A speed-based control method for waste heat comprehensive recovery system of marine low-speed diesel engine

A diesel engine and rotational speed technology, which is applied in mechanical equipment, steam engine devices, combustion engines, etc., to achieve the effect of improving utilization efficiency and simple implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

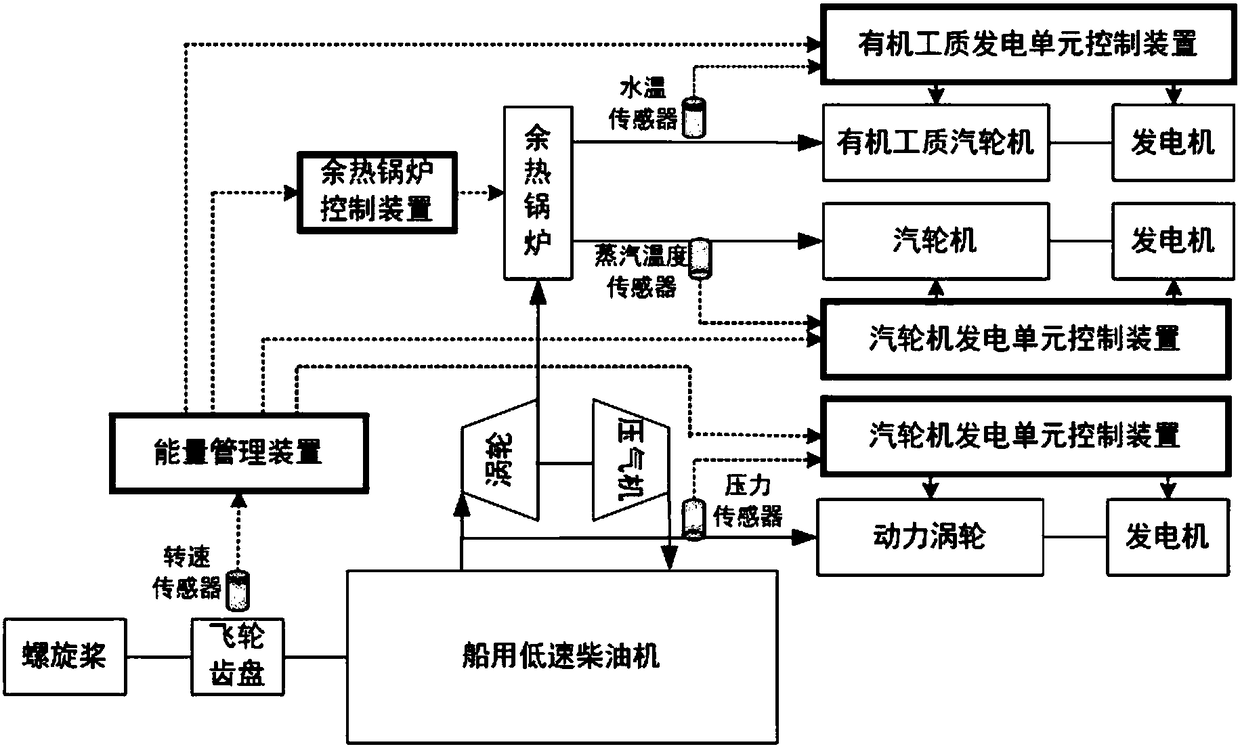

Method used

Image

Examples

Embodiment approach

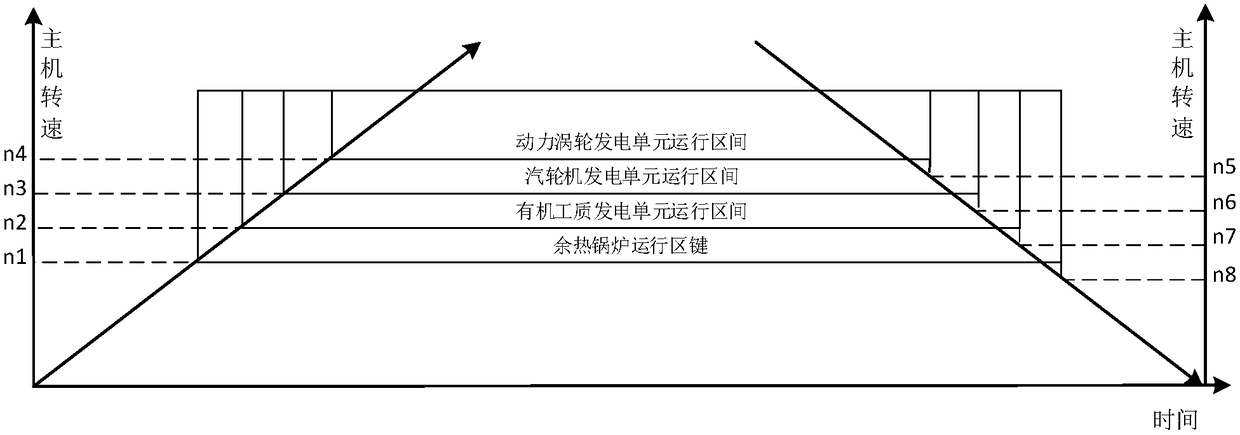

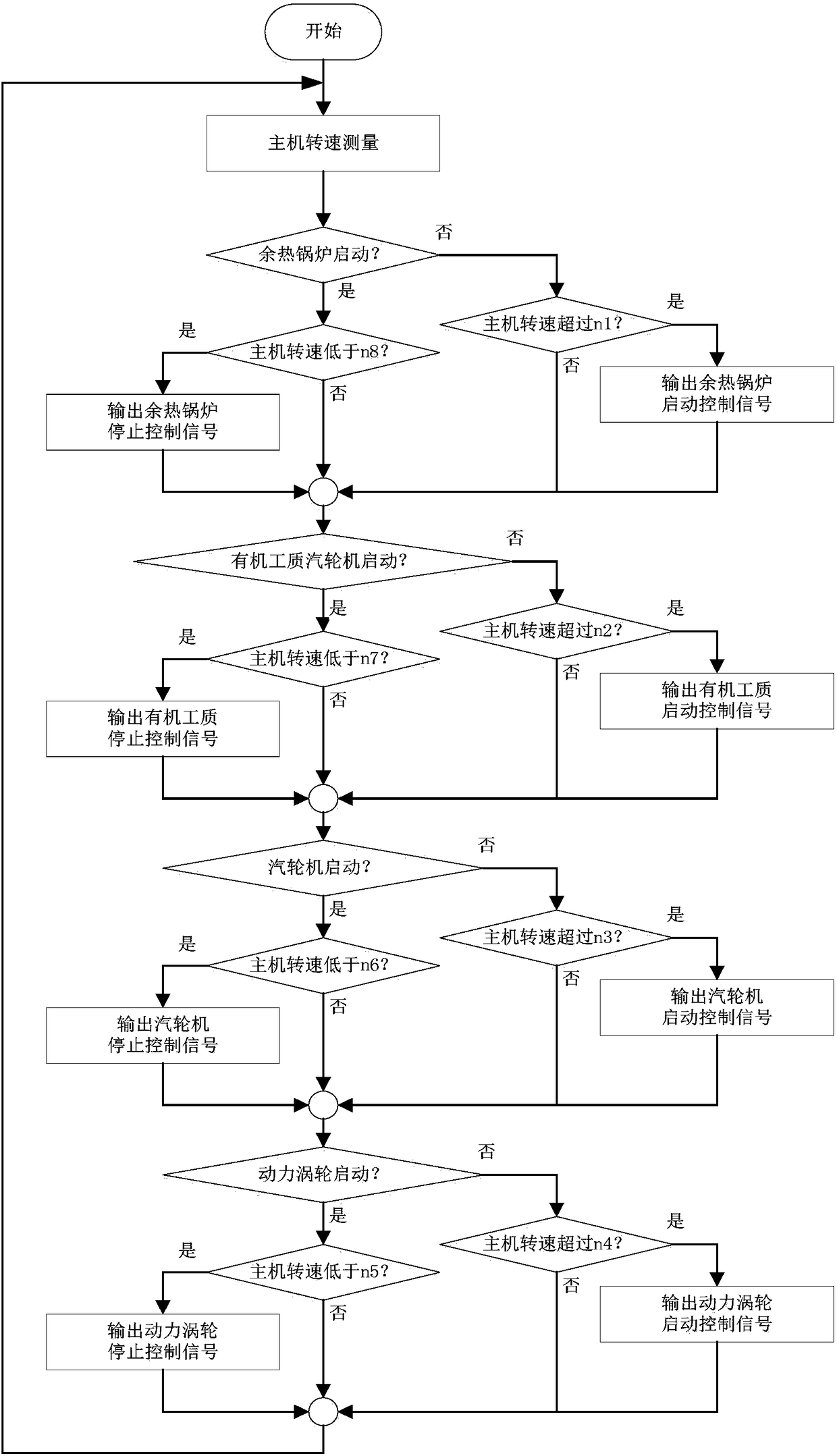

[0035] The first section is the start-up and no-load section of the diesel engine. When the speed of the diesel engine is lower than the set value n1 after starting, or the speed is lower than the set value n8 after deceleration discharge;

[0036] The second section is the boiler working section. When the speed of the diesel engine exceeds the first set value n1 during the speed-up stage, the control device of the waste heat boiler power generation unit closes the bypass flue to start the waste heat boiler. At the same time, the boiler water circulation system works, and the diesel engine discharges The gas passes through the waste heat boiler to heat the furnace water, and the exhaust gas flows through the heat exchangers of each section of the waste heat boiler in turn, and then is discharged into the atmosphere from the outlet flue of the waste heat boiler; The boiler power generation unit control device shuts down the waste heat boiler and opens the bypass flue.

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com