Patents

Literature

31results about How to "Improve the efficiency of waste heat recovery and utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

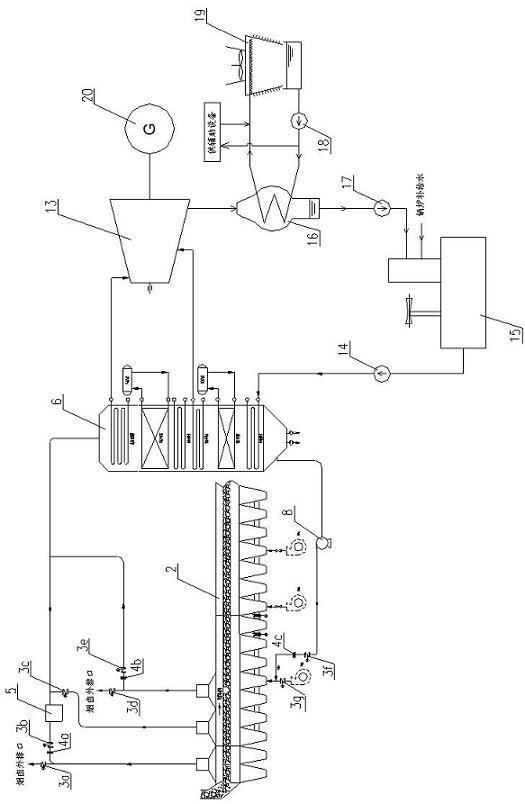

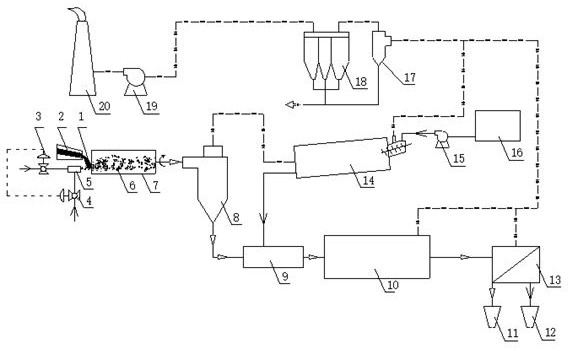

System and method for power generating by jointly recovering waste heat of flue gas of sintering machine and exhaust gas of cooling machine

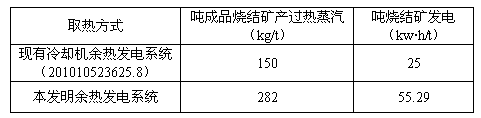

ActiveCN102012167AImprove the efficiency of waste heat recovery and utilizationIncrease feed water temperatureEnergy industryIncreasing energy efficiencyWaste heat recovery unitIron plant

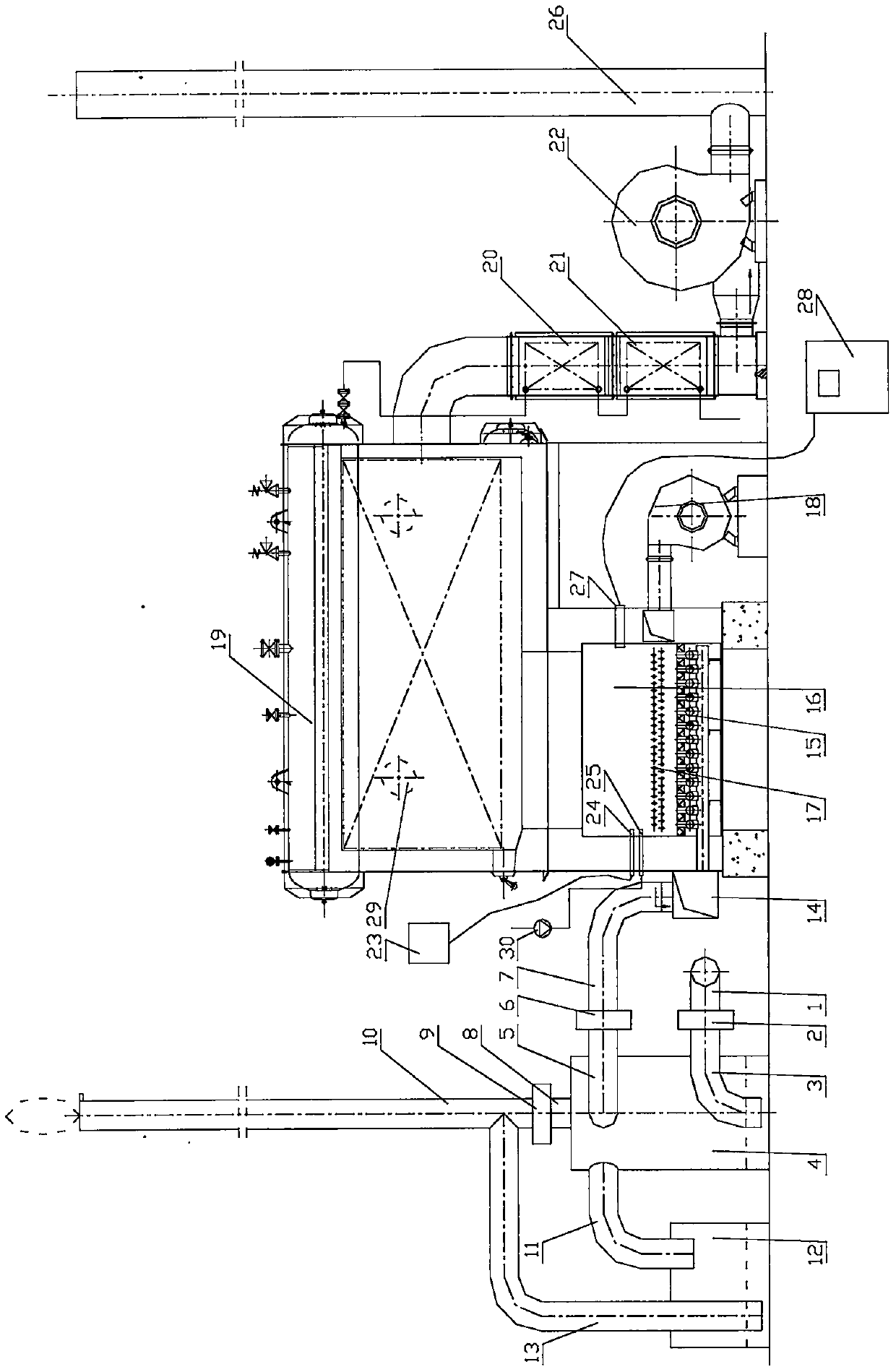

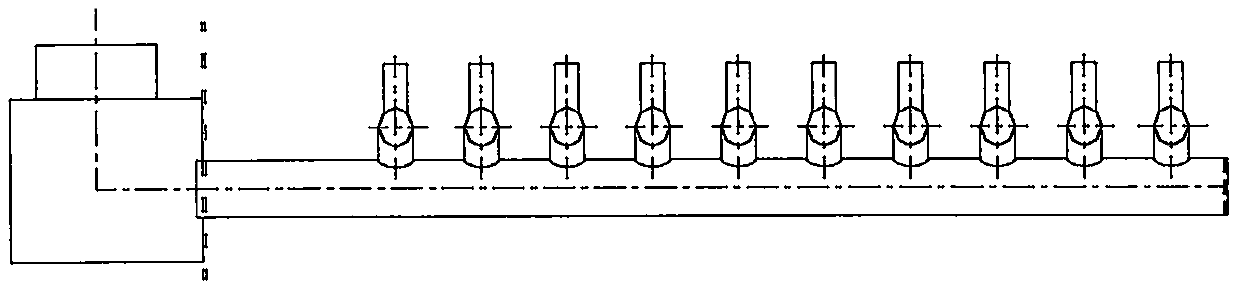

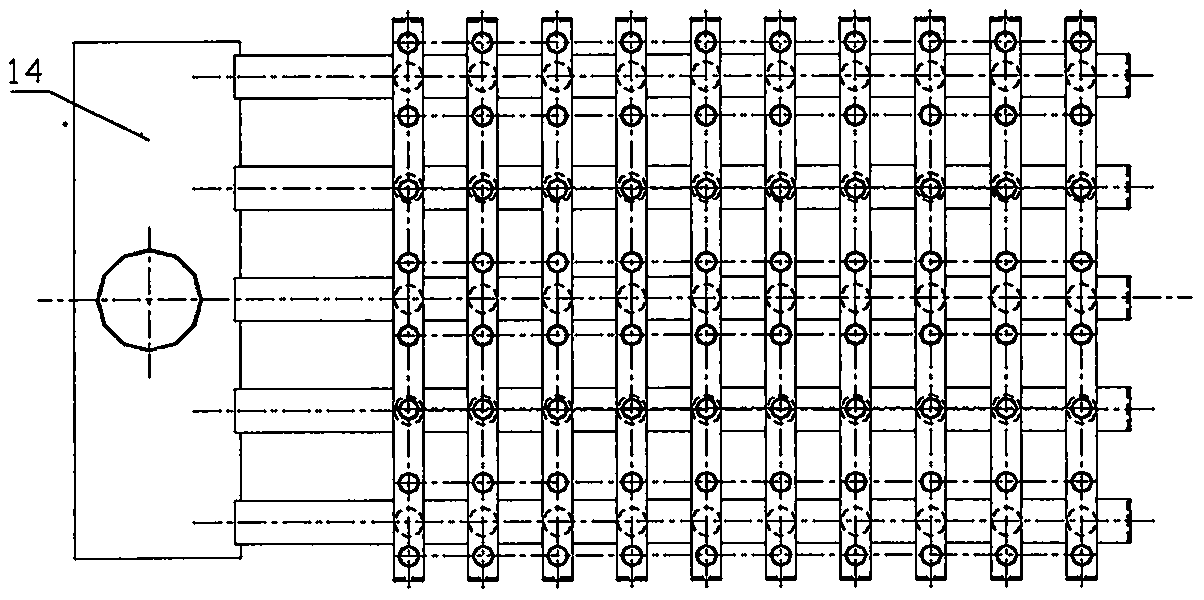

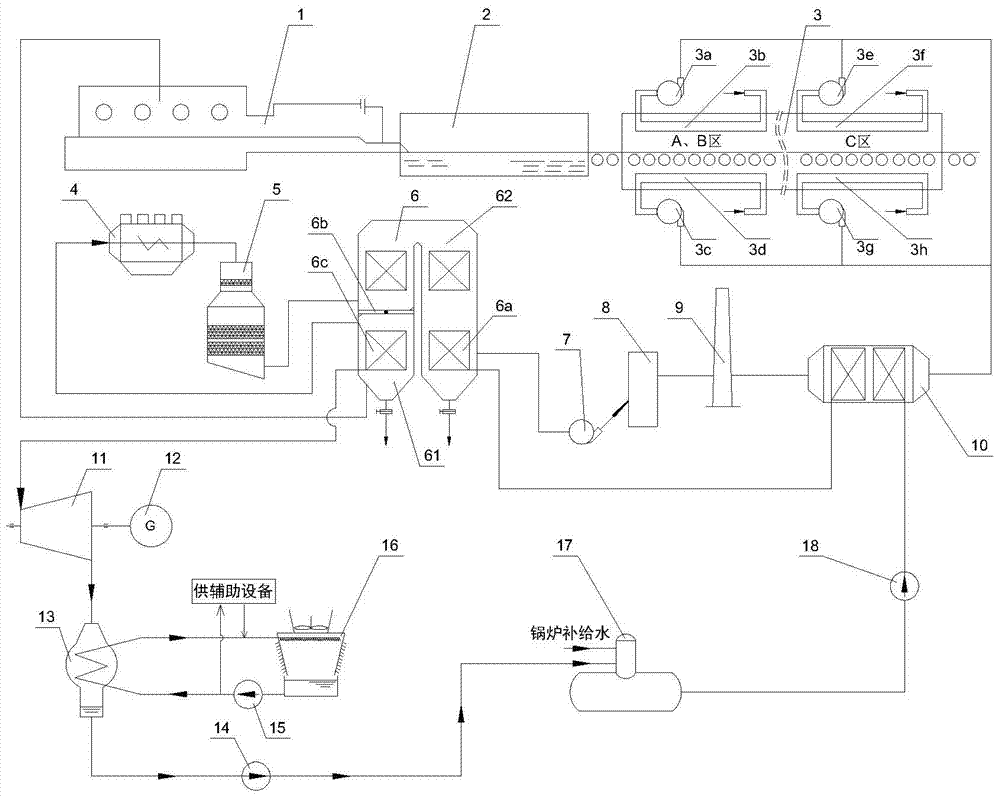

The invention discloses a system and method for power generating by jointly recovering the waste heat of a flue gas of a sintering machine and an exhaust gas of a cooling machine, belonging to the technical field of power generation by using waste sintering heat of a steel and iron plant. The power generating system comprises a sintering machine flue gas waste heat utilizing system, a cooling machine exhaust gas waste heat utilizing system, a turbine generating system and a relevant auxiliary system, wherein a main waste heat discharging boiler is utilized to recover the waste heat of the flue gas of a high-temperature segment of the tail part of the sintering machine; a cooling machine waste heat boiler is utilized to recover the waste heat of the high-temperature exhaust gas of the cooling machine; and a high-temperature electric butterfly valve is arranged between the high-temperature segment and a low-temperature segment of a large flue positioned on the tail part of the sintering machine to prevent the wind pickup temperature of the flue gas from being reduced because a low-temperature flue gas and a high-temperature flue gas are directly mixed so as to ensure the high-temperature flue gas to enter the main waste heat discharging boiler for waste heat recovery. The system and method effectively utilizes the waste heat resources of the high-temperature flue gas of the machine tail of the sintering machine and a hot gas of the high-temperature segment of the cooling machine, enhances the waste heat recovery and utilization efficiency of a sintering process and increases the power generation capacity of the waste heat power generating system.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

