Efficient photocatalytic water-treating process and apparatus

A technology for photocatalytic water and treatment equipment, which is applied in illumination water/sewage treatment, oxidized water/sewage treatment, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

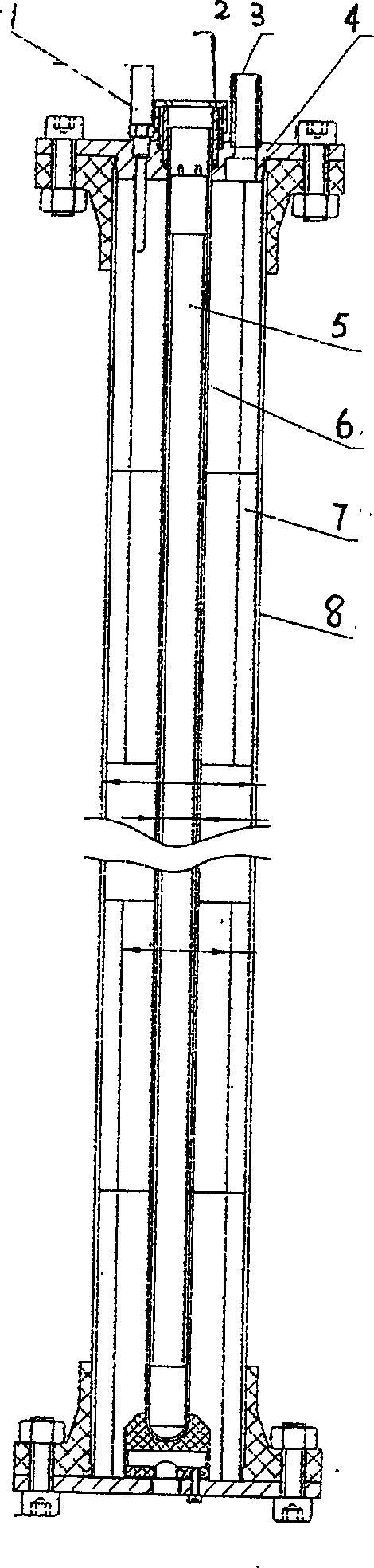

[0036] Prepare sol with butyl titanate, water, glacial acetic acid and n-butanol according to the molar ratio of 1-3:2-4:6-9:8-12, then stand the cleaned and dried stoneware tube upright and seal the bottom, Add sol so that the sol can effectively immerse the inner wall of the tube, let it stand for 4-10 minutes, and then use 3-6cm.min -1 The sol is released at a falling speed of 100°C, and after drying, the temperature is programmed to rise to 400-500°C for 1-2 hours in an intelligent box-type resistance furnace at a rate of 1-3°C per minute. After cooling with the furnace, repeat the above process 4 to 6 times. The thickness of the film measured by SEM is 200-300nm, TiO 2 The particle size is 10-30nm.

