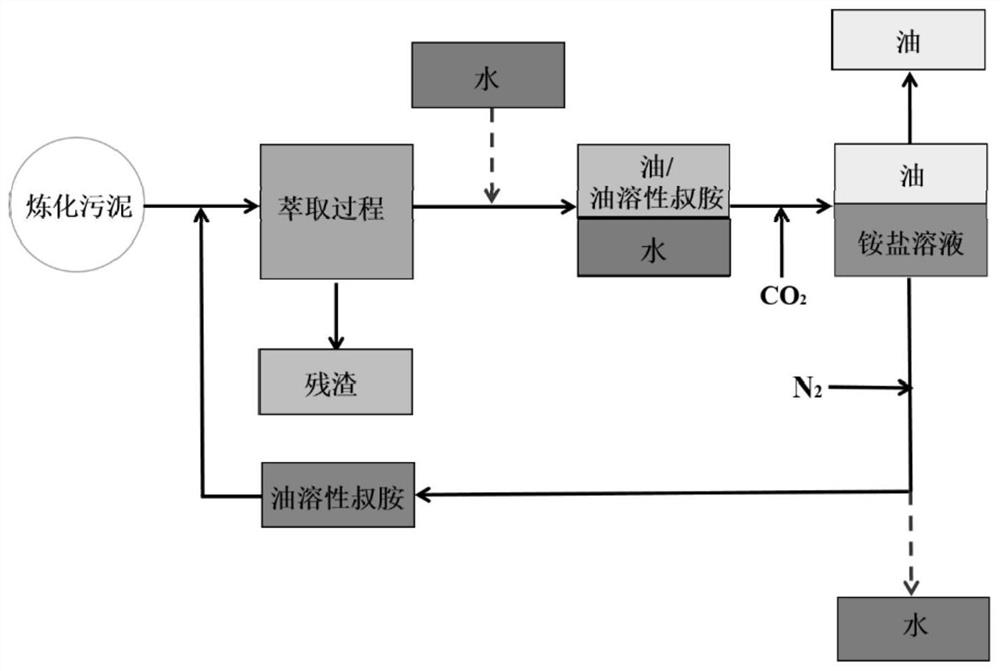

co2/n2 switch-type double-circulation extraction process and its application

A dual-circulation, on-off technology, used in the petroleum industry, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem that the oil-containing solid waste cleaning process is difficult to achieve industrialization, oil-soluble tertiary amines are volatile, and the application range is narrow. and other problems, to achieve the effect of good demulsification effect, good economic effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

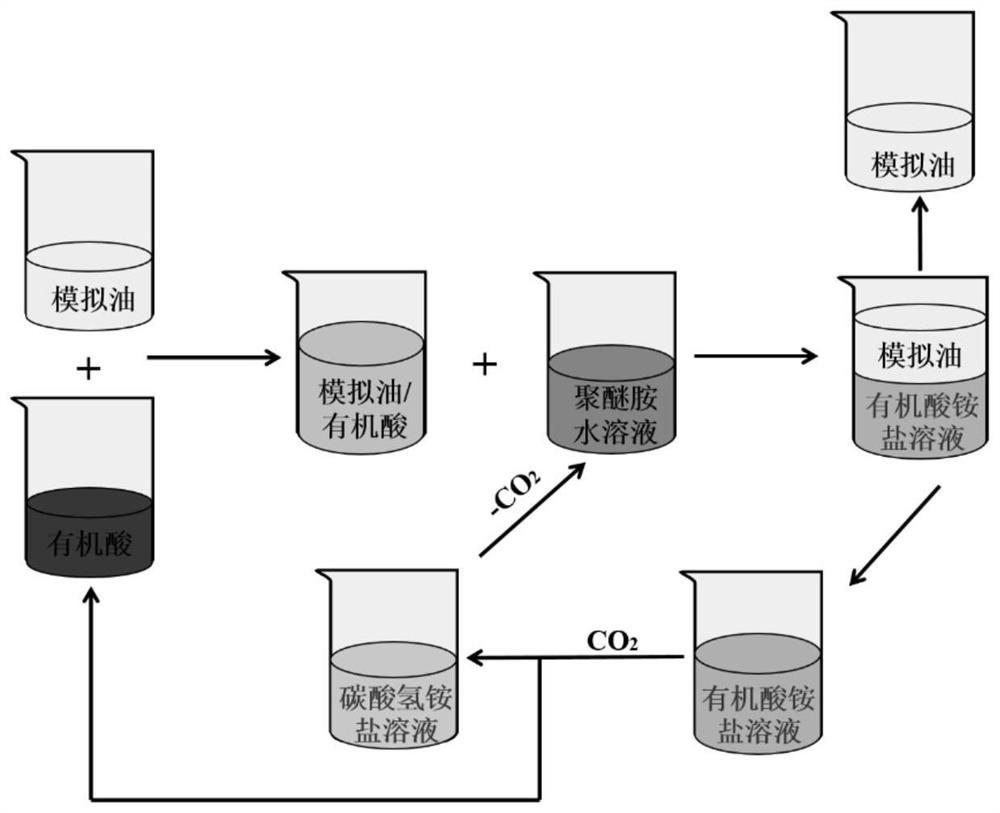

[0058] The medicine of this embodiment is: 50ml deionized water+0.5g polyetheramine D230+0.749g n-decanoic acid+20ml dodecane;

[0059] In this embodiment, dodecane is used to replace oily solid waste, and a double-cycle extraction process is established, such as Figure 9 shown;

[0060] Step S1: Mix 50ml of deionized water and 0.5g of polyetheramine D230 to obtain an aqueous solution of polyetheramine D230;

[0061] Step S2: Put dodecane in a beaker, put the beaker in a hot water bath, the temperature of the hot water bath is 50°C, add n-decanoic acid into the beaker and keep magnetic stirring at the same time;

[0062] Step S3: Adding polyetheramine D230 aqueous solution while continuously performing magnetic stirring is more conducive to making the reaction system react completely so as to achieve a clear ammonium n-decanoate solution and an oil phase, the upper layer is an oil phase, and the lower layer is an ammonium n-decanoate solution;

[0063] Step S4: separate and...