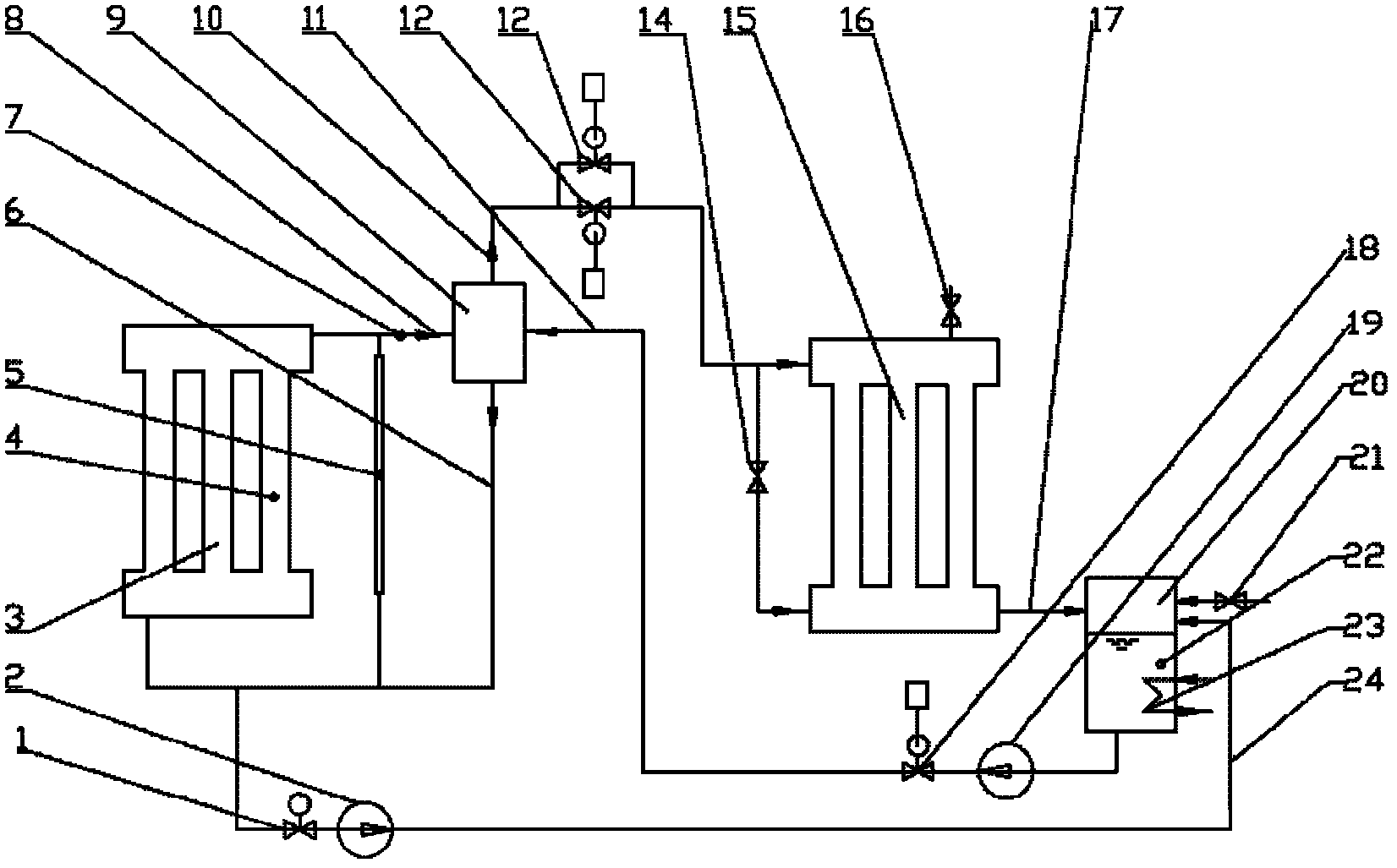

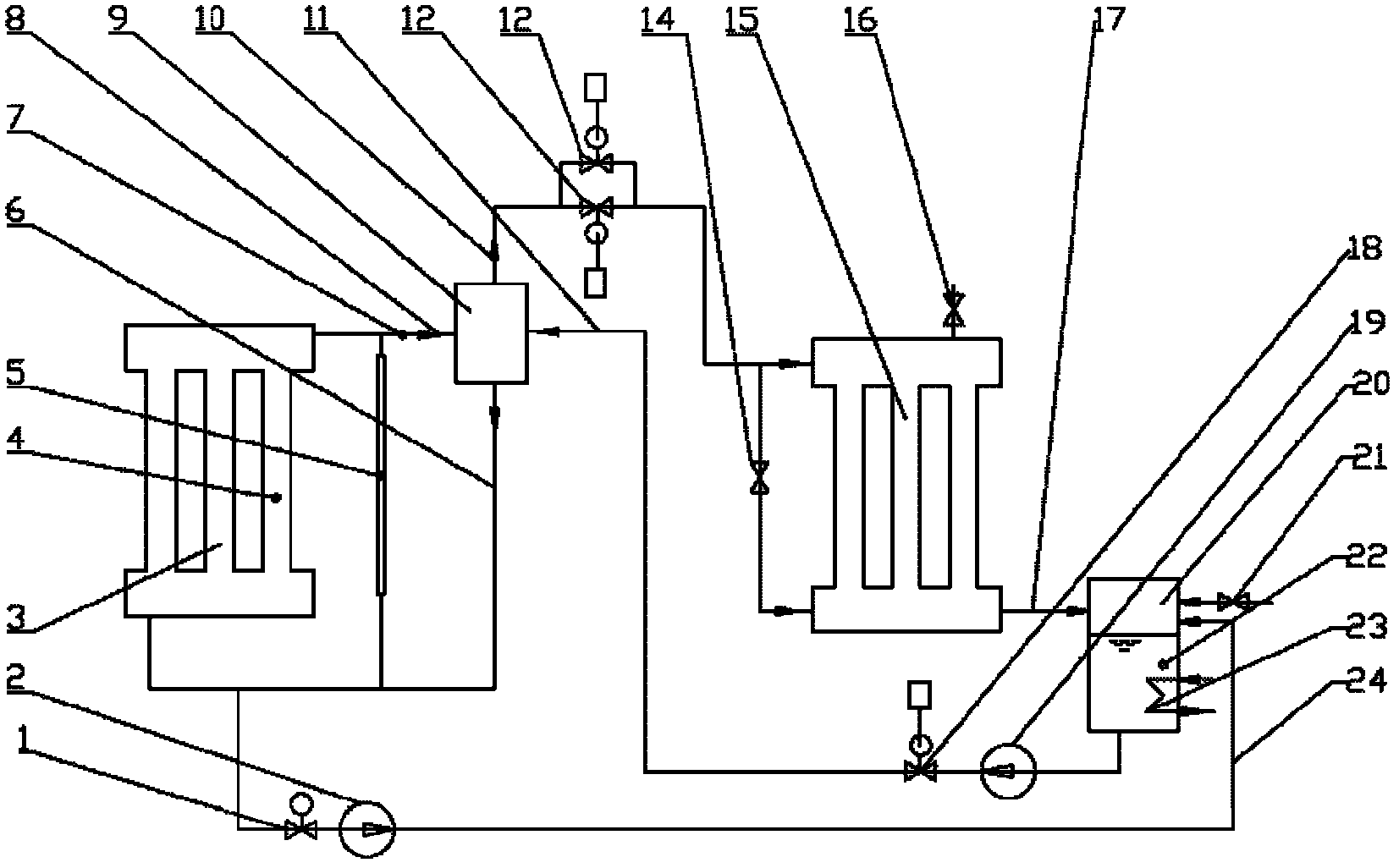

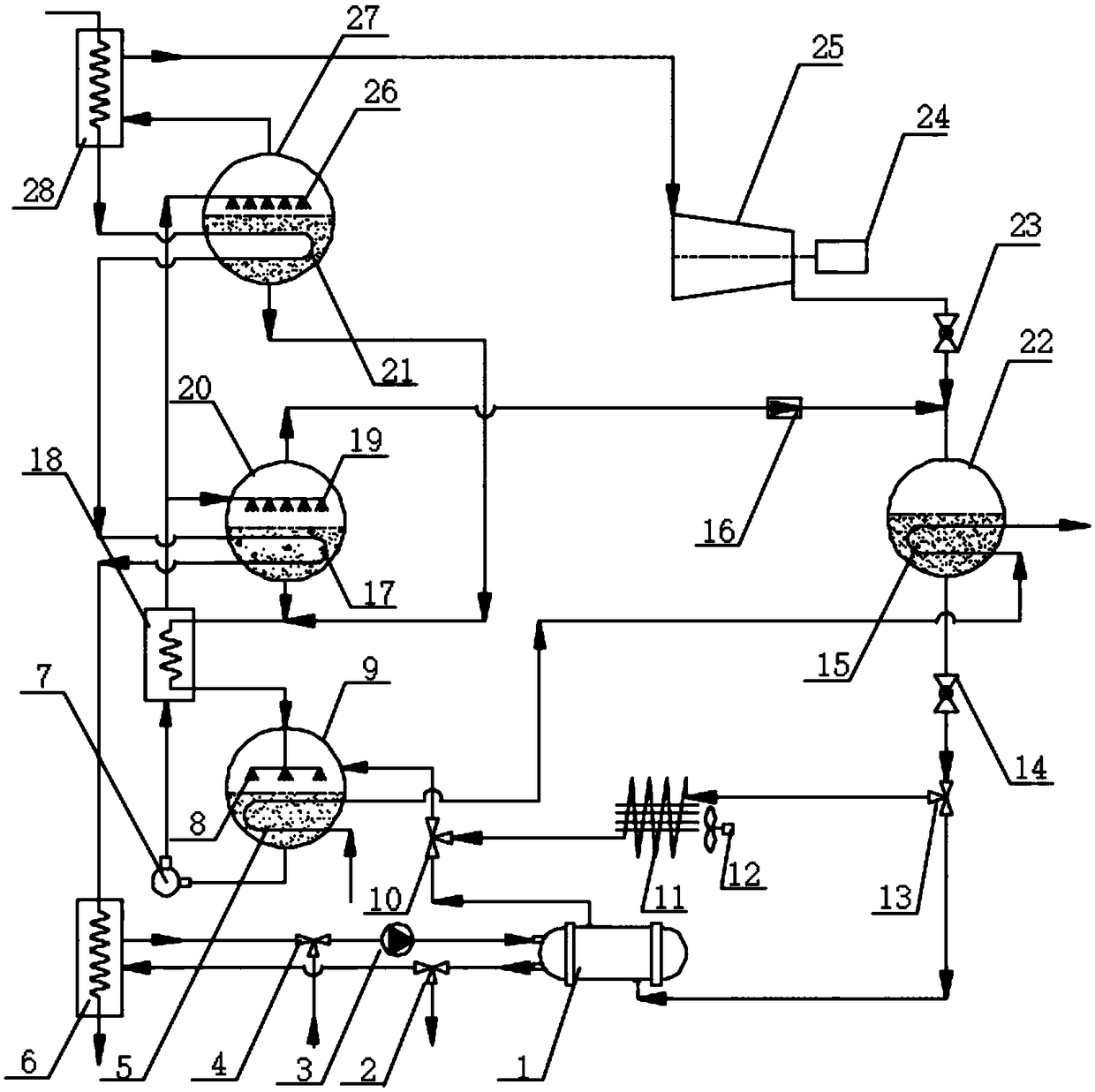

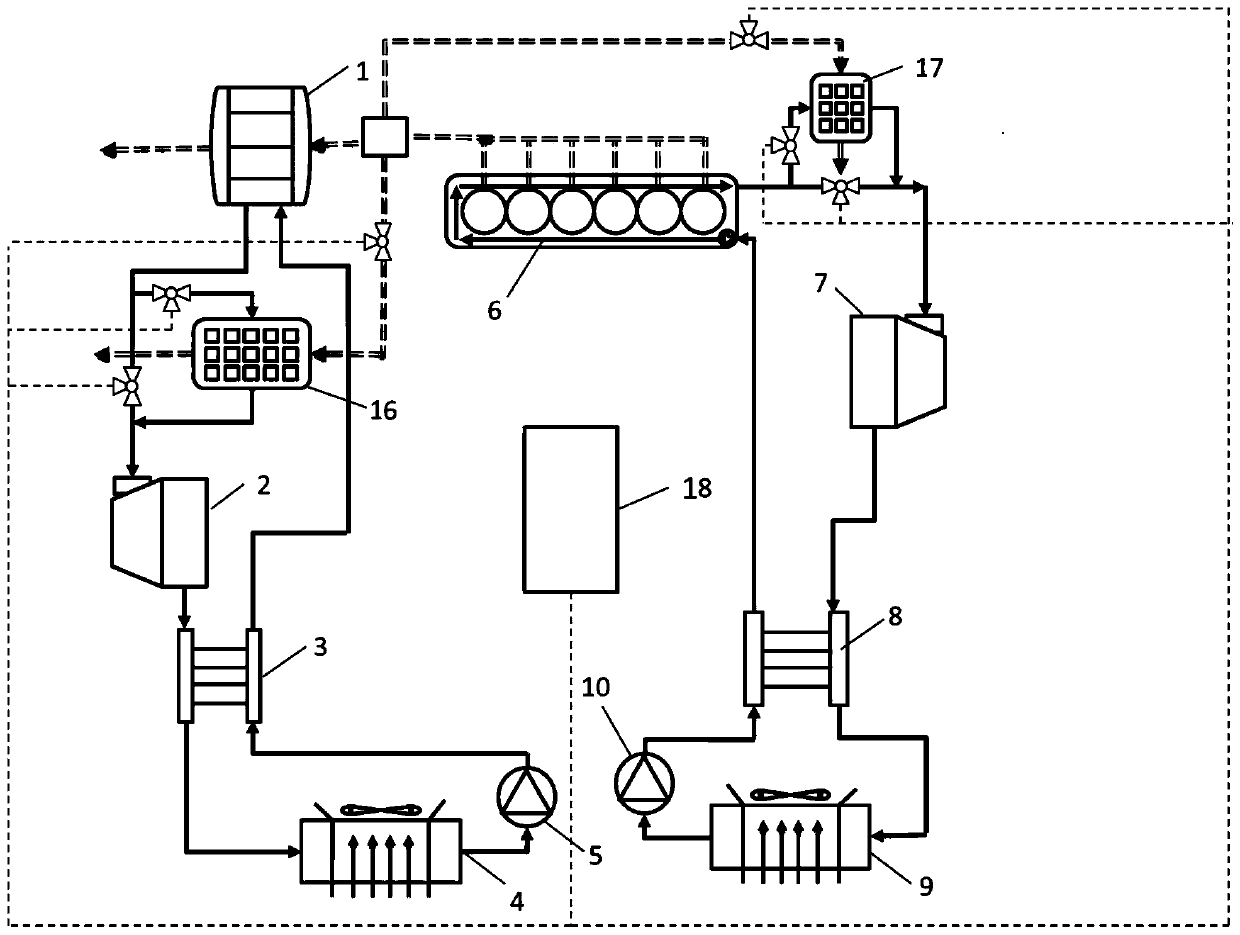

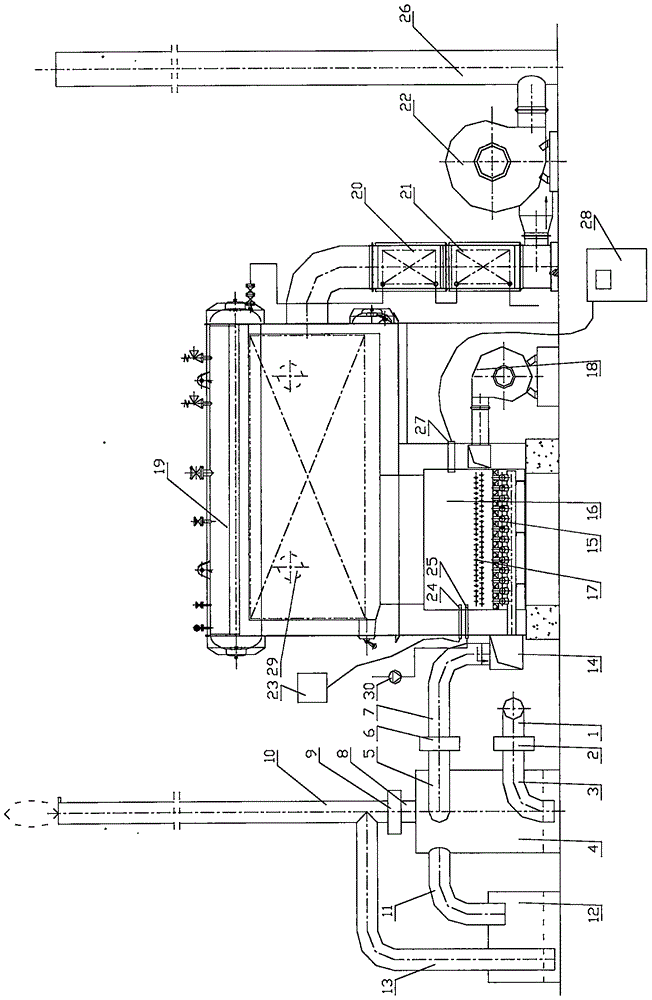

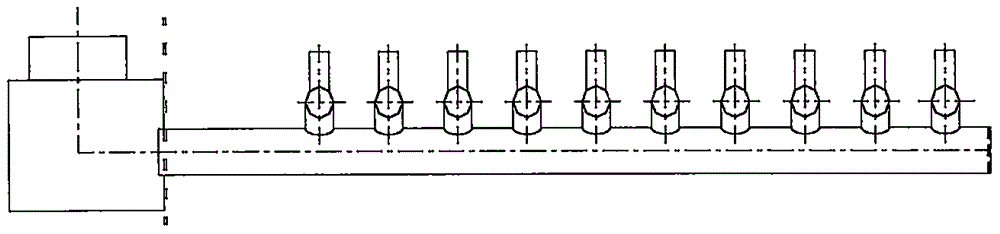

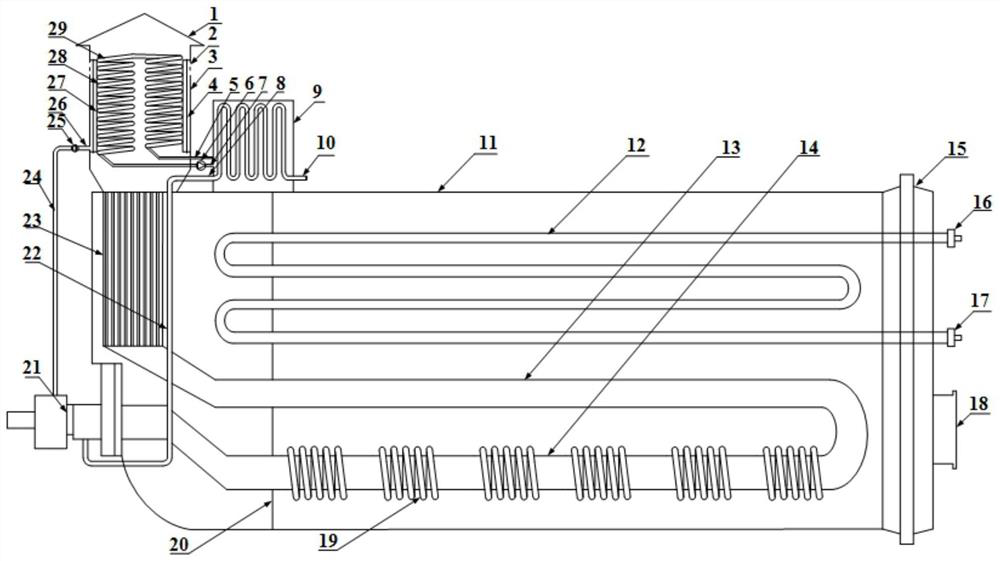

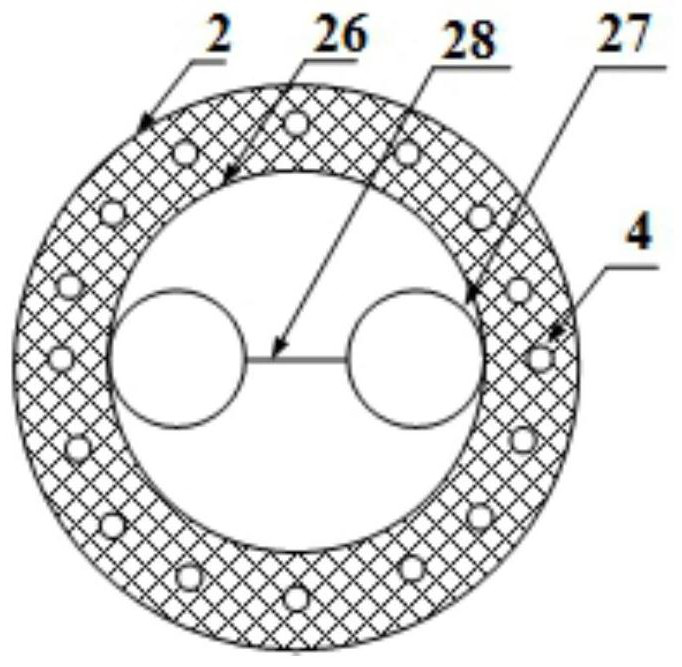

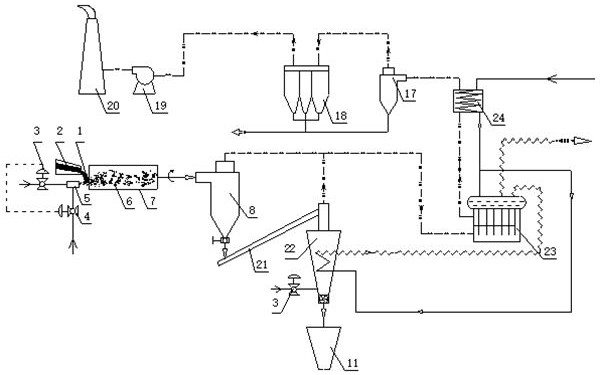

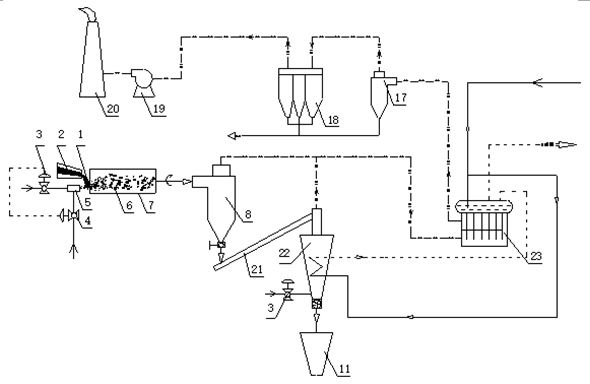

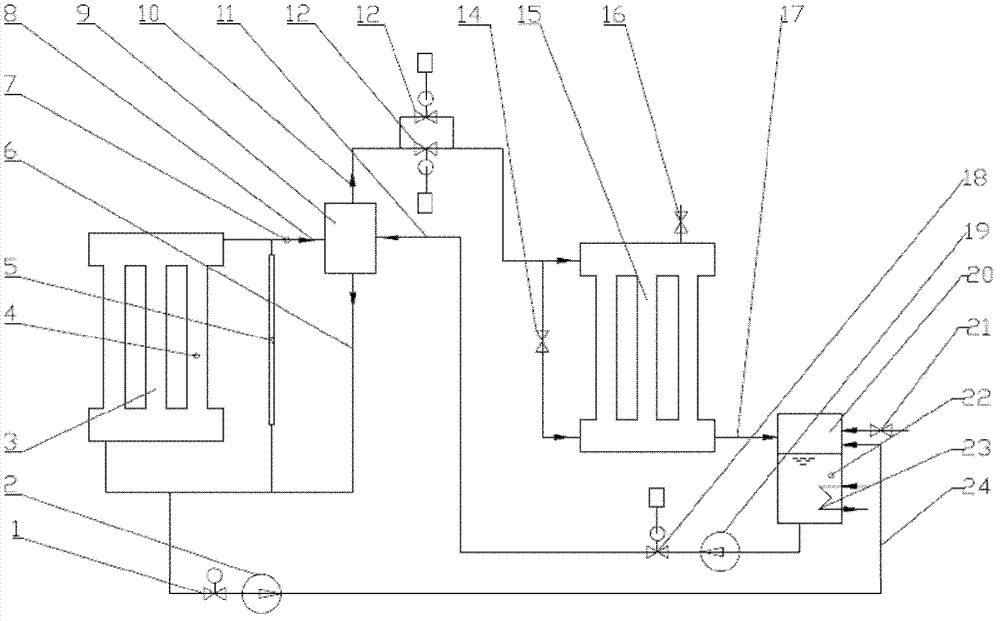

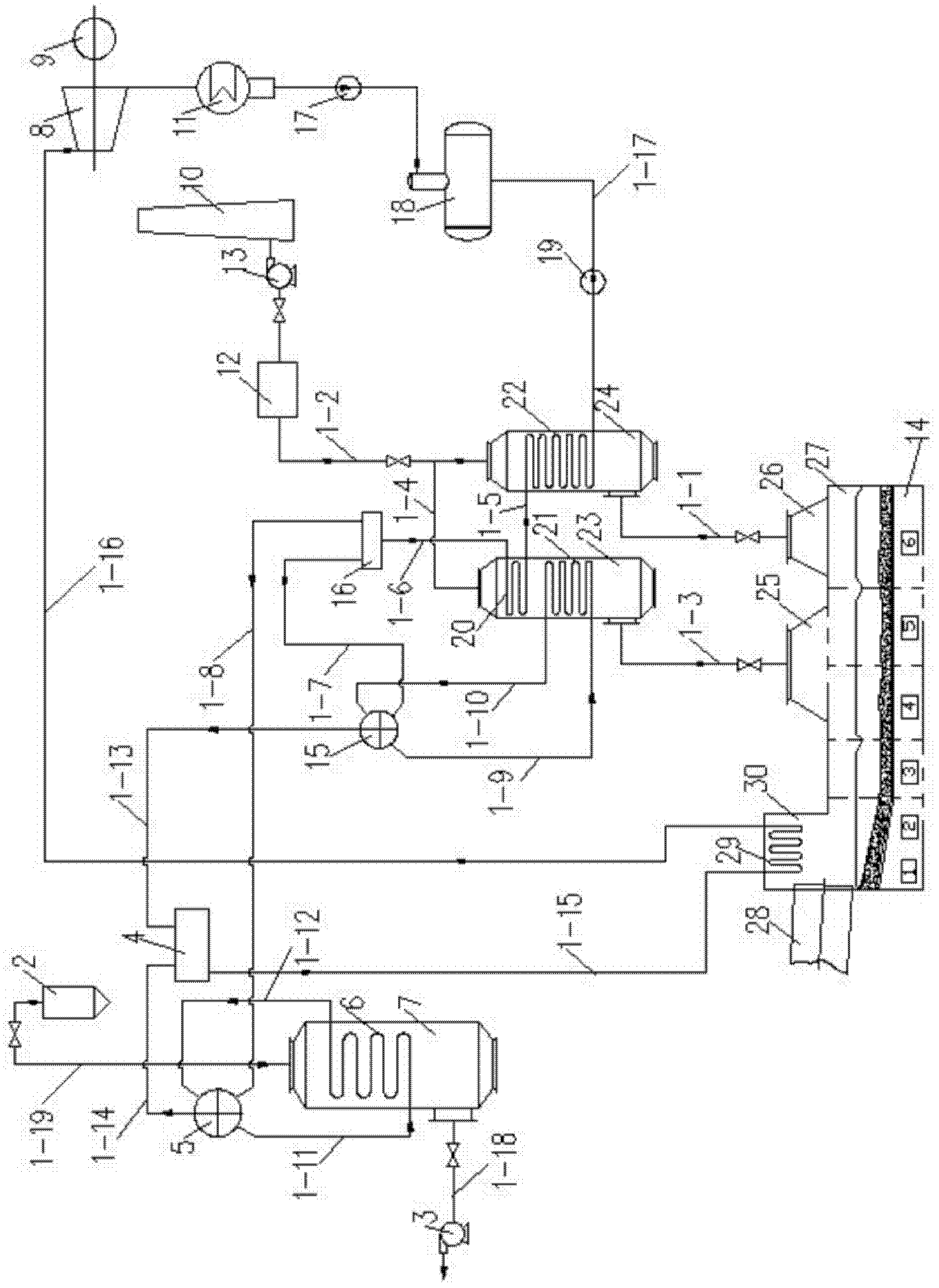

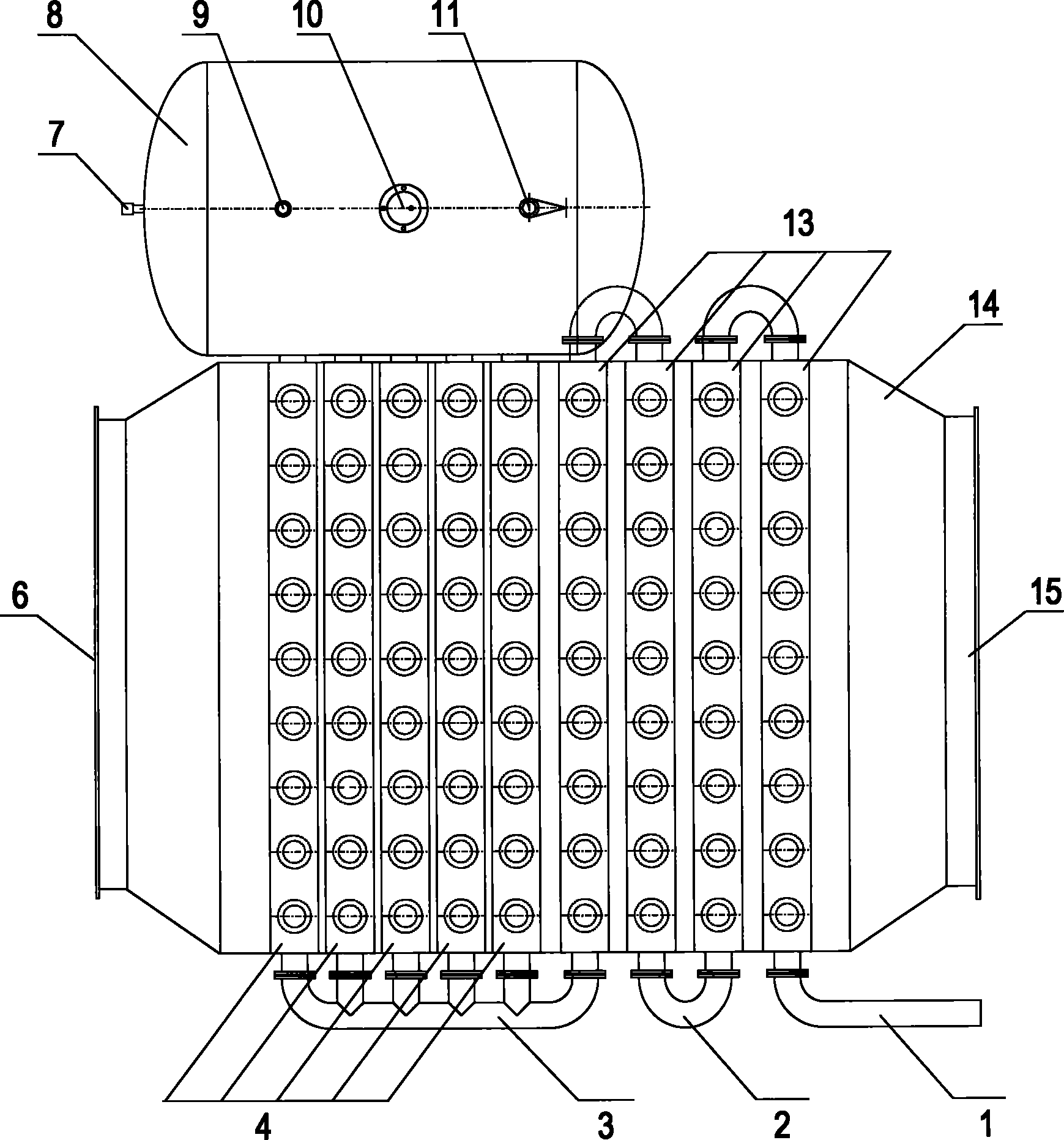

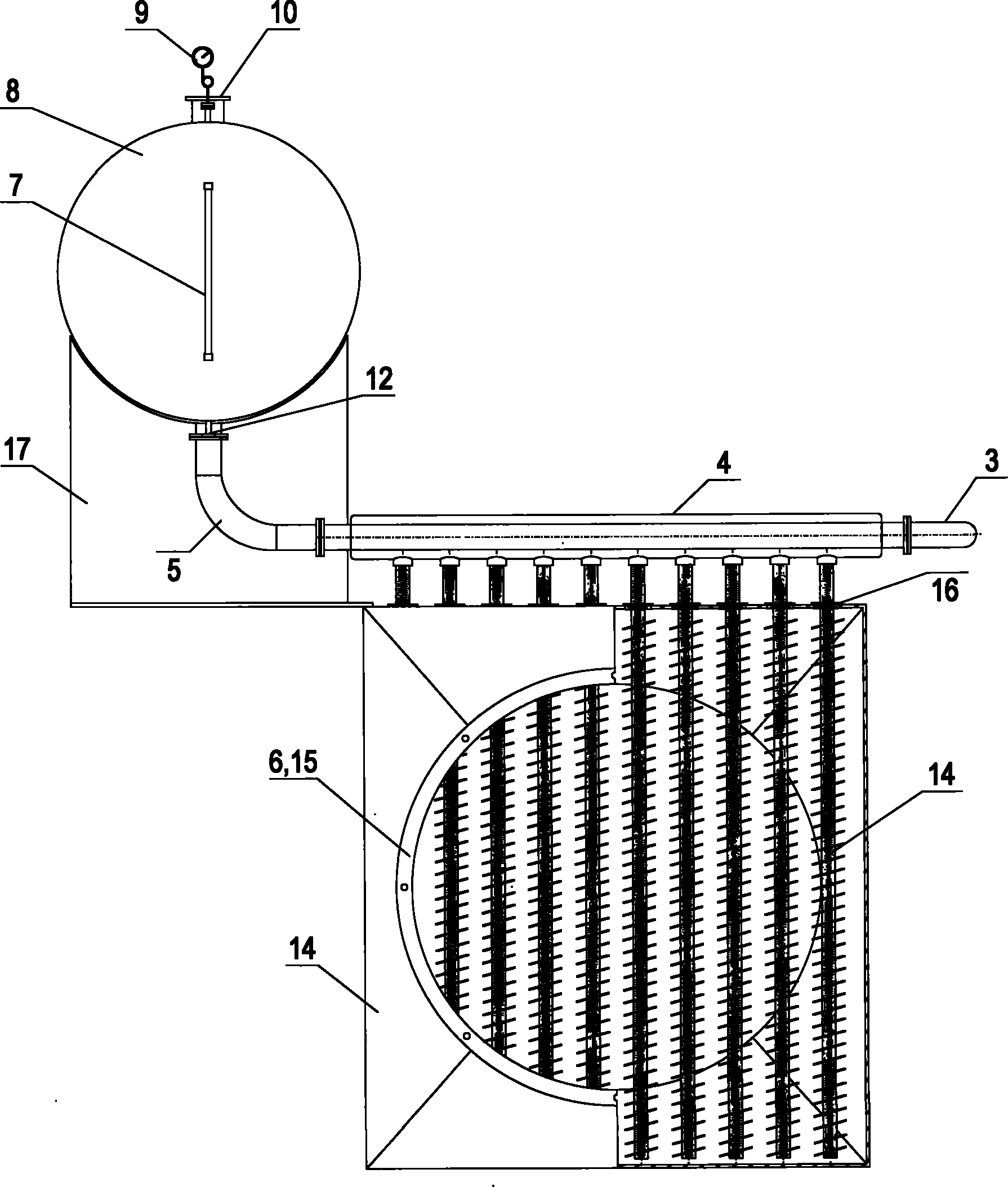

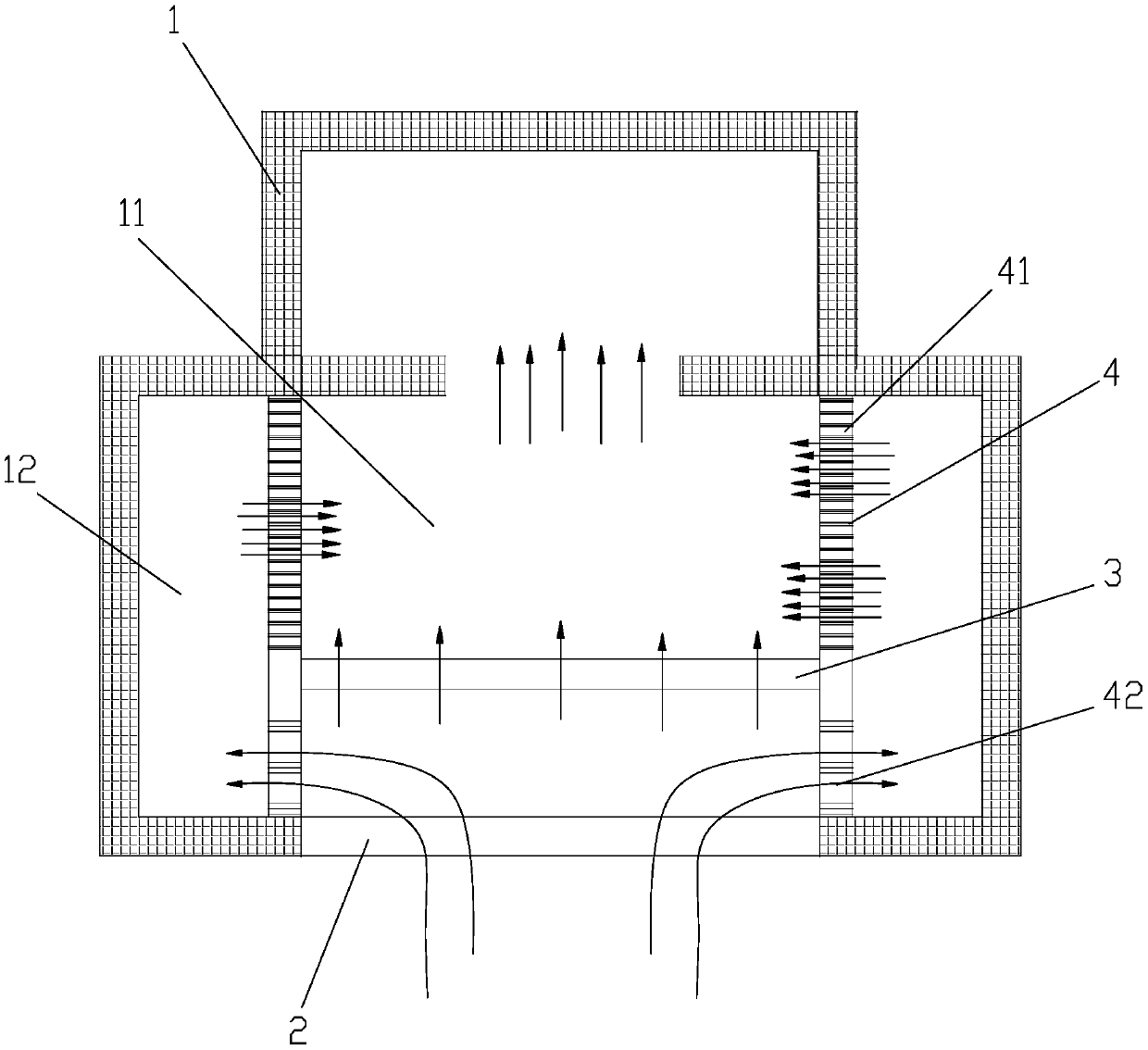

Branch control phase inversion heat exchange system and method based on vapor-liquid heat exchanger

ActiveCN102252543AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersEngineeringLiquid storage tank

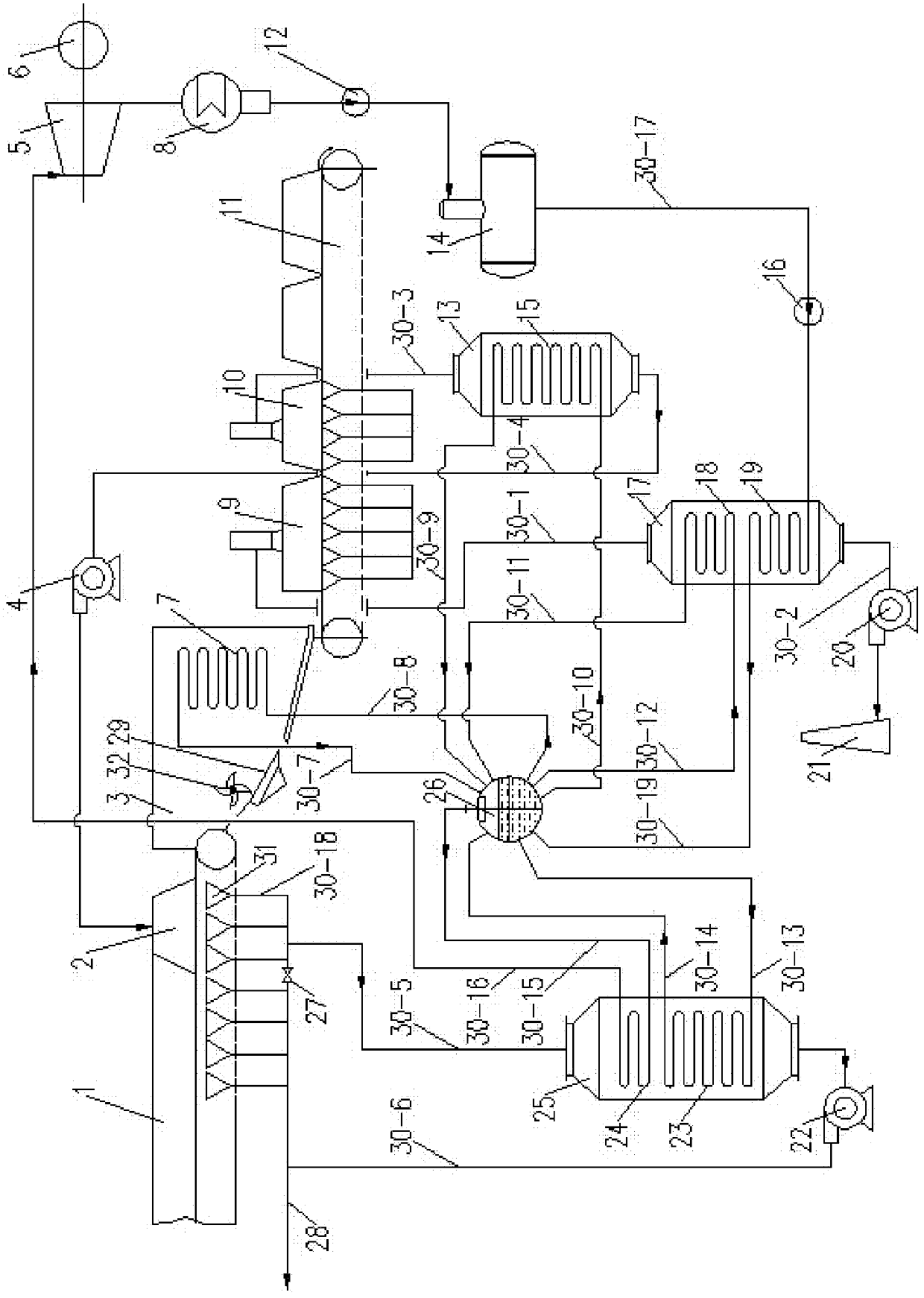

The invention relates to a branch control phase inversion heat exchange system and a branch control phase inversion heat exchange method based on a vapor-liquid heat exchanger. The system comprises a liquid storage tank (20), a heat source heat exchanger (3), a cold source heat exchanger (15) and a vapor-liquid heat exchanger (9); an upper collection tank of the heat source heat exchanger (3) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet steam pipe (8); a vapor-liquid heat exchanger outlet steam pipe (10) which is arranged on the vapor-liquid heat exchanger (9) is divided into two branches which are communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (15); the lower collection tank of the cold source heat exchanger (15) is communicated with the upper part of the liquid storage tank (20) through a cold source heat exchanger liquid outlet pipe (17); the bottom of the liquid storage tank (20) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet condensation liquid pipe (11); and the vapor-liquid heat exchanger (9) is communicated with a lower collection tank of the heat source heat exchanger (3) through a heat exchanger outlet condensation liquid pipe (6). The branch control phase inversion heat exchange system can solve the phenomena of overcooling and overheating and improve heat exchanging efficiency.

Owner:SHANXI SANHESHENG IND TECH

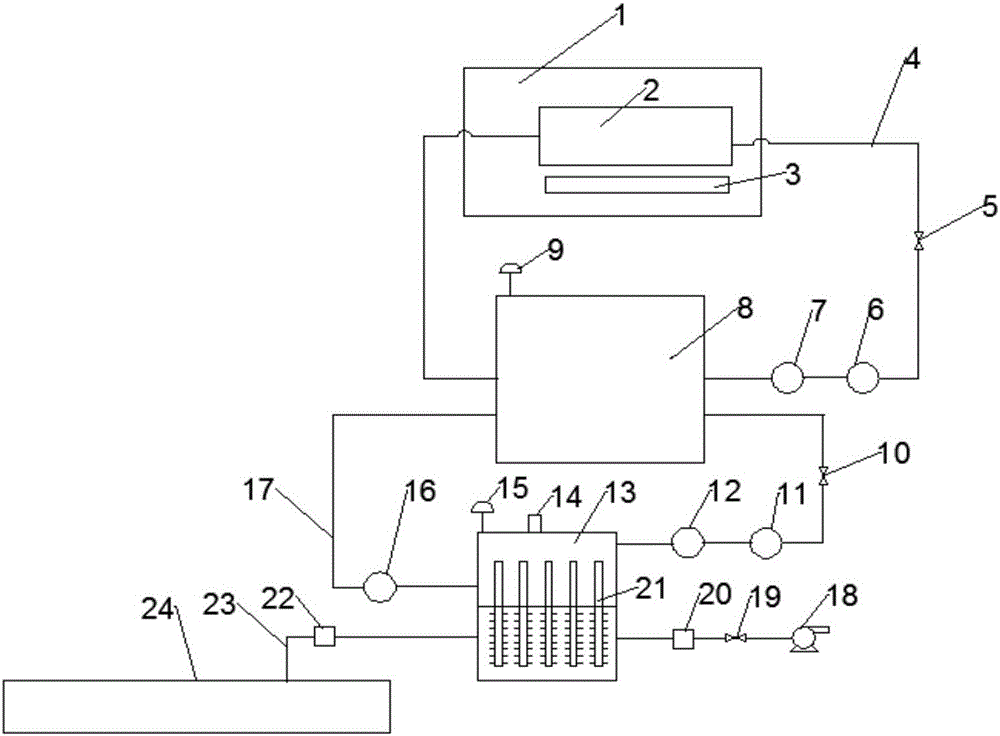

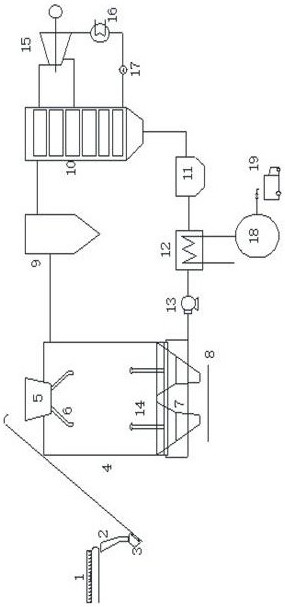

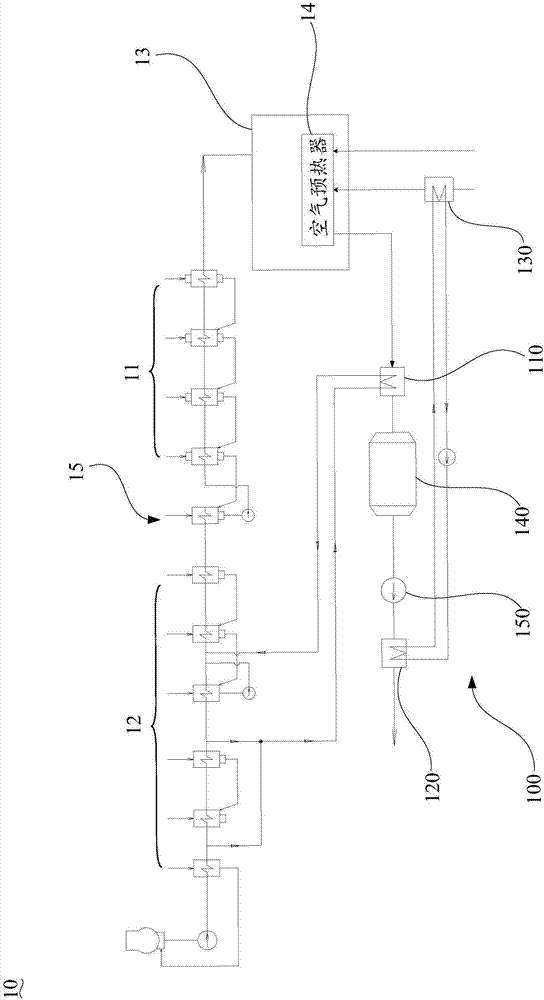

Low grade residual heat continuous recycle system for kiln

InactiveCN106403628ANo cloggingImprove the efficiency of waste heat recovery and utilizationDrying gas arrangementsIncreasing energy efficiencyWater leakageShell and tube heat exchanger

