System for extracting iron particles and zinc powder from dust of steel and iron plant

A steel plant and dust technology, applied in the system field of extracting iron particles and zinc powder, can solve the problems of increasing production costs, low metal reduction rate, and affecting production efficiency, so as to reduce production energy consumption and cost, realize resources, and realize The effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below through the accompanying drawings, but it does not constitute a limitation to the present invention.

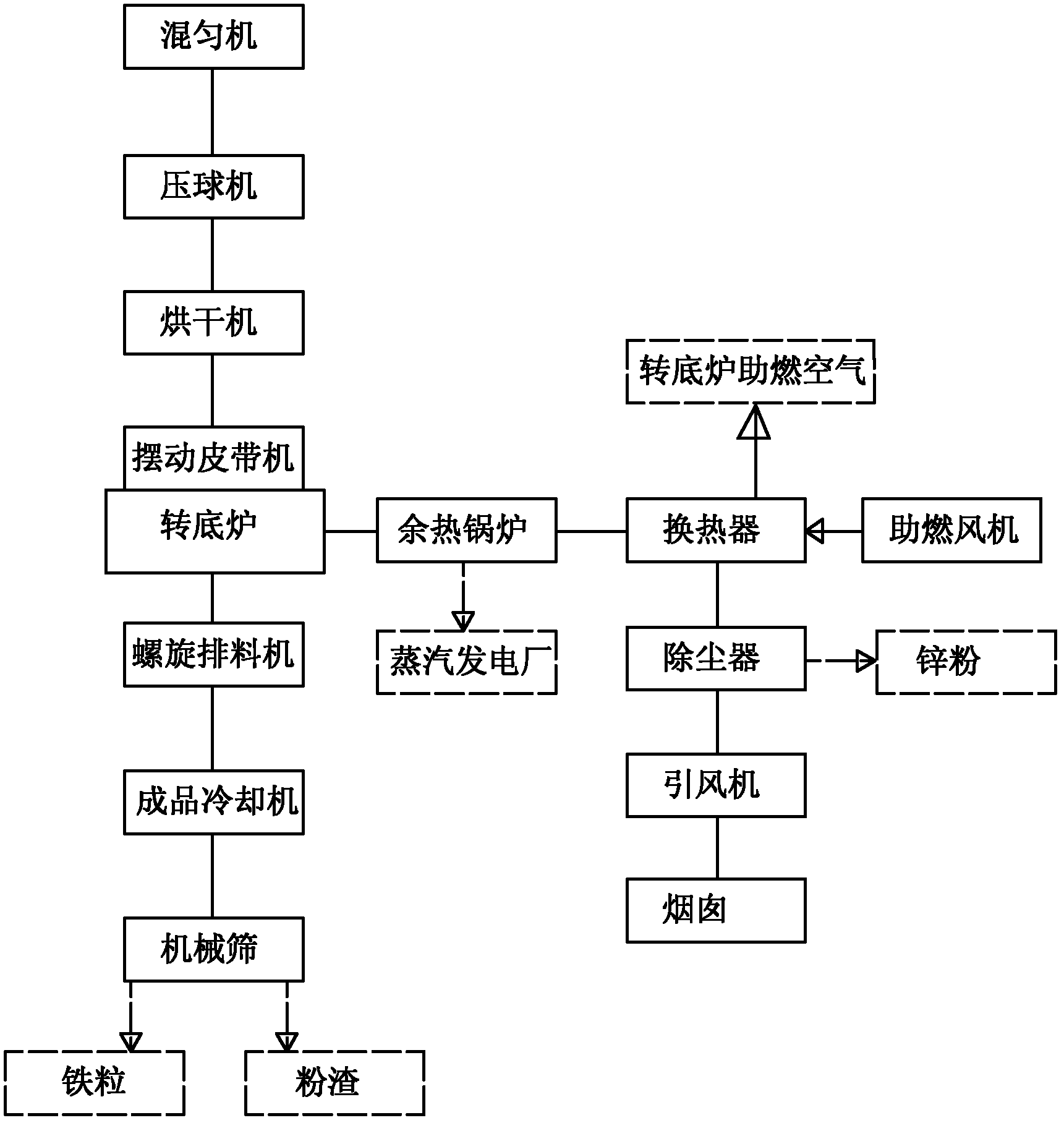

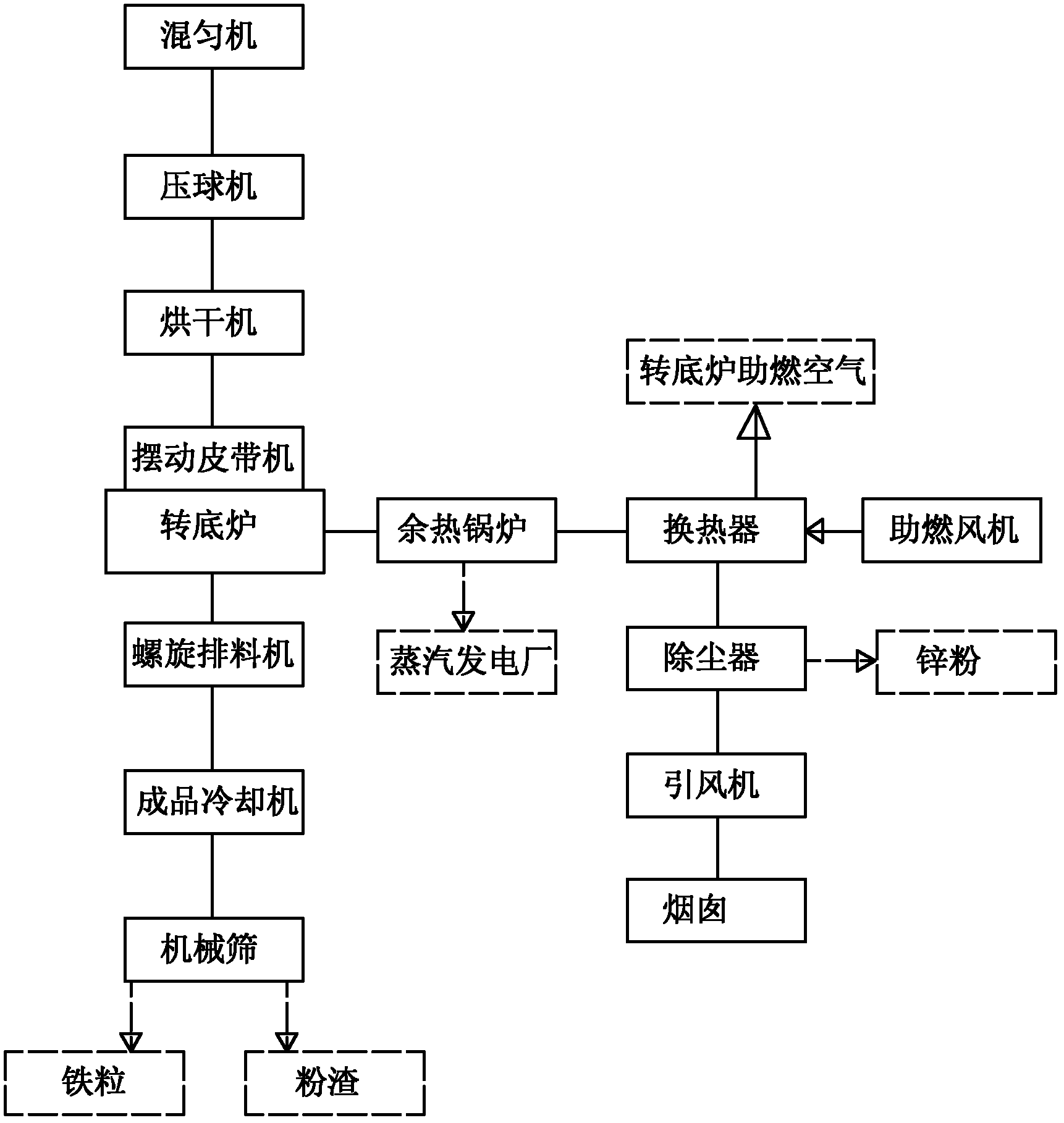

[0012] Such as figure 1 As shown, a system for extracting iron particles and zinc powder from iron and steel plant dust, which includes a mixer, a ball press machine, a dryer, a swing belt conveyor, a rotary hearth furnace, a spiral discharge machine, a finished product cooler, Mechanical sieve, waste heat boiler, heat exchanger, combustion-supporting fan, dust collector, induced draft fan, chimney; the input port of the mixer receives iron and steel plant dust, dolomite and adhesive, and the output port of the mixer is provided by the conveying equipment (can be Conveying pipe or belt conveyor, etc., the same below) The input port of the ball pressing machine is connected, the output port of the ball pressing machine is connected with the input port of the dryer by the conveying equipment, and the output port of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com