Catalytic ozonation treatment method for refining sewage

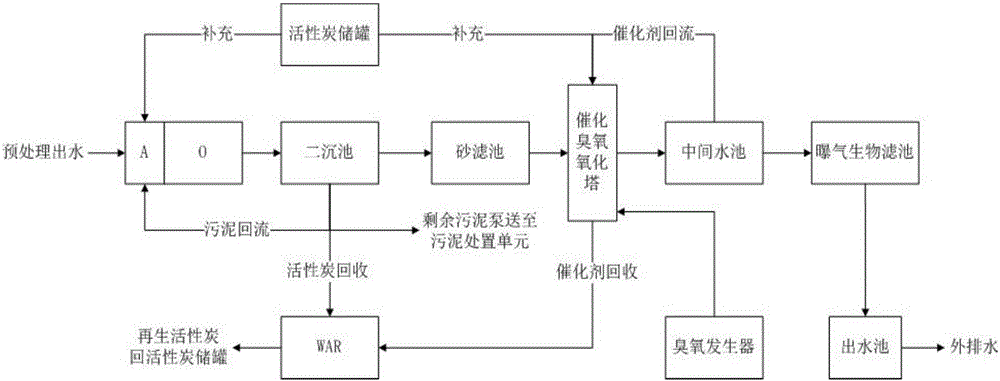

A technology for refining and chemical sewage and ozone oxidation, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve problems such as the reduction of catalytic activity, reduce consumption and meet environmental protection standards. , to achieve the effect of deep processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] According to the technical process provided by the present invention, the oily sewage air flotation water (COD 869.3mg / L) of a certain refinery is processed, and the main processing unit process conditions are as follows: the amount of coal-based powdered activated carbon added to A pool is 60mg / L; A / O tank residence time is 8 / 20h, COD load is 0.8kg COD / m 3 d, the sludge concentration is 5g / L, the sludge internal return ratio is 300%, the sludge external return ratio is 100%, and the aeration intensity of the aerobic tank is 7m 3 / m 2 h, the hydraulic retention time of the secondary sedimentation tank is 1.0h; the sand filter uses quartz sand as the filler, and the filtration rate is 6m / h; the catalytic ozonation tower is filled with coal-based powdered activated carbon loaded with copper oxide and iron oxide, and the hydraulic retention time The ozone dosage is 40mg / L; the ozone concentration is 50mg / L; the residence time of the intermediate pool is 1.0h; the biologic...

Embodiment 2

[0038] According to the technical process provided by the present invention, the saline sewage air flotation effluent (COD 1257.2mg / L) of a certain refinery is processed, and the main processing unit process conditions are as follows: the amount of wood-based powdered activated carbon added to pool A is 80mg / L ; A / O tank residence time is 12 / 24h, COD load is 1.0kg COD / m 3 d, sludge concentration 6g / L, sludge internal reflux ratio 300%, sludge external reflux ratio 100%, aerobic tank aeration intensity 8m 3 / m 2 h, the hydraulic retention time of the secondary sedimentation tank is 1.5h; the sand filter uses wood-based granular activated carbon as filler, and the filtration rate is 5m / h; the catalytic ozonation tower is filled with cerium oxide granular activated carbon, and the hydraulic retention time is 1.0h; The dosage of ozone is 50mg / L; the concentration of ozone is 80mg / L; the residence time of the middle pool is 0.5h; the filler of the biological aerated filter is cera...

Embodiment 3

[0041] According to the technical process provided by the present invention, the oily sewage air flotation water (COD 869.3mg / L) of a certain refinery is processed, and the main processing unit process conditions are as follows: the amount of coconut shell-based powdered activated carbon added to the A pool is 40mg / L ; A / O tank residence time is 6 / 12h, COD load is 0.3kg COD / m 3 d, sludge concentration 2g / L, sludge internal reflux ratio 200%, sludge external reflux ratio 80%, aerobic tank aeration intensity 5m 3 / m 2 h, the hydraulic retention time of the secondary sedimentation tank is 0.5h; the sand filter uses anthracite as filler, and the filtration rate is 5m / h; the catalytic ozonation tower is filled with coconut shell-based granular activated carbon, and the hydraulic retention time is 1.5h; the dosage of ozone The ozone concentration is 20mg / L; the residence time of the middle pool is 1.5h; the biological aerated filter is filled with zeolite, the filtration rate is 2m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com