The invention provides a low grade residual heat continuous recycle system for a kiln, which is used for recycling low grade residual heat of the kiln. The low grade residual heat continuous recycle system comprises a heat pipe exchanger, a draught fan, a first water pump, a second water pump, a third water pump, a heat storage water tank and a drying room; the heat pipe exchanger is internally provided with a smoke section and a hot water section, wherein the kiln is communicated with the smoke section and the draught fan of the heat pipe exchanger through a smoke pipeline in sequence, the hot water section of the heat pipe exchanger, the first water pump, the heat storage water tank and the third water pump are communicated end to end through a first hot water pipeline in sequence, and the drying room, the second water pump and the upper end of the heat storage water tank are communicated end to end through a second hot water pipeline in sequence. The low grade residual heat of the kiln can be continuously stably recycled, comprehensive use efficiency is higher, problems of blockage of a water pipe and scrapping of a whole system caused by water leakage of one part of a traditional shell-and-tube heat exchanger are avoided, and safety and reliability are realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

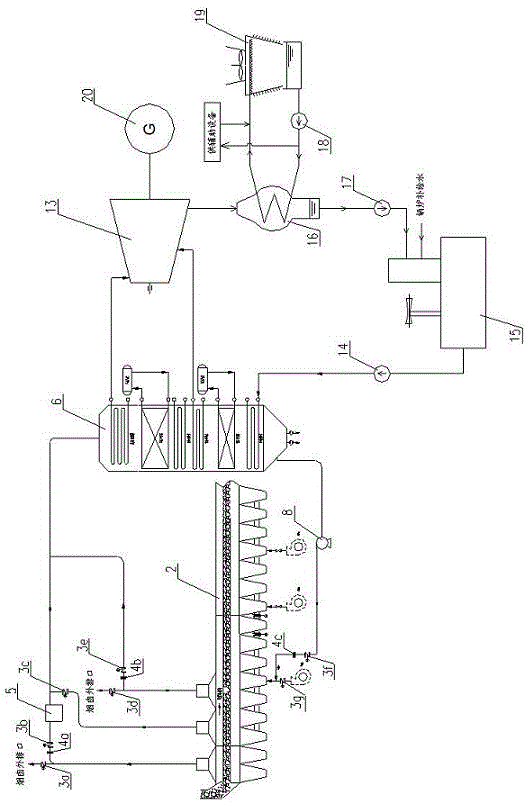

Cement kiln waste-heat utilization system and method for directly driving rotating equipment by turbine

ActiveCN104654816AAvoid energy lossImprove the efficiency of waste heat recovery and utilizationEnergy industryIncreasing energy efficiencyAutomotive engineeringGrinding mill

The invention provides a cement kiln waste-heat utilization system and a method for directly driving rotating equipment by a turbine. The system and the method belong to the technical field of cement kiln waste-heat utilization. The waste-heat utilization system comprises a waste-heat recovery device, a high-temperature fan turbine drive device, a kiln tail exhaust fan turbine drive device, a cement grinding mill turbine drive device and a circulating cooling water device. According to the system and the method, superheated steam generated by the cement kiln waste heat is utilized to directly drive rotating equipment such as a high-temperature fan, a kiln tail exhaust fan and a cement grinding mill, the energy loss during the multistep energy transformation process from heat energy to electric energy to kinetic energy of waste heat power generation is avoided, and the cement kiln waste heat recovery and utilization efficiency is effectively improved.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Flue gas waste heat recycling system and method

PendingCN113587187AFull recoveryReduce consumptionLighting and heating apparatusWaste gas energyFlue gasAbsorption heat pump

