System and method for combined recovery of waste heat from flue gas from glass melting furnace and waste heat from annealing kiln

A technology for glass melting furnaces and power generation systems, applied in waste heat treatment, charge composition/state, lighting and heating equipment, etc., to achieve the effects of preventing corrosion, increasing power generation, preventing poisoning and surface clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

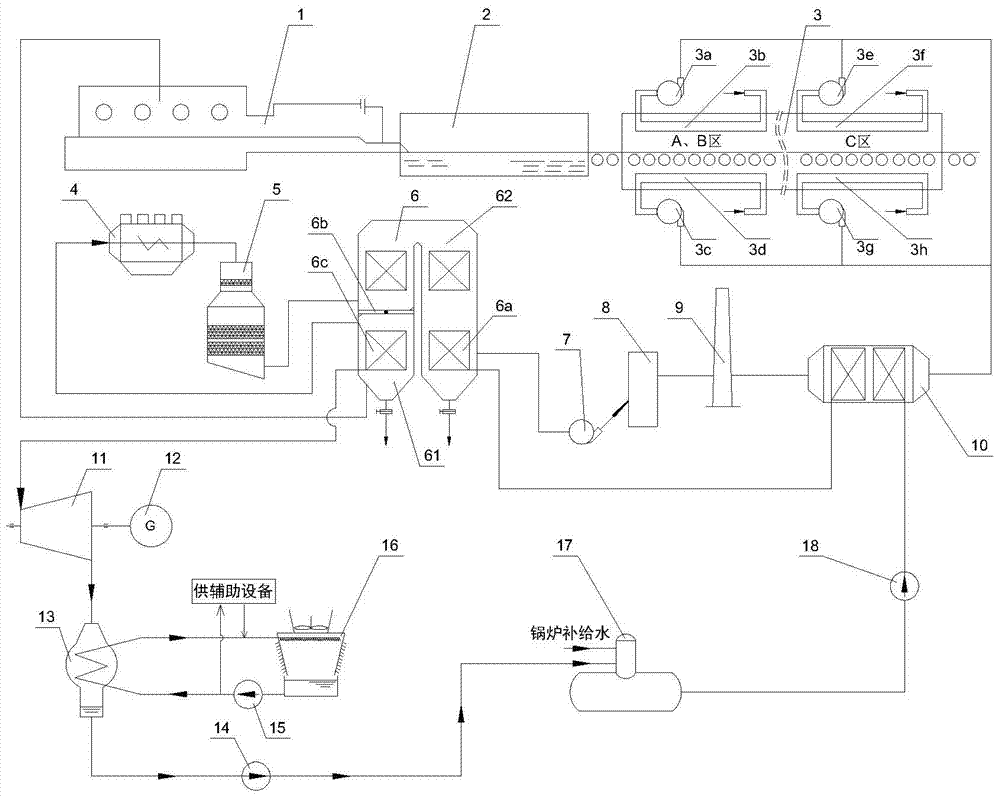

[0019] As shown in Figure 1, the combined recovery power generation system of glass melting furnace flue gas and annealing kiln waste gas waste heat of the present invention includes glass melting furnace flue gas treatment and waste heat utilization system, annealing kiln waste gas waste heat utilization system, steam turbine power generation system and related auxiliary system.

[0020] Glass melting furnace flue gas treatment and waste heat utilization system, including high-temperature electrostatic precipitator 4, denitrification reactor 5, waste heat boiler 6, induced draft fan 7, desulfurization device 8 and chimney 9, etc.; waste heat boiler 6 is divided into high-temperature sections by baffle 6b 61 and low-temperature section 62; the flue gas inlet of the high-temperature section 61 of the waste heat boiler is connected with the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com