Vehicle-mounted compatibility test platform for automobile exhaust thermoelectric power generation system and test method thereof

A technology of compatibility testing and temperature difference power generation, which is applied in the testing of machines/structural components, testing of electrical devices in transportation, measuring electricity, etc., can solve the lack of comprehensive performance detection and vehicle compatibility evaluation of vehicle exhaust temperature difference power generation systems Insufficiency and other problems, to reduce impact, optimize vehicle compatibility, and improve utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

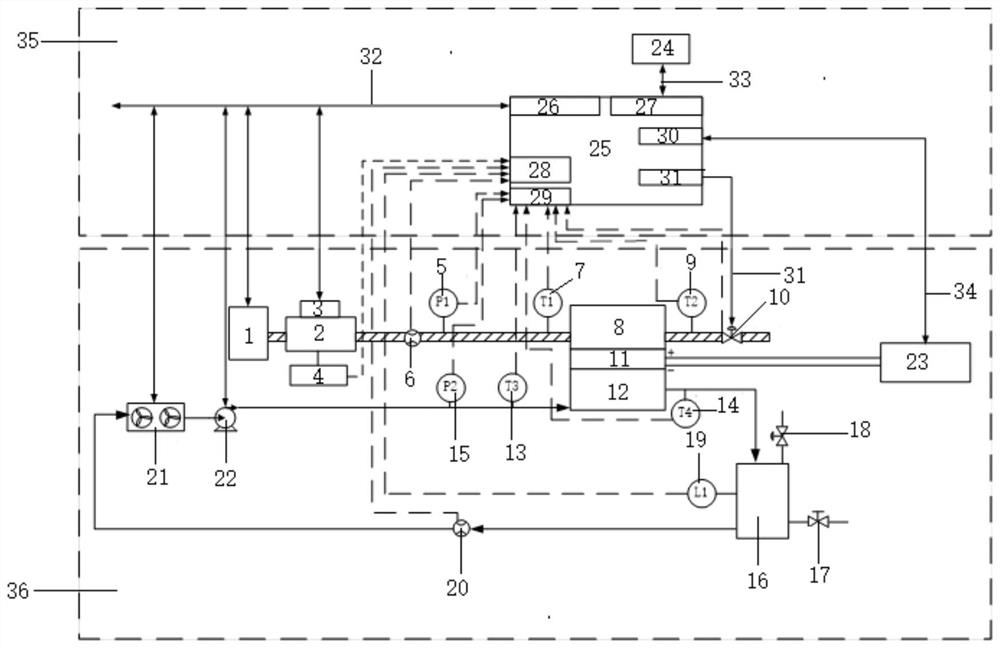

[0029] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as figure 1 As shown, the technical solution adopted by the device of the present invention is: a vehicle-mounted compatibility test platform for an automobile exhaust temperature difference power generation system, including a temperature difference power generation and performance detection unit 36 and a monitoring unit 35; Machine 1, engine 2, ECU3, fuel consumption meter 4, first pressure sensor P1, first flow sensor 6, first temperature sensor T1, heat exchanger 8, second temperature sensor T2, pressure regulating valve 10, thermoelectric device group 11 , cooling water tank 12, third temperature sensor T3, fourth temperature sensor T4, second pressure sensor P2, kettle 16, hand valve 17, water injection valve 18, liquid level sensor L1, second flow sensor 20, radiator 21, water pump 22 and programmable electronic load 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com