A treatment process for waste gas from papermaking

A technology of treatment process and process equipment, applied in the field of papermaking waste gas treatment technology, can solve problems such as hidden safety hazards, unsatisfactory waste gas treatment effect, secondary pollution safety, etc., and achieve good treatment effect, low treatment cost and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

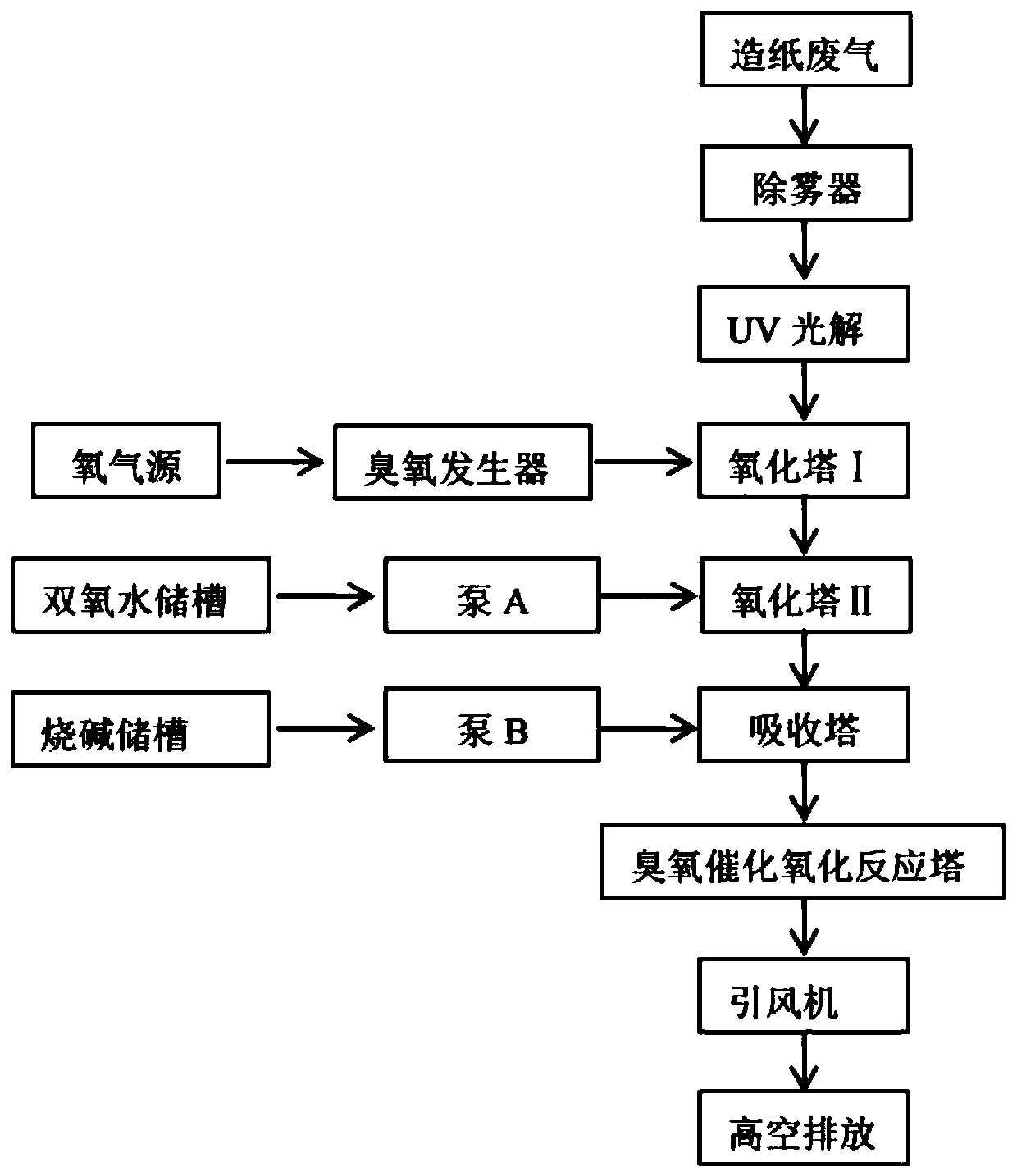

[0054] The overall technological process of a papermaking waste gas treatment process is:

[0055] (1) The papermaking waste gas first passes through the demister to absorb and remove the mist and dust in the waste gas, and the waste water generated is directly discharged to the ditch through the drainage pipe, and the waste gas discharged from the demister enters the UV photolysis generator and undergoes UV photolysis. After the post-treatment of the generator, the malodorous organic gas in the exhaust gas is cracked into free pollutant molecules, and then enters the oxidation tower I;

[0056] (2) After the oxygen source passes through the ozone generator, ozone is generated and enters the oxidation tower Ⅰ to react with the pollutant molecules in the free state to generate small-molecule harmless or low-harm compounds (such as CO 2 、H 2 O etc.);

[0057] (3) After being treated in the oxidation tower I, the exhaust gas enters the oxidation tower II, is sprayed and oxidize...

Embodiment 2

[0059] The technological process is the same as that of Example 1, the air intake flow rate: working condition 1000m 3 / h, the dimensionless odor of imported waste gas is 773, after being treated by this set of equipment, the specific parameters are as follows:

[0060] (1) The corrugated plate demister uses a mixed material of steel mesh and PP (polypropylene) as filler;

[0061] (2) UV photocatalytic oxidation reactor: special ultraviolet lamp tube (150W amalgam quartz tube) for C-wave UV253.7nm and 185nm band ultraviolet light waste gas treatment, equipped with catalyst nano-titanium dioxide.

[0062] (3) The size of the upper part of the oxidation tower I The size of the lower part is 600mm*600mm*800mm. It is connected to the ozone generator, and the oxygen cylinder supplies gas. The gas supply volume is adjusted by the valve. The ozone smell is smelled at the gas intake port of the 3# tower, and there is no ozone gas smell at the final exhaust outlet.

[0063] (4) The ...

Embodiment 3

[0068] The process flow is the same as that in Example 1, the intake flow rate: the working condition is 1000m3 / h, the odor of the imported waste gas is dimensionless 773, after being processed by this set of equipment, the specific parameters are as follows:

[0069] (1) The corrugated plate demister uses a mixed material of steel mesh and PP (polypropylene) as filler;

[0070] (2) UV photocatalytic oxidation reactor: special ultraviolet lamp tube (150W amalgam quartz tube) for C-wave UV253.7nm and 185nm band ultraviolet light waste gas treatment, equipped with catalyst nano-titanium dioxide.

[0071] (3) The size of the upper part of the oxidation tower I The size of the lower part is 600mm*600mm*800mm. It is connected to the ozone generator, and the oxygen cylinder supplies gas. The gas supply volume is adjusted by the valve. The ozone smell is smelled at the gas intake port of the 3# tower, and there is no ozone gas smell at the final exhaust outlet.

[0072] (4) The siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com