Box-type shearing machine with adjustable shearing height and shearing method

A shearing machine, a high degree of technology, applied in the direction of shearing device, cutter for shearing device, shearing machine equipment, etc. Easy to disassemble and assemble, improve the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

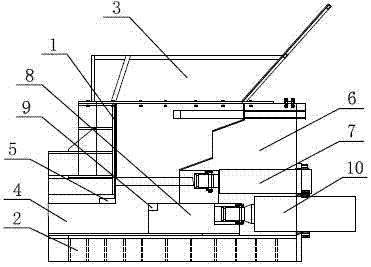

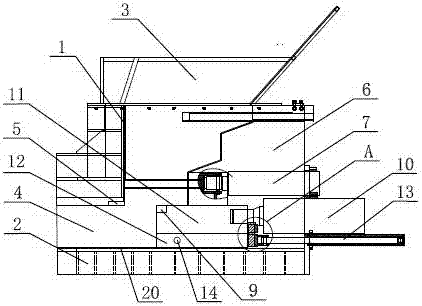

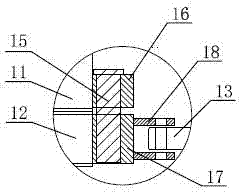

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0028] Such as figure 2 Shown, the present invention comprises the box body that upper box body 1 and lower box body 2 are formed, and upper box body 1 top opening is installed feed hopper 3, and upper box body 1 left side inner wall is a vertical plane, left bottom and lower box body A discharge port 4 is arranged between the 2, and an upper blade 5 is installed on the bottom of the upper box body 1 at the discharge port 4 . A pusher head 6 is installed on the right side of the upper box body 1. One side of the pusher head 6 located in the upper box body 1 is a stepped slope, and the other side is connected to the piston rod of the pusher cylinder 7. The cylinder body of the pusher cylinder 7 It is fixed on the box body and can push the pushing head 6 to move horizontally in the upper box body 1 . The bottom of the pushing head 6 is eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com