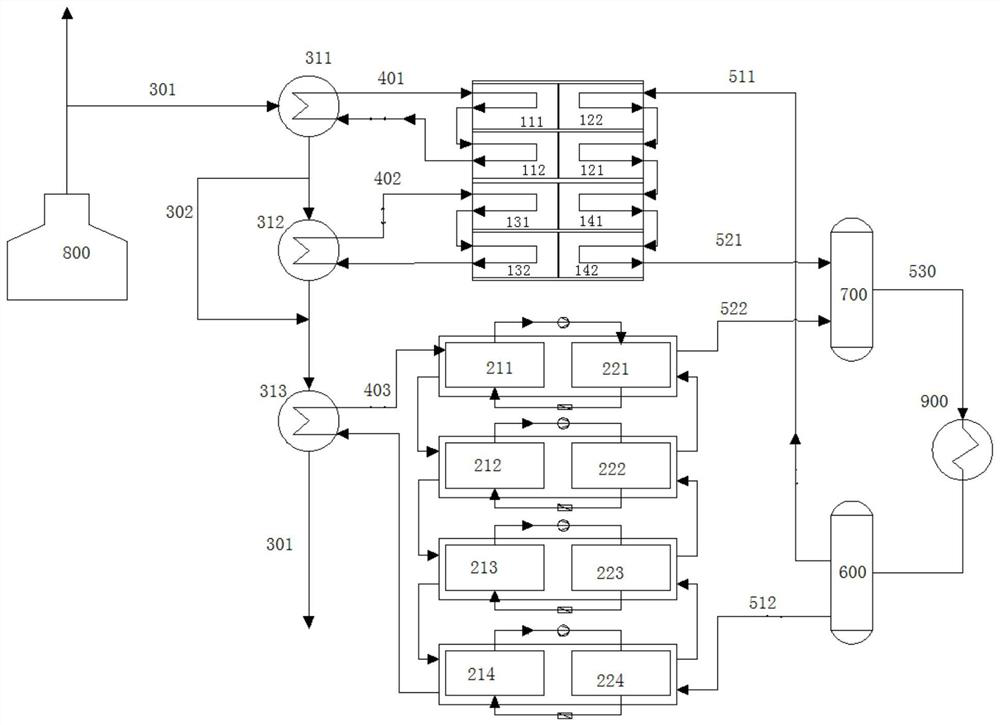

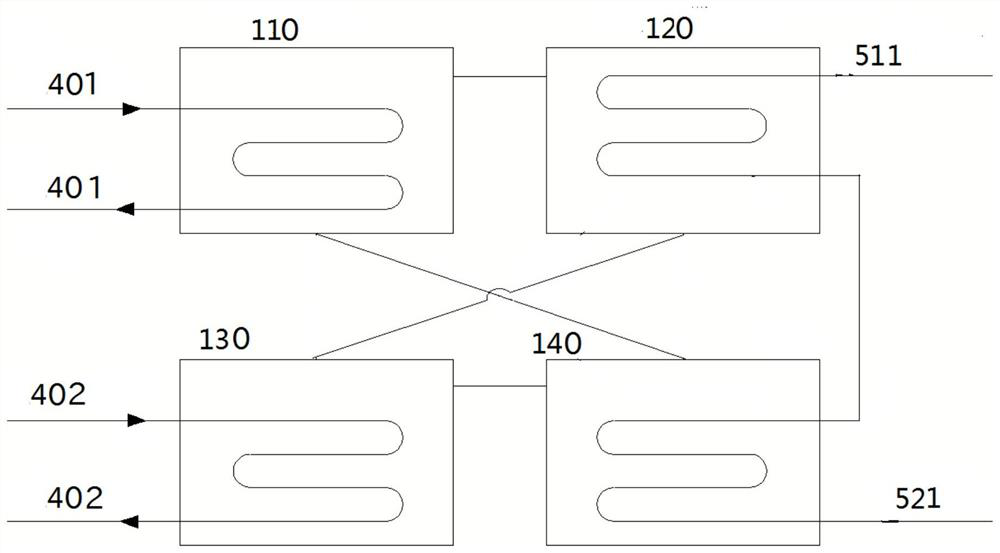

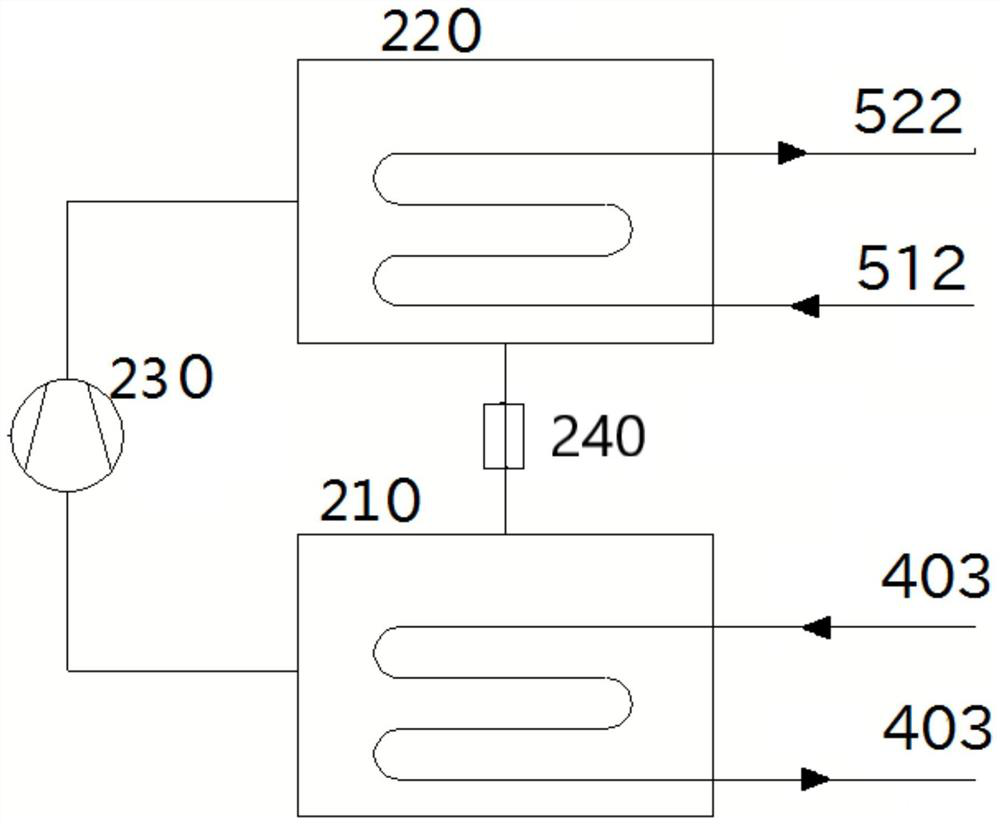

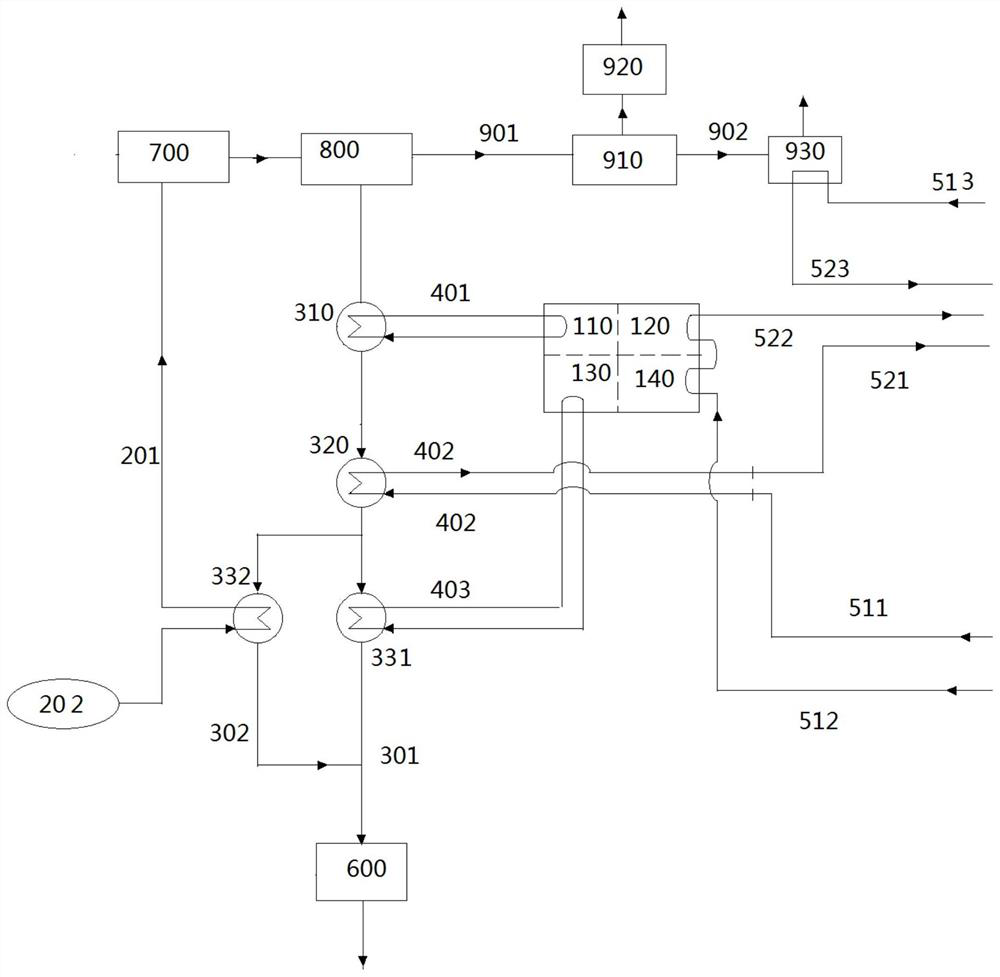

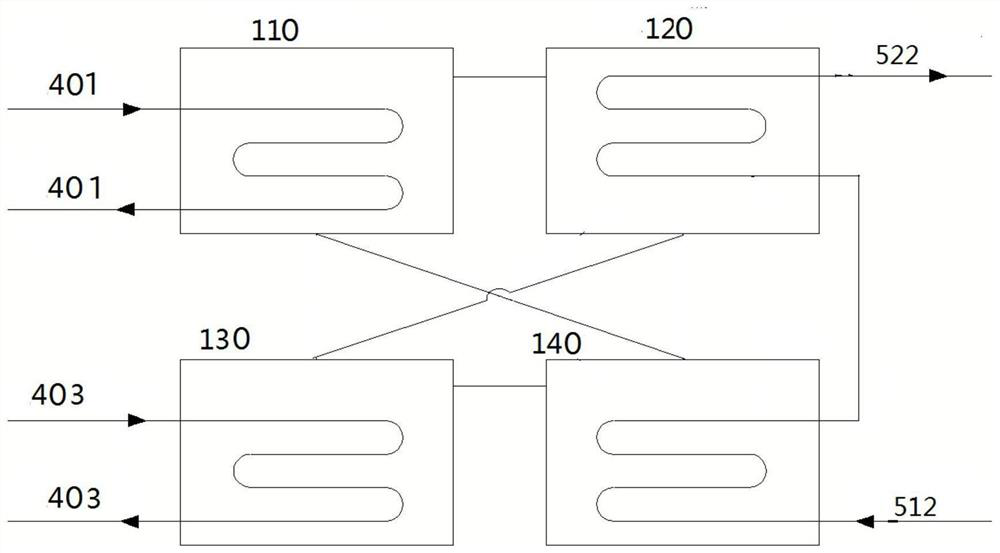

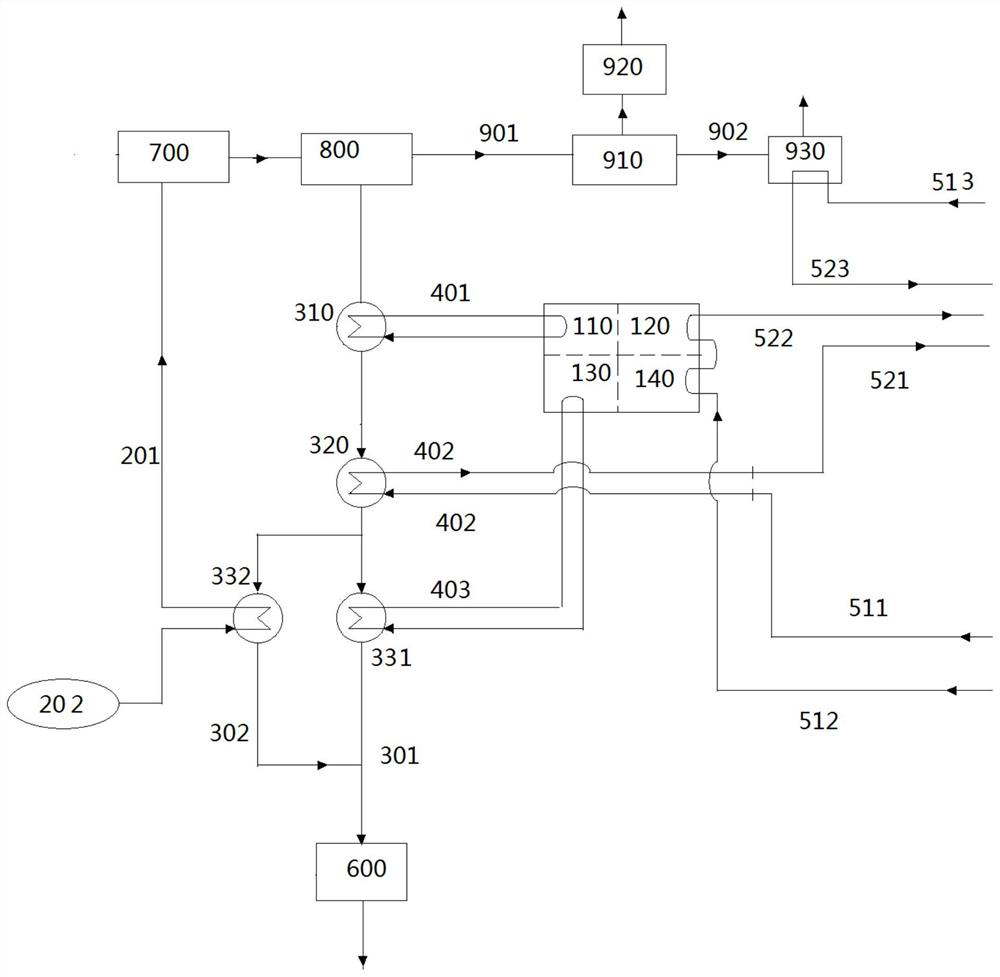

The invention discloses a flue gas waste heat recycling system comprising a smoke exhaust pipe (301), flue gas sequentially enters a first-stage heat exchanger (311), a second-stage heat exchanger (312) and a third-stage heat exchanger (313) through the smoke exhaust pipe to release heat, and first-stage waste heat water in a first-stage waste heat water circulating pipe (401), second-stage waste heat water in a second-stage waste heat water circulating pipe (402) and third-stage waste heat water in a third-stage waste heat water circulating pipe (403) are heated correspondingly; the first-stage waste heat water enters an absorption heat pump generator (110) for cooling through the first-stage waste heat water circulating pipe, the second-stage waste heat water enters an absorption heat pump evaporator (130) for cooling through the second-stage waste heat water circulating pipe, and the third-stage waste heat water enters a compression heat pump evaporator (210) for cooling through the third-stage waste heat water circulating pipe; and heat supply network water sequentially enters an absorption heat pump to be heated through a first heat supply network water return pipe (511), and the heat supply network water further enters a compression heat pump to be heated through a second heat supply network water return pipe (512). The flue gas waste heat energy is utilized in a gradient mode, and heat is recycled more sufficiently.

Owner:吉林宏日新能源股份有限公司

Stepped waste heat recycling device and working method

ActiveCN108895708AAchieve effectImprove energy efficiency ratioMachines/enginesFluid circulation arrangementWater vaporSuperheater

The invention discloses a stepped waste heat recycling device and a working method. The stepped waste heat recycling device comprises an absorption-type heat pump system and a heat-work conversion system. The device is integrated with an absorption-type heat pump and heat engine technology and is driven by a waste heat working medium, the waste heat working medium sequentially passes through a superheater, a high-pressure generator, a low-pressure generator and a waste heat recoverer, high-temperature and high-pressure steam produced by the high-pressure generator of the device is super-heated, then a turbine motor expands to output mechanical work for generating power, the dead steam exhausted by the turbine motor and the high-temperature and high-pressure steam produced by the low-pressure generator enters a condenser to be condensed and to release heat for heat supply and heating in winter, a steam generator produces cold energy for refrigeration and cooling, and the effects of combined heat and power generation in winter and combined cold and power generation in summer are achieved. The device fully recovers waste heat energy of a working medium in a stepped waste heat recycling mode, makes waste heat mass-energy utilization most economized, effectively reduces atmosphere heat pollution while the energy utilization rate is improved and has the lots of advantages of saving energy, reducing emissions, economic in operation and wide in application range.

Owner:JIANGSU UNIV OF SCI & TECH

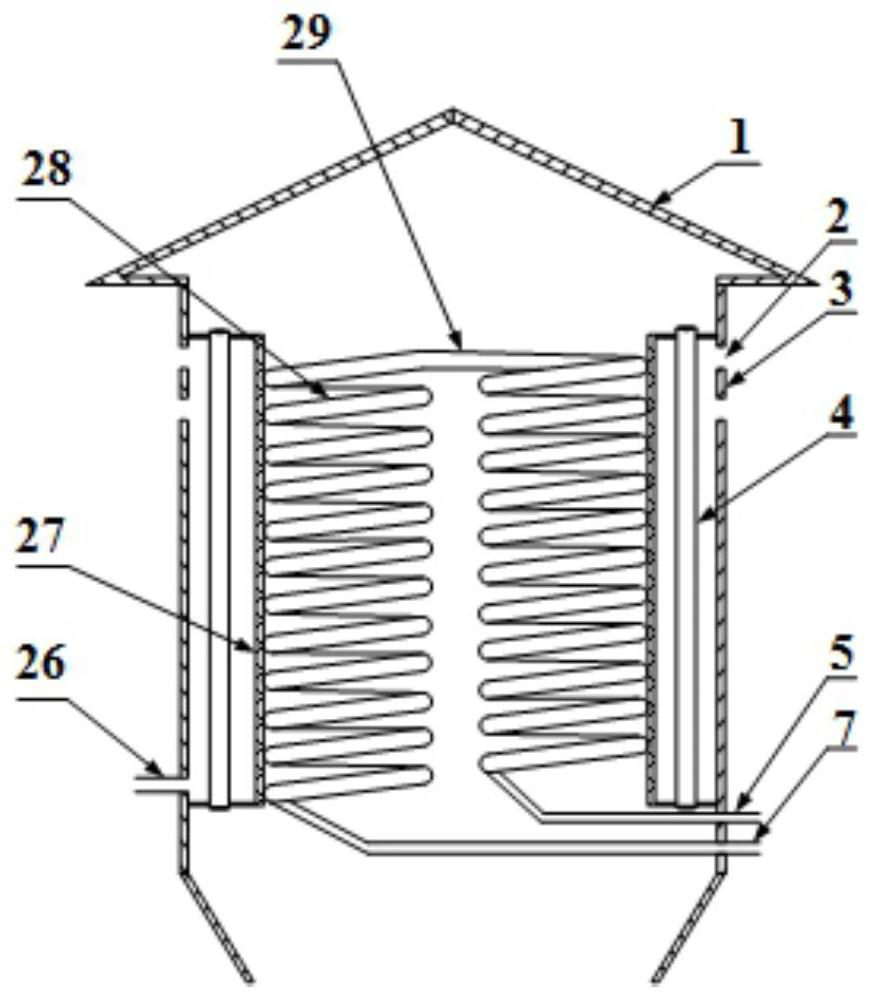

Exhaust gas waste heat energy-saving recovery system

InactiveCN104121789ASimple structureImprove the efficiency of waste heat recovery and utilizationStationary tubular conduit assembliesHeat exchange apparatusWater flowExhaust fumes

The invention discloses an exhaust gas waste heat energy-saving recovery system. The exhaust gas waste heat energy-saving recovery system comprises an exhaust gas channel and a water flow channel, wherein the exhaust gas channel is in the shape of a long barrel, a gas inlet and a gas outlet are formed in the two ends of the exhaust gas channel respectively, the water flow channel is arranged in the exhaust gas channel, the water flow channel is a continuously bent coil pipe, a water inlet and a water outlet are formed in the two ends of the water flow channel respectively, and the water inlet and the water outlet penetrate through the pipe wall of the exhaust gas channel. Due to the mode, the exhaust gas waste heat energy-saving recovery system is simple and reasonable in structure and high in waste heat recovery and utilization efficiency, and a heated body can have a high temperature.

Owner:无锡博成洋超声设备有限公司

Biomass combined heat and power generation flue gas waste heat recycling system and method

PendingCN113958992AFull recoveryFully recycleBioreactor/fermenter combinationsBiological substance pretreatmentsFlue gasCogeneration

The invention discloses a biomass combined heat and power generation flue gas waste heat recycling system. Flue gas sequentially enters a first-stage heat exchanger (310), a second-stage heat exchanger (320) and a third-stage heat exchanger (330) through a smoke exhaust pipe (301) to heat primary waste heat water and third-stage waste heat water in a first-stage waste heat water circulating pipe (401) and a third-stage waste heat water circulating pipe (403), and finally the flue gas is discharged into a biogas digester; the primary waste heat water enters an absorption heat pump generator (110) to be cooled; the third-stage waste heat water enters an absorption heat pump evaporator (130) to be cooled; heat supply network water enters the second-stage heat exchanger (320) through a heat supply network water first return pipe (511) and a second-stage waste heat water circulating pipe (402) to be heated and then is converged into a heat supply network; the heat supply network water sequentially enters an absorption heat pump absorber (140) and an absorption heat pump condenser (120) through a second heat supply network water return pipe (512) to be heated and then is converged into the heat supply network; and external air (200) enters a third-stage heat exchanger second unit (332) through an air inlet pipe (201) to be heated and then enters a drying device (700).

