Environment-friendly, low-cost and high-strength artificial stone and method for preparing same

A low-cost, high-strength technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of ecological environment damage, limited oil resources, etc., achieve high-end living space, rich sources, and good light transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

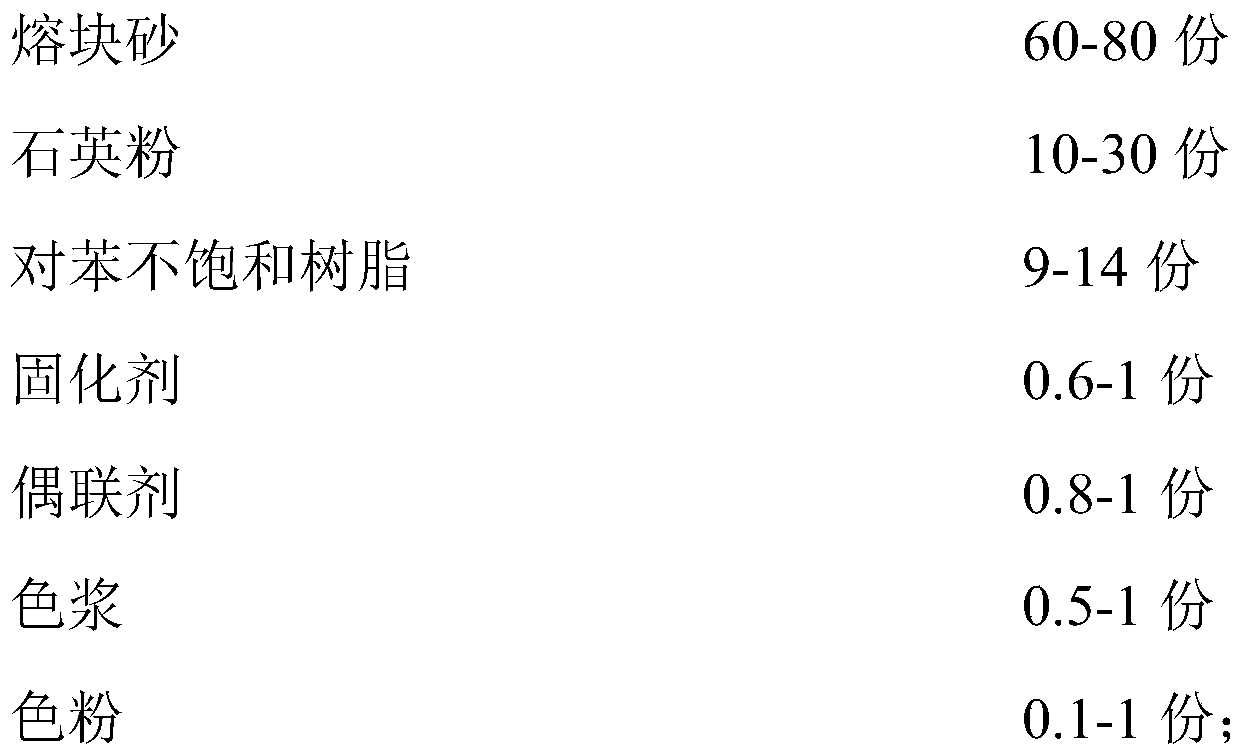

[0040] A kind of environmental protection low-cost high-strength artificial stone, the consumption (mass parts) of each raw material is:

[0041]

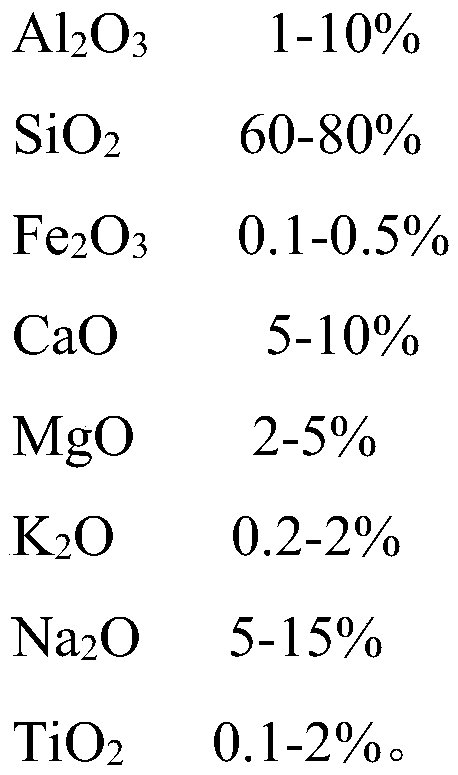

[0042] Wherein, the chemical composition of the frit sand is:

[0043]

[0044] The tailings quartz powder is 350 mesh quartz powder;

[0045] The composite color paste is formed by mixing titanium white paste, scarlet paste and iron yellow paste in a ratio (mass fraction) of 7:1:2.

[0046] The composite toner is formed by mixing titanium dioxide, iron red powder, and phthalocyanine blue powder in a ratio (mass fraction) of 6:1:1.

