Air conditioner distributed air supply duct structure of shunting locomotive cab

A technology for shunting locomotives and driver's cabs, which is applied to the heating/cooling of locomotives, railway car body parts, and railway vehicles, and can solve the problems of high wind speed in the driver's cab, affecting the comfort of the driver's air conditioner, and high wind speed on the driver's head , to achieve the effect of avoiding high wind speed, preventing shutdown protection, and preventing wind speed from being too high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

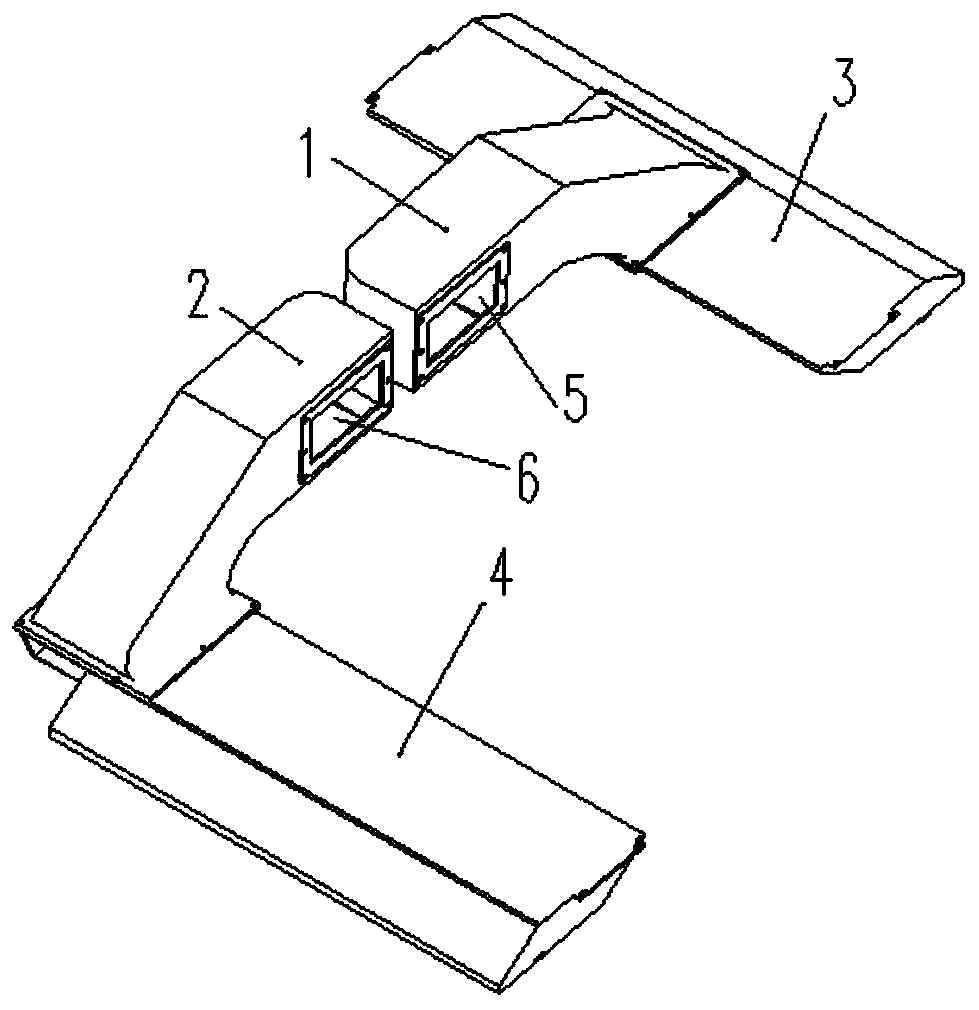

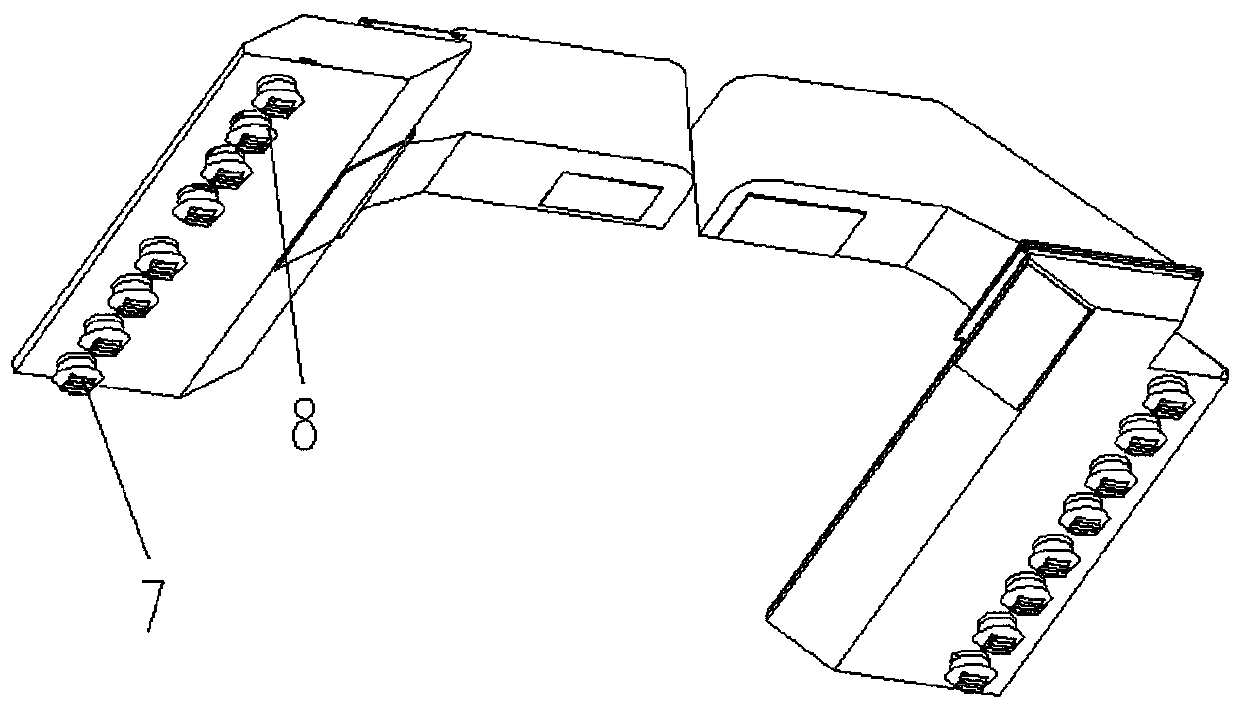

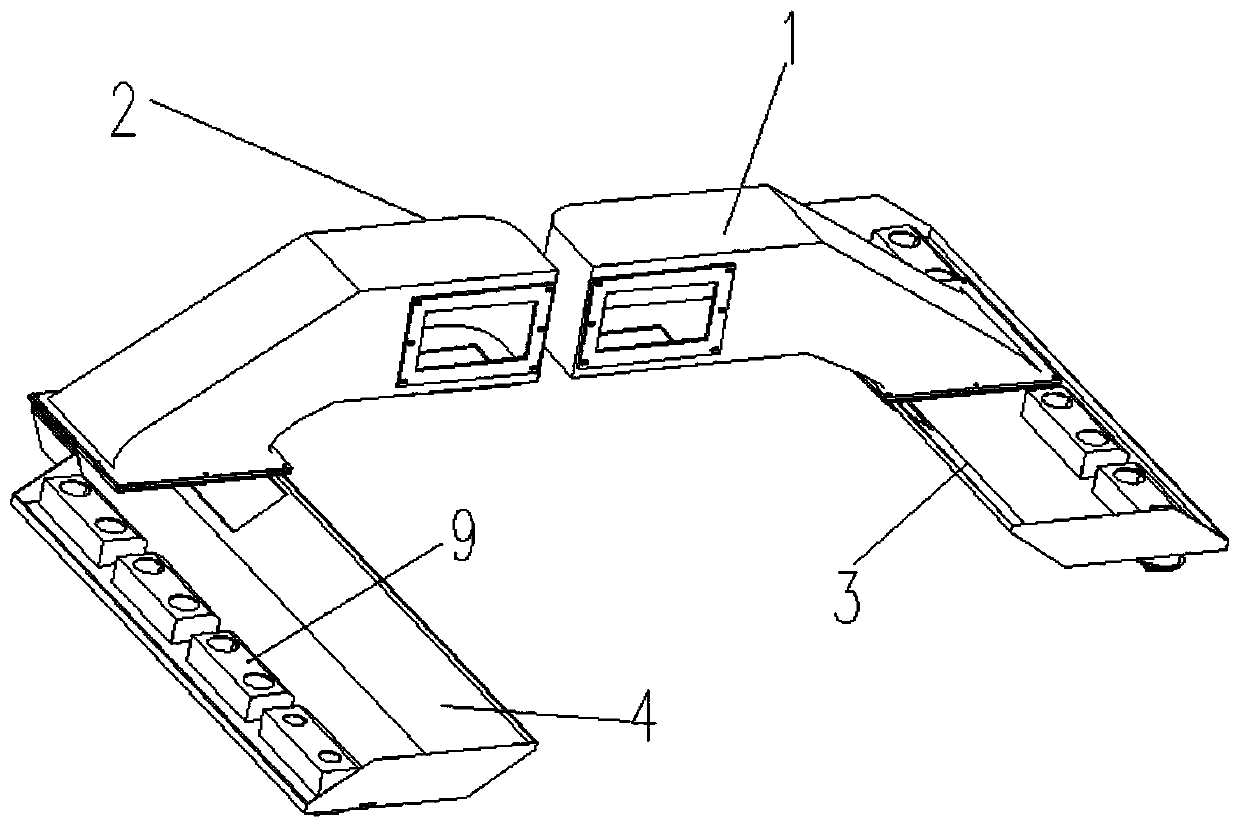

[0026] A distributed air-supply air duct structure for the cab of a shunting locomotive, such as Figure 1-3 As shown, it includes the upper left air duct 1 and the upper right air duct 2 placed on the top of the driver's cab, the upper left air duct 1 is provided with a butt hole 5 for the air outlet of the air conditioner, and the upper left air duct 1 and the upper left air duct 3 connected; the upper right air duct 2 is provided with a butt hole 6 of the air outlet of the air