Slag waste heat recycling device

A waste heat recovery and slag technology, applied in fluid heaters, heat exchange equipment, indirect heat exchangers, etc., can solve the problems of affecting the efficiency of waste heat recovery and utilization, damage to the discharge conveyor belt, and low work efficiency, so as to reduce heat loss, The effect of slowing down the loss of heat and improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

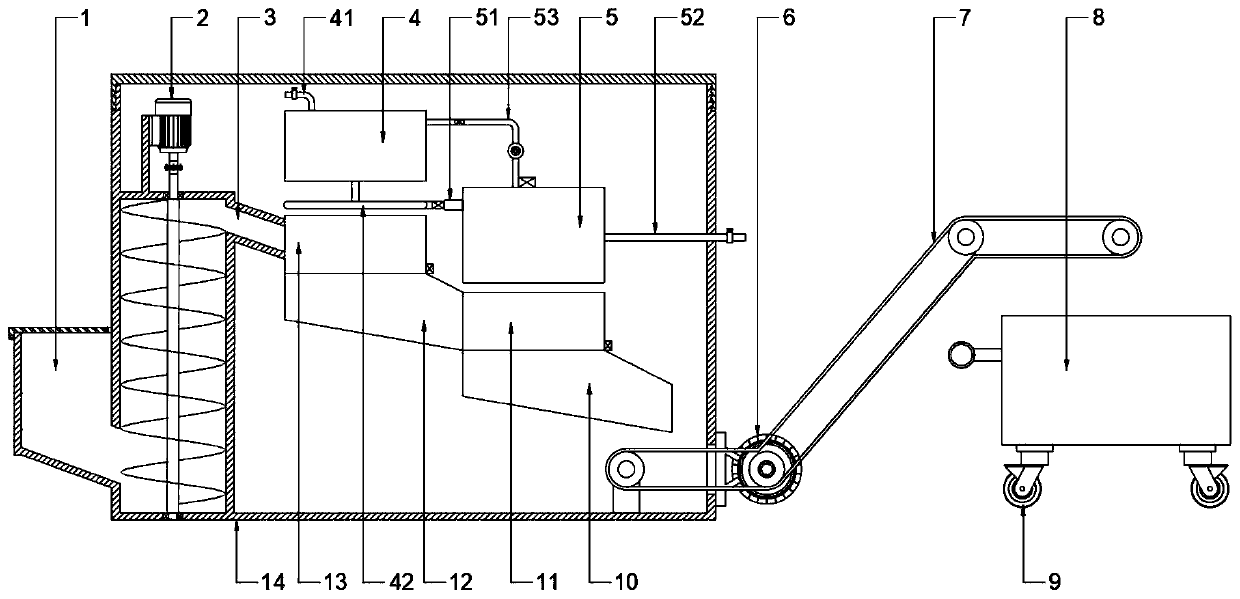

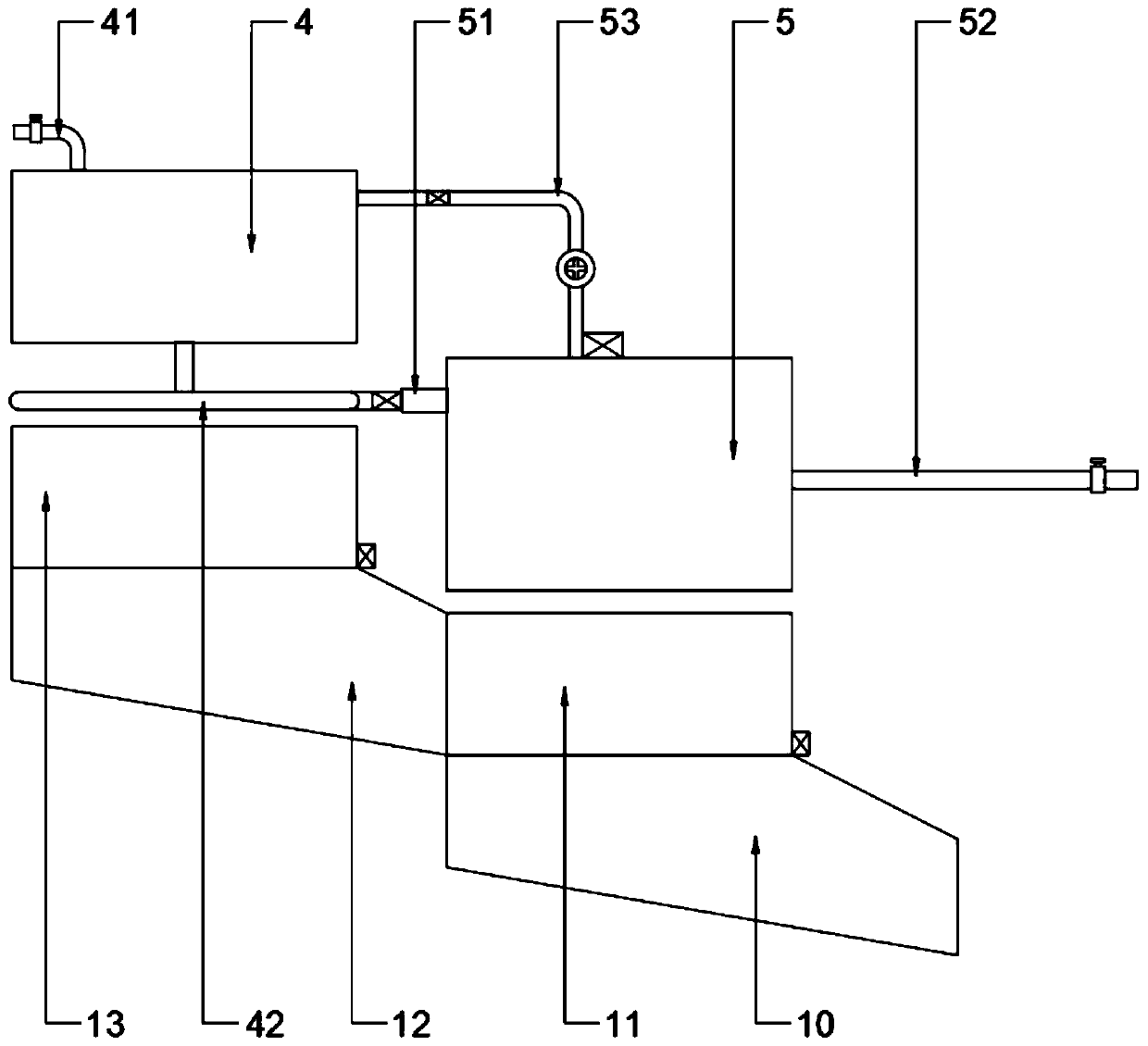

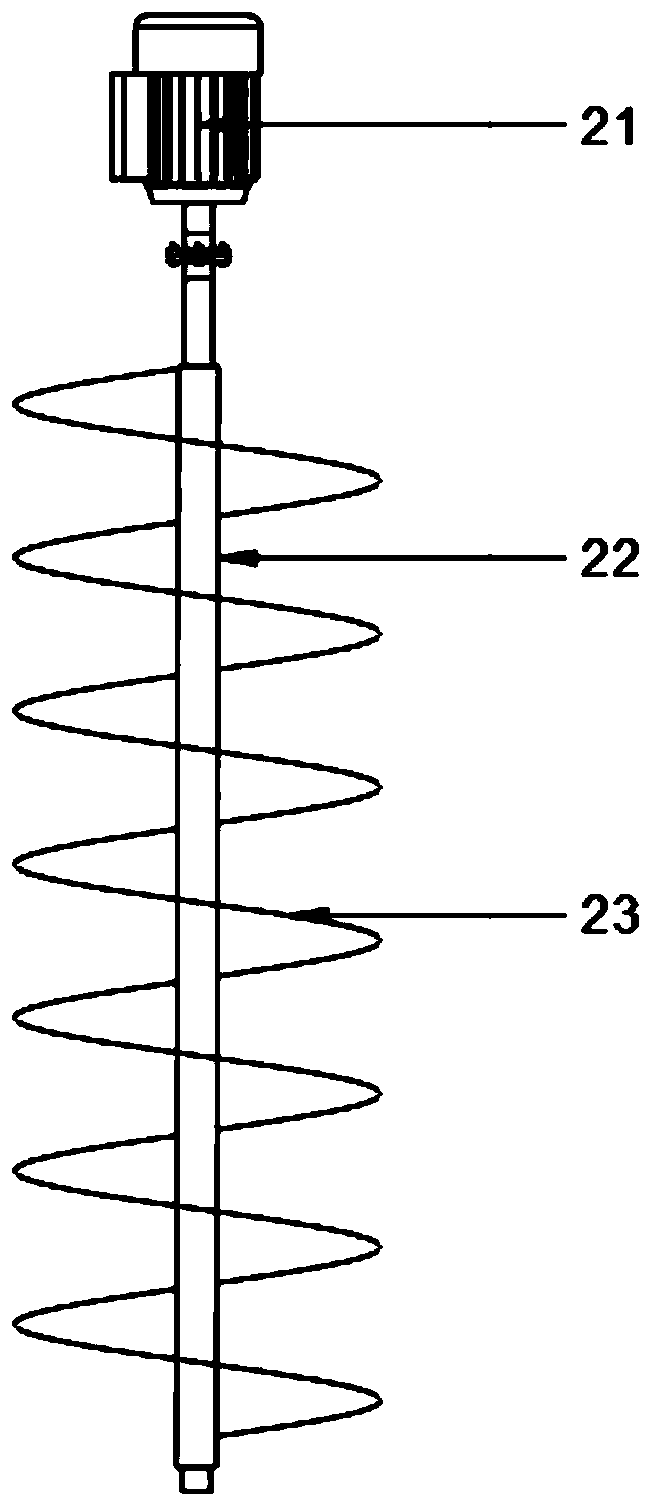

[0026] see Figure 1~4 , in an embodiment of the present invention, a slag waste heat recovery and utilization device includes a box body 14 and a waste heat recovery mechanism arranged inside the box body 14, and a feeding hopper 1 is connected to one side of the box body 14 and the feeding hopper 