Soil fast-filter bed system for purifying bioreactor tail gas

A bioreactor and reactor technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve undiscovered problems, achieve low operating costs, good effluent quality, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

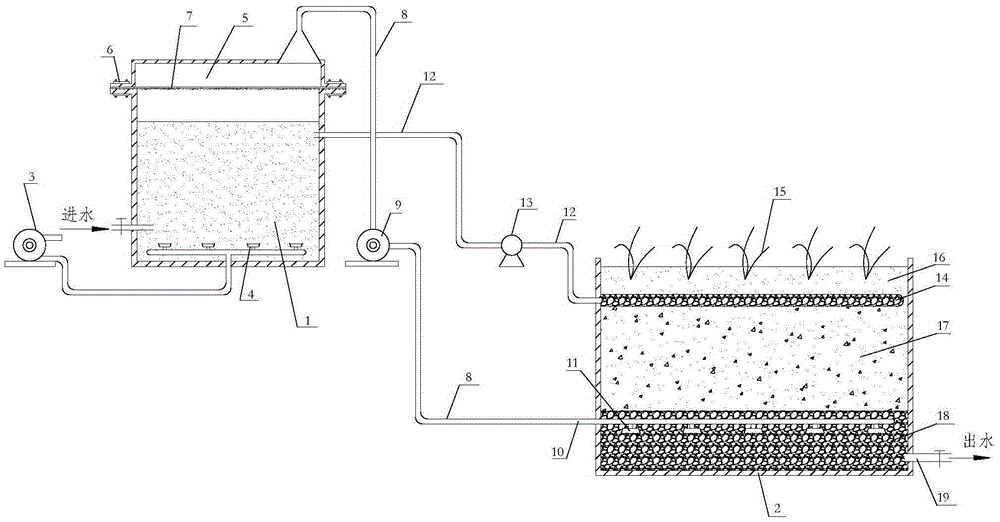

[0017] Such as figure 1 As shown, the soil fast filter bed purification bioreactor tail gas system of the present invention includes a biological fluidized bed reactor, a water and gas transport part and a soil fast filter bed. Bioreactors include biological fluidized bed reactors and membrane bioreactors.

[0018] An aeration head 4 is installed at the bottom of the biological fluidized bed reactor 1, and the system is aerated by an air blower 3. An airtight gas collection hood 5 is installed above the reactor and the reactor is connected by a flange 6, and the joint is sealed with a rubber gasket 7, and the exhaust gas collected is aerated through the gas transmission pipeline 8, fan 9, gas distribution pipe 10 and rubber diaphragm microporous Device 11 is discharged into the soil quick filter bed. Sewage is discharged into the reactor from the water inlet after the flow is adjusted, and the effluent from the biological fluidized bed reactor 1 enters the soil rapid filter ...

Embodiment 2

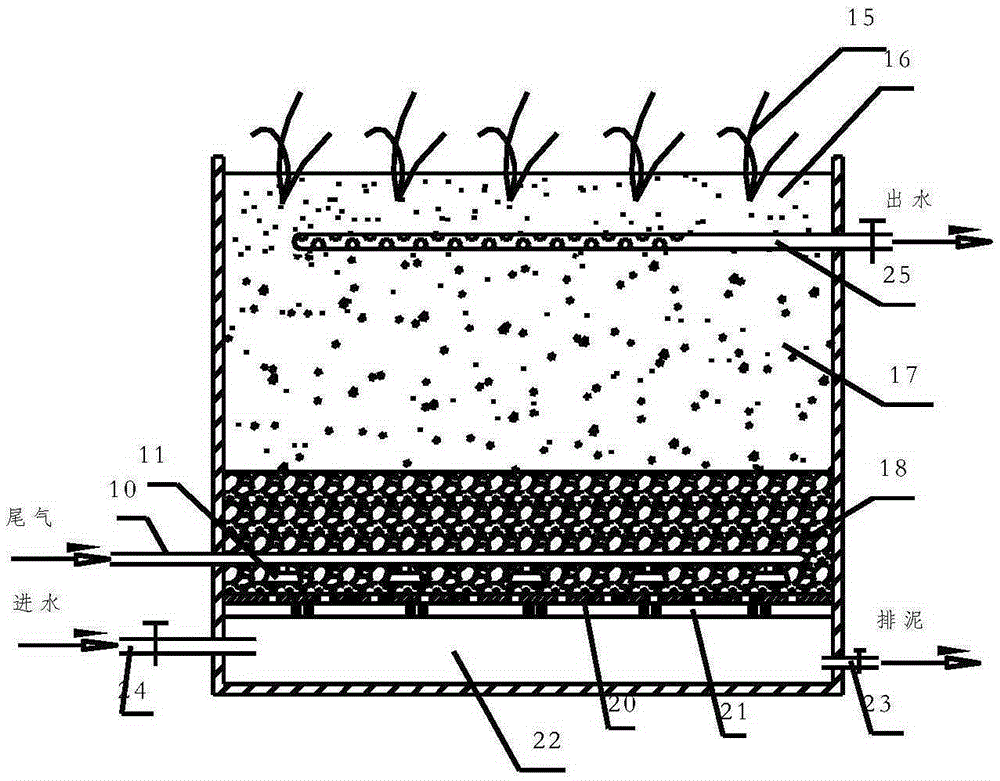

[0021] Same as Example 1, the difference is that the quick soil filter bed adopts an inverted infiltration structure, such as figure 2 As shown, the soil rapid filter bed is provided with anti-seepage walls around and at the bottom, and the bottom of the soil rapid filter bed is a reservoir 22, wherein a bottom water inlet pipe 24 and a mud discharge port 23 are provided, and the upper part of the reservoir is supported by 21 supporting frames The upper matrix acts as a perforated water distribution board 20 on the supporting frame, on which the gravel layer 18, the artificial soil layer 17 and the soil layer 16 are filled in sequence. The diameter of the gravel layer filled with gravel is 2-4cm, and an air distribution pipe 10 is arranged inside. The rubber membrane microporous aerator 11 is installed under the air distribution pipe, and the tail gas of the reactor is sent to the soil quick filter bed. The artificial soil layer is filled with sandy loam. Plants 15 grow on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com