Deep treatment method of ethylene waste lye

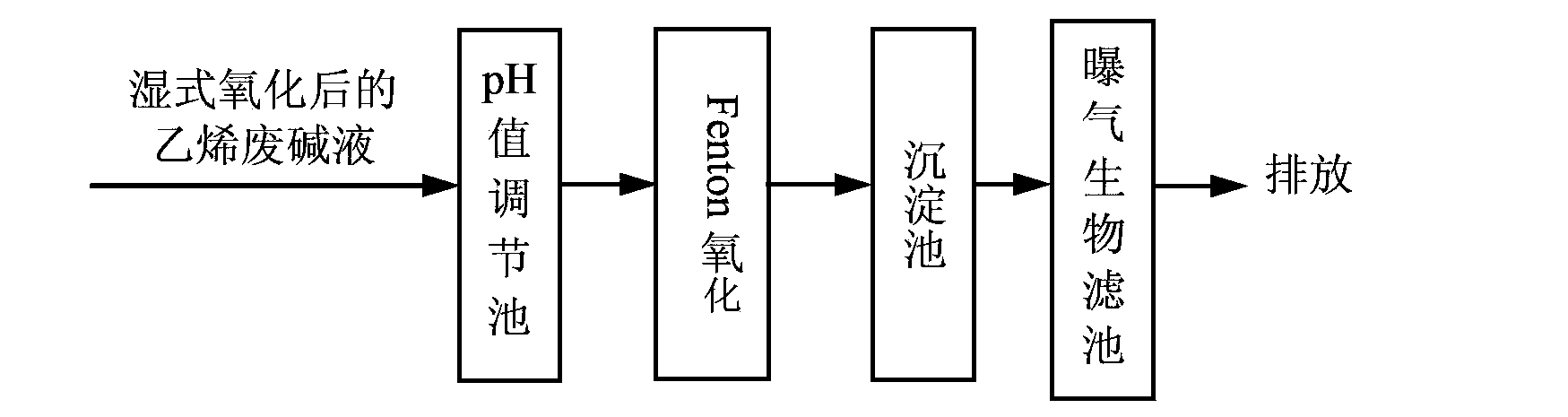

A technology for ethylene waste lye and advanced treatment, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Deterioration of the effect and other problems, to achieve the effect of reducing the load of biochemical treatment, improving the quality of the effluent, and achieving a good decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

