Sinter vertical cooling device capable of realizing gradient heat recovery and complete waste gas circulation

A technology of cascade recovery and cooling device is applied in the field of sintered ore vertical cooling device and cooling device. Long-term continuous and safe operation of equipment, etc., to improve the effect of gas-solid heat transfer, improve the efficiency of waste heat recovery and utilization, and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

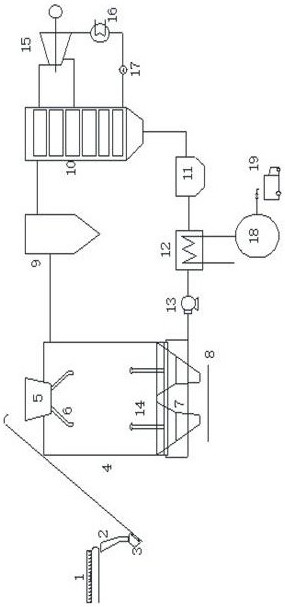

[0017] Embodiment 1: see figure 1 , a sinter vertical cooling device for heat cascade recovery of waste gas full cycle, the device includes a sintering machine 1, a feeding pipe 2, a material truck 3, a vertical cooling furnace 4, a material bin 5, a material distribution pipe 6, and a discharge pipe 7. Belt 8. Gravity dust collector 9. Waste heat boiler 10. Multi-tube dust collector 11. Hot water generator 12. Circulation fan 13. Air distributor 14. Turbine generator set 15. Condenser 16. Water pump 17. Heat storage station 18 and hot water truck 19, the feed bin 5 is arranged on the top of the shaft furnace 4, the distribution pipe 6 is arranged under the feed bin 5, the discharge pipe 7 is arranged at the bottom of the shaft furnace, and the shaft furnace 4 The gravity dust collector 9 and the waste heat boiler 10 are connected to the multi-tube dust collector 11, the hot water generator 12, and the circulating fan 13. 1. The water pump 17 is connected to the waste heat bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com