Glass fiber tube burring device

A glass fiber tube and frame body technology is applied in the field of glass fiber tube hair removal devices, which can solve the problems of burrs, unfavorable deep processing production, and uneven surface of the glass fiber tube blank tube wall, and achieve smooth surface and burr removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

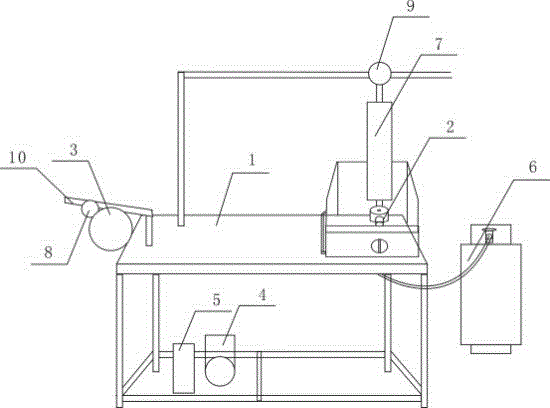

[0012] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

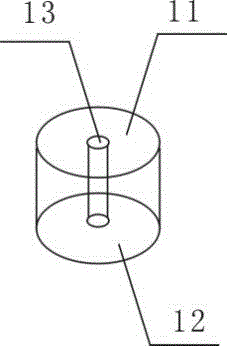

[0013] Such as figure 1 As shown, a glass fiber tube hair removal device of the present invention includes a frame body 1, a hair removal device 2 is arranged on the frame body 1, a receiving guide wheel 3 is arranged at one end of the frame body 1, and a motor 4 is arranged at the bottom of the frame body 1 And the frequency converter 5, the hair removal device 2 is connected with the external fire source 6, the flame insulation chamber 7 is arranged above the hair removal device 2, the pressure roller 8 is arranged on the material receiving guide wheel 3, the guide wheel 9 is arranged above the flame insulation chamber 7, and the pressure roller 8 is provided with pinch wheel handle 10. The hair removal device 2 is a "soil"-shaped structure, including a cover 11 and a base 12, and a through hole 13 is arranged in the middle. The raw material blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com