Temperature response monomer-based soap-free emulsion polymerization method

A temperature-responsive, soap-free emulsion technology, applied in the field of soap-free emulsion polymerization, to achieve the effects of preparing polymers with high molecular weight, mild polymerization conditions and wide selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

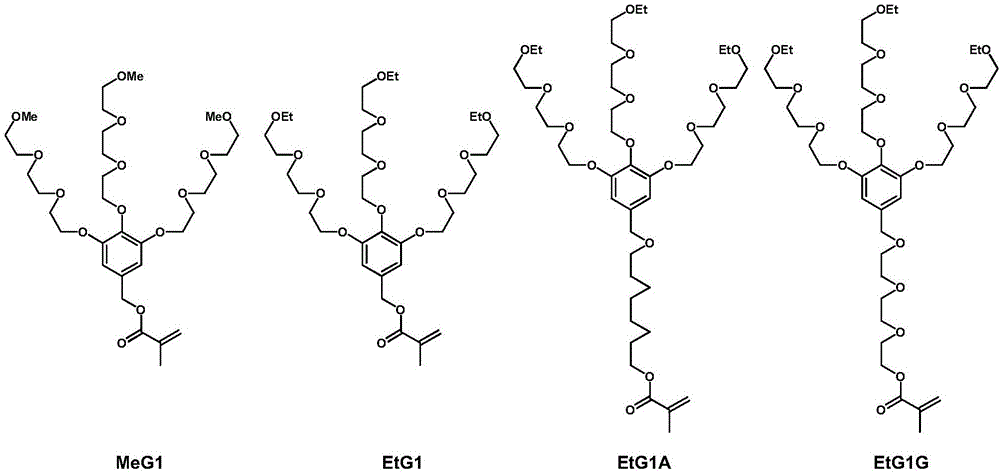

[0022] Example 1: The specific steps are as follows: put 0.5g of temperature-responsive monomer MeG1 into a reaction tube, and add 2.5mg of 4,4'-azo(4-cyanovaleric acid) (AVCA) as a water-soluble free radical initiator , and then add 5 mL of distilled water. Add magnets to stir at room temperature to make the mixture even, then seal the reaction tube, replace nitrogen, and then place the reaction tube in an oil bath at 65°C, the system changes from clear to milky white, and reacts for 6 hours. Yield 82%. The polymer molecular weight (Mn) was 1,300,000. The product became a viscous oil.

Embodiment 2

[0023] Embodiment two: concrete steps are as follows:

[0024] Take 0.2 g of temperature-responsive monomer EtG1 into the reaction tube, add 1 mg of 4,4'-azo(4-cyanovaleric acid) (AVCA) as a water-soluble free radical initiator, and then add 2 mL of distilled water. Add magnets at room temperature to stir to make the mixture even, then seal the reaction tube, replace nitrogen, and then place the reaction tube in an oil bath at 65°C, the system changes from clear to milky white, and reacts for 4 hours. Yield 75%. The polymer molecular weight (Mn) was 2,200,000. The product became a viscous oil.

Embodiment 3

[0025] Embodiment three: concrete steps are as follows:

[0026] Take 0.5g of temperature-responsive monomer EtG1 and 0.5g of non-temperature-responsive styrene, add 2.5mg of 4,4'-azo(4-cyanovaleric acid) (AVCA) as a water-soluble free radical initiator, and then add Distilled water 10mL. Add magnets at room temperature to stir to make the mixture even, then seal the reaction tube, replace nitrogen, and then place the reaction tube in an oil bath at 65°C, the system changes from clear to milky white, and reacts for 4 hours. The product is in the form of a viscous emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com