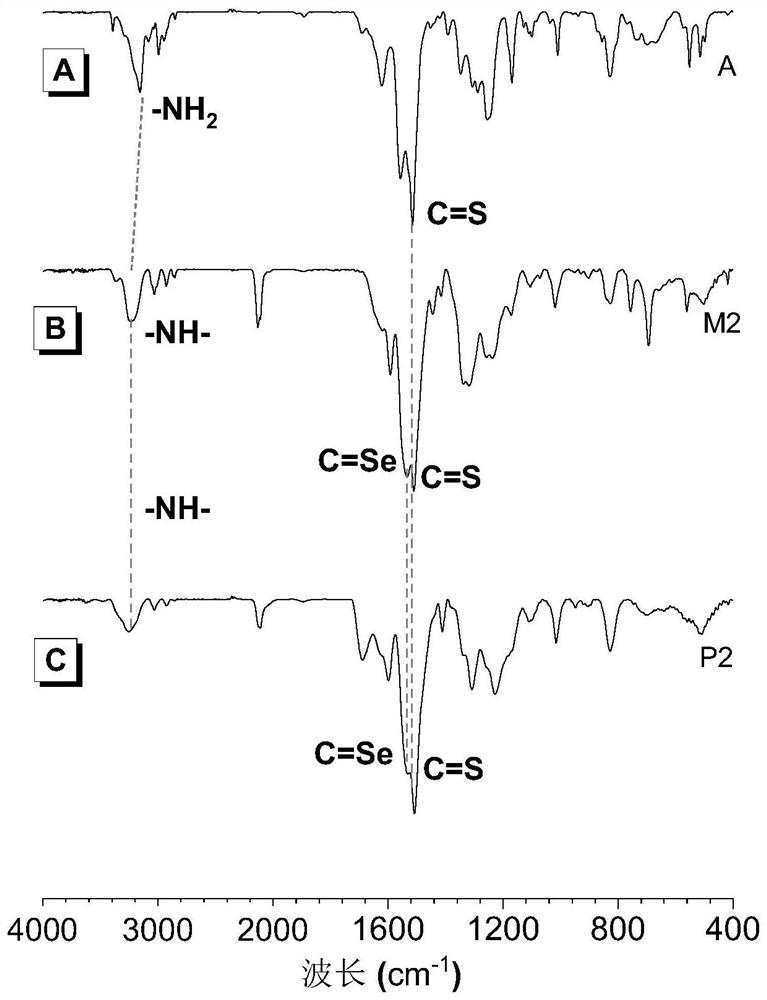

[0067] A sequence controllable polythiourea-selenourea, its structural formula is as shown in P2:

[0068]

[0069] The sequence-controllable polythiourea-selenourea is prepared by one-pot two-step multi-component polymerization of elemental sulfur, elemental selenium, asymmetric amine, and isonitrile, and the reaction equation is shown in formula (2):

[0070]

[0071] Wherein, monomer 1 is sublimated sulfur, monomer 4 is elemental selenium, both monomers 1 and 4 can be purchased from the market, and isonitrile monomer 2 is 1,4-diisocyanobenzene, according to literature (Tian Tian, Rongrong Hu Asymmetric amine mono Body 3 is 2-(4-aminophenyl)ethylamine, which can be purchased from the market, and in this example, it was purchased from Anaiji Company.

[0072] The preparation steps of the sequence controllable polythiourea-selenourea are as follows:

[0073] Weigh 3.2mg (0.10mmol) of monomer 1, 12.8mg (0.10mmol) of monomer 2 and 13.6mg (0.10mmol) of monomer 3 into a ...

Embodiment 3

[0076] A sequence-controllable polyselenourea, the structural formula of which is shown in P3:

[0077]

[0078] The sequence-controllable polyselenourea is prepared by one-pot two-step multi-component polymerization of elemental selenium, asymmetric amine, and isonitrile, and the reaction equation is shown in formula (3):

[0079]

[0080] Wherein, monomer 4 is elemental selenium, which can be purchased from the market, and isonitrile monomer 2 is 1,4-diisocyanobenzene, according to the literature (TianTian, Rongrong Hu, and Ben Zhong Tang, Room Temperature One-Step Conversion from Elemental Sulfur to Functional Polythioureas through Catalyst-FreeMulticomponent Polymerizations.J.Am.Chem.Soc., 2018,140,6156-6163.) prepared by the disclosed method, asymmetric amine monomer 3 is 2-(4-aminophenyl)ethylamine, It can be purchased from the market, and in this example, it was purchased from Anaiji Company.

[0081] The preparation steps of the sequence controllable polyselen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com