Owner:吉林宏日新能源股份有限公司

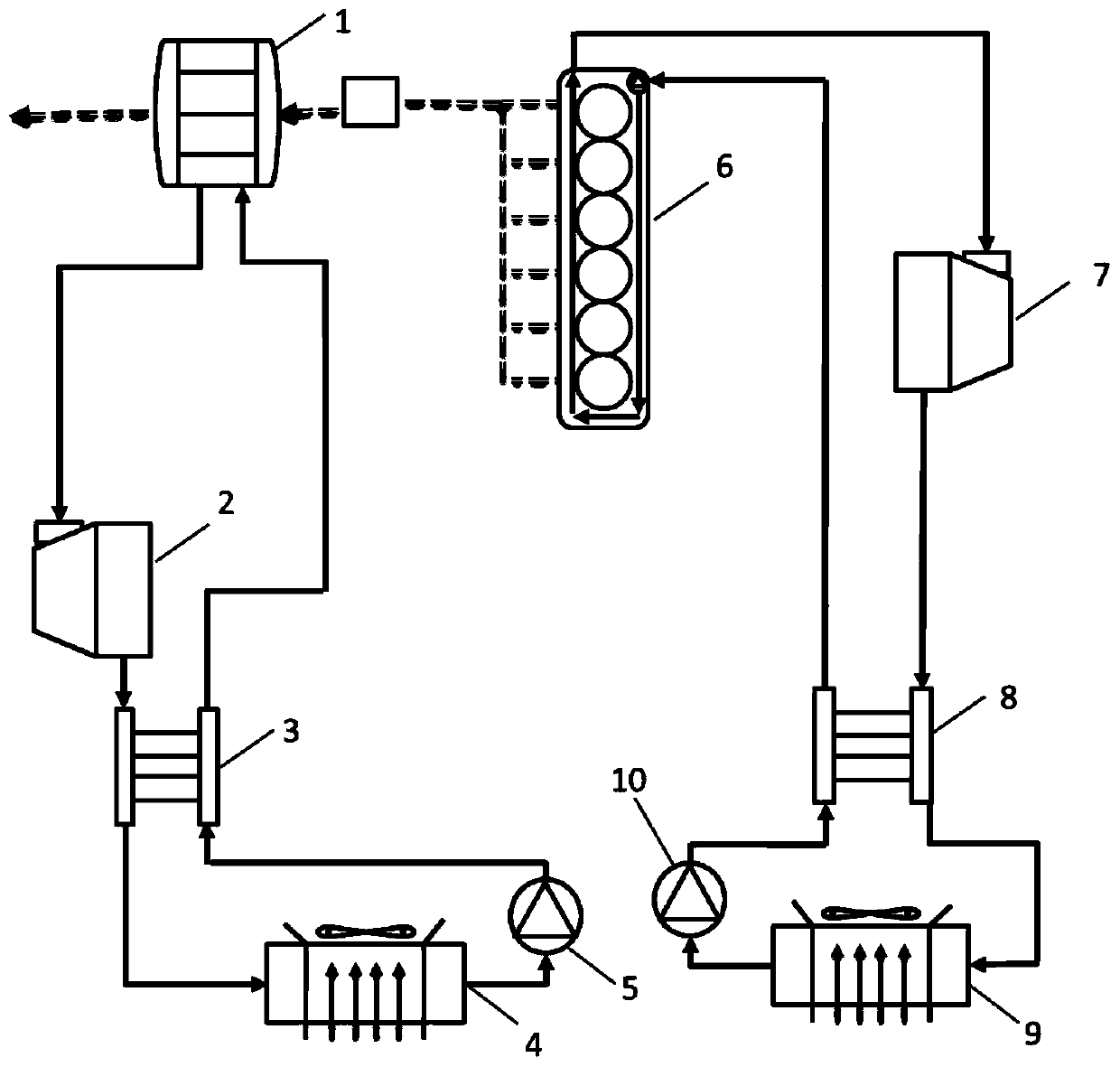

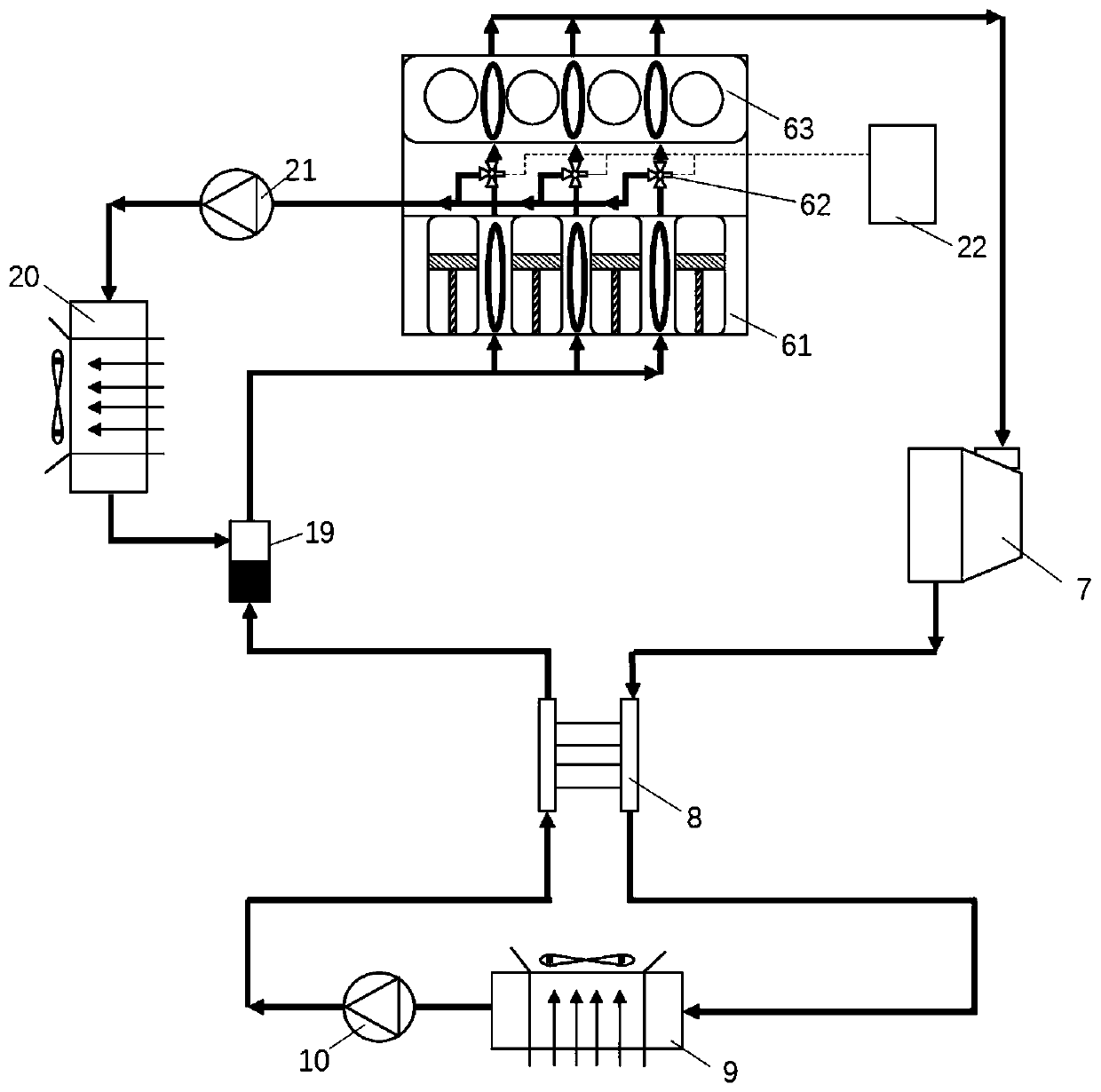

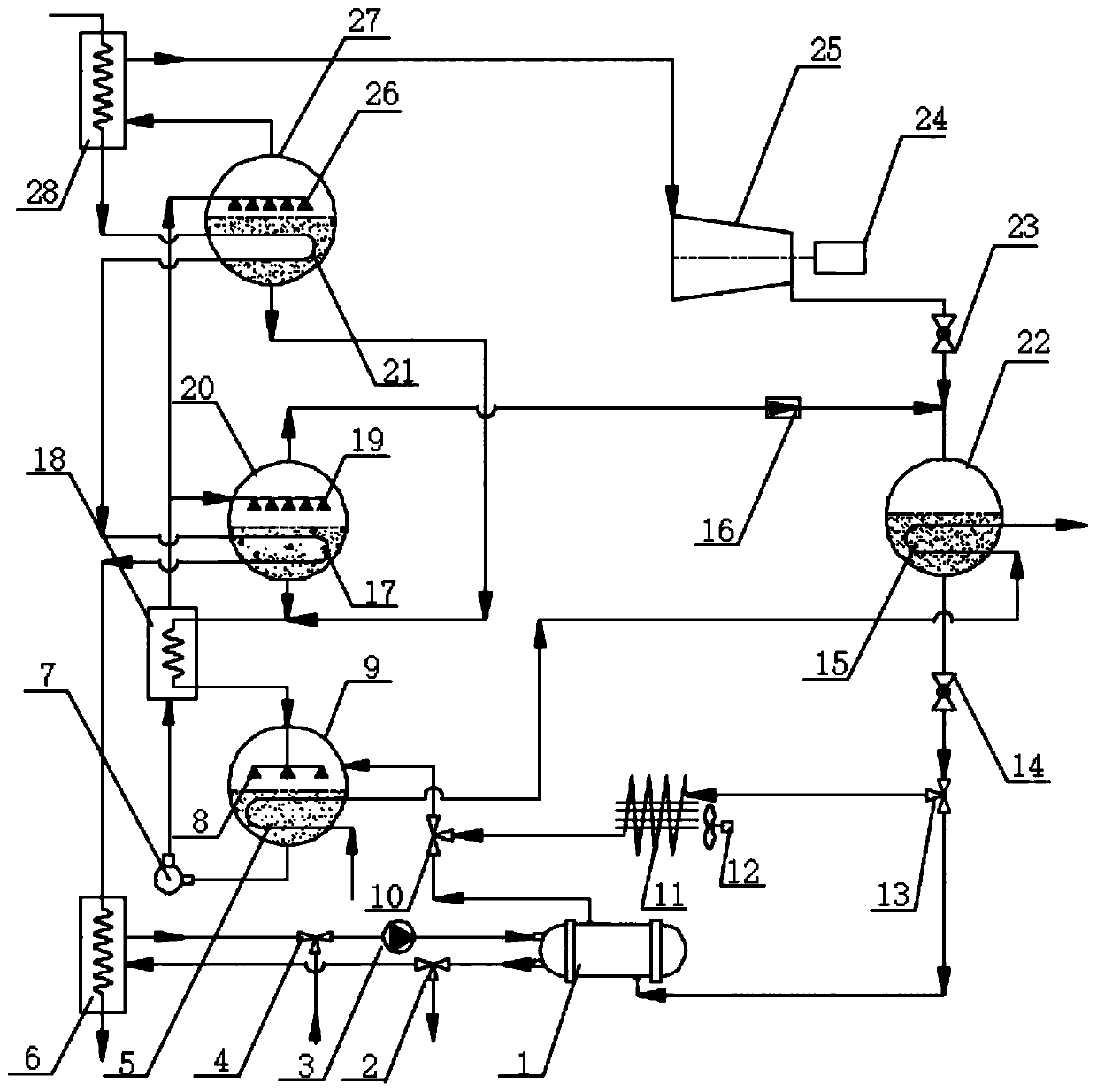

Vehicle-mounted Rankine cycle waste heat recycling system

InactiveCN111022214AImprove the efficiency of waste heat recovery and utilizationInternal combustion piston enginesEngine componentsOrganic Rankine cycleIn vehicle

The invention discloses a vehicle-mounted Rankine cycle waste heat recycling system. The vehicle-mounted Rankine cycle waste heat recycling system comprises a low-grade organic Rankine cycle device, and a high-grade organic Rankine cycle device. The low-grade organic Rankine cycle device comprises an engine (6), a low-grade expander (7), a low-grade condenser (9) and a low-grade working medium pump (10), low-grade organic working media of the low-grade organic Rankine cycle device can exchange heat with the engine (6), the high-grade organic Rankine cycle device comprises a high-grade evaporator (1), a high-grade expander (2), a high-grade condenser (4) and a high-grade working medium pump (5), and high-grade organic working media of the high-grade organic Rankine cycle device enter the high-grade evaporator (1) to exchange heat with smoke gas exhausted out of the engine (6). According to the vehicle-mounted Rankine cycle waste heat recycling system, the engine waste heat recycling efficiency can be improved.

Owner:WEICHAI POWER CO LTD

Formaldehyde tail gas combustion and heat recovery system and operation method thereof

ActiveCN106838937APrevent automatic pressure reliefPrevent deflagrationIncinerator apparatusSteam generation using hot heat carriersRam-air intakeCombustion

The invention discloses a formaldehyde tail gas combustion and heat recovery system which comprises an air intake system, an ignition device, a combustion device, an insulation hearth, a secondary air device, a hearth flame-out protection device and a heat recovery system part; the insulation hearth is located at the front of the air intake system; the ignition device is arranged on the inner wall of the rear wall of the insulation hearth and is located above the secondary air device; the combustion device and the secondary air device are located in the insulation hearth; the secondary air device is located above the combustion device and is arranged on the left inner wall and the right inner wall of the insulation hearth; an air outlet of the air intake system communicates with an air inlet of the combustion device; and an air outlet of a blower communicates with an air inlet of the secondary air device. The formaldehyde tail gas combustion and heat recovery system and the operation method of the formaldehyde tail gas combustion and heat recovery system are good in safety and high in heat utilization rate.

Owner:ZHEJIANG SHUANGFENG BOILER

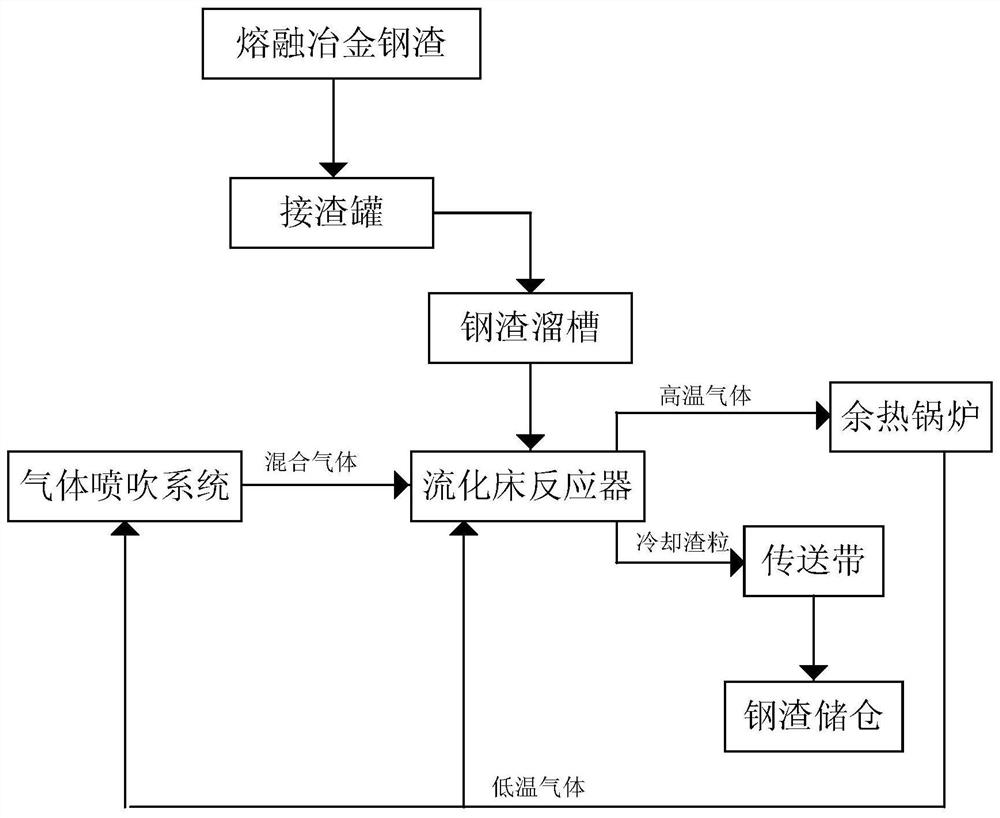

Method and device for realizing steel slag quenching and waste heat recovery by using water and carbon dioxide

ActiveCN110982967BImprove the efficiency of waste heat recovery and utilizationStimulate thermal potentialCement productionRecycling and recovery technologiesSlagFluidized bed

A method and device for realizing steel slag quenching and waste heat recovery by using water and carbon dioxide, the method is: mixing carbon dioxide and water vapor; the mixed gas is sprayed into a fluidized bed heat exchanger through an injection system, and enters a gas circulation pipeline through a waste heat boiler; Part of the gas is returned to the gas injection system, and the rest is passed into the air distribution plate; the molten metallurgical steel slag is introduced into the fluidized bed heat exchanger for gas quenching, and the generated steel slag particles are suspended under the action of the air flow; the high-temperature gas enters the waste heat boiler for heat exchange to form low-temperature gas Enter the gas circulation pipeline; when the steel slag particles are below 800°C, an exothermic reaction occurs; when the temperature of the high-temperature gas is 450±5°C, supplement CO 2 ; When the material temperature is below 150°C, close the gas injection system; the device includes a steel slag chute, a fluidized bed heat exchanger and a gas injection system. The method of the invention has high utilization efficiency of steel slag waste heat recovery, good steel slag stability, small occupied area, short treatment cycle and low gas consumption.

Owner:JIANGXI UNIV OF SCI & TECH

Efficient water jacket heating furnace

PendingCN112902450AImprove utilization efficiencyMixed burn thoroughlyCombustion processStorage heatersEngineeringWater jacket

The invention discloses an efficient water jacket heating furnace. The efficient water jacket heating furnace comprises a water jacket, a chimney, a heat exchanger, a medium coil pipe and a smoke pipe; a circulating liquid coil pipe is arranged in the chimney; a gas coil pipe is arranged in the heat exchanger; the medium coil pipe and the smoke pipe are arranged in the water jacket; a honeycomb pipe communicated with the chimney is arranged in the water jacket; the honeycomb pipe is connected with a fire cylinder through the smoke pipe; the fire cylinder is connected with a combustor; a liquid flowing cavity is formed in an inner cavity of the heat exchanger; the circulating liquid coil pipe is connected with the heat exchanger and enables liquid media in the circulating liquid coil pipe and the heat exchanger to flow and replace; the gas coil pipe is connected with a gas pipe of the combustor; an airflow channel is formed in a cavity of the chimney; and the chimney is connected with an air pipe of the combustor. The efficient water jacket heating furnace has the advantages that gas and air are mixed and burnt more thoroughly, and the utilization efficiency of the gas is improved; and air and fuel gas entering the combustor are preheated through flue gas waste heat, the flue gas waste heat recycling efficiency is effectively improved, and the heat efficiency of the water jacket heating furnace is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

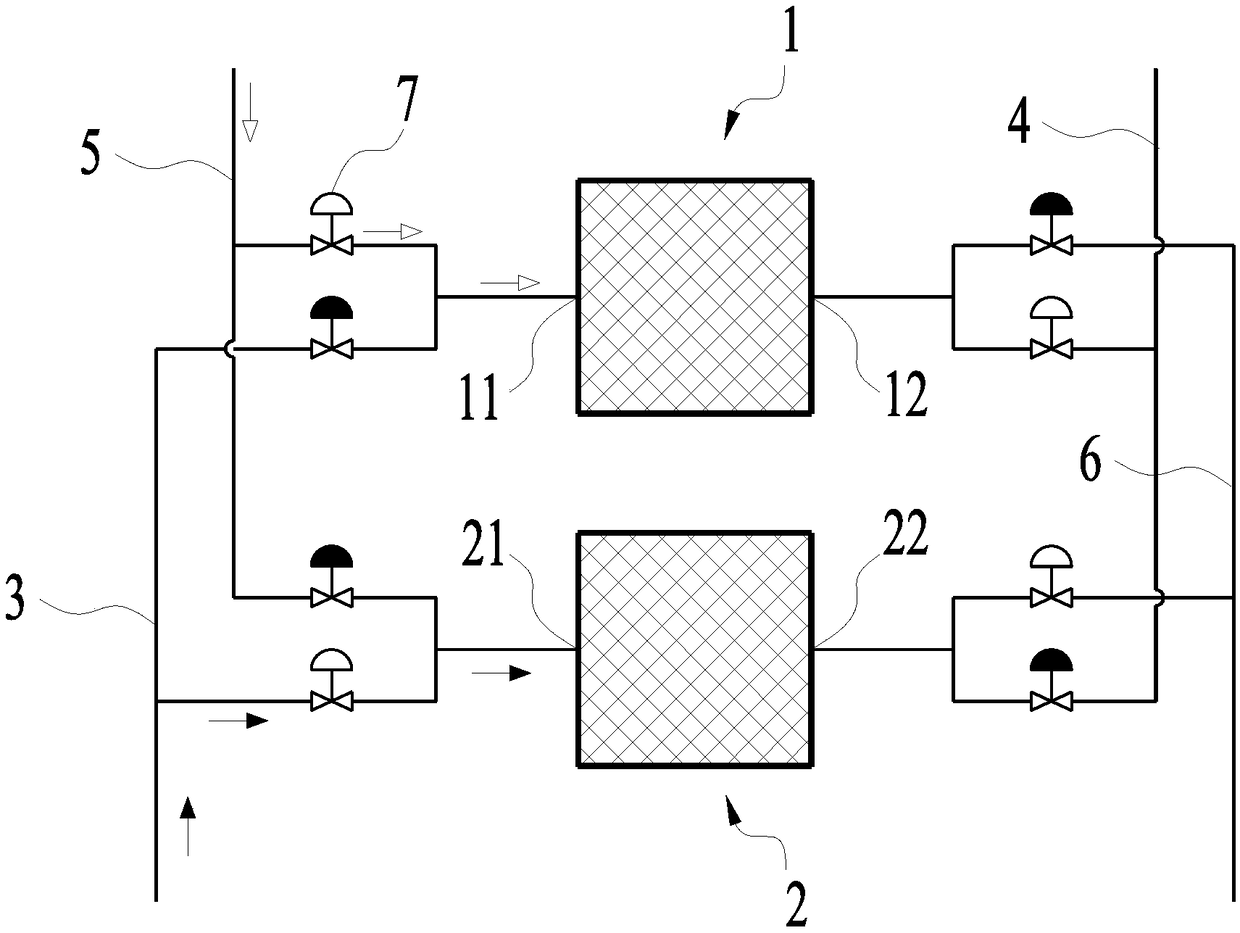

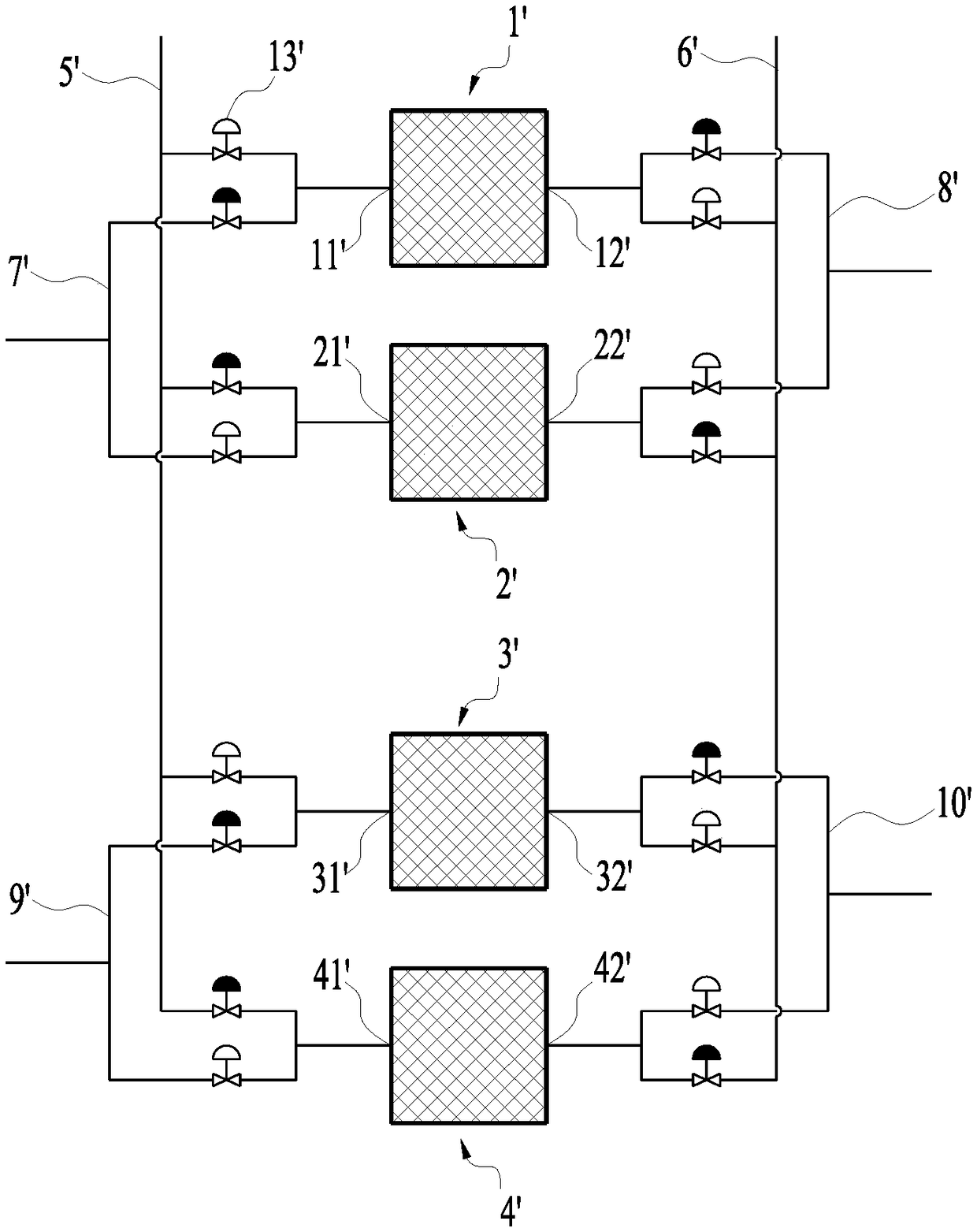

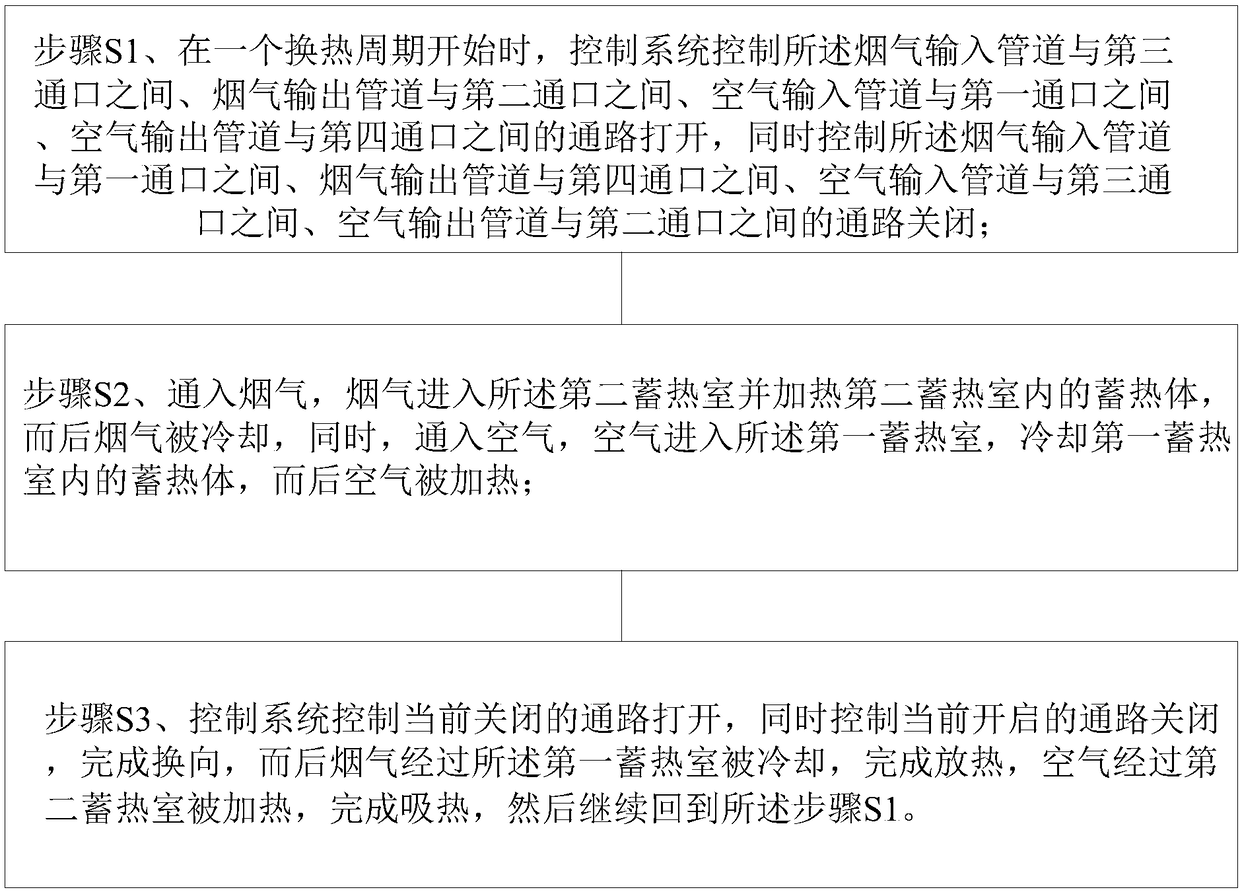

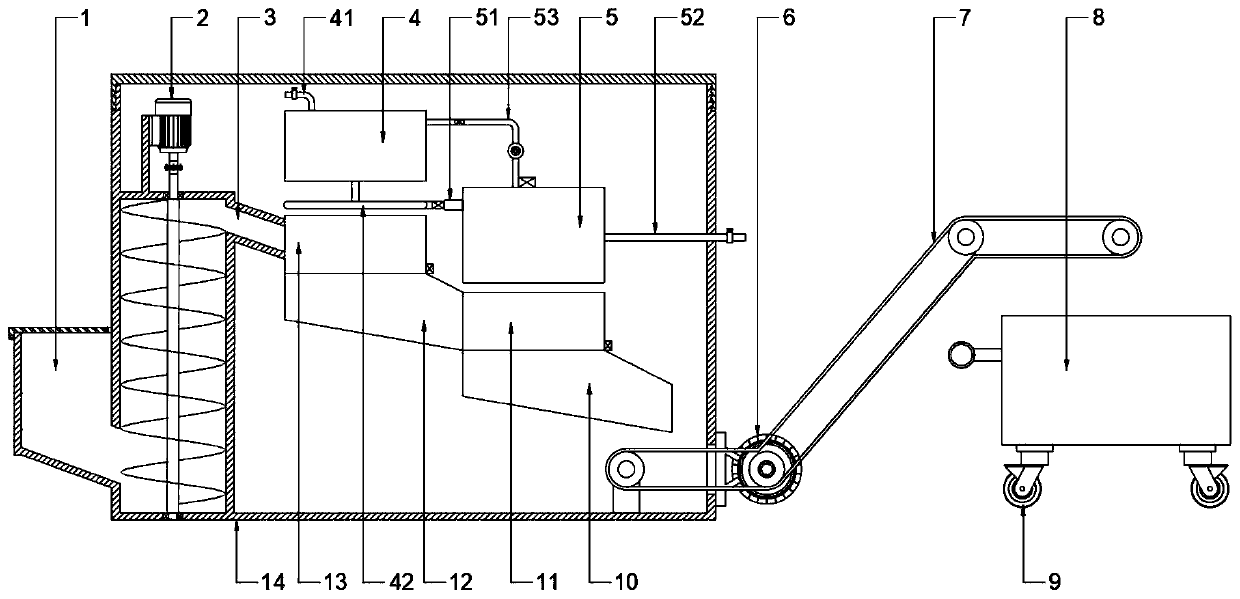

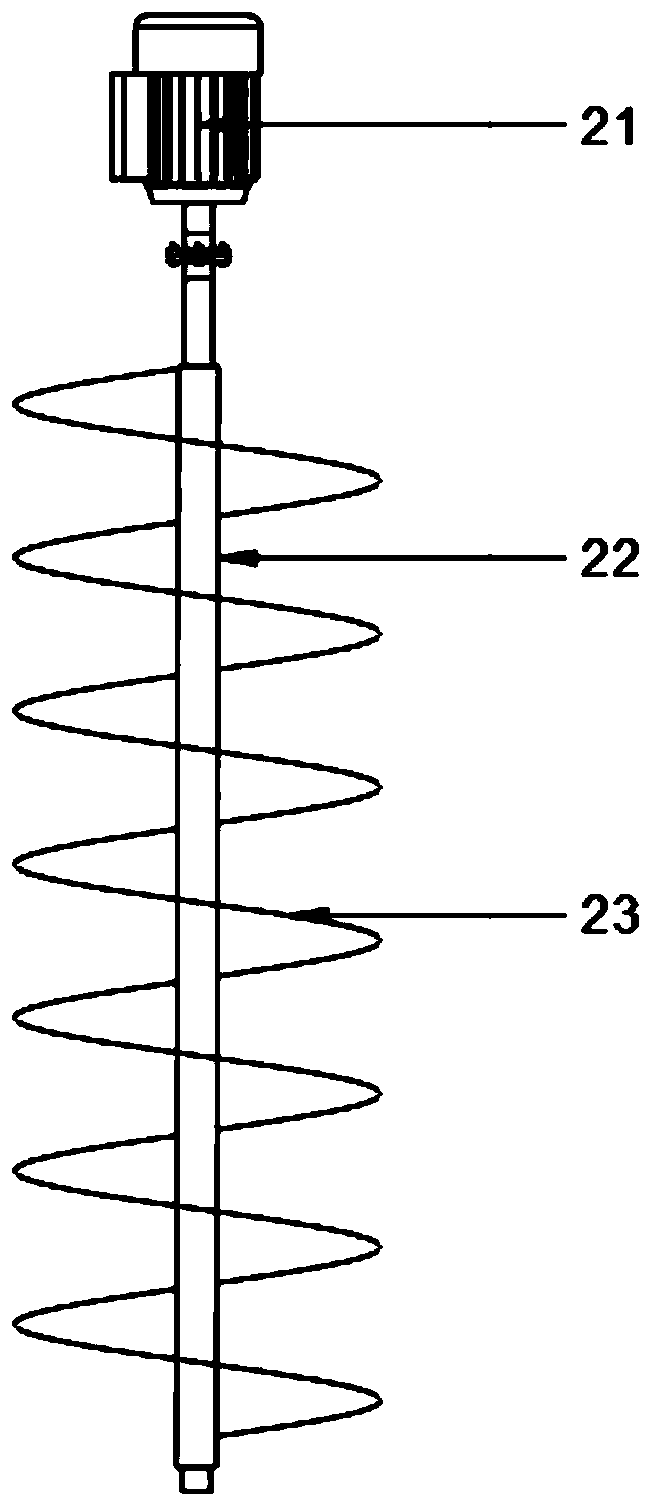

Furnace kiln continuous heat exchange control device and control method

InactiveCN109373773AImprove continuous combustion stabilityReduce complexityFurnace safety devicesControl devices for furnacesFurnace temperatureCombustion