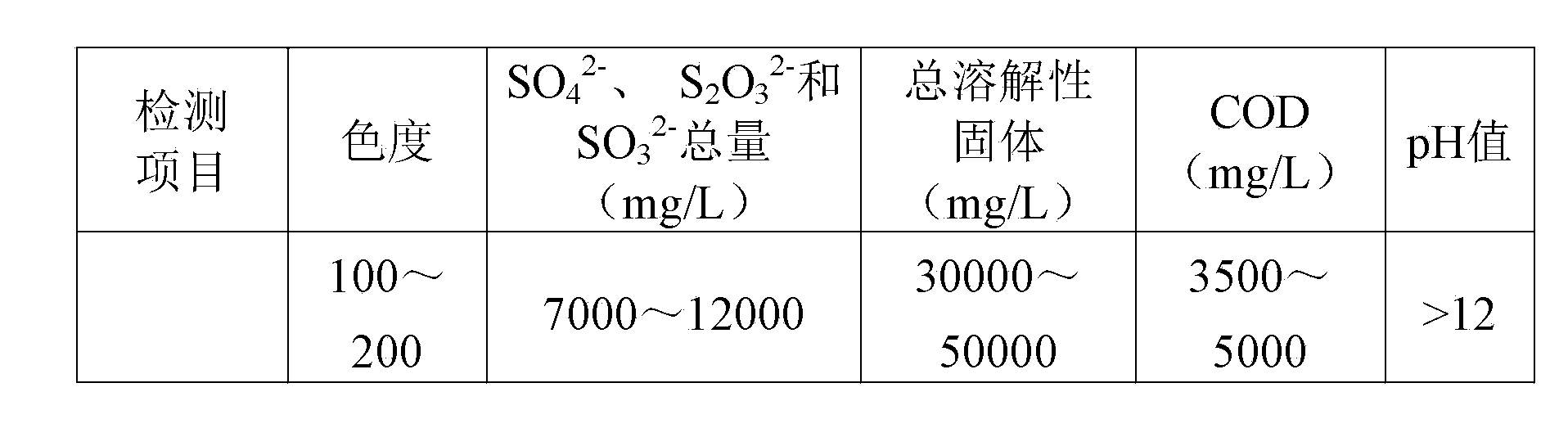

[0037] The water quality characteristics of the ethylene waste lye after wet oxidation pretreatment in an ethylene workshop are as follows, COD: 3960mg / L, chroma: 200, pH value: 12.4, conductivity: 41700us / cm, total dissolved solids: 34850mg / L , SO 4 2- , S 2 o 3 2- and SO 3 2- Total amount: 14537.2mg / L. The processing method is as follows:

[0038] (1) First, add acid to the ethylene waste lye after wet oxidation pretreatment, adjust the pH value of the wastewater to 3.0, and the acid is sulfuric acid; secondly, raise the temperature of the wastewater to 30°C, and add ferrous sulfate (FeSO 4 ·7H 2 O) and hydrogen peroxide (H 2 o 2 ), stirred mechanically for 4h to complete the reaction; among them, H 2 o 2 / Fe 2+ The molar ratio of H is 10.0, H 2 o 2 The mass ratio of / COD was 3.0.

[0039] (2) Add sodium hydroxide solution to the ethylene waste lye after Fenton oxidation treatment, adjust the pH value to 8.5, and carry out precipitation treatment to realize ...

Embodiment 2

[0045] The water quality characteristics of the ethylene waste lye after wet oxidation pretreatment in an ethylene workshop are as follows, COD: 3717mg / L, chroma: 150, pH value: 13.1, conductivity: 38300us / cm, total dissolved solids: 32750mg / L , SO 4 2- , S 2 o 3 2- and SO 3 2- Total amount: 7607.8mg / L. The processing method is as follows:

[0046] (1) First, add an acid to the ethylene waste lye after wet oxidation pretreatment to adjust the pH value to 3.5, and the acid is sulfuric acid. Next, raise the temperature of the wastewater to 35°C, add ferrous sulfate (FeSO 4 ·7H 2 O) and hydrogen peroxide (H 2 o 2 ), stirred mechanically for 3h to complete the reaction; among them, H 2 o 2 / Fe 2+ The molar ratio of H is 15.0, H 2 o 2 The mass ratio of / COD was 4.0.

[0047] (2) Add sodium hydroxide solution to the ethylene waste lye after Fenton oxidation treatment, adjust the pH value to 9.0, and carry out precipitation treatment to realize solid-liquid separati...

Embodiment 3

[0053] The water quality characteristics of ethylene waste lye after wet oxidation pretreatment in an ethylene workshop are as follows: COD: 3474mg / L, chroma: 100, pH value: 13.4, conductivity: 37200us / cm, total dissolved solids: 37550mg / L , SO 4 2- , S 2 o 3 2- and SO 3 2- Total amount: 12186.9mg / L. The processing method is as follows:

[0054] (1) First, add an acid to the ethylene waste lye after wet oxidation pretreatment to adjust the pH value to 4.0, and the acid is sulfuric acid. Next, raise the temperature of the wastewater to 40°C, add ferrous sulfate (FeSO 4 ·7H 2 O) and hydrogen peroxide (H 2 o 2 ), stirred mechanically for 2h to complete the reaction; among them, H 2 o 2 / Fe 2+ The molar ratio of H is 10.0, H 2 o 2 The mass ratio of / COD was 2.5.

[0055] (2) Add sodium hydroxide solution to the ethylene waste lye after Fenton oxidation treatment, adjust the pH value to 9.5, and carry out precipitation treatment to realize solid-liquid separation....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com