1 is rotatably provided with a feed door, which can effectively prevent the dust from overflowing during the process of conveying the slag, and the feed hopper 1 and the feed door are both made of heat insulating materials, which can slow down Dissipate, improve the utilization efficiency, and prevent the heat from being transferred to the feed hopper 1 and the feed door to burn the operator; the waste heat recovery mechanism includes a material conveying component 2 and a waste heat utilization component, and the material conveying component 2 is set in the box body 14 and its bottom is communicated with the feed hopper 1, and the discharge end of the conveying component 2 is provi...

Embodiment 2

[0036] see figure 1 , in the embodiment of the present invention, a slag waste heat recovery and utilization device, in order to improve the waste heat utilization rate and safety of the device, on the basis of embodiment 1, the top of the box 14 is provided with an upper cover, when used for a period of time Finally, open the upper cover to clean the inner wall of the box body 14 and the internal parts to prevent too much dirt and absorb the waste heat of the slag; the side walls of the box body 14 and the upper cover are hollow structures and the hollow structures are filled with Asbestos insulation reduces the heat loss of the slag, improves the recovery of waste heat from the slag, and avoids damage to operators caused by heat overflow.

[0037] The working principle of the present invention is:

[0038] When working, add water to the inside of the heating water tank 4 through the first water inlet pipe 41 to keep the water level above the minimum water level. The water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com