[0047] In this embodiment, an environmentally friendly, low-cost, high-strength artificial stone preparation method includes the following steps:

[0048](1) Stir and mix tert-butyl peroxy-2-ethylhexanoate, γ-methacryloxypropyltrimethoxysilane, composite color paste and p-phenylene unsaturated resin to obtain a premix; and Use tailings quartz sand, coal gangue, limestone, albite, and potassium...

Embodiment 2

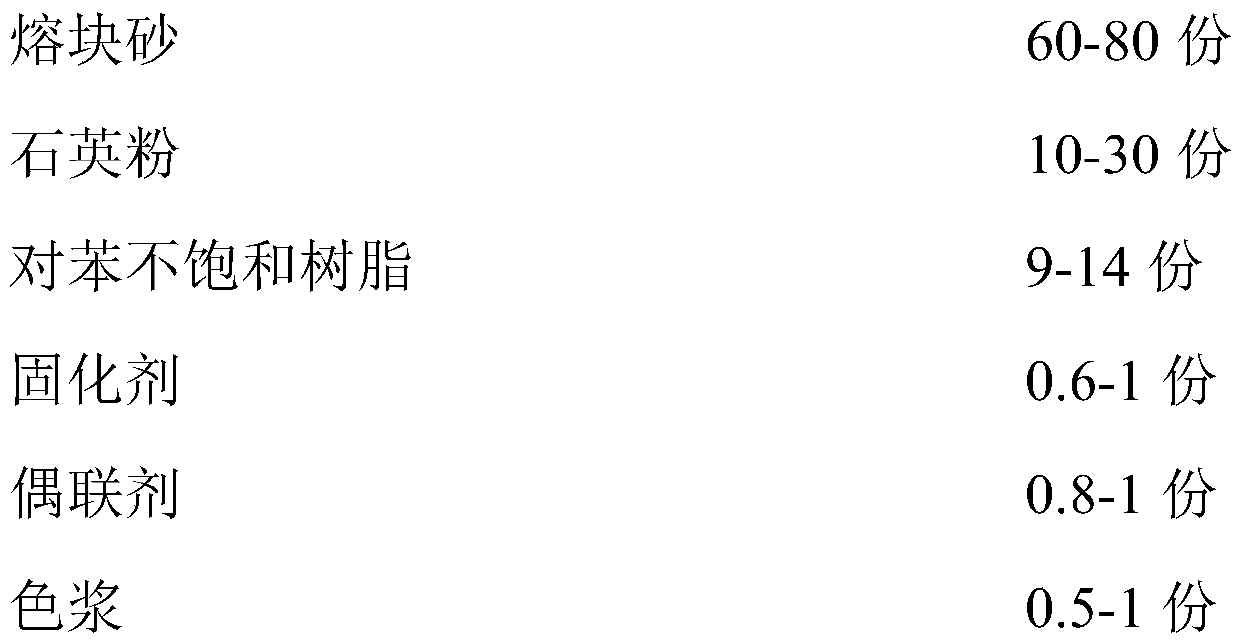

[0056] A kind of environmental protection low-cost high-strength artificial stone, the consumption (mass parts) of each raw material is:

[0057]

[0058] Wherein, the chemical composition of the frit sand is

[0059]

[0060]

[0061] The tailings quartz powder is 450 mesh quartz powder;

[0062] The composite color paste is formed by mixing titanium white paste, carbon black paste and iron yellow paste in a ratio (mass fraction) of 6:3:2.

[0063] The composite toner is formed by mixing titanium dioxide, iron black powder and iron yellow powder in a ratio (mass fraction) of 5:2:1.

[0064] In this embodiment, an environmentally friendly, low-cost, high-strength artificial stone preparation method includes the following steps:

[0065] (1) Stir and mix tert-butyl peroxy-2-ethylhexanoate, γ-methacryloxypropyltrimethoxysilane, composite color paste and p-phenylene unsaturated resin to obtain a premix; and Use tailings quartz sand, coal gangue, limestone, albite, and...

Embodiment 3

[0073] A kind of environmental protection low-cost high-strength artificial stone, the consumption (mass parts) of each raw material is:

[0074]

[0075] Wherein, the chemical composition of the frit sand is

[0076]

[0077] The frit sand is the blast furnace gas recovered and purified by using tailings quartz sand, coal gangue, limestone, albite, and potassium feldspar in the mass ratio of 9:3:1:1:2 in the production process of iron and steel plants and coking coal plants. Heating the rotary frit furnace with coke oven gas as fuel to a high temperature of 1380°C for melting, and then quenching with water to form frit particles of 8-16 mesh, 16-26 mesh, 26-40 mesh, and 40-70 mesh.

[0078] The tailings quartz powder is 500 mesh quartz powder;

[0079] The composite color paste is formed by mixing titanium white paste, iron red paste and iron black paste in a ratio (mass fraction) of 9:3:1.

[0080] The composite toner is formed by mixing titanium dioxide, iron black ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com