Intelligent plate welding device and method for end surface of steel bundle

An end-face, intelligent technology, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of harsh environment, high risk in the working area, unable to fully automatic and unmanned welding, etc., to meet the rhythm requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

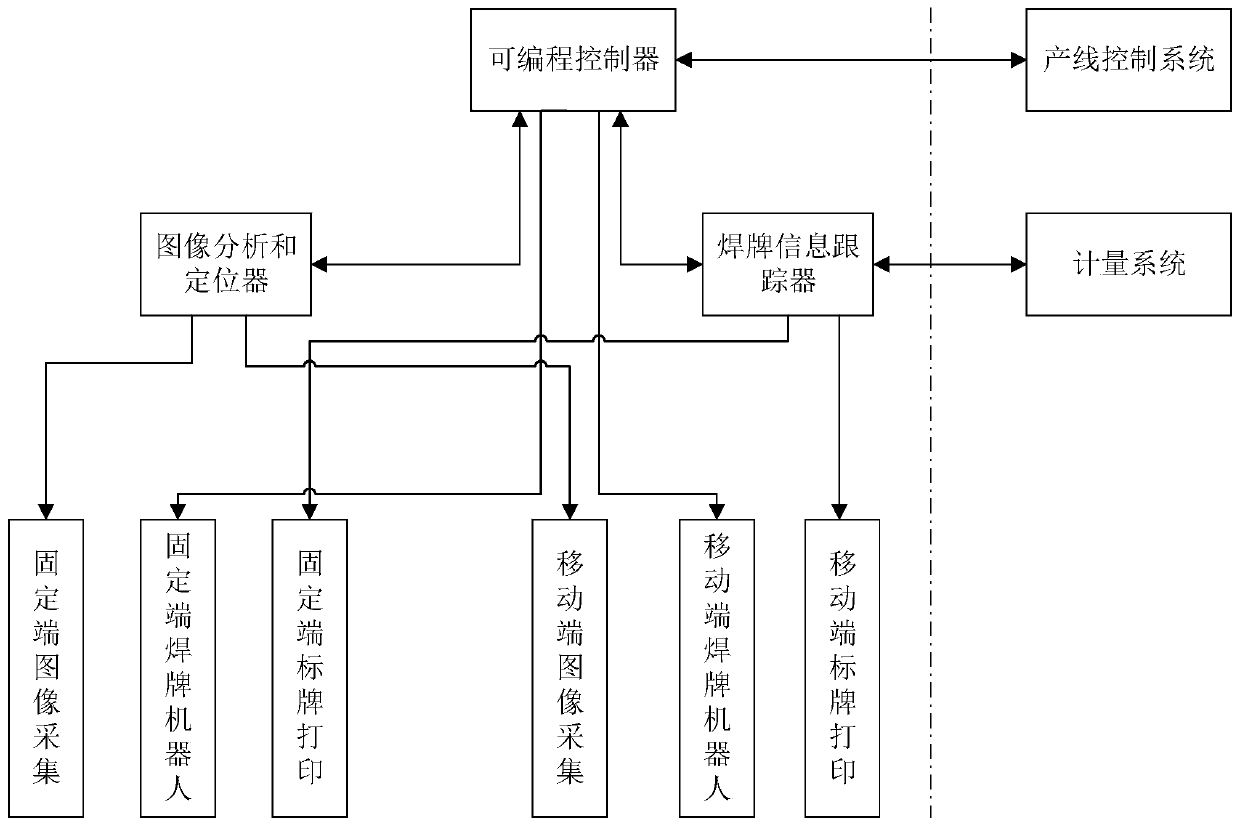

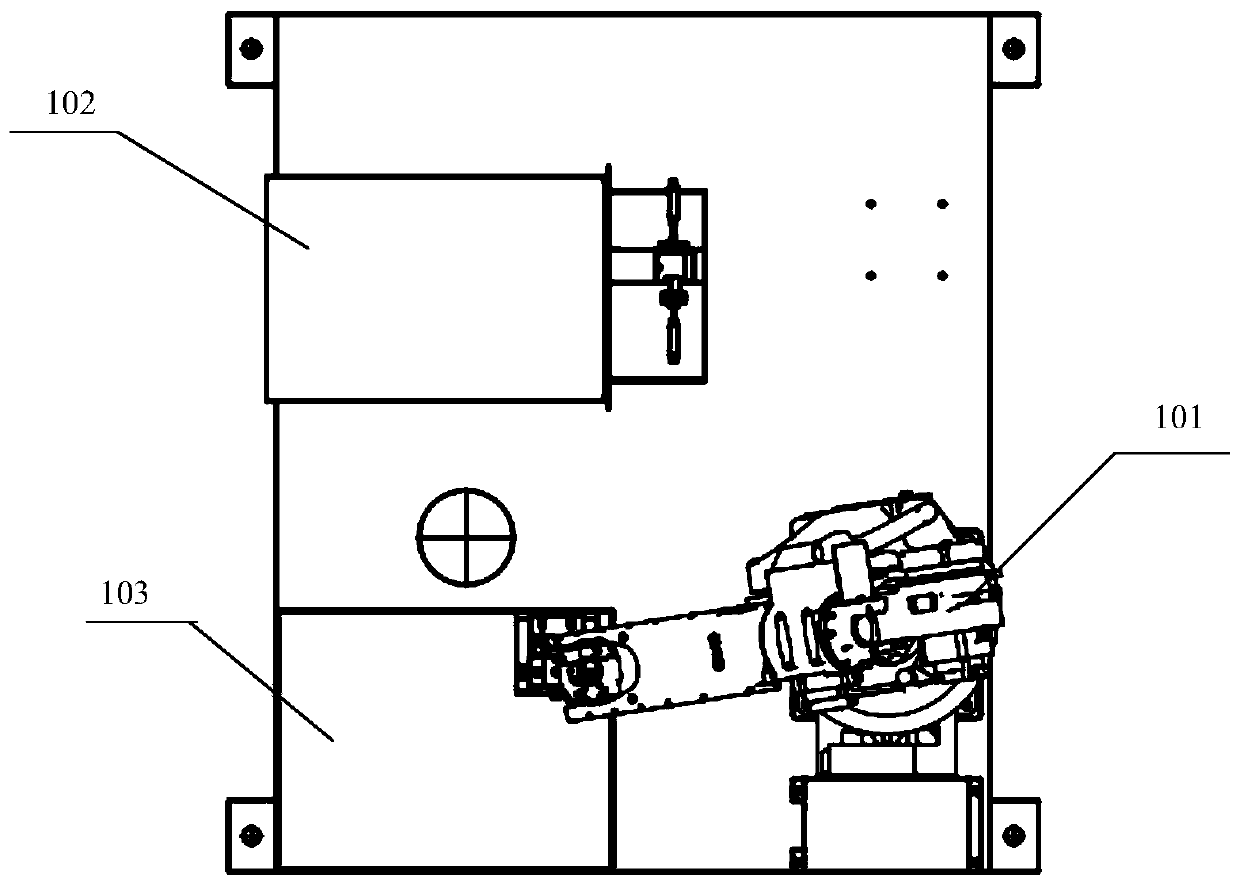

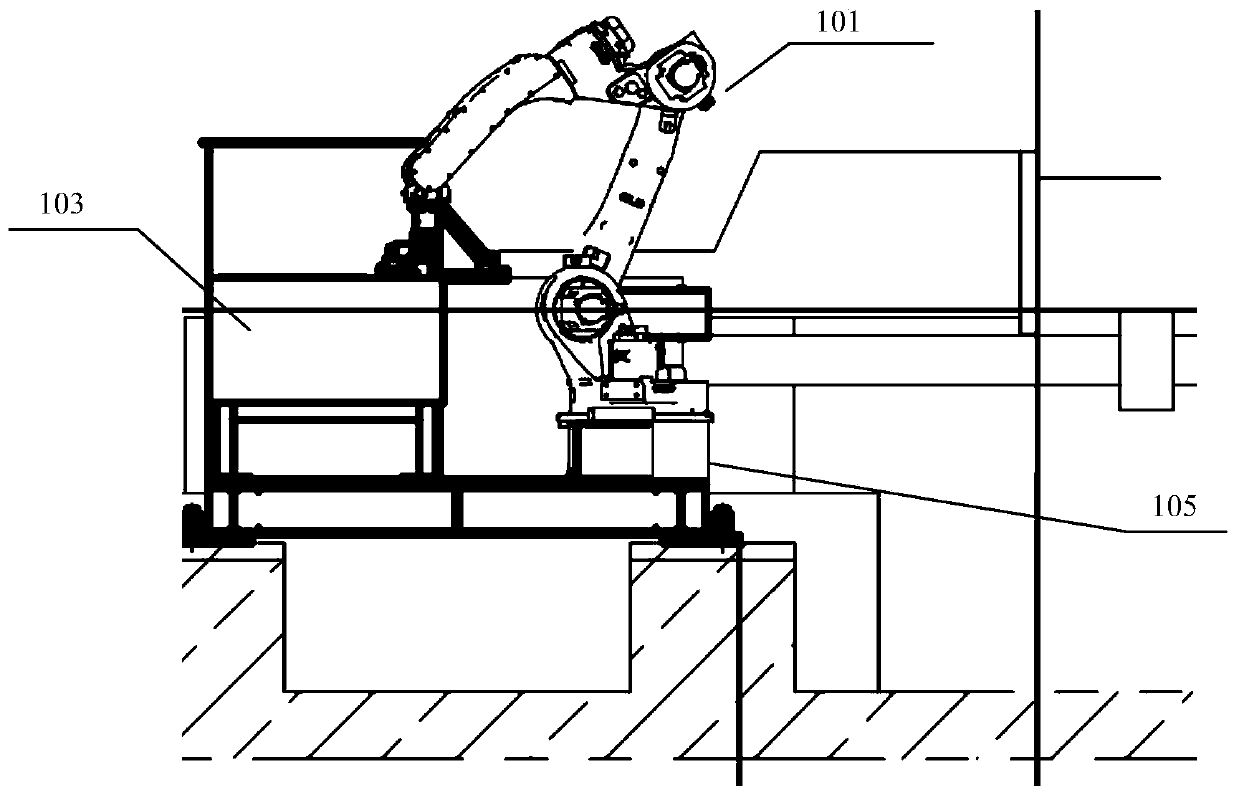

[0040] A set of intelligent plate welding device for the end face of steel bundles proposed by the present invention uses industrial robots combined with image processing of machine vision to realize the fully automatic unmanned plate welding function in the production process.

[0041] After the steel bundles produced by bars are bundled and weighed, the original metering system will send the label data including specifications, weight and other information to the welding label information tracker, and the welding label information tracker will add the information to the steel bundle tracking queue. At the same time, the steel bales that have been weighed are transported to the baling transport chain in turn to wait for welding. The programmable controller of the welding system receives the transport chain movement signal of the production line system, and thus calculates the position of the unwelded steel bales. And carry out real-time tracking, calculate and determine the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com