Seal structure between wind chamber and the lower part of sintering ring cold machine trolley of steel and iron plant

A technology of sintering annular cooler and sealing structure, which is applied in the treatment of discharged materials, furnace types, furnaces, etc., can solve the problems of not realizing the full recycling of flue gas, affecting the utilization temperature of waste heat flue gas, and reducing the quality of circulating flue gas. , to achieve the effect of reducing the power consumption rate of the plant, reducing the strength and prolonging the life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

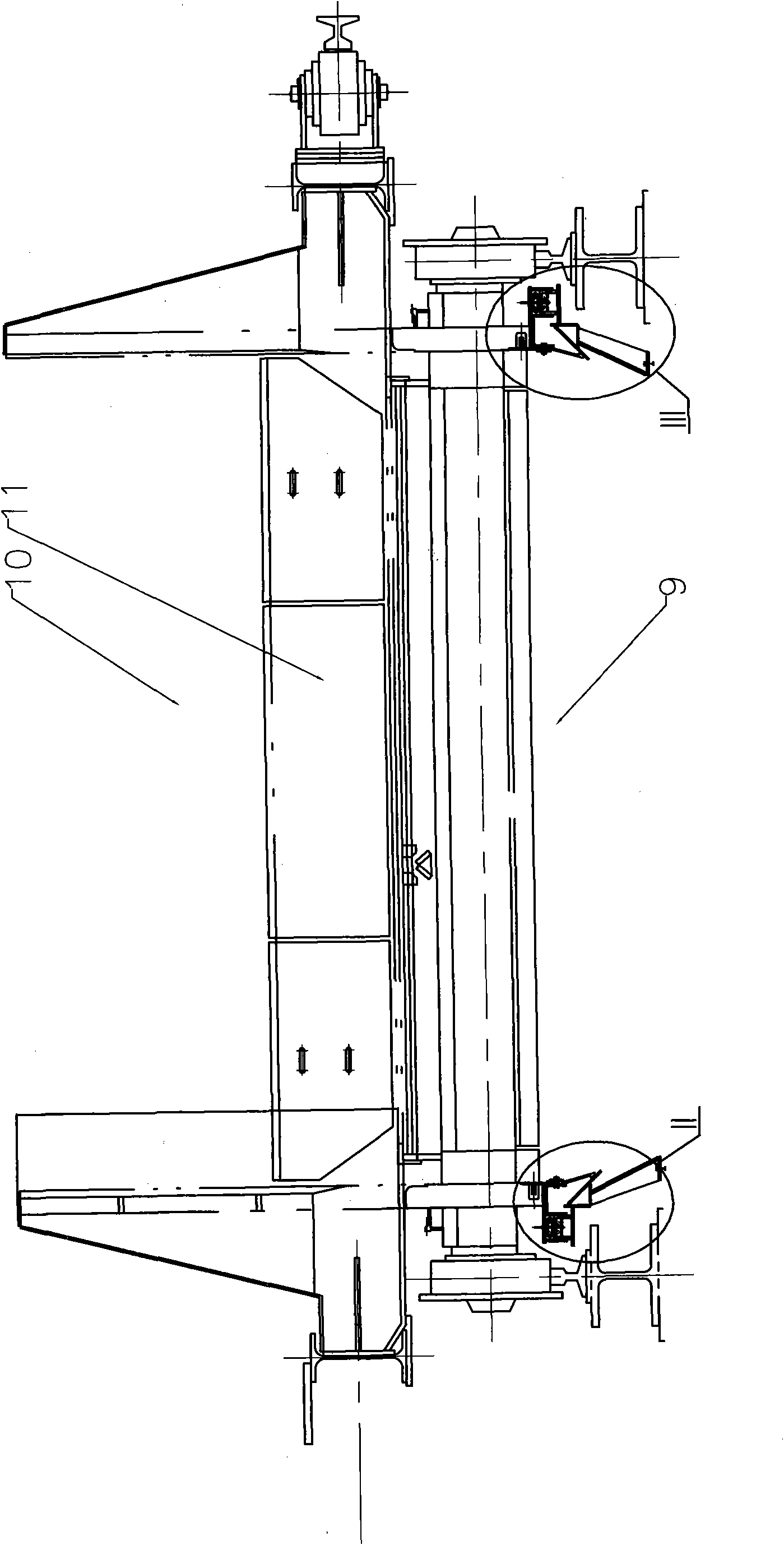

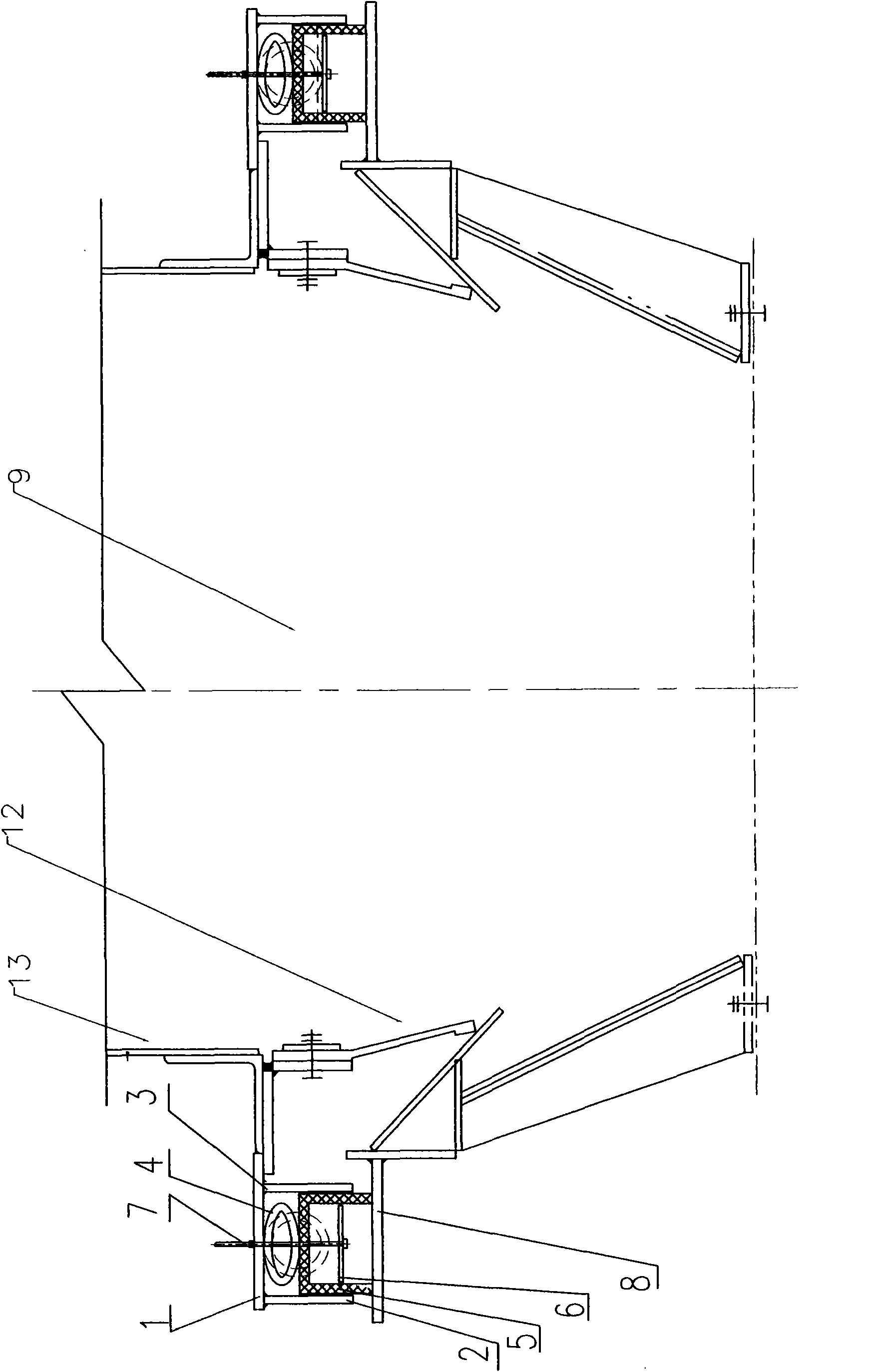

[0022] Such as figure 1 , figure 2 As shown, this embodiment provides a sealing structure between the lower part of the sintering ring cooler trolley and the bellows designed in the present invention, mainly including the outer seal, the seal contact plate 8 and the inner seal rubber 12, which are characterized in that The outer seal is composed of a seal support 1, an outer limit plate 2, an inner limit plate 3, an elastic rubber cylinder 4, a sealing groove rubber 5, a supporting plate 6, and an adjustable connecting screw 7. The supporting plate 6 is set on the sealing Groove rubber 5, and through the adjustable connecting screw 7 and seal support 1 adjustable connection, between the seal groove rubber 5 and seal support 1, there is an elastic rubber cylinder 4, the inner limit plate 3 and The outer limit plate 2 is respectively set on the inner and outer sides of the sealing groove rubber 5, and the outer sealing member and the inner sealing rubber 12 are fixed on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com