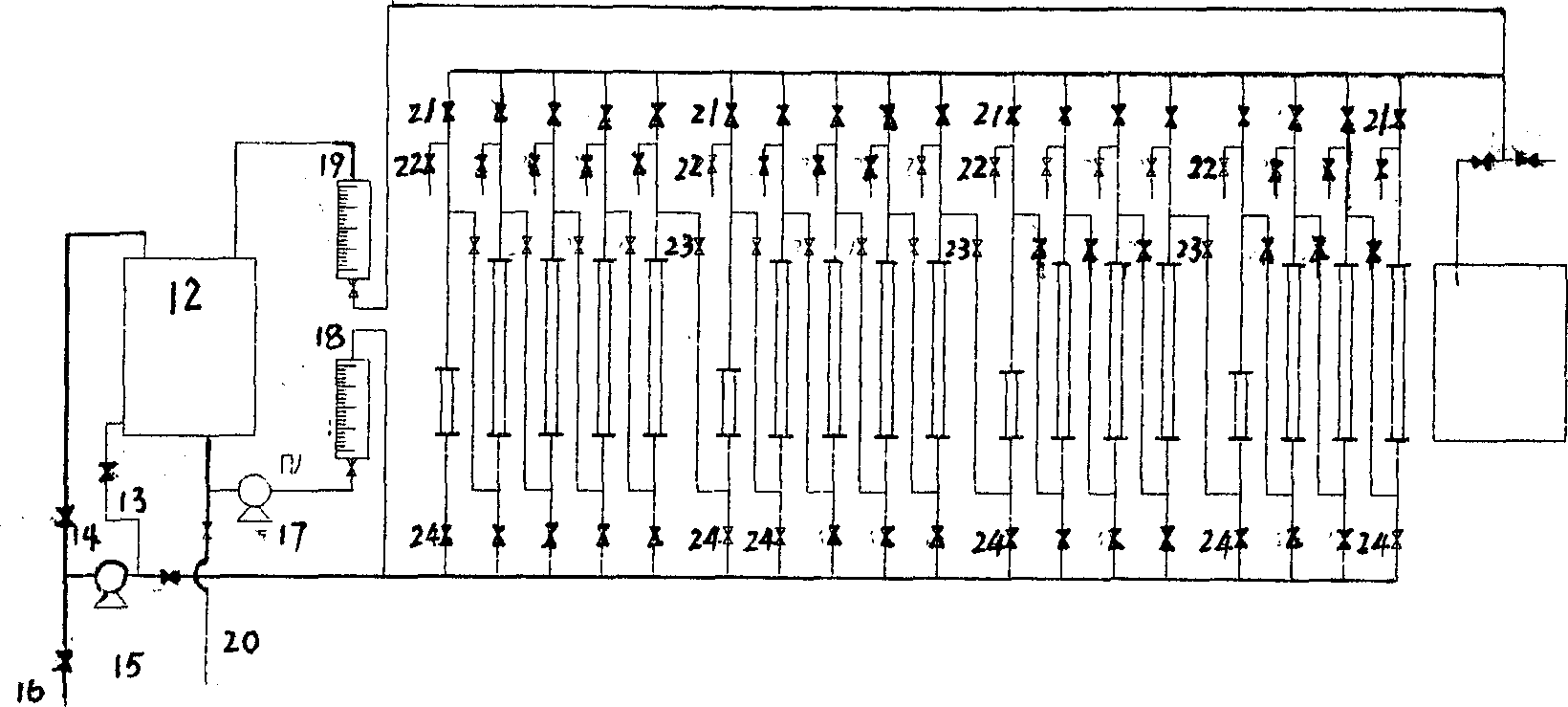

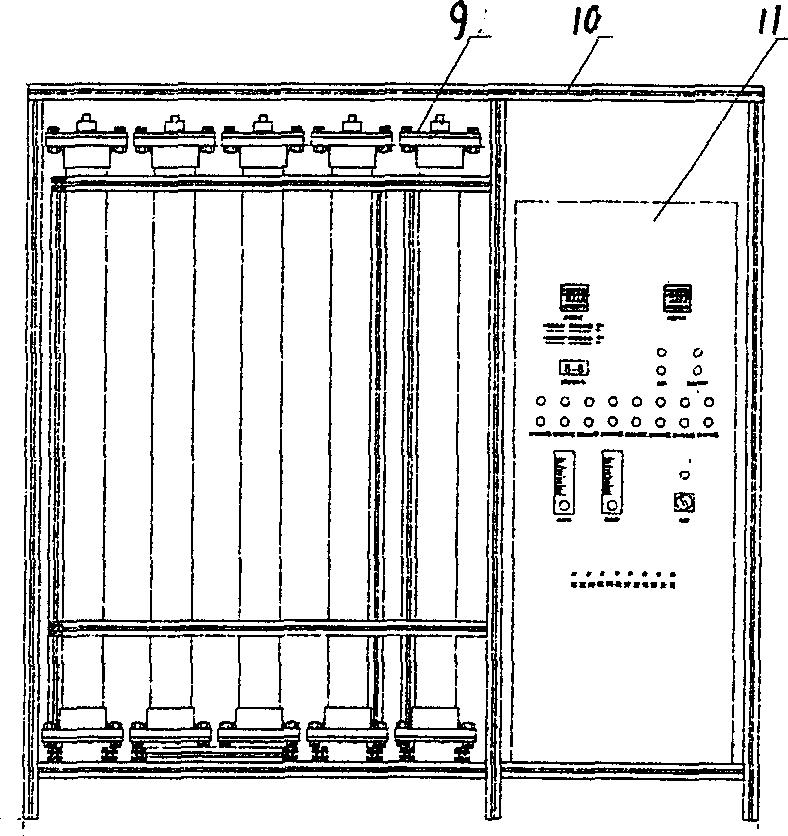

[0037] Will load TiO 2 Thin film stoneware tubes according to attached figure 1 The composition shown is TiO 2 Photocatalytic membrane reaction tube. The wastewater enters from the bottom of the membrane reaction tube and flows out from the upper end. The residence time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com