The invention provides a furnace kiln continuous heat exchange control device. The device comprises a first heat storage chamber, a second heat storage chamber, a flue gas input pipeline, a flue gas output pipeline, an air input pipeline and an air output pipeline, wherein the flue gas input pipeline, the flue gas output pipeline, the air input pipeline and the air output pipeline are communicatedwith the first heat storage chamber and the second heat storage chamber. Valves are arranged on the pipelines,wherein the pipelines is used for connecting the first heat storage chamber, the second heat storage chamber with the the flue gas input pipeline, the flue gas output pipeline, the air input pipeline and the air output pipeline. The control system controls the valves between the pipelinesand the heat storage chambers to be opened and closed periodically, so that the first heat storage chamber and the second heat storage chamber can be switched periodically between heat absorption andheat release modes. The furnace kiln continuous heat exchange control device and the furnace kiln continuous heat exchange control method have the advantages that the structure and the working process is simple, the problem of short heat exchange period, high furnace temperature and large furnace pressure fluctuation in heat storage combustion caused by frequent heat exchange in the prior art canbe solved, the continuous combustion stability of the heat storage chamber can be improved, and the waste heat recovery efficiency can be improved.

Owner:HUATIAN ENG & TECH CORP MCC +2

Slag waste heat recycling device

InactiveCN111322630AReduce lossImpact recyclingFluid heatersIndirect heat exchangersThermal insulationSlag

The invention discloses a slag waste heat recycling device. The slag waste heat recycling device comprises a box body, and a conveying assembly and a waste heat utilizing assembly which are arranged in the box body. The conveying assembly is arranged in the box body, and the bottom of the conveying assembly communicates with a feed hopper. The discharge end of the conveying assembly is provided with a material guide pipe communicating with the waste heat utilizing assembly. The side, away from the feed hopper, of the box body is further provided with a discharging assembly, and the feeding endof the discharging assembly is located on the lower side of the discharging end of the waste heat utilizing assembly. The slag waste heat recycling device is filled with a thermal insulation materialand thermal insulation asbestos, the slag heat loss is reduced, the recycling efficiency is improved, and meanwhile the injuries caused by overflow heat to operators are avoided; a cylinder closely sleeves the periphery of a feeding spiral blade, so that slag is prevented from falling from a seam, and meanwhile a conveying motor is isolated and protected; by means of a reflux pipe with a water pump and a second water temperature sensor, the temperature of hot water is ensured; and by means of a slag temperature sensor, slag not meeting the temperature requirement is conveyed to a next link intime.

Owner:黄福明

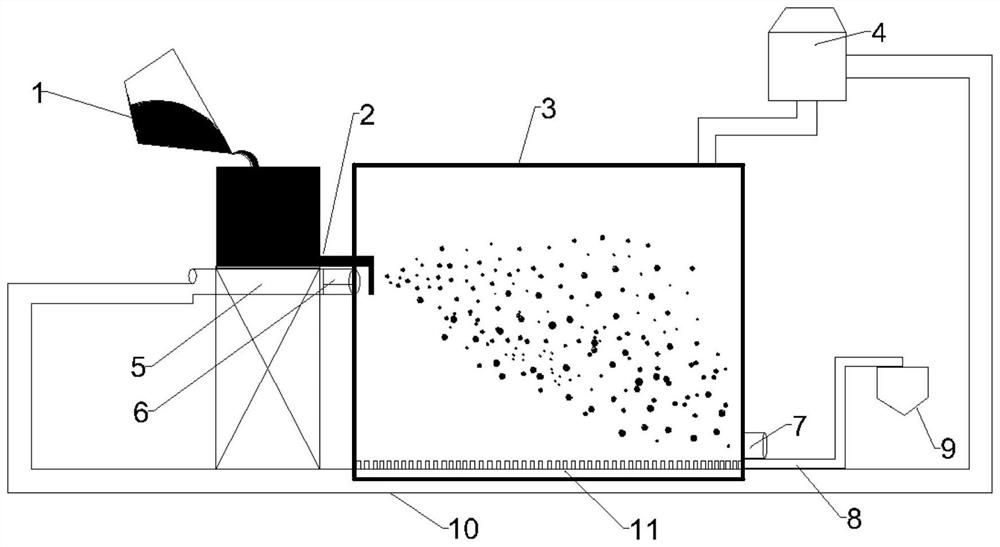

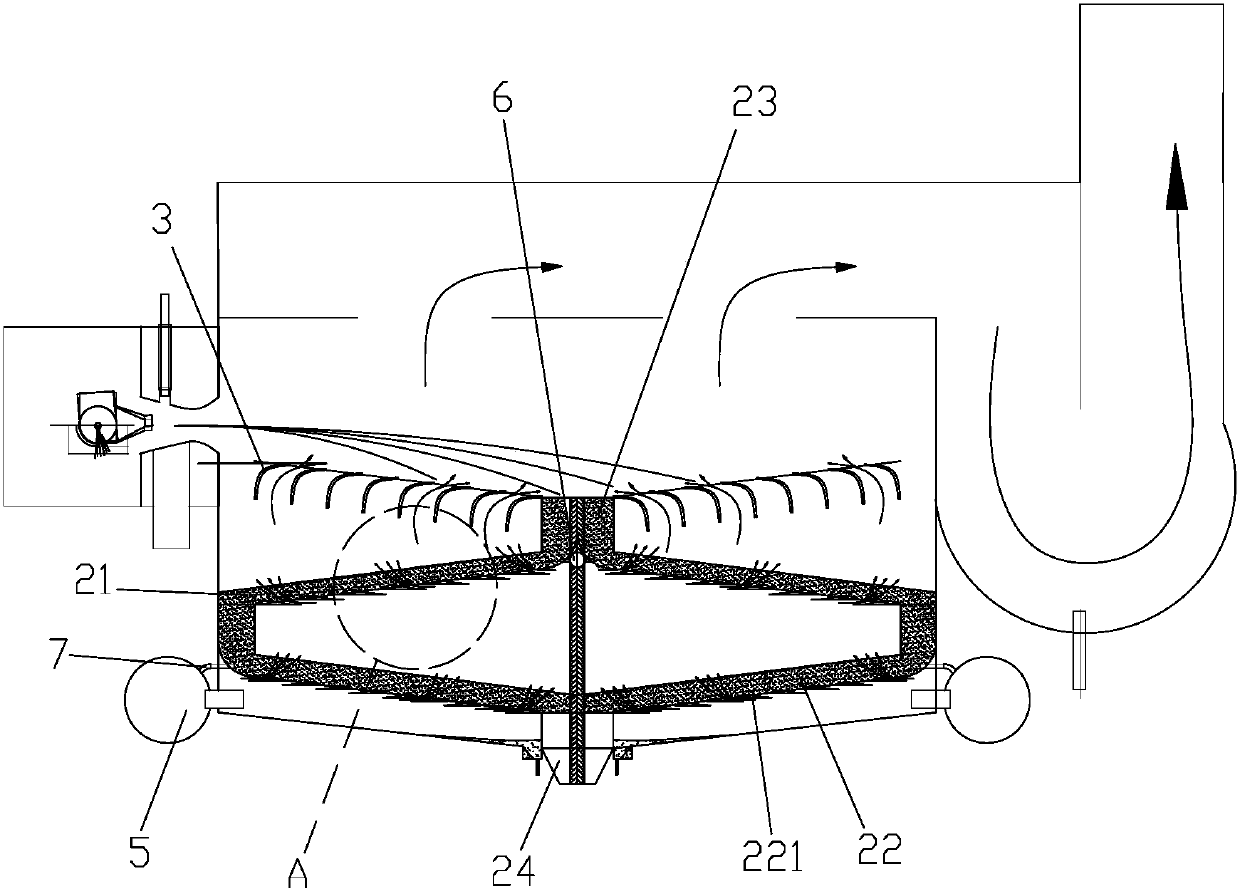

Device and method for granulating blast furnace slag and recycling waste heat

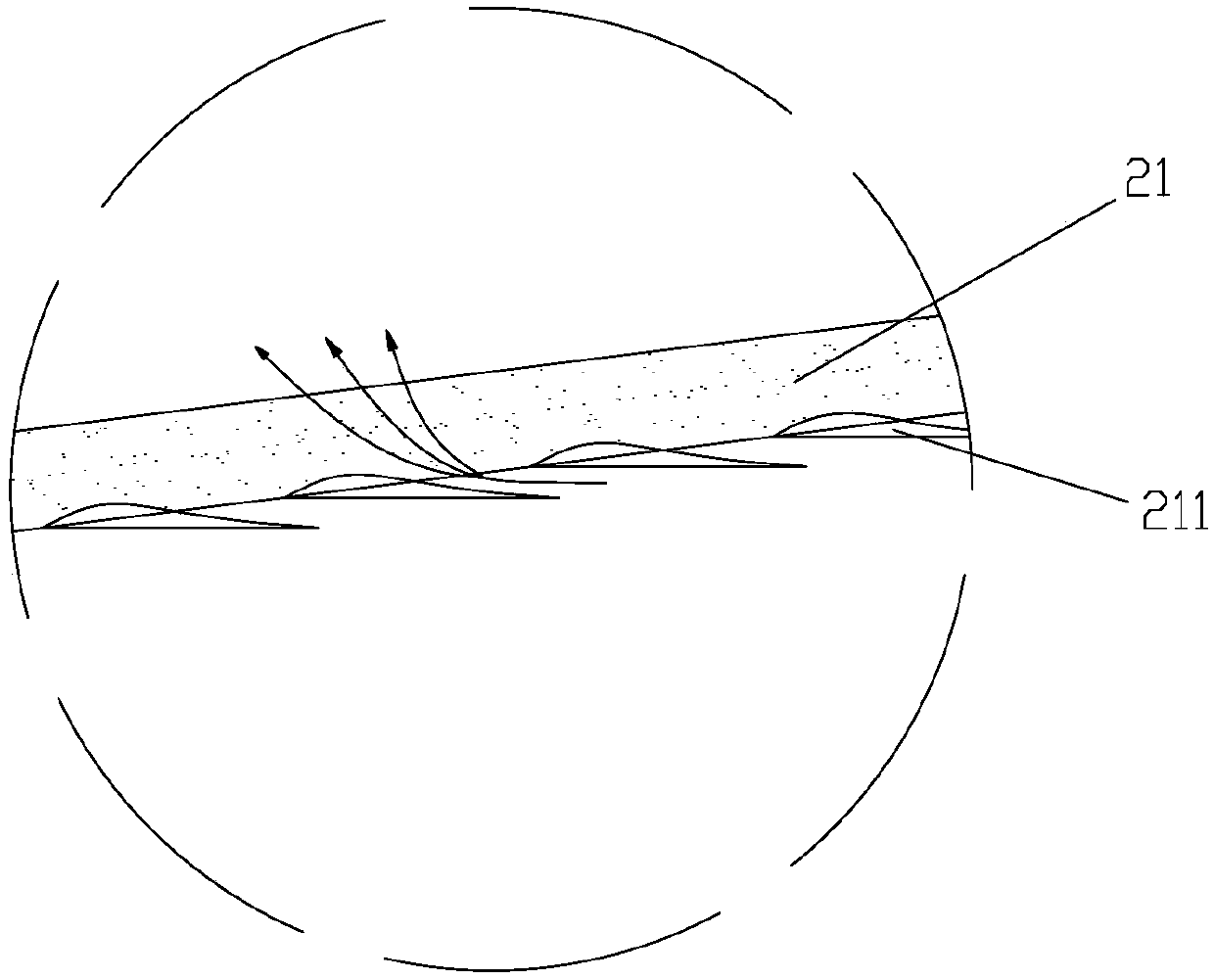

PendingCN113322360AAvoid it happening againImprove waste heat recovery efficiencyBlast furnace componentsBlast furnace detailsSludgeAerosol Mist

The invention discloses a device and method for granulating blast furnace slag and recycling waste heat. The device comprises an aerial fog granulation nozzle assembly, a fluid director (7), a cyclone separator (8) and a waste heat recoverer. The aerial fog granulation nozzle assembly comprises a slag flow controller (2), a compressed air flow control valve (3), a water quantity control valve (4) and an aerial fog spray gun (5). Mixing heat exchange of medium-temperature gas and high-temperature granular slag (6) and solidification of the high-temperature granular slag are realized in the fluid director, and the medium-high-temperature gas and the high-temperature granular slag after heat exchange are guided into the cyclone separator. The cyclone separator is used for separating medium-high-temperature gas and high-temperature granular slag and conveying the medium-high-temperature gas and the high-temperature granular slag into the waste heat recoverer. Complete granulation of the blast furnace slag is achieved, slag sensible heat recovery is organically coupled with sludge drying, high-temperature steam preparation, power generation and low-temperature hot water preparation, waste heat recovery of medium-temperature gas and high-temperature granulated slag in the slag granulation treatment process is achieved, and the waste heat recovery and utilization efficiency is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD +1

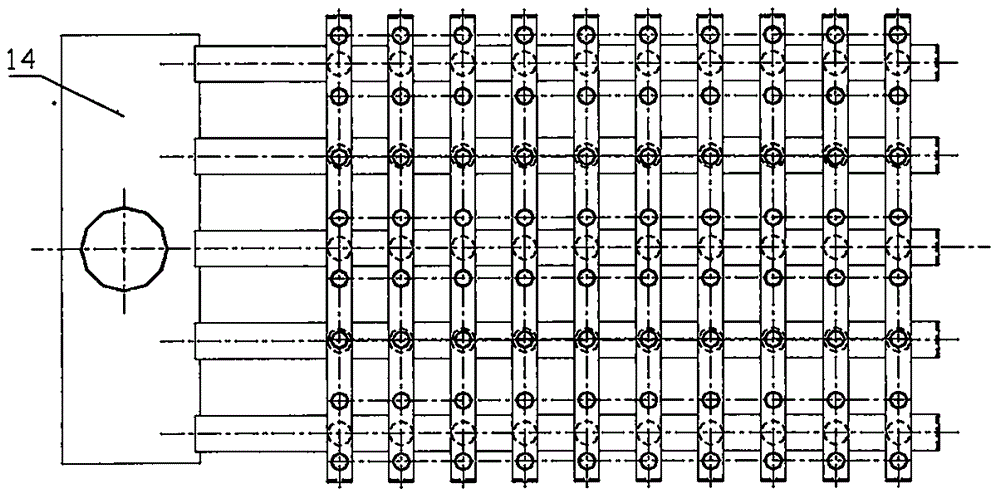

Sinter vertical cooling device capable of realizing gradient heat recovery and complete waste gas circulation

InactiveCN112577313AImprove uniformityImprove heat transfer performanceIncreasing energy efficiencyVertical furnacesProcess engineeringShaft furnace

The invention relates to a sinter vertical cooling device capable of realizing gradient heat recovery and complete waste gas circulation. The device comprises a sintering machine, a discharging pipe,a skip car, a vertical cooling furnace, a stock bin, distributing pipes, discharging pipes, a belt, a gravity dust remover, a waste heat boiler, a multi-pipe dust remover, a hot water generator, a circulating fan, an air distributor, a steam turbine generator unit, a condenser, a water pump, a heat storage station and a hot water car, wherein the stock bin is arranged at the top of the vertical cooling furnace, the distributing pipes are arranged below the stock bin, the discharging pipes are arranged at the bottom of the vertical cooling furnace, the vertical cooling furnace is connected withthe multi-pipe dust remover, the hot water generator and the circulating fan through the gravity dust remover and the waste heat boiler, the heat storage station is connected with the hot water generator, and the steam turbine generator unit is connected with the waste heat boiler through the condenser and the water pump. According to the sinter vertical cooling device, the vertical cooling furnace adopts an optimized structural form, so that efficient heat exchange is achieved, and the sinter cooling requirement is met.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A formaldehyde tail gas combustion and heat recovery system and its operating method

ActiveCN106838937BPrevent automatic pressure reliefPrevent deflagrationIncinerator apparatusSteam generation using hot heat carriersCombustionHearth

The invention discloses a formaldehyde tail gas combustion and heat recovery system which comprises an air intake system, an ignition device, a combustion device, an insulation hearth, a secondary air device, a hearth flame-out protection device and a heat recovery system part; the insulation hearth is located at the front of the air intake system; the ignition device is arranged on the inner wall of the rear wall of the insulation hearth and is located above the secondary air device; the combustion device and the secondary air device are located in the insulation hearth; the secondary air device is located above the combustion device and is arranged on the left inner wall and the right inner wall of the insulation hearth; an air outlet of the air intake system communicates with an air inlet of the combustion device; and an air outlet of a blower communicates with an air inlet of the secondary air device. The formaldehyde tail gas combustion and heat recovery system and the operation method of the formaldehyde tail gas combustion and heat recovery system are good in safety and high in heat utilization rate.

