Furnace slag split-flow heat exchange device

A heat exchange device and slag technology, which is applied in furnaces, waste heat treatment, furnace components, etc., can solve the problem of high wind speed in the area of particles entering the hot air flue and air distribution board, and avoid excessive wind speed and high waste heat recovery and utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present application will be further described below in conjunction with the accompanying drawings and specific embodiments.

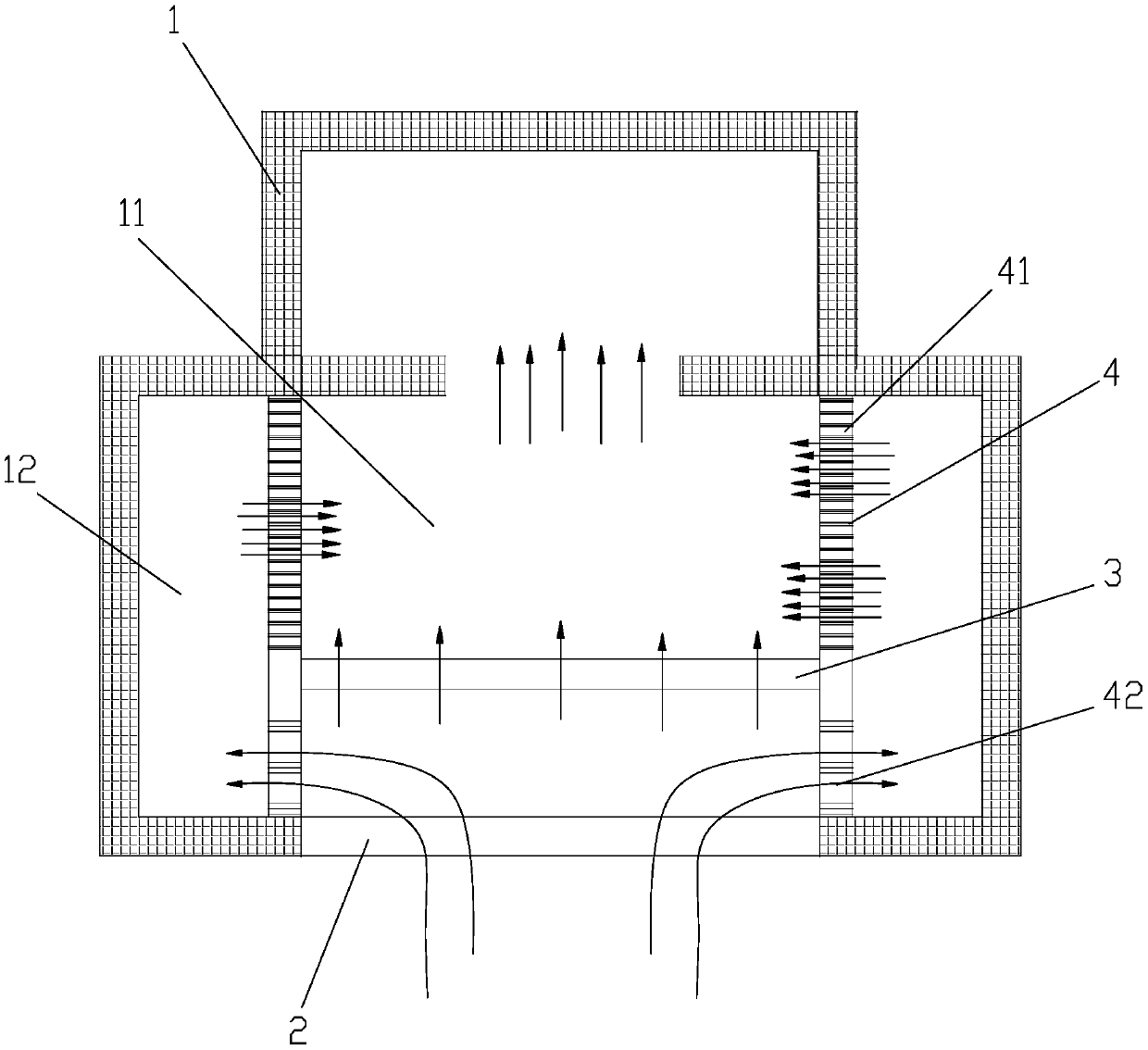

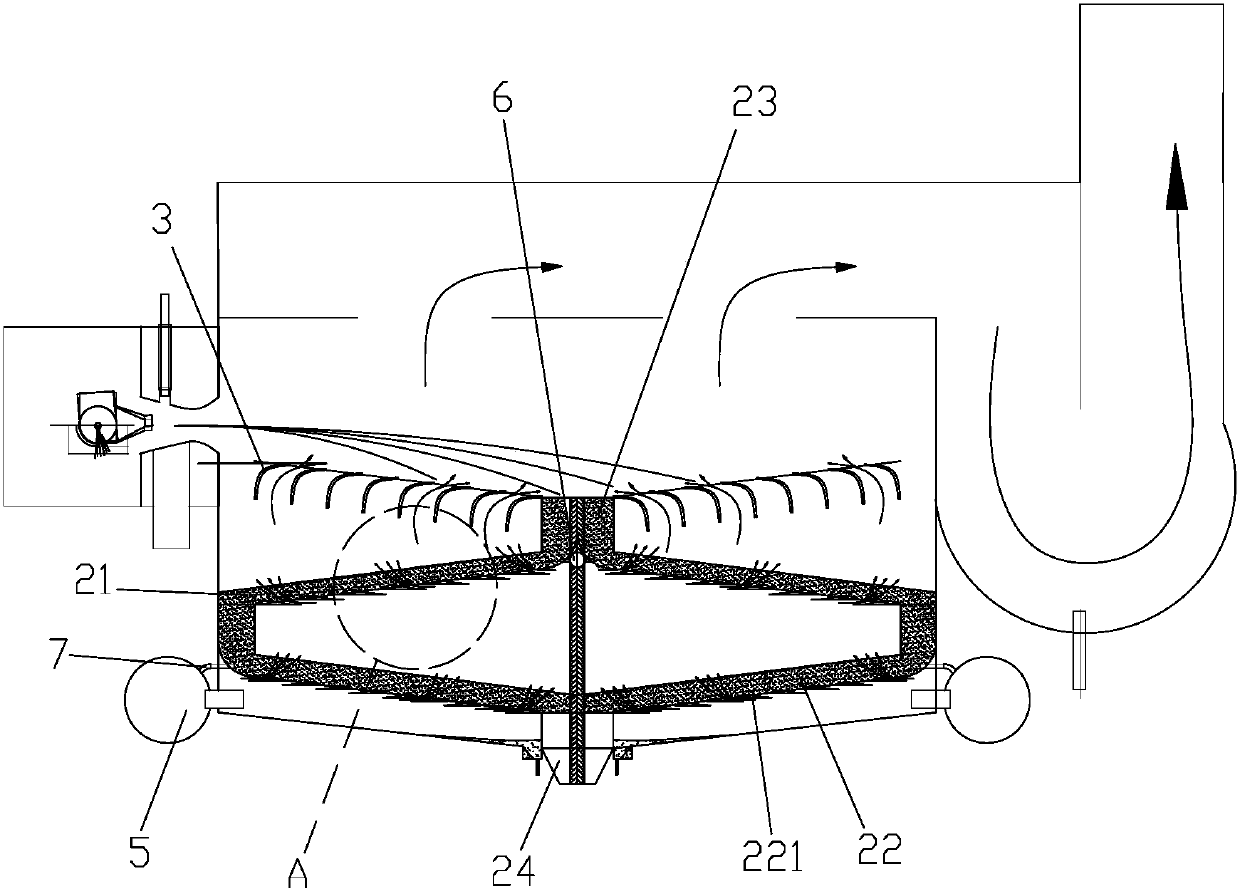

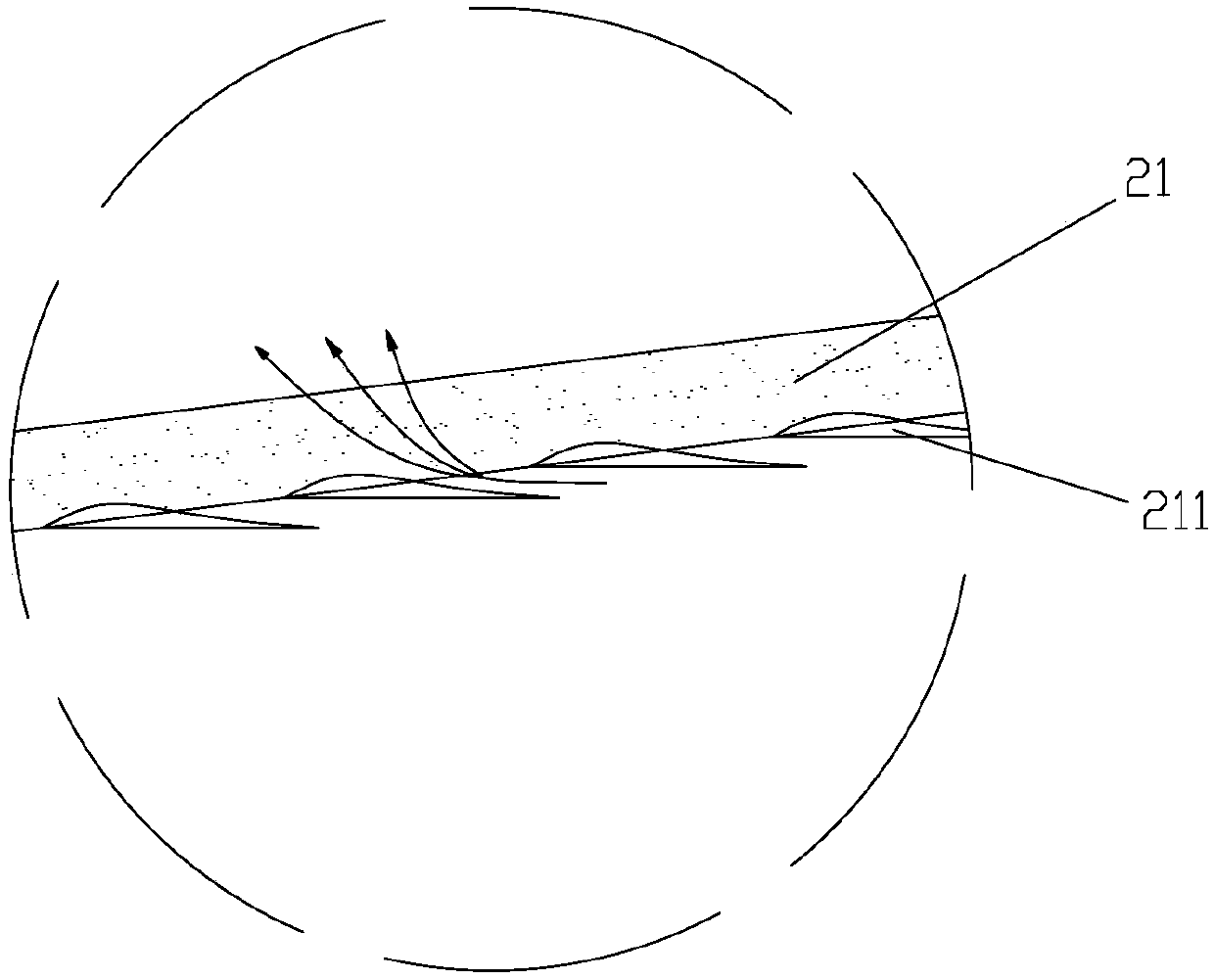

[0021] Such as Figure 1 to Figure 3 As shown, a slag shunt heat exchange device includes an airtight casing 1, and a slag collection chamber is arranged inside the airtight casing 1, and it is characterized in that a heat exchange material for carrying and transporting slag is arranged in the slag collection chamber. bed 2, an air distribution plate 3 is provided above the heat exchange material bed 2, the slag collection chamber includes a heat exchange chamber 11 located above the air distribution plate, and the inside of the side wall of the airtight casing 1 is provided with The distribution chamber 12, the upper end of the air distribution plate 3 is provided with a heat storage structure 4 for absorbing slag radiation heat, and the heat storage structure is provided with a channel 41 connecting the heat exchange chamber and the distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com