Method and device for realizing steel slag quenching and waste heat recovery by using water and carbon dioxide

A carbon dioxide and waste heat recovery technology, applied in the field of iron and steel metallurgy, can solve the problems of difficulty in efficient utilization of low-temperature sensible heat, difficulty in efficient utilization of low-temperature sensible heat, poor uniformity of steel slag particle size, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The molten metallurgical steel slag adopts the steel slag produced in the converter workshop, and its composition contains 46.92% CaO, SiO 2 17.96%, Fe 2 o 3 17.73%, MgO 8.99%, Al 2 o 3 3.73%, P 2 o 5 1.76%, TiO 2 1.23%, MnO1.68%;

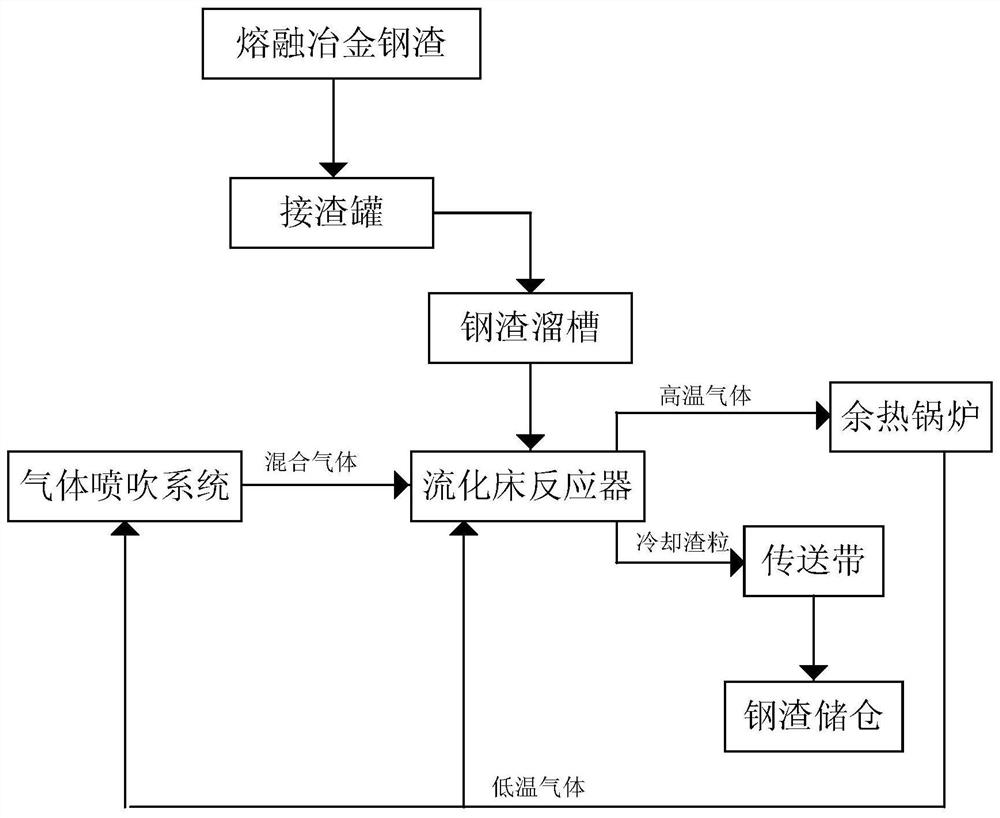

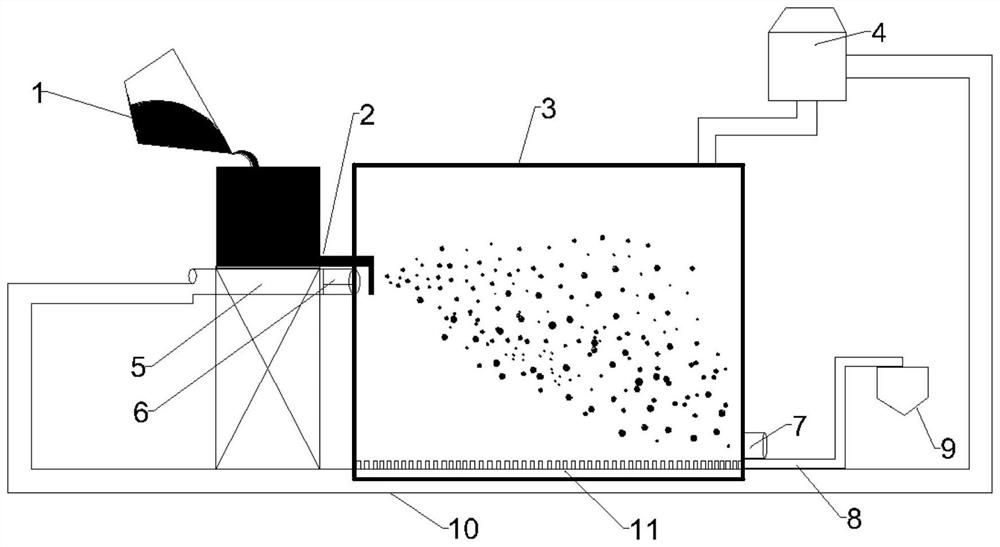

[0072] Process such as figure 1 shown, proceed as follows:

[0073] 1. Mix carbon dioxide and water vapor in the gas injection system to form a mixed gas; CO in the mixed gas 2 The volume fraction of the gas is 70%, and the rest is water vapor; the pressure of the mixed gas is 0.8MPa;

[0074] 2. The mixed gas is sprayed into the fluidized bed heat exchanger through the gas injection system, and discharged from the gas outlet of the fluidized bed heat exchanger, and enters the waste heat boiler; after being discharged from the waste heat boiler, it enters the gas circulation pipeline; the gas The circulation pipe is connected to the inlet of the gas injection system, and the middle part of the gas circulation pipe is connected...

Embodiment 2

[0091] The molten metallurgical steel slag adopts the steel slag produced in the electric furnace workshop, and its composition contains 49.64% CaO, SiO 2 41.64%, Fe 2 o 3 0.83%, MgO 0.16%, Al 2 o 3 4.23%, SO 3 0.62%, P 2 o 5 2.76%, MnO0.12%;

[0092] Method is with embodiment 1, and difference is;

[0093] (1) CO in the mixed gas 2 The volume fraction of the gas is 80%; the pressure of the mixed gas is 0.5MPa;

[0094] (2) The total amount of CaO in the molten metallurgical steel slag is 496.4kg; the total heat recovered by the waste heat boiler = 1.671×10 9 J; δCaO = 89%;

[0095] The heat recovery rate of molten metallurgical steel slag is 99.166%.

Embodiment 3

[0097] The molten metallurgical steel slag adopts the steel slag produced in the refining workshop, and its composition contains 39.89% CaO, SiO 2 31.68%, Fe 2 o 3 3.86%, MgO 12.73%, SO 3 1.13%, Al 2 o 3 4.92%, CaCO 3 2.42%, P 2 o 5 1.23%, MnO 2.14%;

[0098] Method is with embodiment 1, and difference is:

[0099] (1) CO in the mixed gas 2 The volume fraction of the gas is 90%, and the rest is water vapor; the pressure of the mixed gas is 0.3MPa;

[0100] (2) The total amount of CaO in the molten metallurgical steel slag is 398.9kg; the total heat recovered by the waste heat boiler = 1.5573×10 9 J; δCaO = 85.07%;

[0101] The heat recovery rate of molten metallurgical steel slag is 92.432%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com