Cold Rolling Pickling Wastewater Recycling Process System

A technology of pickling wastewater and treatment process, which is applied in the field of resource treatment process system, can solve the problems such as the inability to achieve resource utilization of wastewater, and achieve the effect of high degree of automatic operation of equipment, reduction of total hardness, and favorable effect of advanced treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

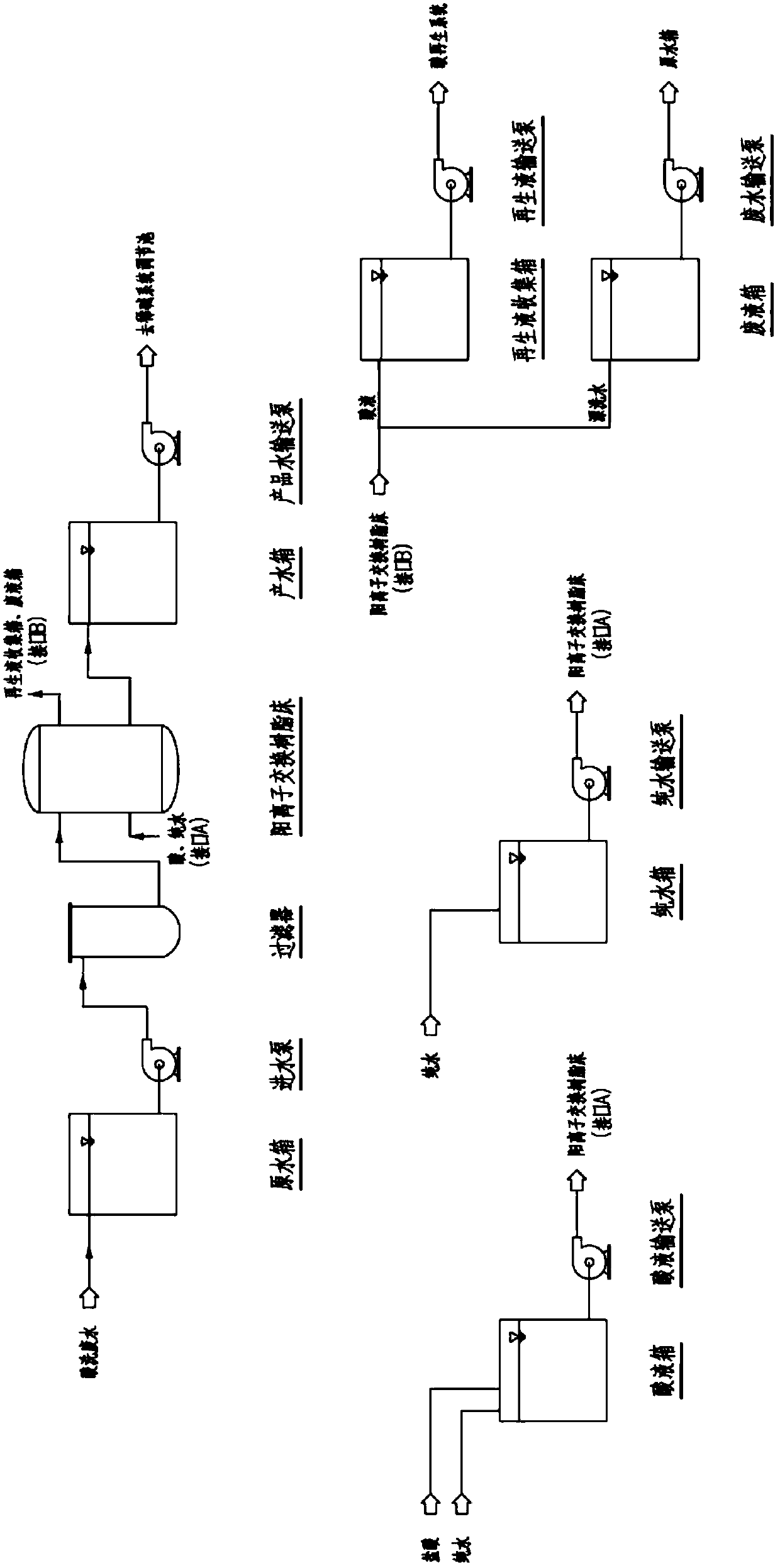

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

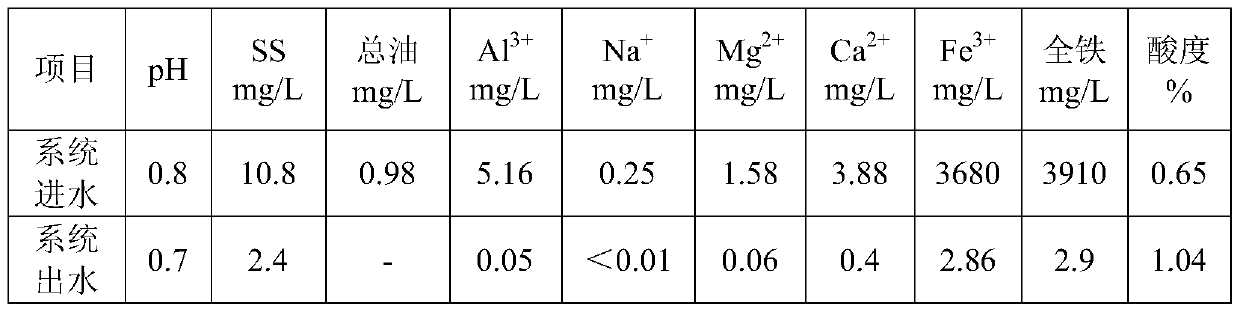

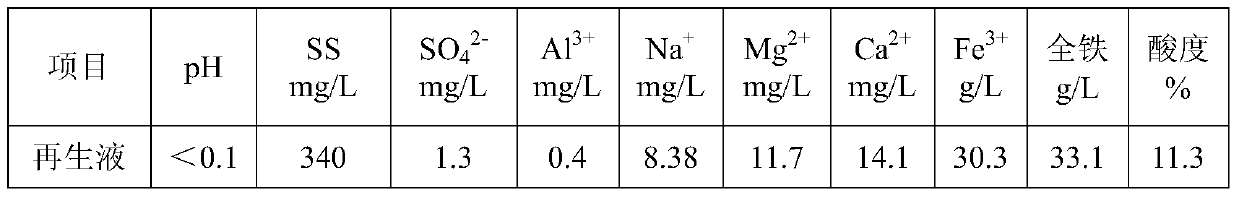

[0029] The total oil in the pickling wastewater is ≤1.0mg / L, the suspended matter is ≤50mg / L, the iron ion is ≤5000mg / L, and the acidity is 0.5-2%. Cold rolling pickling wastewater resource treatment process system, including: raw water tank, water inlet pump, filter, cation exchange resin bed, product water tank, product water delivery pump, acid tank, acid delivery pump, pure water tank, pure water Transfer pump, regeneration liquid collection tank, regeneration liquid transfer pump, waste liquid tank, waste water transfer pump.

[0030] The filter is made of PVDF material. When the pressure difference between the inlet and outlet of the filter reaches the limit value, the original design flux can be restored by feeding compressed air or steam for cleaning. PVDF (polyvinylidene fluoride) filters have excellent mechanical properties, good toughness,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com