Owner:ZHEJIANG SHUANGFENG BOILER

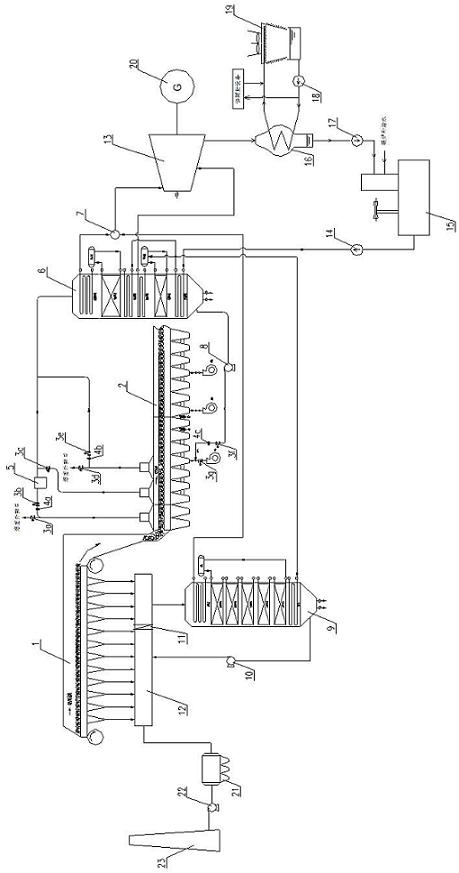

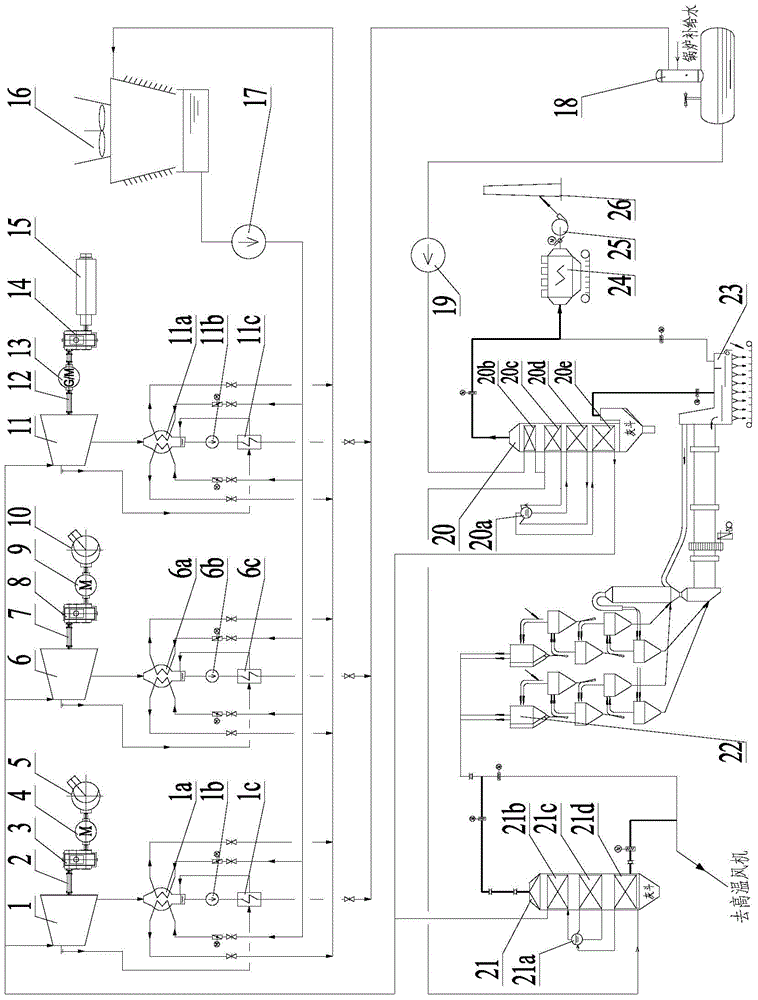

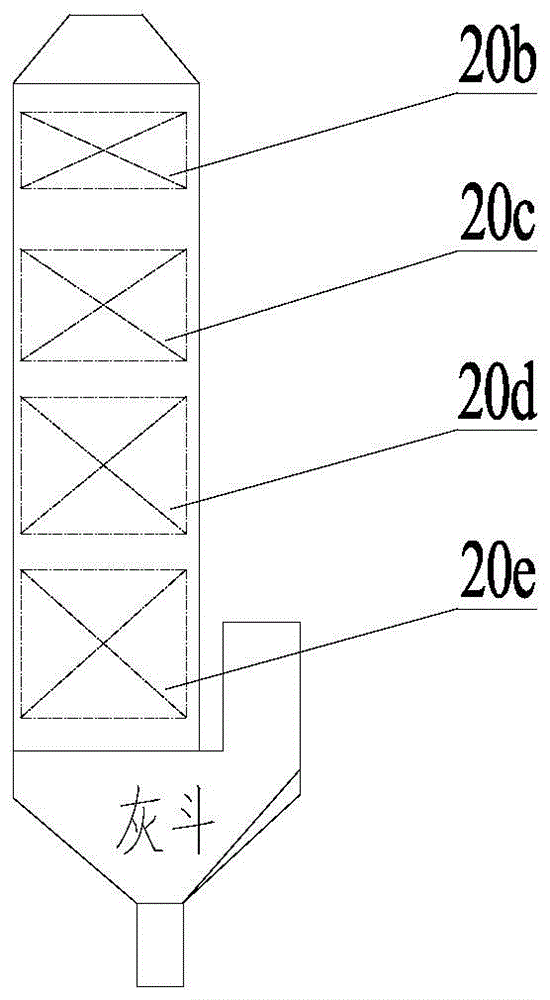

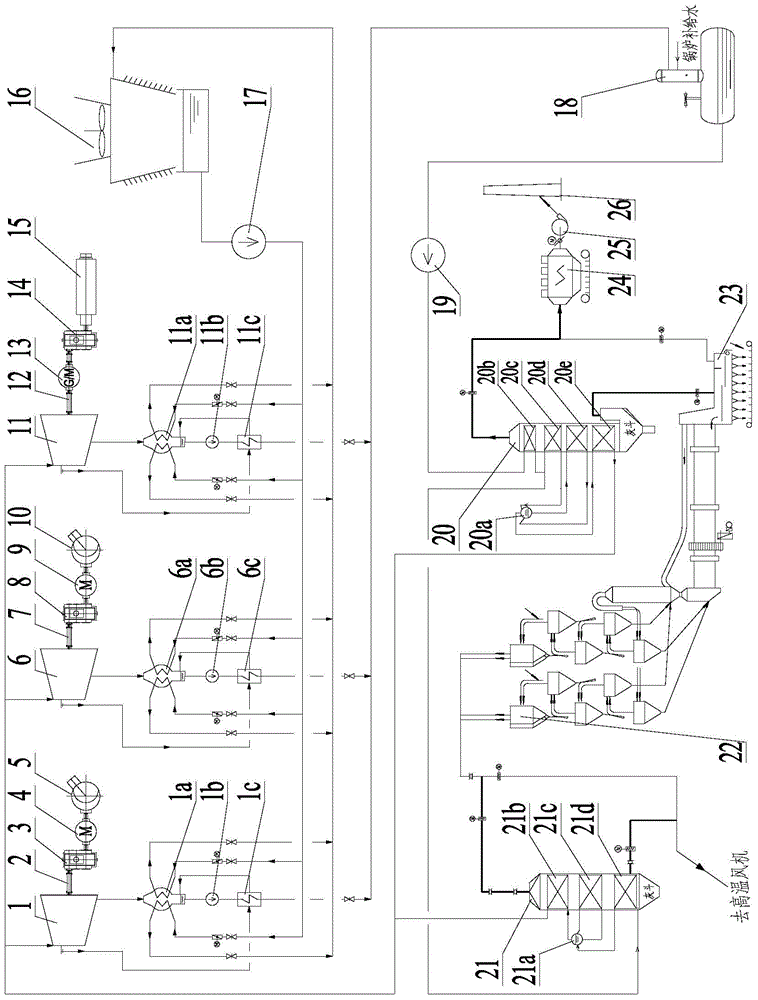

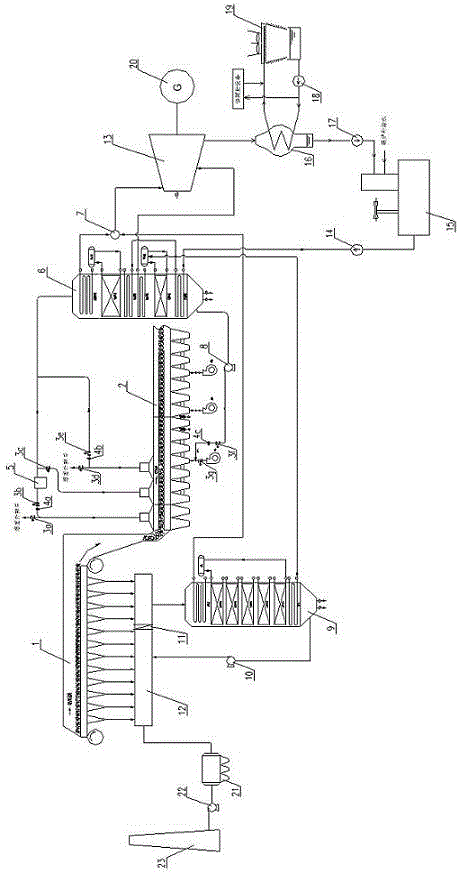

Waste heat comprehensive utilization power generation system and power generation method for sintering production line

InactiveCN102353276BImprove the efficiency of waste heat recovery and utilizationIncrease power generationEnergy industryIncreasing energy efficiencyProduction lineFlue gas

The invention provides a waste heat comprehensive utilization power generation system for a sintering production line, which is characterized in that: a blanking port hood is arranged between a discharge port of a sintering machine and a feed port of a cooling machine, and an evaporator D is arranged in the blanking port hood; a hood A and a hood B are arranged at the feed port of the cooling machine, and the hood A is communicated with a heat exchanger A; the hood B is communicated with a heat exchanger B, and a hood C is arranged at the discharge port of the sintering machine; the hood C iscommunicated with a heat exchanger C, and water in a waste heat boiler continuously flows into an evaporator A, an evaporator B, an evaporator C and the evaporator D to be heated into hot water; and hot steam drives a generator through a steam turbine to generate power. The waste heat comprehensive utilization power generation system reasonably utilizes the waste heat resources of the whole sintering production line and the heat of a lot of flue gas generated when a sintering ore is cooled by the cooling machine, thereby greatly improving the waste heat recovery utilization efficiency of the sintering process, and increasing generating capacity.

Owner:西安陕鼓工程技术有限公司

Branch control phase inversion heat exchange system and method based on vapor-liquid heat exchanger

ActiveCN102252543BWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersLiquid storage tankEngineering

The invention relates to a branch control phase inversion heat exchange system and a branch control phase inversion heat exchange method based on a vapor-liquid heat exchanger. The system comprises a liquid storage tank (20), a heat source heat exchanger (3), a cold source heat exchanger (15) and a vapor-liquid heat exchanger (9); an upper collection tank of the heat source heat exchanger (3) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet steam pipe (8); a vapor-liquid heat exchanger outlet steam pipe (10) which is arranged on the vapor-liquid heat exchanger (9) is divided into two branches which are communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (15); the lower collection tank of the cold source heat exchanger (15) is communicated with the upper part of the liquid storage tank (20) through a cold source heat exchanger liquid outlet pipe (17); the bottom of the liquid storage tank (20) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet condensation liquid pipe (11); and the vapor-liquid heat exchanger (9) is communicated with a lower collection tank of the heat source heat exchanger (3) through a heat exchanger outlet condensation liquid pipe (6). The branch control phase inversion heat exchange system can solve the phenomena of overcooling and overheating and improve heat exchanging efficiency.

Owner:SHANXI SANHESHENG IND TECH

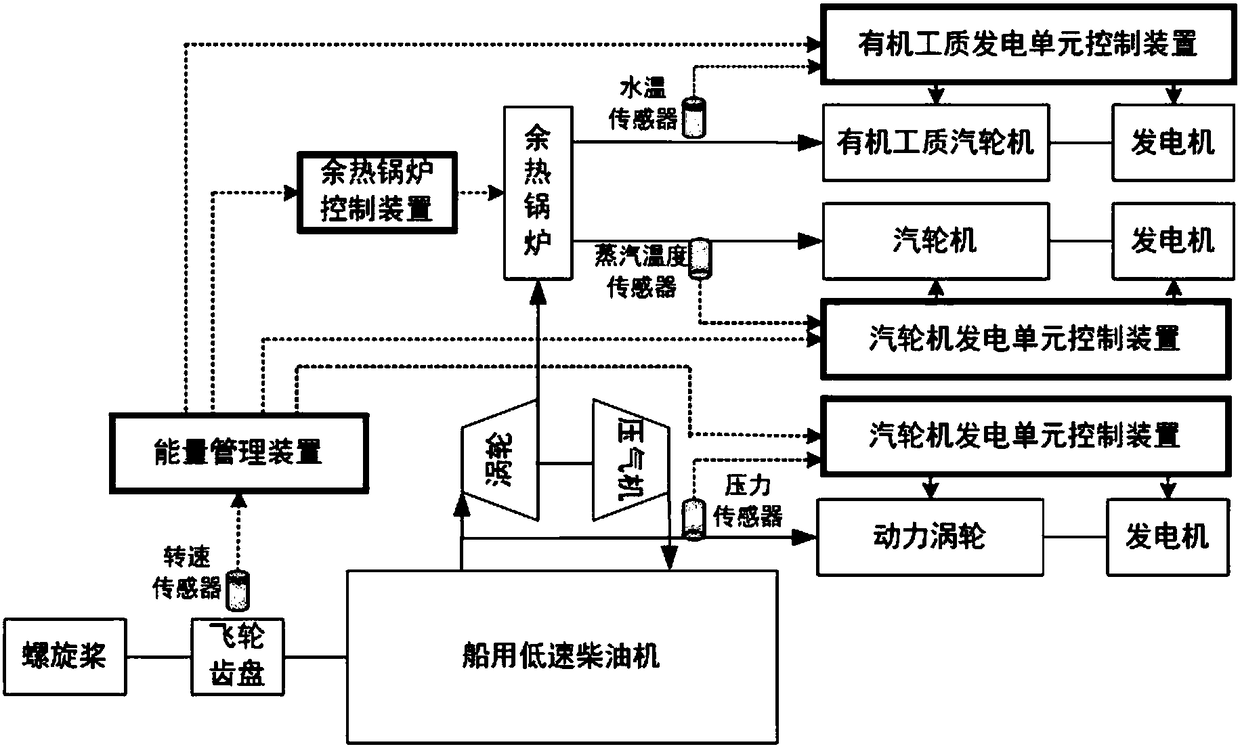

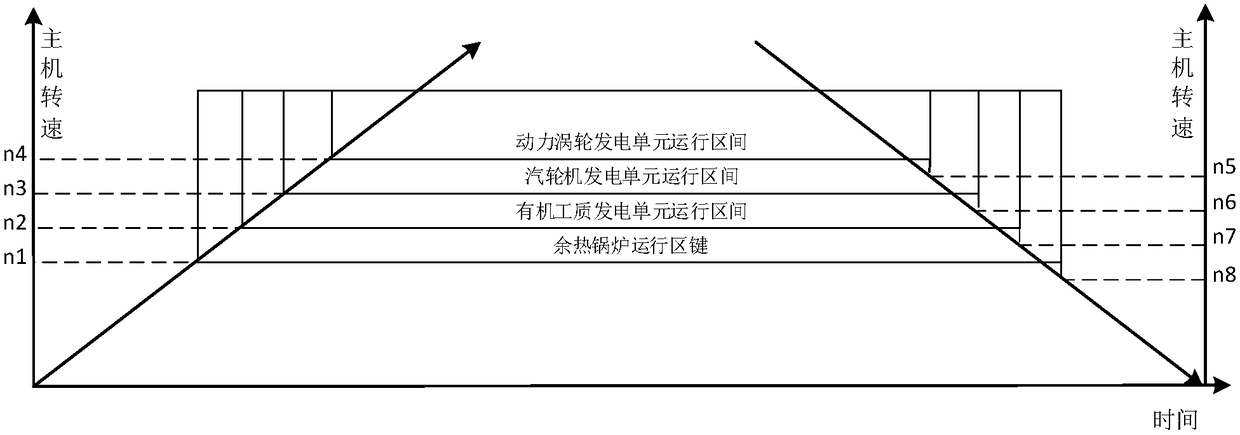

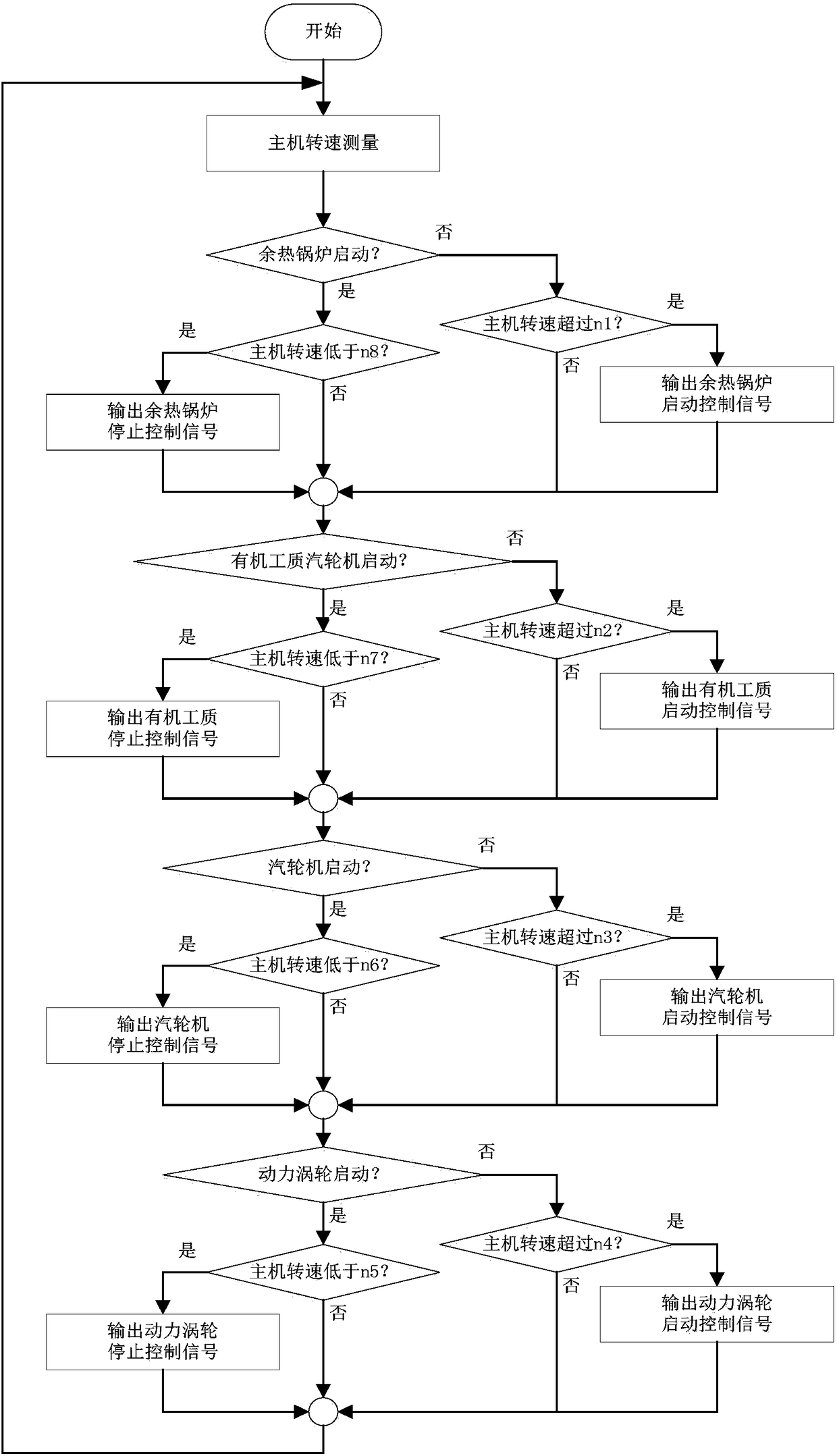

A speed-based control method for waste heat comprehensive recovery system of marine low-speed diesel engine

ActiveCN106499453BEasy to implementEfficient implementationInternal combustion piston enginesSteam engine plantsLow speedTurbocharger

Owner:HARBIN ENG UNIV

A waste heat cascade recycling device and working method

ActiveCN108895708BAchieve effectImprove energy efficiency ratioMachines/enginesFluid circulation arrangementWorking fluidWater vapor

The invention discloses a waste heat cascade recovery and utilization device and a working method. The device includes: an absorption heat pump system and a thermal power conversion system. The device is coupled with absorption heat pump and heat engine technology, driven by waste heat working fluid, which flows through the heater, high-pressure generator, low-pressure generator and waste heat recovery device in sequence, and the high-temperature and high-pressure steam generated by the high-pressure generator of the device is superheated The turbine expands and outputs mechanical power to generate electricity. The exhaust steam discharged from the turbine and the low-pressure generator produce high-temperature and high-pressure water vapor, which enters the condenser to condense and release heat for heating in winter. The evaporative generator generates cold energy for cooling. , to achieve the effect of cogeneration of heat and power in winter and cogeneration of cooling and power in summer. The device fully recovers the waste heat energy of the working medium in the way of waste heat cascade recycling, making the most economical use of waste heat and energy. While improving the energy utilization rate, it effectively reduces atmospheric heat pollution. It has energy saving and emission reduction, economical operation and wide application range. many advantages.

