Method and device for treating industrial wastewater by multi-stage wet oxidation

A technology for industrial wastewater and wet oxidation, applied in oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve high energy consumption, low efficiency of industrial wastewater treatment, and increase of industrial wastewater treatment cost and other issues to achieve the effect of improving processing efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

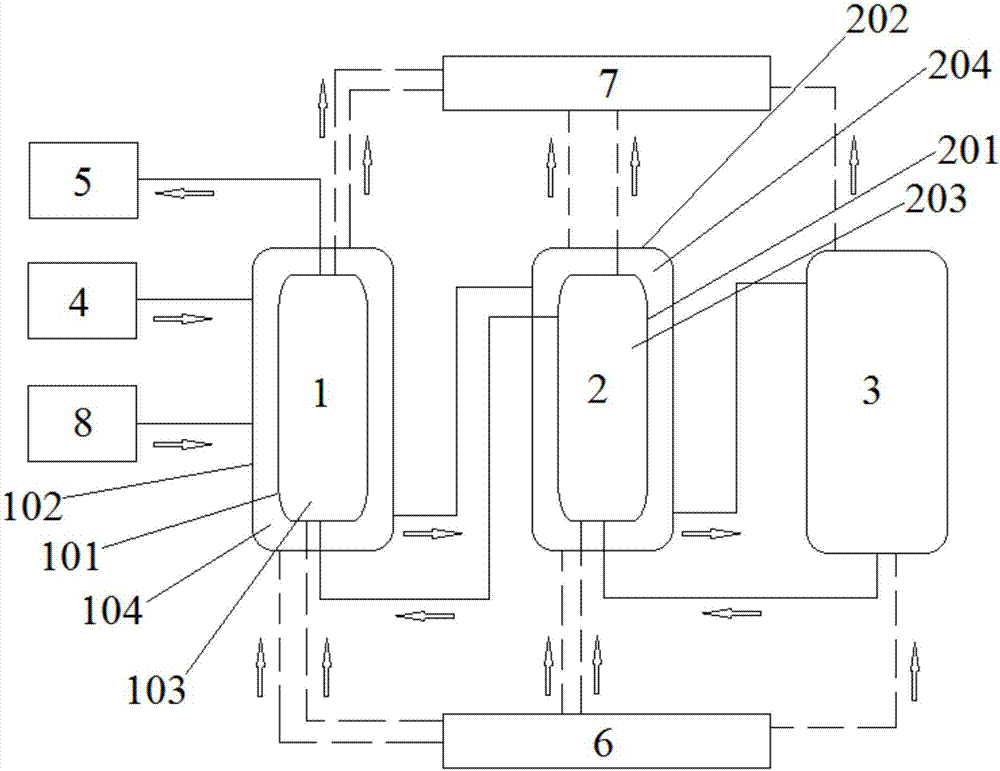

[0032] A method for multi-stage wet oxidation treatment of industrial wastewater, mainly composed of a three-stage oxidation process, the temperature of the primary oxidation is lower than 100°C, the reactor is a double-layer tank reactor, and the target of the wet oxidation treatment is the easiest to oxidize Degraded organic pollutants; the temperature of the secondary oxidation is 100-200 ° C, the reactor is a double-layer tank reactor, and the target of wet oxidation treatment is organic pollutants that are difficult to be oxidized and degraded, and the source of heat of reaction is three The effluent of the first-stage oxidation and the effluent of the third-stage oxidation are heated for the second-stage oxidation and then the heat for the first-stage oxidation; the temperature of the third-stage oxidation is 200-250°C, and the reactor is a self-priming oxygenation reactor. The oxidized organic pollutants have been treated in the process of primary oxidation and secondary...

Embodiment 2

[0034] Taking the refractory chemical wastewater with a COD concentration of 100,000mg / L as an example, the treatment methods for other industrial wastewater are similar.

[0035] The high-concentration refractory chemical wastewater enters the primary oxidation reactor, and performs wet oxidation reaction at a temperature lower than 100°C. The reactor is a double-layer tank reactor, and oxygenated and aerated. The degraded organic pollutants are treated, and the inner and outer layers are subjected to wet oxidation treatment, and the respective COD removal rates are 5-10%; the temperature of the secondary oxidation is 100-200 ° C, and the reactor is a double-layer tank reactor , and carry out oxygenation and aeration. For the organic pollutants that are difficult to be oxidized and degraded, both the inner layer and the outer layer are subjected to wet oxidation treatment, and the respective COD removal rates are 5-15%; the temperature of the third-stage oxidation is 200-250 ...

Embodiment 3

[0038] A method for treating industrial wastewater by multi-stage wet oxidation, in which the industrial wastewater is subjected to primary oxidation, secondary oxidation and tertiary oxidation in sequence, the temperature of the primary oxidation is lower than the temperature of the secondary oxidation, and the temperature of the secondary oxidation is lower than the temperature of the tertiary oxidation temperature, and the tertiary oxidation supplies heat for the secondary oxidation and the primary oxidation in turn.

[0039] Wherein, the temperature of primary oxidation is less than 100°C, the temperature of secondary oxidation is 100-200°C, and the temperature of tertiary oxidation is 200-250°C. The primary oxidation is carried out in the primary oxidation reactor 1, the secondary oxidation is carried out in the secondary oxidation reactor 2, and the tertiary oxidation is carried out in the tertiary oxidation reactor 3.

[0040] The primary oxidation reactor 1 comprises a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com