Waste heat comprehensive utilization power generation system and power generation method for sintering production line

A technology of power generation system and production line, applied in waste heat treatment, energy industry, machine/engine, etc., can solve the problems of insufficient utilization of flue gas heat, waste of waste heat resources of high temperature flue gas, etc., to improve the efficiency of waste heat recovery and utilization, and increase power generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

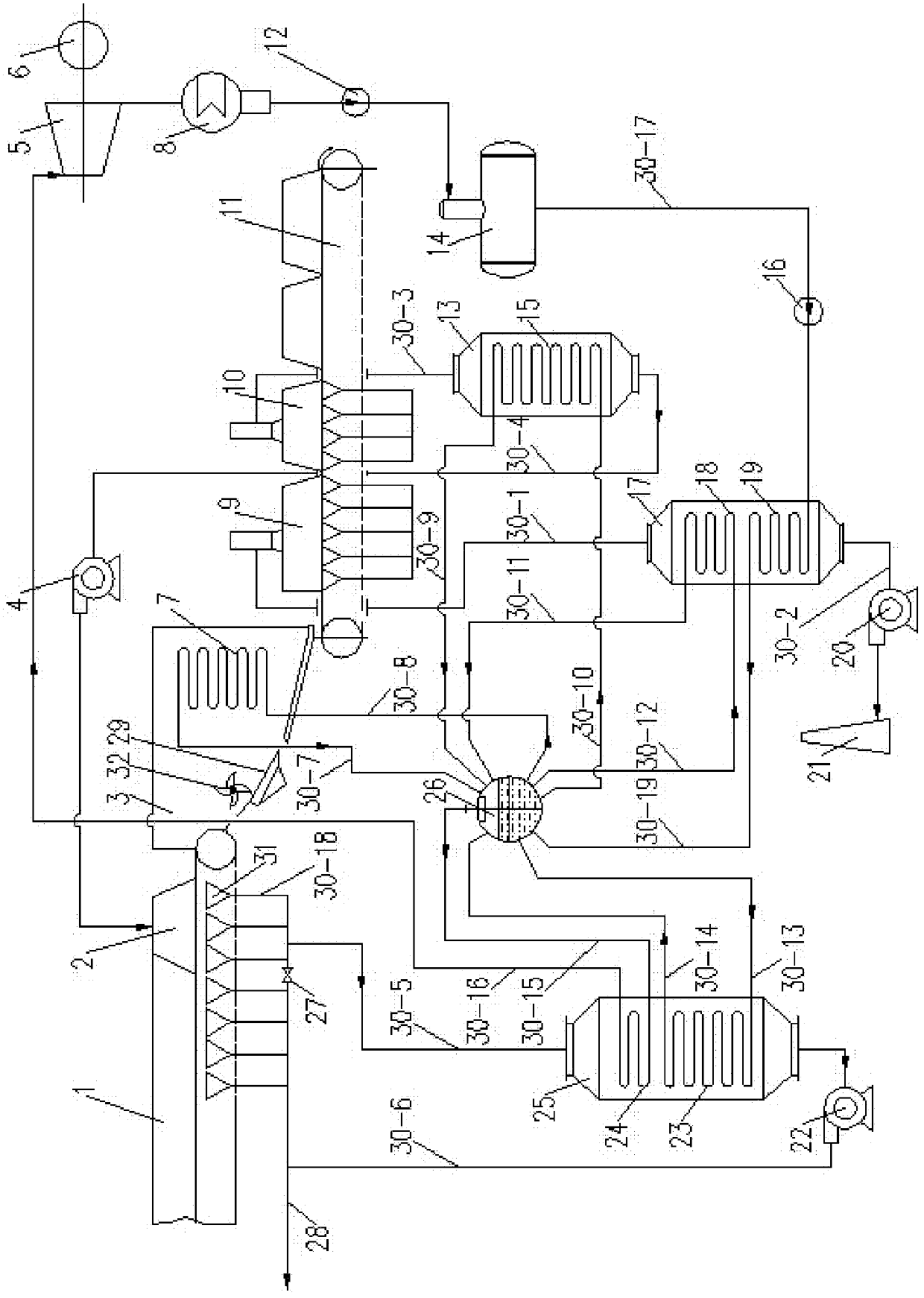

[0020] Such as figure 1 As shown, the present invention provides a sintering production line waste heat comprehensive utilization power generation system, including sintering machine 1, cooling machine 11, heat exchanger A17, heat exchanger B13, heat exchanger C25, waste heat boiler 26, steam turbine 5 and generator 6 ; A blanking port smoke hood 3 is arranged between the discharge port of the sintering machine 1 and the feed port of the cooling machine 11, and a discharge port connecting the discharge port of the sintering machine 1 and the feed port of the cooling machine 11 is arranged in the blanking port smoke cover 3 The material belt 29, the crusher 32 arranged above the blanking belt 29; the cooling machine 11 is provided with two fume hoods near the feed inlet, which are respectively the fume hood A9 and the fume hood B10; the sintering machine 1 includes The fume hood C2 at the material outlet and more than three bellows 31, each bellows 31 is connected to an eightee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com