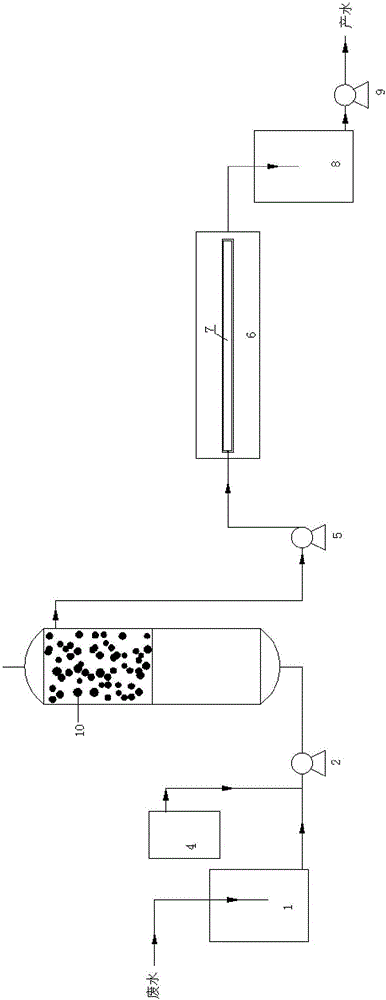

Method and device for deeply treating oil refinery wastewater through ultraviolet and catalytic ozonation

A technology for ozone catalytic oxidation, refining and chemical wastewater, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Low, improve the dissolution efficiency, the effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A refining and chemical plant in Shaanxi, daily treatment of refining and chemical wastewater 600m 3 , the COD of the external drainage is between 55-60mg / L. In order to meet the requirements of wastewater treatment upgrading and transformation, the COD of the external drainage is required to be ≤40mg / L. Pilot test, the processing capacity of the device is 10m 3 / h, when the ozone gas concentration is 150mg / L, the wastewater residence time in the enhanced reactor is 20min, and the COD is reduced from 60mg / L to 38mg / L, meeting the treatment requirements after the discharge standard is raised.

Embodiment 2

[0018] A refinery in Shandong, daily treatment of refinery wastewater 1000m 3 , after degreasing, flocculation and sedimentation, and biochemical treatment, the COD is reduced to below 60mg / L. Faced with increasingly stringent environmental protection policies, the biochemical effluent of the sewage field on the site needs to undergo advanced treatment, requiring COD ≤ 40mg / L. The method for advanced treatment of refinery wastewater by ultraviolet synergistic ozone catalytic oxidation of the present invention is used for on-site pilot test, and the treatment capacity of the device is 20m 3 / h, when the ozone gas concentration is 180mg / L, the residence time of wastewater in the enhanced reactor is 30min, and the COD is reduced from 60mg / L to 35-40mg / L, which meets the discharge requirements after the sewage field standard is raised.

Embodiment 3

[0020] A refinery in Gansu, daily treatment of refinery wastewater 2000m 3 , the COD of the external drainage after wastewater treatment is between 55-60mg / L. In order to realize the protection of the ecological environment in the western region, it is required that the COD of the external drainage should be reduced to below 30mg / L. The method for advanced treatment of refinery wastewater by ultraviolet synergistic ozone catalytic oxidation of the present invention is used for on-site pilot test, and the treatment capacity of the device is 15m 3 / h, when the ozone gas concentration is 200mg / L, the residence time of wastewater in the enhanced reactor is 40min, and the COD is reduced from 60mg / L to below 30mg / L, meeting the discharge requirements after the sewage field standard is raised.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com