Embodiment 2

[0068] The drugs used in this example are: 50ml deionized water+0.5g polyetheramine D230+0.749g n-decanoic acid+20ml white oil;

[0069] In this embodiment, white oil is used to replace oily solid waste, and a double-cycle extraction process is established, such as Figure 10 shown;

[0070] Step S1: Mix 50ml of deionized water and 0.5g of polyetheramine D230 to obtain an aqueous solution of polyetheramine D230;

[0071] Step S2: Put the white oil in a beaker, put the beaker in a hot water bath, the temperature of the hot water bath is 32°C, add n-decanoic acid into the beaker and keep magnetic stirring at the same time;

[0072] Step S3: Adding polyetheramine D230 aqueous solution while continuously performing magnetic stirring is more conducive to making the reaction system react completely so as to achieve a clear ammonium n-decanoate solution and an oil phase, the upper layer is an oil phase, and the lower layer is an ammonium n-decanoate solution;

[0073] Step S4: sepa...

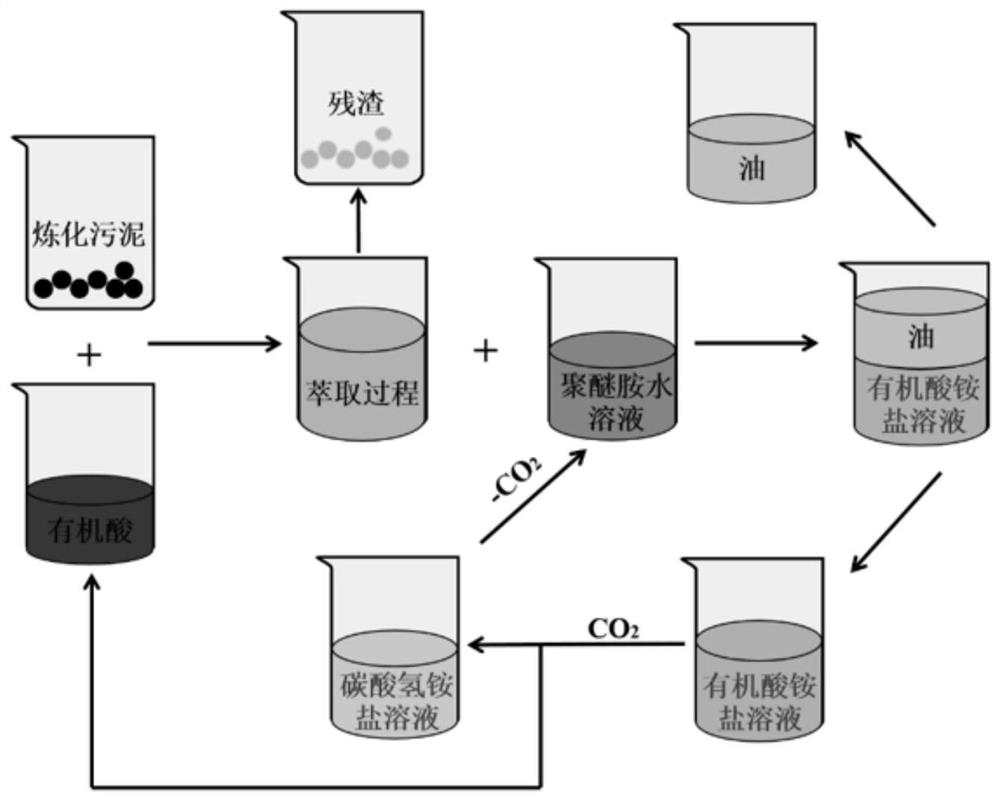

Embodiment 3

[0078] The medicine used in this embodiment is: 50ml deionized water+0.5g polyetheramine D230+0.749g n-decanoic acid+20ml kerosene;

[0079] In this embodiment, kerosene is used to replace oily solid waste, and a double-cycle extraction process is established, such as Figure 11 shown;

[0080] Step S1: Mix 50ml of deionized water and 0.5g of polyetheramine D230 to obtain an aqueous solution of polyetheramine D230;

[0081] Step S2: Put the white oil in a beaker, put the beaker in a hot water bath, the temperature of the hot water bath is 38°C, add n-decanoic acid into the beaker and keep magnetic stirring at the same time;

[0082] Step S3: Adding polyetheramine D230 aqueous solution while continuously performing magnetic stirring is more conducive to making the reaction system react completely so as to achieve a clear ammonium n-decanoate solution and an oil phase, the upper layer is an oil phase, and the lower layer is an ammonium n-decanoate solution;

[0083] Step S4: s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com