Method for preparing rare earth ceria modified inorganic polymeric flocculant by using industrial waste

An inorganic polymer and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of reducing production cost and wastewater treatment cost, improving environmental value, and wide application range of pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

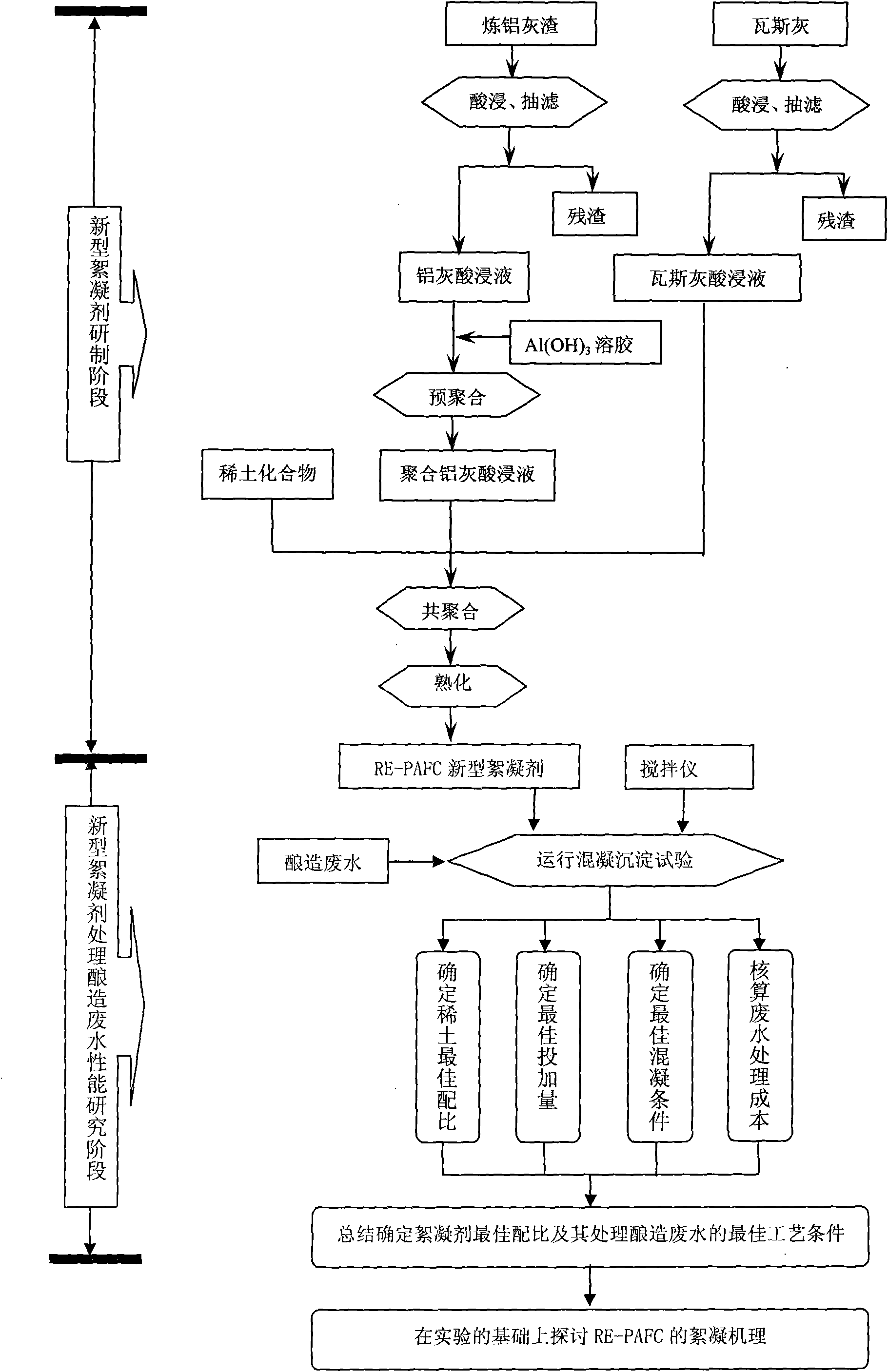

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, using blast furnace gas ash and aluminum smelting slag as main raw materials to prepare rare earth cerium modified inorganic polymer flocculant body products includes the following steps:

[0022] 1. A method for preparing rare earth cerium modified inorganic polymer flocculant (RE-PAFC), which is to use blast furnace gas ash and aluminum smelting slag containing iron salt and aluminum salt material as main raw materials, add rare earth compound, and heat synthesis Obtain; it is characterized in that: the specific synthetic method of described rare earth cerium modified inorganic polymer flocculant is:

[0023] (1) Raw material pretreatment: After the industrial waste blast furnace gas ash and aluminum smelting ash are naturally air-dried respectively, pass through a 60-mesh sieve and set aside;

[0024] (2) Preparation of blast fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com