Heat tube bundle concentric casing tube waste heat recovery boiler

A technology of waste heat recovery boiler and concentric casing, which is applied in the field of waste heat recovery boiler with concentric casing of heat pipe bundles, can solve the problems of low utilization value, waste of energy, environment, and poor utilization, etc., to improve the efficiency of waste heat recovery and utilization, condensation The effect of large area and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

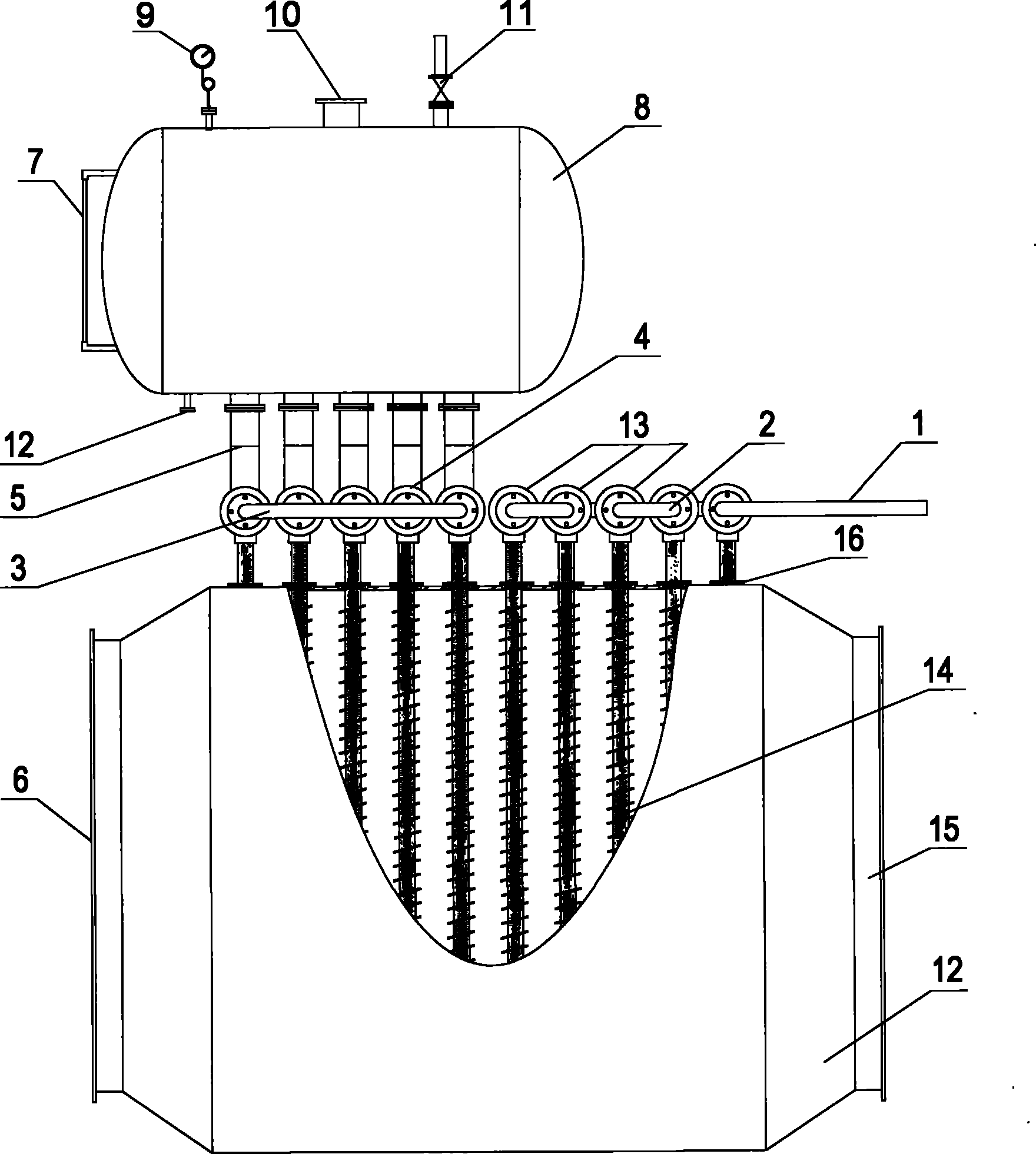

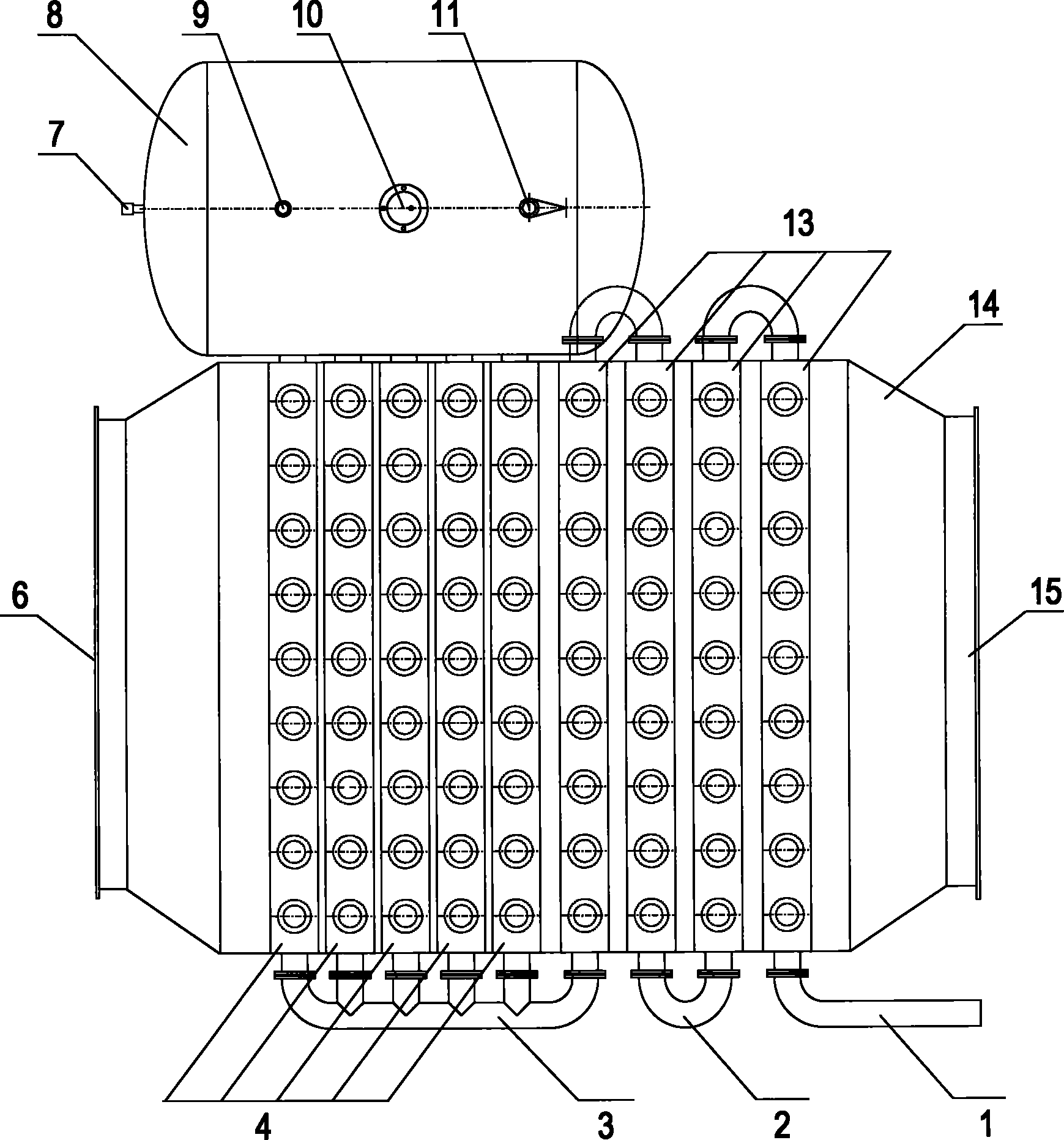

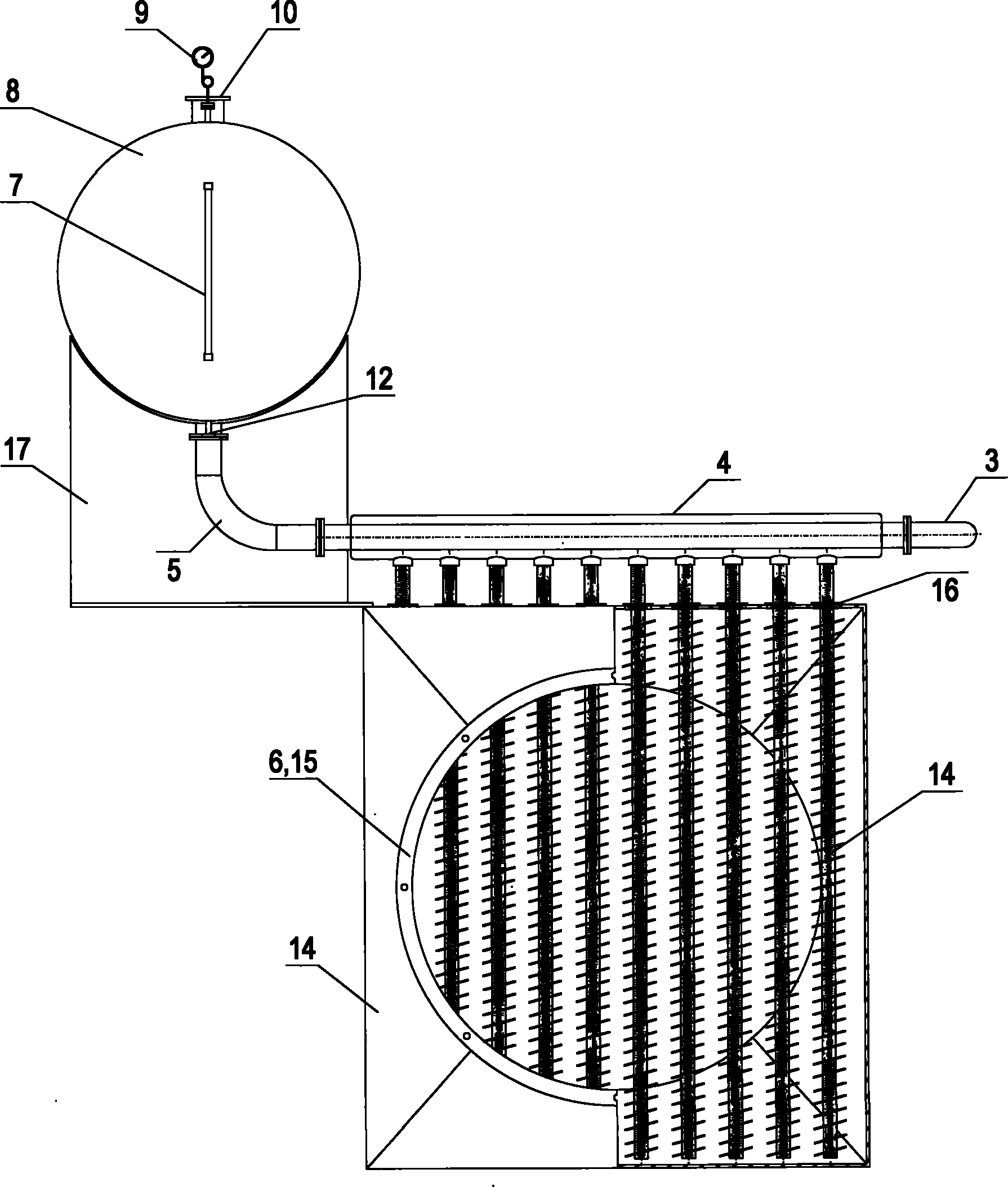

[0035] Steel-Water Helical Fin Heat Tube Bundle Concentric Casing Steam Waste Heat Recovery Boiler

[0036] Structure: 10 concentric casing heat exchangers with heat-exhausting tube bundles; each heat-tube bundle exchanger is composed of 12 spiral-finned heat pipes;

[0037] Heat pipe bundle concentric casing heat exchanger connection mode: series-parallel;

[0038] Heat tube bundle concentric casing heat exchanger material: boiler steel;

[0039] Working fluid: pure water + degasser;

[0040] Operating temperature: 20°C-+400°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com