Wholly-aromatic high-temperature-resistant nylon as well as preparation method and application thereof

An all-aromatic, high-temperature-resistant technology, applied in the field of polymer material preparation, can solve problems such as large environmental pollution, complex production process, and reduction of salt content in the final spinning solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

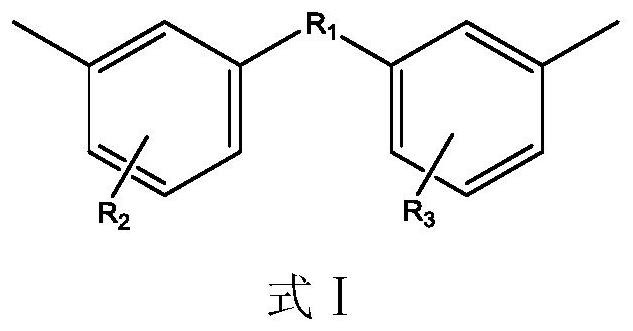

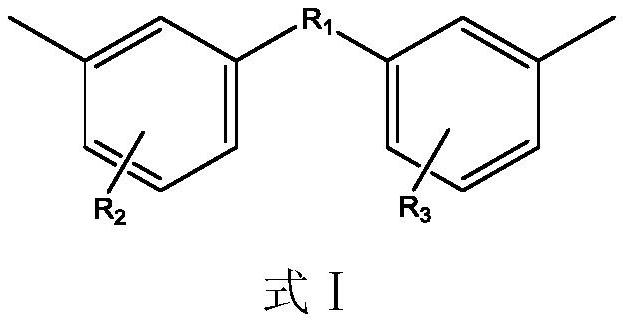

[0034] The first aspect of the present invention provides a preparation method of all aromatic high temperature resistant nylon, the preparation method comprising the following steps:

[0035] 1) Prepolymerize meta-aromatic diacid, meta-aromatic diamine, high temperature resistant branching aid, end-capping agent and antioxidant to prepare fully aromatic nylon prepolymer;

[0036] 2) The wholly aromatic nylon prepolymer prepared in step 1) is subjected to solid-phase thickening to prepare fully aromatic high-temperature-resistant nylon.

[0037] In the preparation method of the all-aromatic high-temperature-resistant nylon provided by the present invention, the step 1) is to combine meta-position aromatic diacid, meta-position aromatic diamine, high-temperature resistant branching auxiliary agent, end-capping agent and antioxidant Agents and prepolymerization to obtain fully aromatic nylon prepolymers. specific:

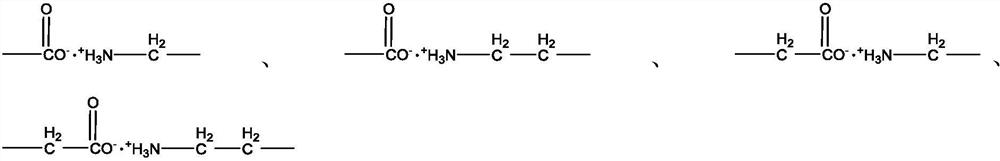

[0038] In the step 1), the meta-aromatic diacid and the meta-...

Embodiment 1

[0069] The mixed diacid (the molar ratio of isophthalic acid and 4,6-dimethylisophthalic acid is 8:1) and m-xylylenediamine are salted in water at a molar ratio of 0.97:1 to obtain a fully aromatic 5000g fully aromatic nylon salt, 10g benzoic acid, 10g sodium phosphite and 50g six (4-carboxyphenoxy) cyclotriphosphazene are dropped into the reactor, and the air in the reactor is replaced with high-purity nitrogen for 3 ~4 times, heat up to 230~250°C, react for 1~3h, then drain 10~30% of the solvent, continue to react for 1~3h, then cool down to normal temperature and discharge, centrifuge to remove the solvent to obtain a prepolymer. Then put the prepolymer into the drum reactor, and increase the viscosity in the solid phase for 4 hours to obtain a wholly aromatic high-temperature-resistant nylon with a relative viscosity of 2.18.

Embodiment 2

[0071] Salt the mixed diacid (the molar ratio of isophthalic acid and 4,6-dimethylisophthalic acid is 6:1) and m-xylylenediamine in water at a molar ratio of 0.97:1 to obtain a fully aromatic 5000g fully aromatic nylon salt, 10g benzoic acid, 10g sodium phosphite and 50g six (4-carboxyphenoxy) cyclotriphosphazene are dropped into the reactor, and the air in the reactor is replaced with high-purity nitrogen for 3 ~4 times, heat up to 230~250°C, react for 1~3h, then drain 10~30% of the solvent, continue to react for 1~3h, then cool down to normal temperature and discharge, centrifuge to remove the solvent to obtain a prepolymer. Add the prepolymer into the drum reactor and increase the viscosity in the solid phase for 4 hours to obtain a wholly aromatic high-temperature-resistant nylon with a relative viscosity of 2.14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com