Method for recycling dedusting sludge of steel smelting converter and solid waste resources of steel and iron plant

A steelmaking converter and resource recovery technology, applied in the direction of recycling technology, etc., can solve the problems of resource waste, environmental pollution, uneven distribution, etc., and achieve good social benefits, stable economic benefits, and high adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

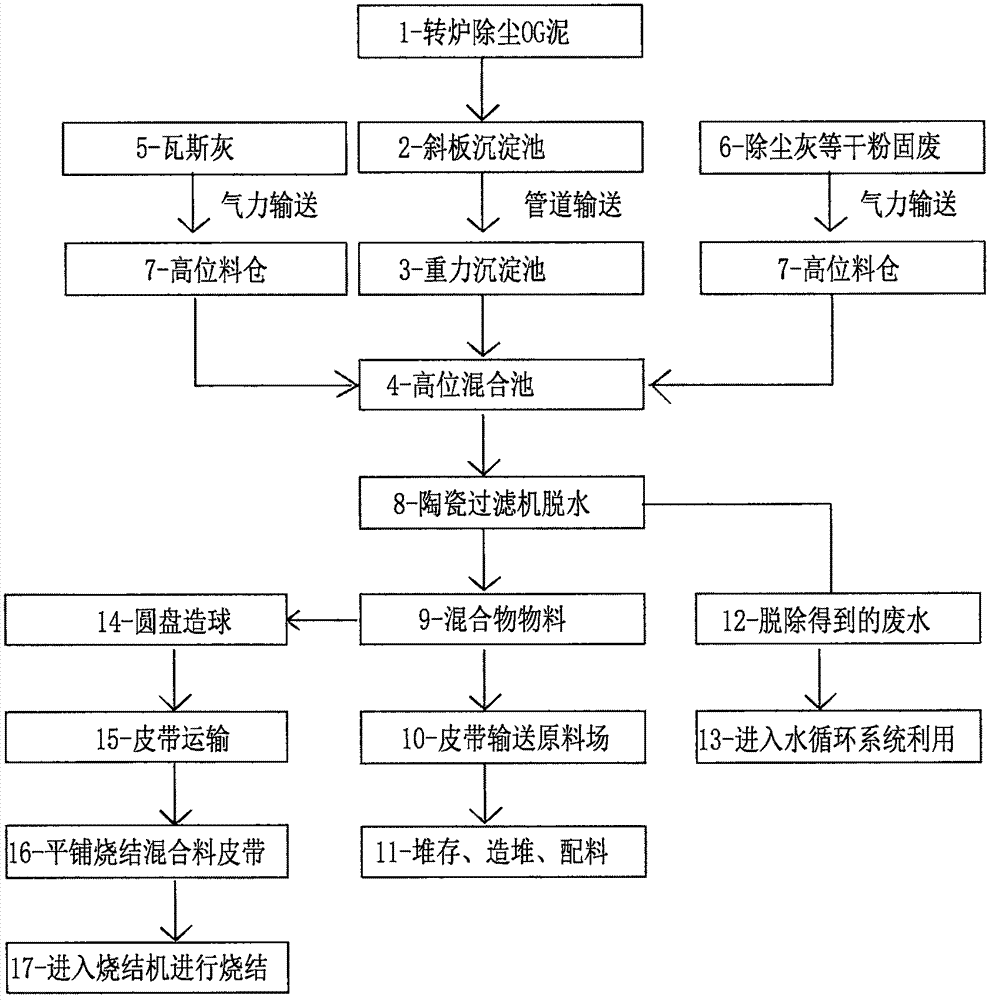

[0024] (1) The converter dedusting OG mud 1 produced by converter steelmaking wet dedusting is passed through the inclined plate sedimentation tank 2 to obtain OG mud with a concentration of about 25%, and is transported to the gravity sedimentation tank 3 through pipelines for sedimentation and collection;

[0025] (2) Pneumatically transport dry powder solid waste 6 such as gas ash 5 produced in the production process of the metallurgical blast furnace and dust ash produced in other processes to the respective high-level bins of the solid waste treatment center;

[0026] (3) Transport the OG slurry to the transition tank of the solid waste treatment center through pipelines, and quantitatively enter the high-level mixing tank 4, add gas ash 5, dedusting dry ash 6, etc. to the high-level mixing tank 4, stir and mix with the OG slurry to mud with a concentration of 35%-55%;

[0027] (4) The slurry obtained in step (3) is entered into ceramic filter 8 for dehydration to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com