Method for preparing biofuel by using flue gases as raw materials

A technology for biofuels and flue gas, which is applied in the fields of botanical equipment and methods, fuels, horticultural methods, etc., can solve problems such as insufficient raw materials for biofuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

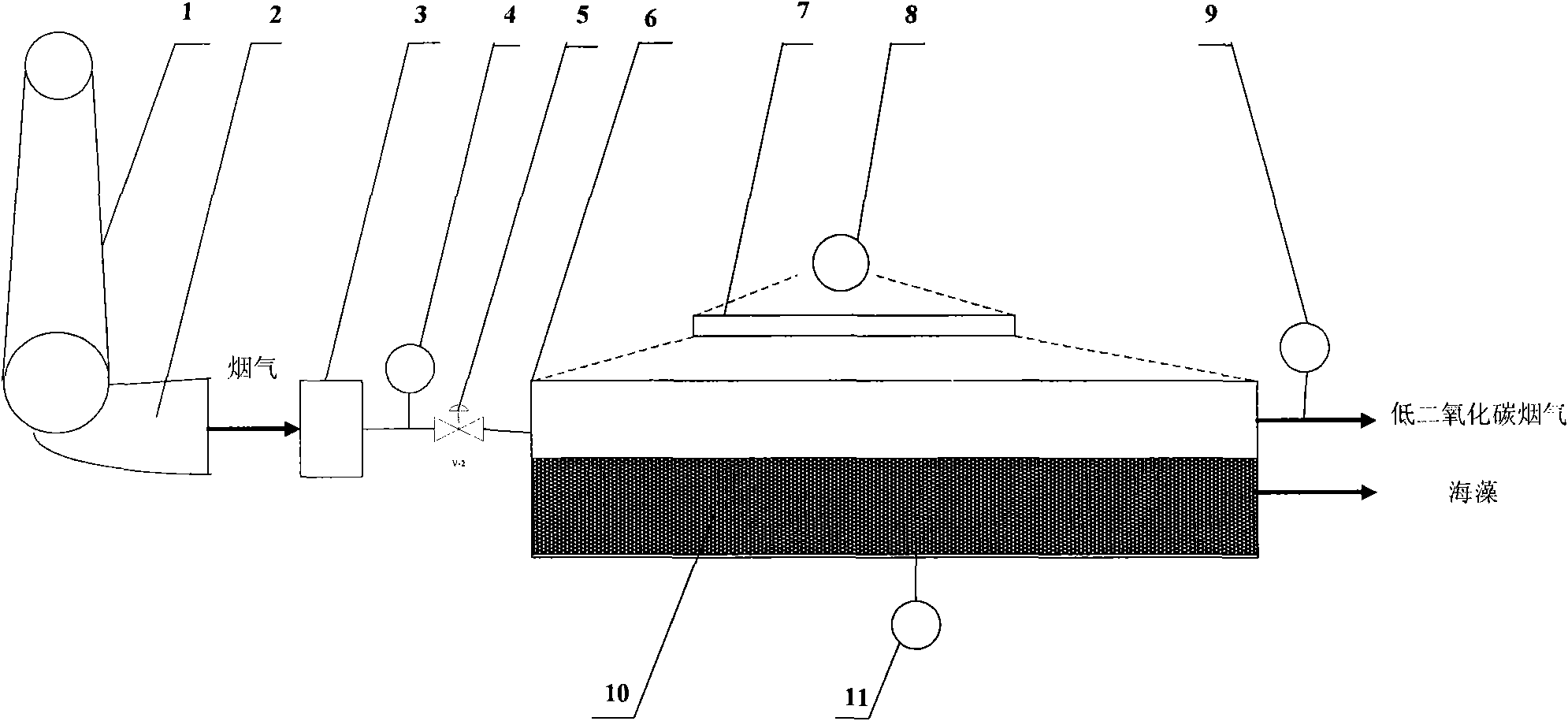

[0013] The specific implementation process is to obtain through a special flue gas generation system. The flue gas is consistent with the flue gas composition of the steel plant heating furnace. The content of carbon dioxide can fluctuate between 2 and 20%. The flue gas is cooled to normal temperature through the cooler and enters the Closed photobioreactor, the photobioreactor is composed of many unit pipelines, which can realize the volume ratio of the area of algae in contact with sunlight and the volume ratio of the photobioreactor to 1000m 2 / m 3 Above, seaweed is arranged in the unit pipeline, and water is passed through at the same time. The water can be industrial water. The photobioreactor is placed in the sun, and the intensity of light can be controlled by a special light regulator. During the growth of seaweed, according to Different formulations of culture solution are added according to the growth cycle. The pH value of the seaweed culture solution is between 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com