conditioner, and the upper right air duct 2 communicates with the right air duct 4; the bottom of the left air duct 3 and the bottom of the right air duct 4 are provided with A number of air outlets, the inside of the left air duct 3 and the inside of the right air duct 4 are provided with a static pressure partition chamber 9, one of the static pressure partition chambers 9 is arranged at 1-4 of the air outlets, and several of the air outlets There are several adjustable outlet grilles 7 placed at th...

Embodiment 2

[0028] Based on the above-mentioned embodiment 1, such as figure 2 As shown, the bottom of the left air duct 3 and the bottom of the right air duct 4 are also provided with no less than two non-adjustable air outlet grilles 8 . In this embodiment, there are not less than two non-adjustable air outlet grilles 8 at the bottom of the left air duct 3 and the bottom of the right air duct 4 respectively, which can prevent the air conditioner from freezing and cause the air conditioner to shut down. This is because The air conditioner itself has a pressure alarm. After the evaporator tube freezes, the pressure inside the tube increases, and the alarm will shut down the air conditioner to protect the air conditioner. Therefore, if the air outlet grille is completely closed, the air circulation will be blocked, and the heat will not be exchanged. It will freeze, causing the air conditioner to be shut down for protection. Therefore, it is necessary to set the non-adjustable air outlet ...

Embodiment 3

[0030] Based on the above-mentioned embodiment 2, such as figure 2 As shown, the non-adjustable air grid 8 at the bottom of the left air duct 3 is set away from the upper left air duct 1 end, and the non-adjustable air grid 8 at the bottom of the right air duct 4 is far away from the upper right air duct 2 end. In this embodiment, the non-adjustable air grid 8 set on the left air duct 3 is kept away from the upper left air duct 1, and the non-adjustable air grid 8 set on the right air duct 4 is kept away from the upper right air duct 2, because the non-adjustable wind When the grid is away from the upper left air channel 1 and the upper right air channel 2, it is far away from the operator's seat console in the driver's cab, thereby ensuring that all the air outlet grids on the driver's seat are adjustable air grids 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com