Owner:JIANGSU UNIV OF SCI & TECH

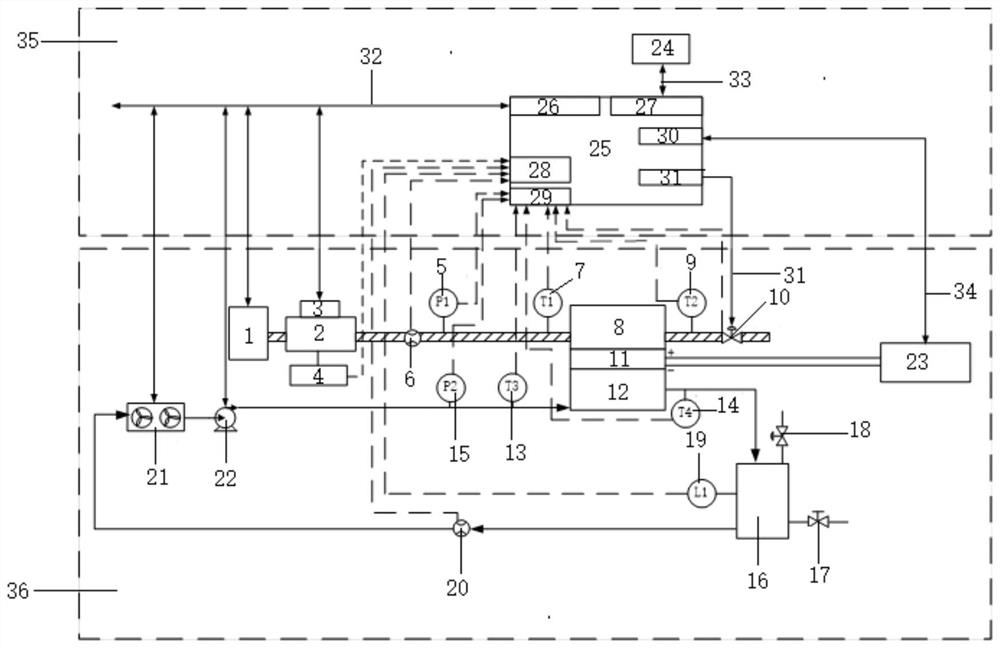

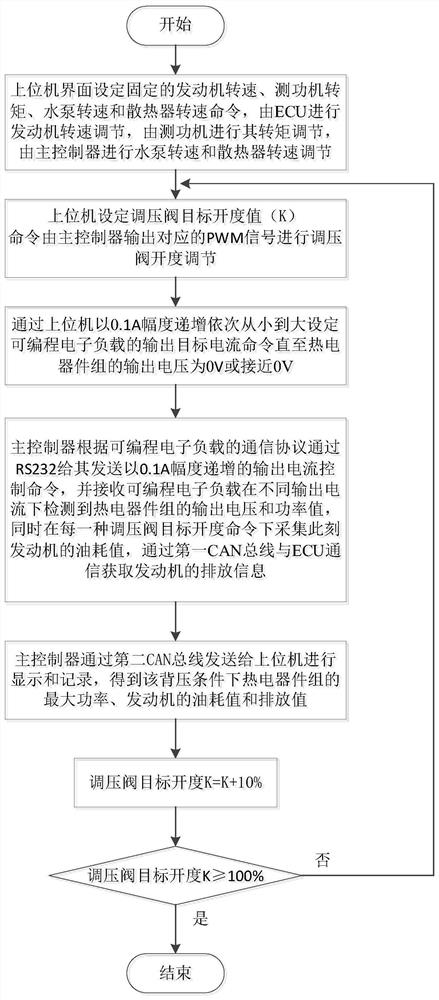

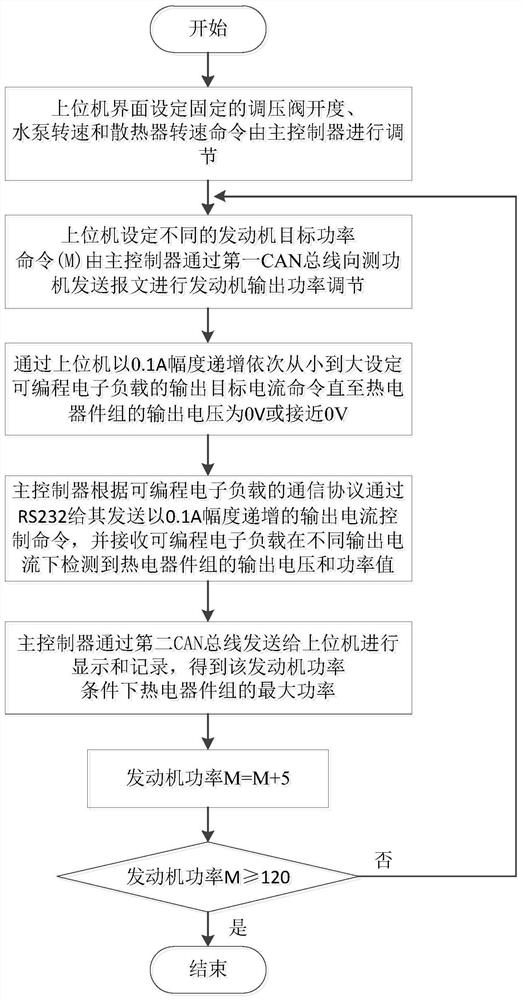

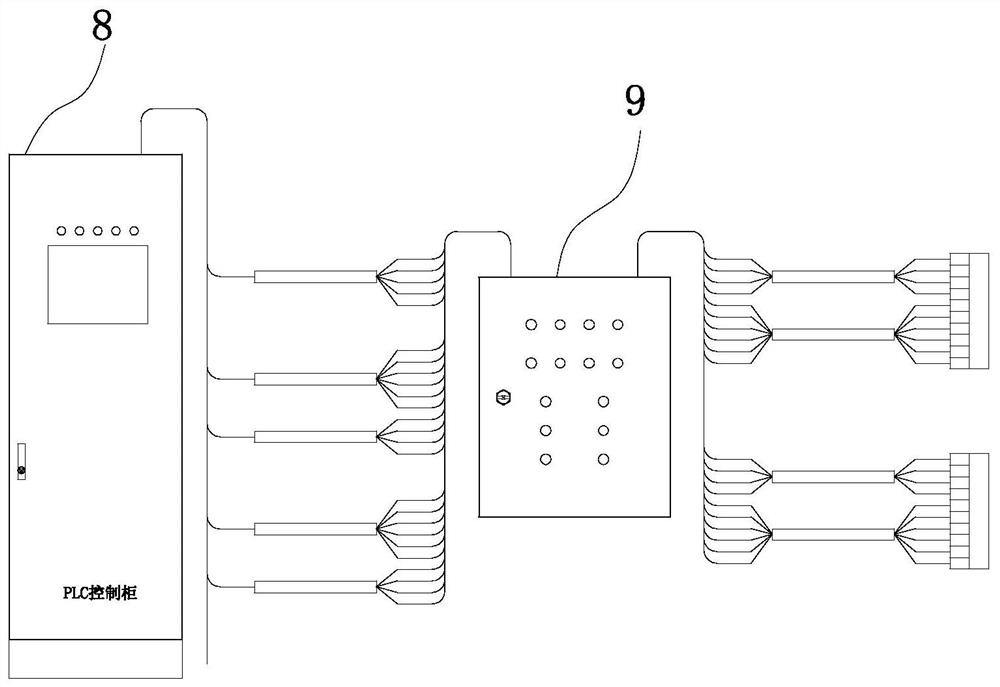

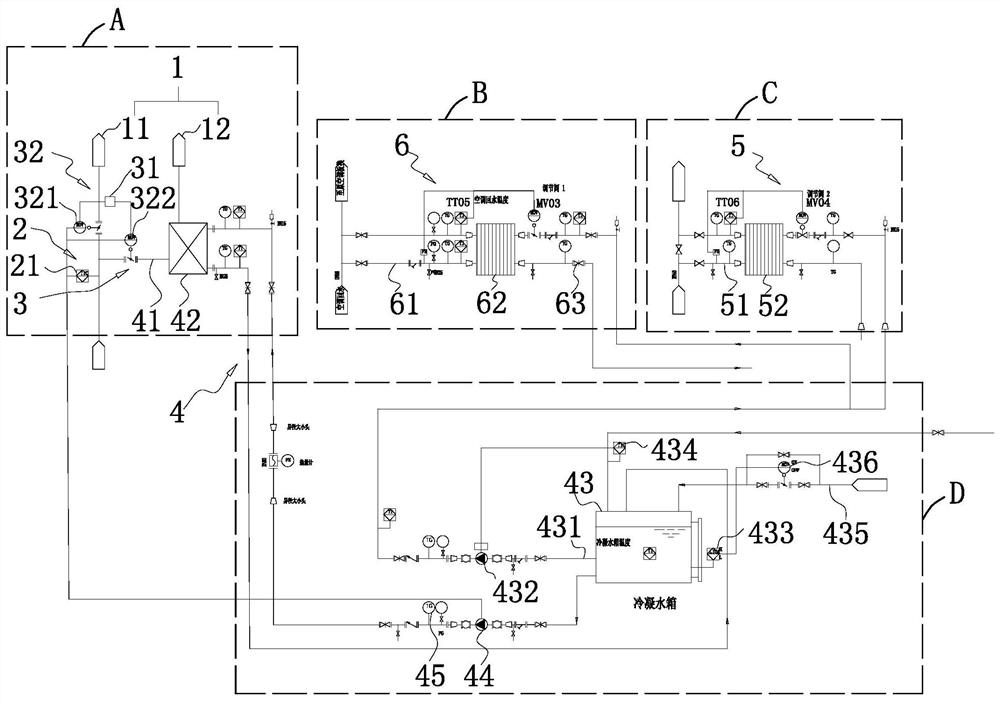

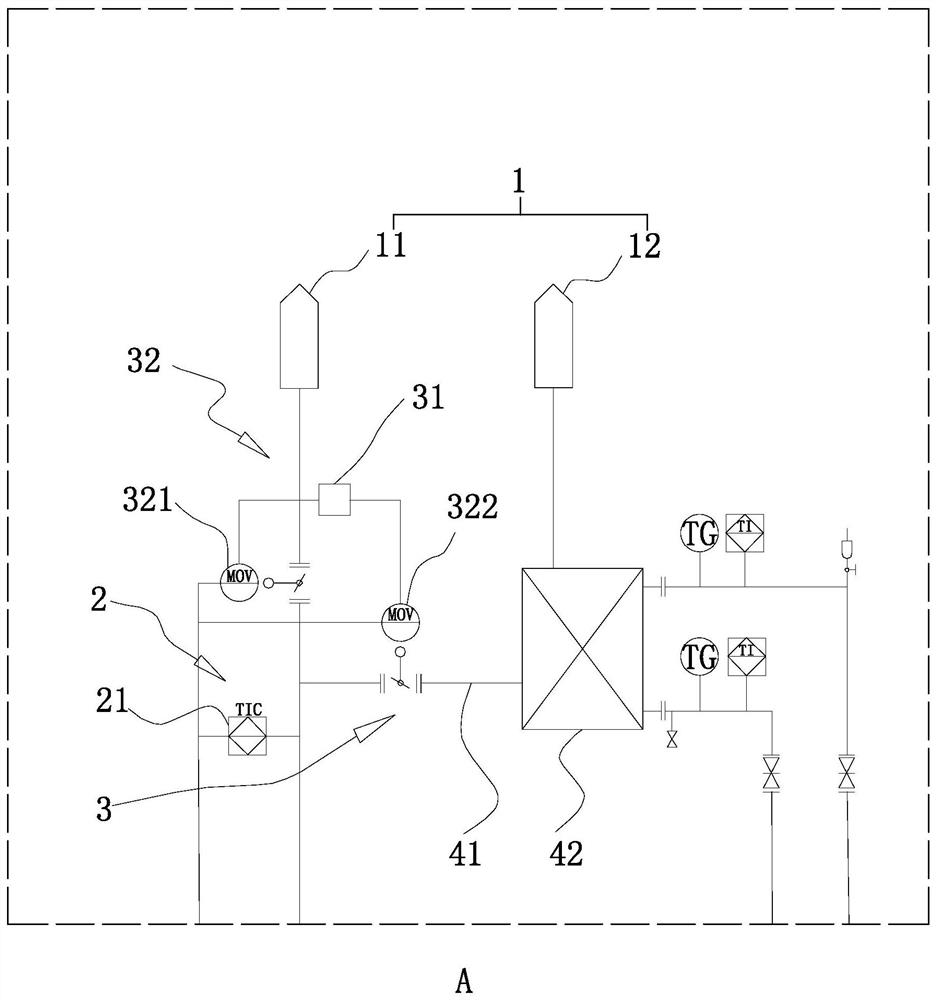

Vehicle-mounted compatibility test platform for automobile exhaust thermoelectric power generation system and test method thereof

PendingCN112362984AOptimize vehicle compatibilityImprove performanceInternal combustion piston enginesExhaust apparatusIn vehicleCooling effect

The invention provides a vehicle-mounted compatibility test platform for an automobile exhaust thermoelectric power generation system and a test method thereof. The vehicle-mounted compatibility testplatform comprises a thermoelectric power generation and performance detection unit and a monitoring unit. The thermoelectric power generation and performance detection unit provides automobile exhaust with adjustable temperature, flow and pressure for the heat exchanger to construct the temperature difference of a thermoelectric device group; the monitoring unit collects signals of all sensors and the working state of an execution part, displays information with an upper computer, and sends an operation command to a main controller by operating an interface of the upper computer to control the operation state of the thermoelectric power generation and performance detection unit. Volt-ampere characteristics of the thermoelectric device group and oil consumption and emission performance ofthe engine under different conditions are tested, and performance evaluation of the heat exchanger structure, the thermoelectric device group electrical topological structure and the cooling effect onautomobile exhaust temperature difference power generation is carried out. The platform can be used for testing the temperature difference power generation performance of automobile exhaust temperature, back pressure, flow, cooling water temperature and cooling water flow, and guidance is provided for vehicle-mounted compatibility optimization of a system.

Owner:HUBEI UNIV OF TECH

Boiler waste heat recovery system, method and equipment and storage medium

PendingCN114353572AImprove the efficiency of waste heat recovery and utilizationReduce lossIndirect heat exchangersHeat exchange apparatusFlueCondensed water

The invention relates to a boiler waste heat recovery system, method and equipment and a storage medium. The boiler waste heat recovery system comprises a smoke exhaust unit, and the smoke exhaust unit comprises a main flue and a bypass flue communicating with the main flue; the flue gas temperature detection unit is used for detecting the flue gas temperature in the main flue in real time; the flue gas conduction control unit comprises a controller and a conduction control piece, and the controller is in control connection with the conduction control piece and controls opening and closing of the main flue and the bypass flue; the flue gas recovery unit comprises a flue gas recovery pipeline, a heat recovery heat exchanger and a condensate water tank; the domestic water unit comprises a domestic water pipeline and a plate heat exchanger communicated with the domestic water pipeline, and the plate heat exchanger is connected with the water outlet end of the condensate water tank through a pipeline; the air conditioner water using unit comprises an air conditioner water using pipeline and a process heat exchanger communicated with the air conditioner water using pipeline, and the process heat exchanger is connected with the water outlet end of the condensate water tank through a pipeline. The flue gas waste heat recovery device has the effects of high flue gas waste heat recovery efficiency and high automation degree.

Owner:上海俊圣机电工程有限公司

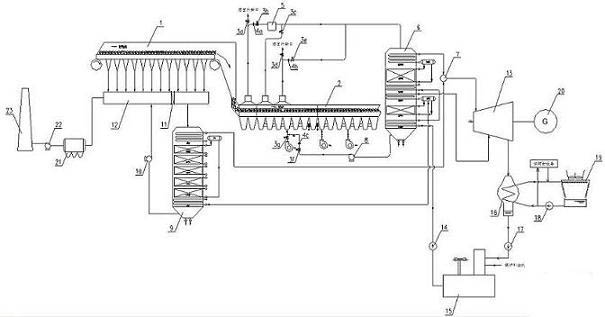

System and method for combined recovery of waste heat from flue gas from glass melting furnace and waste heat from annealing kiln

ActiveCN105371669BIncrease power generationEfficient use ofCharge composition/stateIncreasing energy efficiencyGlass furnaceWaste recycling

The invention discloses a power generating system and a power generating method by jointly recycling waste heat of glass melting kiln flue gas and annealing kiln waste gas and belongs to the technical field of waste recycling in the glass industry. The power generating system comprises a glass melting kiln flue gas treatment and waste heat utilization system, an annealing kiln waste gas waste heat utilization system, a steam turbine generating system and a related auxiliary system, wherein a waste heat boiler is utilized to recycle the glass melting kiln flue gas waste heat, and a water preheater is utilized to recycle the annealing kiln waste gas waste heat, so that a boiler feed-water temperature is increased to prevent corrosion of the tail part heated surface of the boiler; and meanwhile, a high-temperature electric dust collector is arranged to prevent a catalyst in a denitrification reactor from being poisoned and to prevent surface blockage. According to the power generating system, waste heat resources of the glass melting kiln flue gas and the annealing kiln waste gas are effectively utilized, so that the waste heat recycling efficiency of a glass production process is improved, and power generating capacity of a waste heat power generating system is increased.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

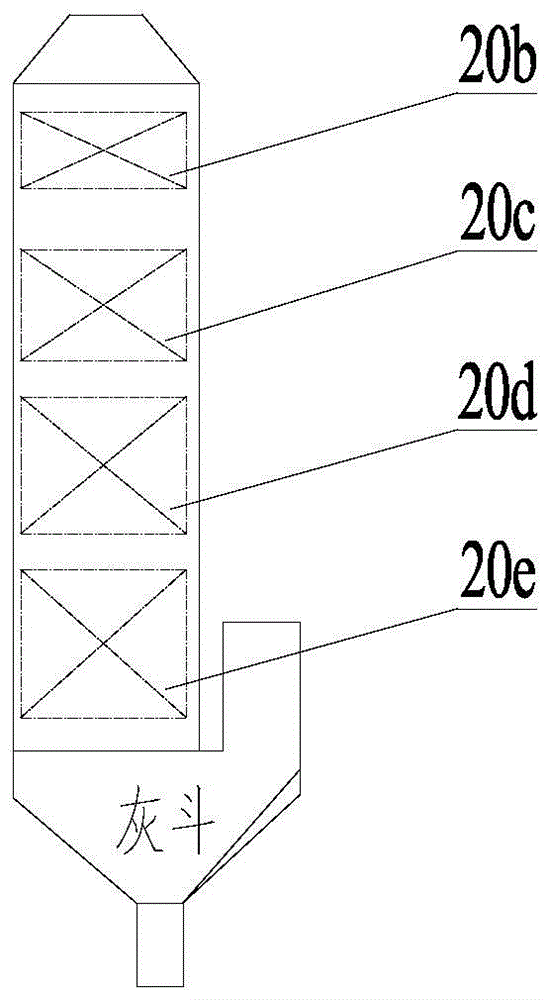

Cement kiln waste heat comprehensive utilization power generation system and method

InactiveCN102506588BImprove the efficiency of waste heat recovery and utilizationIncrease power generationIncreasing energy efficiencyClinker productionElectricityEngineering

The invention provides a cement kiln waste heat comprehensive utilization power generation system which comprises a rotary cement kiln, a grate cooler, an AQC (air quenching cooler) waste heat boiler, an SP waste heat boiler, a steam turbine and a power generator, wherein the AQC waste heat boiler comprises a first heat exchanger, a second heat exchanger and a first boiler barrel, the first heat exchanger is internally provided with a first economizer, the second heat exchanger is internally provided with a second economizer and a first evaporator; the SP waste heat boiler comprises a third heat exchanger and a second boiler barrel, the third heat exchanger is internally provided with a second evaporator; water in the first economizer is heated and then flows into the second economizer and continuously flows to a water supply collection tank and respectively flows into the first boiler barrel and the second boiler barrel; and water in the first boiler barrel is heated circularly in the first evaporator, water in the second boiler barrel is circularly heated in the second evaporator, and heat steam is collected to a steam collection tank, and enters into a fourth evaporator for being continuously heated, and finally enters into the steam turbine to drive the power generator to generate electricity. According to the invention, the recycling efficiency of waste heat of the cement kiln is increased and electric energy production is increased.

Owner:西安陕鼓工程技术有限公司

Thermal power generation system and thermal energy device and flue gas waste heat utilization device thereof

InactiveCN106931424AImprove the efficiency of waste heat recovery and utilizationAchieve recyclingLiquid degasificationEmission preventionAir preheaterThermal energy

The invention relates to a thermal power generation system and a thermal energy device and a flue gas waste heat utilization device thereof. The flue gas waste heat utilization device comprises a first economizer communicating with a waste gas port of a boiler, a second economizer communicating with the first economizer and an air heater communicating with an air preheater. The first economizer conducts heat exchange with flue gas through a condensation water loop, and part of waste heat in the flue gas can be used for working of a steam turbine. Furthermore, the second economizer is matched with the air heater, and part of 'low grade waste heat' cannot be utilized by the first economizer in the flue gas is transformed into 'high grade heat' through a heat exchange loop for heating air entering the air preheater, so that heat entering into the boiler is increased. Meanwhile, the part of waste heat raises the temperature of the boiler flue gas after entering into the boiler, so that the first economizer can use more waste heat to work on the steam turbine. Therefore, through the heat exchange loop, the heat in the flue gas can be recycled, and the efficiency of flue gas waste heat recovery and utilization is effectively improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

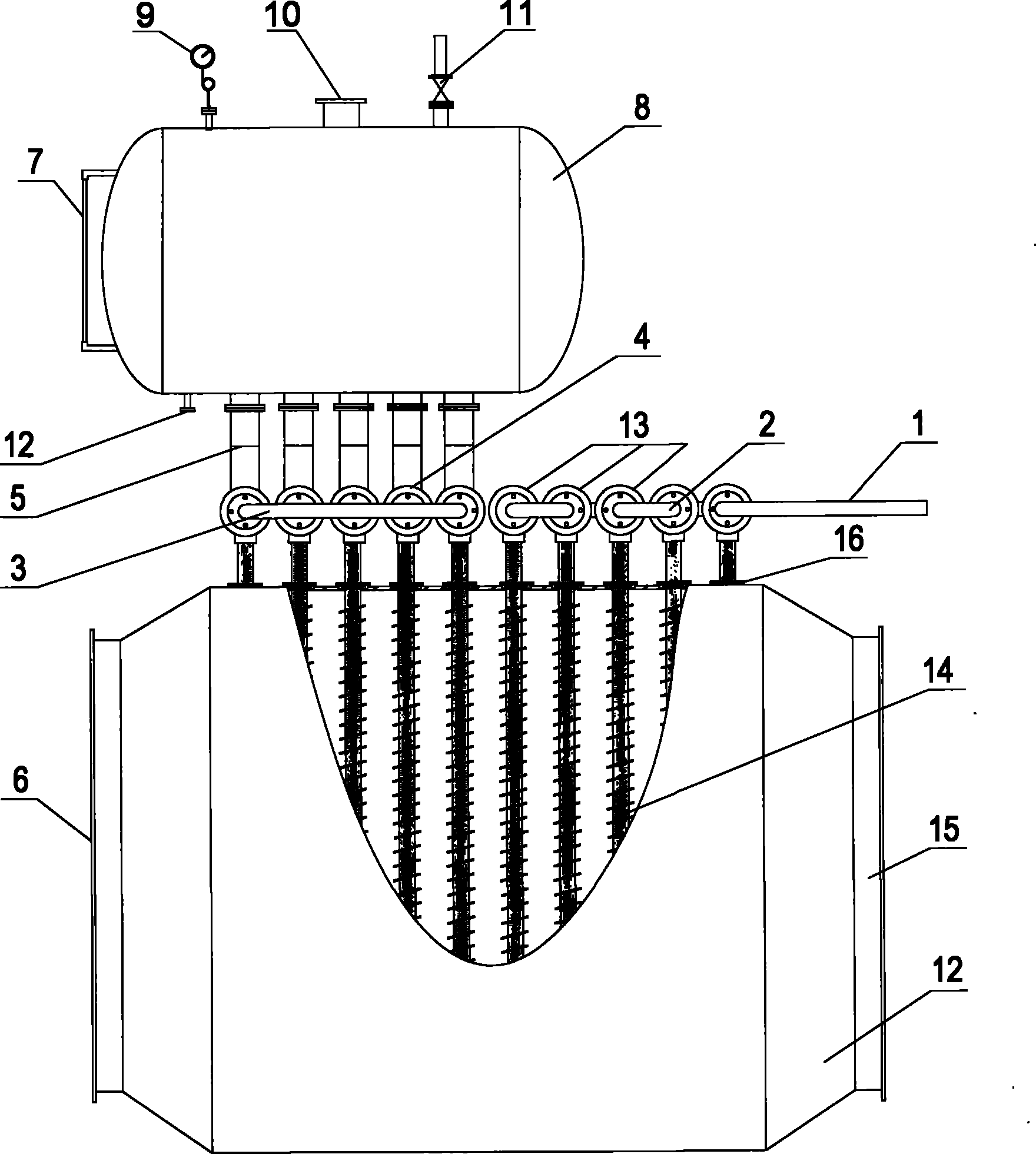

Heat tube bundle concentric casing tube waste heat recovery boiler

InactiveCN101280912BRealize integrationImprove the efficiency of waste heat recovery and utilizationChemical industryIndirect heat exchangersChemical industryEngineering

The invention relates to a heat tube bundle concentric casing tube heat-recovering boiler including a heat exchanger, a steam drum or hot water tank, a flue gas heat collection case, a tube system, the invention is characterized in that the heat exchanger is heat tube bundle concentric double pipe exchanger, more than one set of heat exchanger is arranged on upside cover plate of the flue gas heat collection case, metal fever tube of the heat exchanger is plugged in the flue gas collection heat flow path of the flue gas heat collection case, inner tubes of each set of the are connected in series, series-parallel or parallel by the tube system, and a tube opening of the inner tube of at least a set of heat exchanger has a water-supply tube interface of boiler connected, and a tube opening of the inner tube of at least a set of heat exchanger is communicated with the steam drum or hot water tank with a union tube. The invention has advantages of concentric inner casing tube being circulation column tube of the exhaust-heating boiler, high heat-recovering-using efficiency, compact conformation, dependable performance, thereby being a desired apparatus for small temperature differential waste heat recovery and utilization. The apparatus not only can generate medium, high temperature steam, but also high temperature hot water or assembly utilization. The invention can be abroad used for energy conservation, discharge reduction and environmental conservation of energy-intensive industry such as chemical industry, stone oil industry, electric power industry, coal industry, building material industry etc.

Owner:BAOTOU BOTE TECH

Furnace slag split-flow heat exchange device

PendingCN107806771AAvoid high wind speedImprove the efficiency of waste heat recovery and utilizationWaste heat treatmentSlagAirflow

The invention relates to a furnace slag split-flow heat exchange device. The furnace slag split-flow heat exchange device comprises an airtight shell; a furnace slag collecting chamber is arranged inthe airtight shell; a heat exchange material bed used for bearing and conveying furnace slag is disposed in the furnace slag collecting chamber; an air distribution plate is disposed above the heat exchange material bed; the furnace slag collecting chamber comprises a heat exchange cavity located above the air distribution plate; a split-flow cavity is disposed on the inner side of the side wall of the airtight shell; a heat storage structure used for absorbing radiant heat of the furnace slag is disposed at the upper end of the air distribution plate; the heat storage structure is provided with channels which communicate with the heat exchange cavity and the split-flow cavity; and air holes which communicate with the furnace slag collecting chamber and the split-flow cavity are disposed in the lower end of the air distribution plate. The furnace slag split-flow heat exchange device can perform split flowing on air flow before the air flow enters the air distribution plate area, so that too high air speed of the air distribution plate area is avoided; and the heat storage structure at the upper end of the air distribution plate can be used for absorbing radiant heat during furnaceslag granulation, cooling air flow of the split-flow cavity carries the heat to enter the heat exchange cavity, and the waste heat recovery utilization efficiency is high.

Owner:中山蓝冰节能环保科技有限公司

Cement Kiln Waste Heat Utilization System and Method for Directly Driven Rotary Equipment by Steam Turbine

ActiveCN104654816BAvoid lossImprove the efficiency of waste heat recovery and utilizationEnergy industryIncreasing energy efficiencyEngineeringSuperheated steam

The invention provides a cement kiln waste-heat utilization system and a method for directly driving rotating equipment by a turbine. The system and the method belong to the technical field of cement kiln waste-heat utilization. The waste-heat utilization system comprises a waste-heat recovery device, a high-temperature fan turbine drive device, a kiln tail exhaust fan turbine drive device, a cement grinding mill turbine drive device and a circulating cooling water device. According to the system and the method, superheated steam generated by the cement kiln waste heat is utilized to directly drive rotating equipment such as a high-temperature fan, a kiln tail exhaust fan and a cement grinding mill, the energy loss during the multistep energy transformation process from heat energy to electric energy to kinetic energy of waste heat power generation is avoided, and the cement kiln waste heat recovery and utilization efficiency is effectively improved.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

System and method for power generating by jointly recovering waste heat of flue gas of sintering machine and exhaust gas of cooling machine

ActiveCN102012167BImprove the efficiency of waste heat recovery and utilizationIncrease feed water temperatureEnergy industryIncreasing energy efficiencyWaste heat recovery unitFlue gas

The invention discloses a system and method for power generating by jointly recovering the waste heat of a flue gas of a sintering machine and an exhaust gas of a cooling machine, belonging to the technical field of power generation by using waste sintering heat of a steel and iron plant. The power generating system comprises a sintering machine flue gas waste heat utilizing system, a cooling machine exhaust gas waste heat utilizing system, a turbine generating system and a relevant auxiliary system, wherein a main waste heat discharging boiler is utilized to recover the waste heat of the flue gas of a high-temperature segment of the tail part of the sintering machine; a cooling machine waste heat boiler is utilized to recover the waste heat of the high-temperature exhaust gas of the cooling machine; and a high-temperature electric butterfly valve is arranged between the high-temperature segment and a low-temperature segment of a large flue positioned on the tail part of the sinteringmachine to prevent the wind pickup temperature of the flue gas from being reduced because a low-temperature flue gas and a high-temperature flue gas are directly mixed so as to ensure the high-temperature flue gas to enter the main waste heat discharging boiler for waste heat recovery. The system and method effectively utilizes the waste heat resources of the high-temperature flue gas of the machine tail of the sintering machine and a hot gas of the high-temperature segment of the cooling machine, enhances the waste heat recovery and utilization efficiency of a sintering process and increasesthe power generation capacity of the waste heat power generating system.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com