Cement Kiln Waste Heat Utilization System and Method for Directly Driven Rotary Equipment by Steam Turbine

A technology for rotating equipment and steam turbines, applied in mechanical equipment, cement production, steam engine installations, etc., can solve problems such as large energy loss, and achieve the effect of avoiding energy loss and improving waste heat recovery and utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

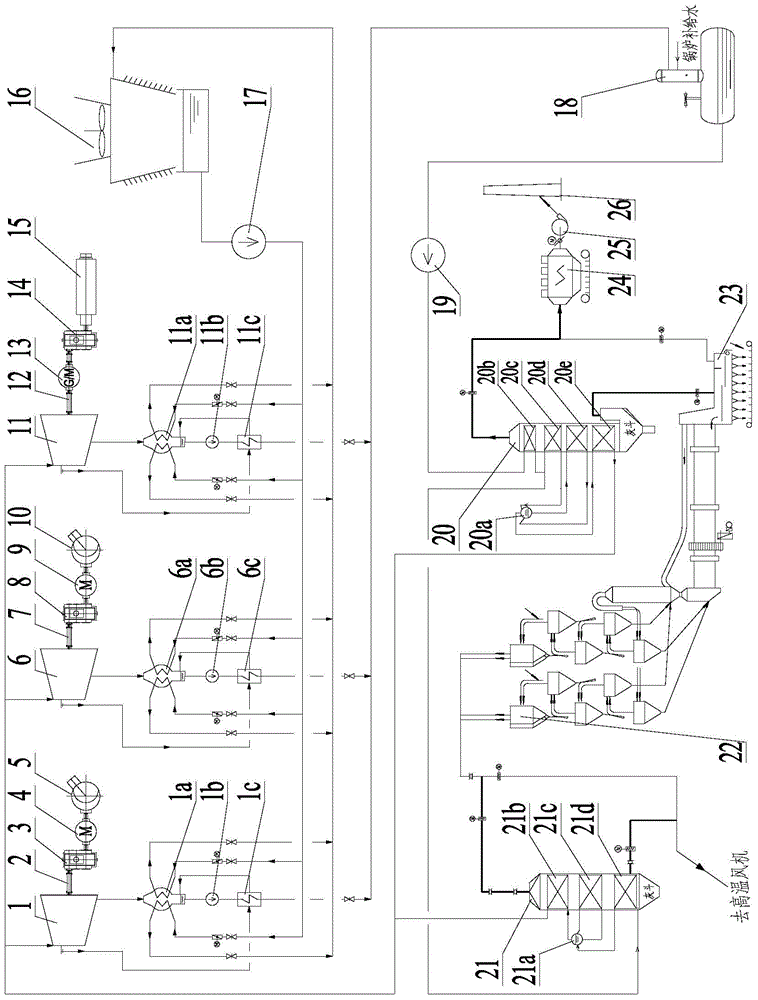

[0025] Such as figure 1 As shown, a cement kiln waste heat utilization system in which the steam turbine directly drives the rotating equipment includes a waste heat recovery device, a high-temperature fan steam wheel drive, a kiln exhaust fan steam wheel drive, a cement mill steam wheel drive, and a circulating cooling water device and exhaust gas treatment devices.

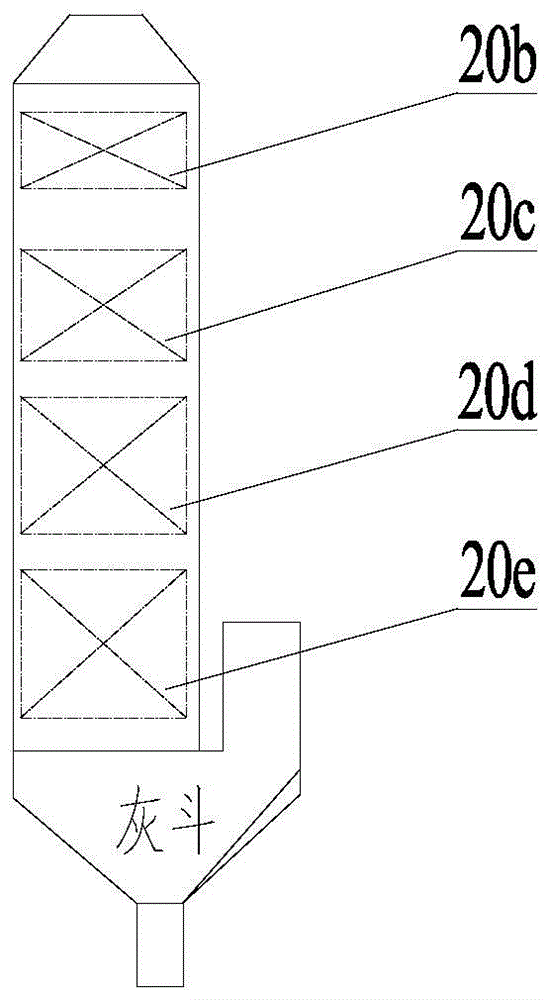

[0026] The waste heat recovery device mainly includes deaerator 18, feed water pump 19, kiln head boiler 20, kiln tail boiler 21, kiln tail preheater 22 and grate cooler 23; the outlet of deaerator 18 is connected with the inlet of feed water pump 19, The outlet of the feed water pump 19 is connected to the inlet of the public economizer 20b of the kiln head boiler 20, and the air intake in the middle of the grate cooler 23 is connected to the inlet of the kiln head boiler 20 through an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com